Documente Academic

Documente Profesional

Documente Cultură

Tank Fertilizer Guide Inspection API 650

Încărcat de

Raul Gallegos ADescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Tank Fertilizer Guide Inspection API 650

Încărcat de

Raul Gallegos ADrepturi de autor:

Formate disponibile

PREAMBLE In recent years, some large non-pressurized liquid fertilizer tanks have experienced failures.

These failures have prompted fertilizer companies to begin an aggressive assessment of large tanks in their inventory in an effort to determine whether these tanks are fit for service. In addition, as the result of these failures, several State regulatory agencies have begun to examine current regulations for the aboveground storage of liquid fertilizer, and, where no regulations exist, to consider promulgating such regulations. The Fertilizer Institute (TFI) is the national trade association representing the fertilizer industry. At the direction of the TFI Executive Committee, a Tank Integrity Work Group was established in September 2000 to look at the issue of inspection and maintenance of large non-pressurized liquid fertilizer tanks. The guidelines herein represent the consensus of the Tank Integrity Work Group and set forth suggested, uniform industry inspection and maintenance guidelines. As recognized, site-specific conditions may require deviations from these guidelines. Ultimately, it is the responsibility of the tank owner and operator, in consultation with a qualified inspector, to implement the appropriate inspection and maintenance protocols to ensure the tank integrity. Neither TFI, the members of the Tank Integrity Task Force nor the inspectors, are liable for any damages or injuries resulting from a company or individual using these suggested guidelines. In general, the Tank Integrity Work Group recommends that all new tanks should be designed and built to American Petroleum Institute (API) Standard 650 and inspections of existing tanks should be based upon API Standard 653, but with modifications for the unique characteristics of a tank storing liquid fertilizer. API Standard 653 can be used as a general guideline for inspection of any aboveground storage tank. For example, tanks that were not built to API Standard 650 criteria or that have been modified subsequently such that they now do not comply with API Standard 650, may still be inspected under the API Standard 653 inspection guidelines. Whether or not the tank was built to API Standard 650 criteria, inspectors of aboveground storage tanks should advise whether the owner/operator may continue service without modification or whether the owner/operator must make repairs to the tank or have the tank further evaluated prior to continuing service.

1.0

PURPOSE 1.1 To provide the fertilizer industry with a suggested uniform program to evaluate the condition of large (100,000 gallons or greater) non-pressurized aboveground liquid fertilizer storage tanks. These guidelines represent the knowledge and experience of professional technical personnel in the fertilizer industry.

1.2 2.0

DEFINITIONS Aboveground Storage Tank (AST) Any storage tank used for liquid fertilizer that is flat bottom, cylindrical, vertical with a fixed roof and constructed of carbon steel, stainless steel, or aluminum. API American Petroleum Institute is the national trade association representing the petroleum industry in areas of exploration and production, transportation, refining, and marketing. API 650 Standard 650 of the American Petroleum Institute, titled, Welded Steel Tanks for Oil Storage. API 653 Standard 653 of the American Petroleum Institute, titled, Tank Inspection, Repair, Alteration and Reconstruction. Authorized Inspection Agency - One of the following types of organizations that employs certified API AST inspectors: 1. 2. 3. 4. The inspection organization operated by the jurisdiction in which the AST is operated. The inspection organization operated by an insurance company licensed or registered to provide AST insurance at the location in question. An owner/operator organization that maintains its own inspection activities relating to ASTs it controls. An independent organization (company or individual) that contracts AST inspection services to an owner/operator as allowed by the local jurisdiction using API Authorized Inspectors.

Authorized Inspector An employee of an Authorized Inspection Agency that is certified as an AST Inspector per API Standard 653 requirements. 2

Baseline Inspection An initial, complete API 653 out-of-service internal and external inspection performed to establish the condition of an existing AST and to determine the ASTs suitability for continued service. Bladders - A non-adhering liner physically attached to the AST and constructed of synthetic material to provide physical separation of liquid product from the tank floor and sidewalls. Bladders are constructed of materials that are compatible with the contact materials. Coatings - An applied material that is chemically/physically bonded to the substance being covered, e.g., the inside of an AST. Coatings include, but are not limited to, paint, epoxy coatings (such as coal tar epoxy), attached fiberglass coverings, and other such products. In-house Inspector - The designated representative of the owner/operator organization who is responsible for various quality control and assurance functions and has working knowledge of API 653 inspection requirements and experience with fertilizer storage tanks. 3.0 SCOPE 3.1 This document represents suggested minimum guidelines for the inspection and maintenance of ASTs, 100,000 gallons or greater, used to store liquid fertilizer and constructed of carbon or stainless steel, or aluminum. These guidelines shall not be used in conflict with any jurisdictional requirements. If any provision presents a conflict with any statutory regulation, the regulation shall govern. If these guidelines are more stringent than the requirements of the regulation, following these guidelines are suggested. For ASTs 100,000 gallons or greater, used to store fertilizer, and known to be built to API Standard 650 (or its predecessor API Standard 12C), the minimum acceptable external or internal inspection criteria will be in accordance with the guidelines and recommendations of API Standard 653. In addition, consideration should be given to other ancillary criteria as itemized in Sections 4, 5, 6, and 7 regarding fertilizer-specific issues.

3.2

3.3

3.4

For ASTs 100,000 gallons or greater, used to store fertilizer and of unknown design or built to known criteria other than API Standard 650, inspection criteria will be in accordance with the guidelines and recommendations of API Standard 653 to the extent possible. An authorized inspector, or an authorized inspector in conjunction with a tank design engineer, may modify the inspection in consideration of original construction details that do not meet API Standard 650 design criteria. The result of the inspection must be equivalent to the API Standard 653. In addition, consideration should be given to other ancillary criteria as itemized in Sections 4, 5, 6, and 7 regarding fertilizer-specific issues. The frequency and extent of inspection of ASTs of 100,000 gallons or greater used to store fertilizer will depend on operating conditions and history, past inspections, repair history, or other conditions of an individual tank and should follow the guidelines given in Section 8. A tank owner may determine that additional or modified inspections are necessary based on operating conditions and history, past inspections, repair history, or other conditions of an individual tank. Tank owners/operators should consult with product manufacturer/supplier to insure product compatibility with tank construction and appurtenance materials. a. Copper and brass should not be used in tank construction or in appurtenances where they will come in contact with liquid fertilizer. Aluminum is not compatible with some liquid fertilizer products including but not limited to, phosphate-based liquid fertilizers or liquid fertilizers containing potassium chloride.

3.5

3.6

3.7

b.

4.0

INSPECTION CONSIDERATIONS 4.1 Exterior Considerations 4.1.1 The owner should consider painting the storage tanks a light or reflective color to reduce radiant heating, particularly when increased temperatures in the vapor zones are a concern. 4

4.1.2

Carbon steel tanks should be painted to minimize corrosion. Tanks should be set on a proper foundation to prevent moisture or debris from gathering at the base of the tank (e.g., set above grade, drainage away from tank). Base material should not be allowed to build up above the level of the tank bottom edge. Tanks set on a concrete foundation should be sealed around the tank floor to foundation interface to provide a moisture barrier. When making repairs to the tank shell, the qualification of welding procedures should be based upon the code or standard to which the tank was originally built. When the original code of construction is unknown, the qualification of welding procedures should be based upon API-653, including the impact toughness requirements of API-650. Shell repair materials should be selected according to the code or standard to which the tank was originally built. When the original code of construction is unknown, repair materials should be selected according to the requirements of API653, and the impact toughness requirements of API-650.

4.1.3

4.1.4

4.1.5

4.1.6

4.2.

Interior Considerations 4.2.1 The condition of the weld seams and weld heataffected zones (HAZs) are of particular concern because these areas tend to be more quickly affected by exposure to liquid fertilizer products. Under tank floor corrosion is a potential problem area and should be considered for additional inspection.

4.2.2

4.2.3

After any washing of an AST, residue and sludge should be pumped out and the floor should be dried thoroughly.

5.0

BLADDERS 5.1 General Matters 5.1.1 Complete data on the bladder -- including the manufacturer of the liner material, its corrosion resistance properties, date of installation, method of attachment, and installation contractor -- should be maintained as part of the permanent record on the tank. The condition of the bladder or lining may need to be established during an internal inspection as a means of assessing continuing integrity. Additional or alternative internal inspection criteria may need to be established where such bladders or linings are known to be present.

5.1.2

5.2

Inspection Criteria for API Inspected Tanks with Bladders 5.2.1 All tanks should have an initial inspection by an API qualified inspector immediately before the installation of a bladder unless they are new construction and were previously inspected in accordance with the new construction design code. Tanks with bladders should have the bladder inspected within two years after the initial installation and if no failure indications are found at five-year intervals thereafter. The bladder inspection should be conducted by the original bladder installer or someone familiar with bladder installations. The bladder inspection should include but not be limited to the Bladder Inspection Criteria of Appendix A. Tanks should be internally inspected within five years of any detection and repair of a bladder leak unless the tank is inspected at the time of the bladder repairs. 6

5.2.2

5.2.3

5.2.4

External inspections shall be conducted on the same schedule as for tanks without bladders (see Section 8). Following any leak repair, the bottom of the tank should be flushed with fresh water to remove corrosive product.

5.2.5

5.3

Inspection Criteria for Non-API Inspected Tanks with Bladders 5.3.1 Tanks with bladders already installed should have an initial baseline inspection by an API qualified inspector within two years. Tanks with bladders should have the bladder inspected within two years after the initial installation and if no failure indications are found at five-year intervals thereafter. The bladder inspection should be conducted by the original bladder installer or someone familiar with bladder installations. The bladder inspection should include but not be limited to the Bladder Inspection Criteria of Appendix A. Such tanks should be internally inspected within five years of any repair of a bladder leak External inspections shall be conducted on the same schedule as for existing tanks without bladders (see Section 8). Following any leak repair, the bottom of the tank should be flushed with fresh water to remove corrosive product.

5.3.2

5.3.3 5.3.4

5.3.5

6.0

FLAMMABILITY 6.1 Fertilizers are generally non-flammable in nature. As such, considerations in API Standard 653 regarding flammability and toxicity may be modified according to the nature of the specific liquid fertilizers used in the tank except where liquid hydrocarbons are used as a fertilizer interface seal. 7

7.0

GRAVITY 7.1 ASTs designed for liquid fertilizer storage utilize a product specific gravity usually exceeding 1.0. This difference in product gravity needs to be properly incorporated in the evaluation of any liquid fertilizer tank.

8.0

INSPECTIONS 8.1 Inspection Intervals 8.1.1 The following inspection frequency guidelines are suggested for liquid fertilizer ASTs, unless excepted under Section 4 above. These guidelines are, in some cases, more frequent than API Standard 653. a. For tanks that have been inspected by an API authorized inspector within the last ten years, the date of that inspection shall become the baseline inspection date for purposes of these guidelines so long as the inspection met the definition of baseline inspection in Section 2.0. For tanks that have not been inspected by an API authorized inspector within the last ten years, a baseline inspection should be conducted by an API authorized inspector within two years of adoption of these guidelines. Monthly visual, walk around inspections should be conducted by an in-house inspector. Yearly external inspection, using the API 653 inspection checklist, should be conducted by an in-house inspector. For non-lined, non-bladder tanks only, an internal inspection, using the API 653 checklist, should be conducted by an in-house inspector every three years, beginning three

b.

c.

d.

e.

years after the date of the baseline inspection. f. Every nine years, beginning within ten years of the baseline inspection, an internal inspection should be conducted by an API authorized inspector.

8.2

Inspectors 8.2.1 8.2.2 The baseline inspection must be done by an API authorized inspector. The monthly visual, yearly external, and three-year internal inspections can be done by an in-house inspector. The ten-year inspection must be done by an API authorized inspector.

8.2.3

9.0

RECORDKEEPING 9.1 When a tank is evaluated, repaired, altered, or reconstructed in accordance with these guidelines, the following information, as applicable, shall be made a part of the owner/operators records for the tank: 9.1.1 Calculations for: a. b. c. 9.1.2 9.1.3 Component evaluation for integrity, including brittle fracture consideration. Re-rating (including liquid level). Repair and alteration considerations.

Construction and repair drawings. Additional support data including, but not limited to, information pertaining to: a. b. c. Inspections (including component thickness readings). Material test reports/certification. Tests performed/results.

d. e. f. g. h. i. j. k. l. m. 9.2 10.0

Radiographs (should be retained for five years). Brittle fracture considerations. Original tank construction data (date, original standard). Location and identification (owner/operators number, serial number). Description of the tank (diameter, height, service). Design conditions (liquid level, specific gravity, allowable stress, and unusual design load). Shell material and thickness by course. Tank perimeter elevations. Construction completion record. Basis for hydrostatic test exemption.

Detailed monitoring records on the tank leak detection system shall be maintained for ten years.

REFERENCES API 650, Welded Steel Tanks for Oil Storage, current edition. API 653, Tank Inspection, Repair, Alteration and Reconstruction, current edition. API 653, Tank Inspection, Repair, Alteration and Reconstruction, Check List for Tank Inspection, Appendix C

10

Appendix A Bladder Inspection Criteria The tank bladder inspection should include but not be limited to the following: a. b. c. d. e. f. g. h. Check bladder flexibility. Visually inspect bladder for signs of discoloration and surface cracking. Visually inspect bladder support system for compliance with original installation. Check all bladder interface connections (flanges, roof columns, manways, etc.). Check sump boot and boot-to-floor seam. Check all leak monitoring port valves. Verify that operating liquid level has not exceeded bladder design height. Exercise extreme care while inspecting and when entering or exiting tank.

11

S-ar putea să vă placă și

- Ground Steel Crude Oil Storage Tank Location and FoundationDocument20 paginiGround Steel Crude Oil Storage Tank Location and Foundationliz aldanaÎncă nu există evaluări

- GP 09-04-01Document31 paginiGP 09-04-01Anbarasan Perumal100% (1)

- 32 Samss 006Document22 pagini32 Samss 006Vajid MadathilÎncă nu există evaluări

- Steel TanksDocument75 paginiSteel TanksAnonymous b3NKZUbÎncă nu există evaluări

- Handbook of Storage Tank Systems: Codes, Regulations, and DesignsDocument4 paginiHandbook of Storage Tank Systems: Codes, Regulations, and DesignsAndi RachmanÎncă nu există evaluări

- GB - Codres 2007 Division 1 - SommaireDocument12 paginiGB - Codres 2007 Division 1 - SommaireNeera JainÎncă nu există evaluări

- Foundation Ring WallDocument3 paginiFoundation Ring WallDaniel Roberto Morales ContrerasÎncă nu există evaluări

- API 653 Daily PointsDocument4 paginiAPI 653 Daily Pointsraobabar21Încă nu există evaluări

- 10 1 1 1018 7352 PDFDocument10 pagini10 1 1 1018 7352 PDFKumararaja KonikkiÎncă nu există evaluări

- Differential Settlements in Steel TanksDocument17 paginiDifferential Settlements in Steel TanksThiago GisbertÎncă nu există evaluări

- API 620 Appendix R Tanks For Storage of Refrigerated Product PDFDocument16 paginiAPI 620 Appendix R Tanks For Storage of Refrigerated Product PDFFatih FıratÎncă nu există evaluări

- API Tank DesignDocument189 paginiAPI Tank DesignShinji46Încă nu există evaluări

- Anaerobic Digester BrochureDocument8 paginiAnaerobic Digester BrochureGrey NghidengwaÎncă nu există evaluări

- Tank Bottom Plate CorrosionDocument5 paginiTank Bottom Plate CorrosionShaalan AI-ZuhairiÎncă nu există evaluări

- Stainless Tanks For H3PO4Document6 paginiStainless Tanks For H3PO4joesuhreÎncă nu există evaluări

- SAES-B-005, Spacing and Diking For Atmospheric and Low-Pressure TanksDocument13 paginiSAES-B-005, Spacing and Diking For Atmospheric and Low-Pressure TanksabdÎncă nu există evaluări

- Analysis and Design of Circular Prestressed Concrete Storage TanksDocument22 paginiAnalysis and Design of Circular Prestressed Concrete Storage TanksLau Kim HwaÎncă nu există evaluări

- General Update of The ASCE Report-Design of Blast Resistant Buildings in Petrochemical FacilitiesDocument4 paginiGeneral Update of The ASCE Report-Design of Blast Resistant Buildings in Petrochemical FacilitiesKevin C. Nair100% (1)

- 4008-ST-DCR-001 - 0 - STRUCTURAL DESIGN CRITERIA - SignedDocument33 pagini4008-ST-DCR-001 - 0 - STRUCTURAL DESIGN CRITERIA - SignedanggiaÎncă nu există evaluări

- Petroleum Tanks BrochureDocument12 paginiPetroleum Tanks BrochureM.Sreeram SanjayÎncă nu există evaluări

- Assessment of Corrosion Damage Acceptance Criteria in API579-ASME/1 CodeDocument12 paginiAssessment of Corrosion Damage Acceptance Criteria in API579-ASME/1 CodeIntegridad de Equipos y Gestión de Activos NelcamÎncă nu există evaluări

- Steel Tank DesignDocument9 paginiSteel Tank DesignJanasheen BondÎncă nu există evaluări

- Development of SA-738 Gr. B High Strength Steel Plate With Excellent Toughness For Power Generating PlantsDocument6 paginiDevelopment of SA-738 Gr. B High Strength Steel Plate With Excellent Toughness For Power Generating PlantsKK SinghÎncă nu există evaluări

- 653 150Rev2PubDocument10 pagini653 150Rev2PubMuhammad HannanÎncă nu există evaluări

- Storage Tank FailureDocument6 paginiStorage Tank Failureramyatan SinghÎncă nu există evaluări

- Design Code SummaryDocument12 paginiDesign Code SummaryShane HancockÎncă nu există evaluări

- Saer 5974 PDFDocument31 paginiSaer 5974 PDFZhiguo YangÎncă nu există evaluări

- Steel Tank SpecsDocument81 paginiSteel Tank Specssofianina05100% (1)

- Ring Foundation Design CriteriaDocument1 paginăRing Foundation Design CriteriaDawson Preethi EAÎncă nu există evaluări

- Development and validation of a leak before break criterion for cylindrical pressure vesselsDocument12 paginiDevelopment and validation of a leak before break criterion for cylindrical pressure vesselsArun KumarÎncă nu există evaluări

- For Buildings and Other Structures For Wind LoadsDocument28 paginiFor Buildings and Other Structures For Wind LoadsMarinos Giannoukakis100% (1)

- To Rerate or Not To RerateDocument6 paginiTo Rerate or Not To ReratekblaxtonÎncă nu există evaluări

- Prepared By: M.SIRAJUDIN (Sr. Static Equipment Engineer) July 29, 2010Document31 paginiPrepared By: M.SIRAJUDIN (Sr. Static Equipment Engineer) July 29, 2010Mohammad SirajuddinÎncă nu există evaluări

- Pressure Vessel DesignDocument8 paginiPressure Vessel DesignHector Javier Cruz CampaÎncă nu există evaluări

- MATERIAL SCIENCE - Material Selection For Storage TankDocument11 paginiMATERIAL SCIENCE - Material Selection For Storage TankShu Jia TanÎncă nu există evaluări

- Guide To Storage Tanks and EquipmentDocument296 paginiGuide To Storage Tanks and EquipmentFrancisco Chavez100% (4)

- Acid CorrosionDocument26 paginiAcid CorrosionTamer Abd ElrasoulÎncă nu există evaluări

- Materials For JointsDocument25 paginiMaterials For Jointshariharanoilgas100% (1)

- Structure Analysis I Structure Analysis IDocument66 paginiStructure Analysis I Structure Analysis IbimantioÎncă nu există evaluări

- 650-680 Rev 4 - Hydrostatic Test ExemptionsDocument3 pagini650-680 Rev 4 - Hydrostatic Test ExemptionsAnonymous 6S9tcbhÎncă nu există evaluări

- Chattopadhyay - Material-Selection-For-A-Pressure-Vessel PDFDocument10 paginiChattopadhyay - Material-Selection-For-A-Pressure-Vessel PDFRenan Gustavo PazÎncă nu există evaluări

- 01 Samss 016Document13 pagini01 Samss 016nasrpkÎncă nu există evaluări

- Bolted Storage Tank ComparisonDocument9 paginiBolted Storage Tank ComparisoncorrokokoÎncă nu există evaluări

- Introducing HydrocarbonsDocument5 paginiIntroducing HydrocarbonsUbong P. EffiongÎncă nu există evaluări

- RC Simple Notions of Moment DistributionDocument136 paginiRC Simple Notions of Moment Distributionامين الزريقيÎncă nu există evaluări

- Standaardmethode Opslagtanks - Generic Approach Liquid Storage TanksDocument28 paginiStandaardmethode Opslagtanks - Generic Approach Liquid Storage TanksNenadÎncă nu există evaluări

- MOUNDED BULLETS FOR LPG STORAGEDocument41 paginiMOUNDED BULLETS FOR LPG STORAGEMarco Dos Santos NevesÎncă nu există evaluări

- Risk Engineering Position Paper 01 Atmospheric Storage Tanks 2015Document28 paginiRisk Engineering Position Paper 01 Atmospheric Storage Tanks 2015SardeniantoÎncă nu există evaluări

- Tank ComponentsDocument4 paginiTank ComponentssafwanÎncă nu există evaluări

- Industrial Tank Talk 37Document2 paginiIndustrial Tank Talk 37hyperm2mÎncă nu există evaluări

- Sodium Leak Through Pin HolesDocument9 paginiSodium Leak Through Pin HolesAvinash ChittellaÎncă nu există evaluări

- Sts 02360Document22 paginiSts 02360Sowjanya VenigallaÎncă nu există evaluări

- LIQUID FERTILIZER STORAGE TANK INSPECTION GUIDELINESDocument17 paginiLIQUID FERTILIZER STORAGE TANK INSPECTION GUIDELINESJade GeronimoÎncă nu există evaluări

- Article - Ovreview API 653Document2 paginiArticle - Ovreview API 653Eugenia Le FosseÎncă nu există evaluări

- Tank Inspection Scope API 653Document3 paginiTank Inspection Scope API 653Faraj Libya100% (1)

- A Guide To The Implementation of API 653Document3 paginiA Guide To The Implementation of API 653Anbarasan PerumalÎncă nu există evaluări

- A Guide To Storage Tank Repair Based On API 653 StandardDocument7 paginiA Guide To Storage Tank Repair Based On API 653 Standardmanish318Încă nu există evaluări

- Guidelines For Internal & External Inspections of Field Erected TanksDocument4 paginiGuidelines For Internal & External Inspections of Field Erected TanksbaÎncă nu există evaluări

- New SP001Document4 paginiNew SP001Deyci Yamile Peña Santos100% (1)

- Pressure Vessels Field Manual: Common Operating Problems and Practical SolutionsDe la EverandPressure Vessels Field Manual: Common Operating Problems and Practical SolutionsEvaluare: 4 din 5 stele4/5 (12)

- Tecson V FaustoDocument2 paginiTecson V FaustoAviLopezÎncă nu există evaluări

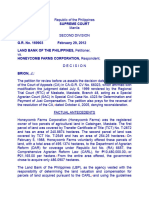

- G.R. No. 169903 February 29, 2012Document17 paginiG.R. No. 169903 February 29, 2012ericson dela cruzÎncă nu există evaluări

- The Psychological and Performance Demands of Association Football RefereeingDocument23 paginiThe Psychological and Performance Demands of Association Football RefereeingAnonymous A1DOvPjÎncă nu există evaluări

- Attempted Rape Conviction AffirmedDocument2 paginiAttempted Rape Conviction AffirmedClavel TuasonÎncă nu există evaluări

- Jurisprudence The Comparative Study of Legal Positivism & Historical School of Thought A Critique On LegislationDocument17 paginiJurisprudence The Comparative Study of Legal Positivism & Historical School of Thought A Critique On Legislationharsh sahuÎncă nu există evaluări

- Court rules on quieting of title and ownership over disputed landDocument3 paginiCourt rules on quieting of title and ownership over disputed landWilton Norman Jvmantoc100% (1)

- The Legal Profession in England and WalesDocument8 paginiThe Legal Profession in England and WalesNita Lorina MariaÎncă nu există evaluări

- G.R. No. 175073Document1 paginăG.R. No. 175073kaye choiÎncă nu există evaluări

- Criminal Law Book2 UP Sigma RhoDocument240 paginiCriminal Law Book2 UP Sigma RhoJP Ramos DatinguinooÎncă nu există evaluări

- Fundraising Event Proposal TemplateDocument6 paginiFundraising Event Proposal TemplateGalih Raditya PutraÎncă nu există evaluări

- Consti Law PP V PomarDocument1 paginăConsti Law PP V PomarRenz FactuarÎncă nu există evaluări

- Ramos Vs PeraltaDocument5 paginiRamos Vs PeraltaKarla Marie TumulakÎncă nu există evaluări

- PetitionDocument8 paginiPetitionJason SansoneÎncă nu există evaluări

- Matrushakti AgencyDocument4 paginiMatrushakti AgencyAnonymous joDvxoXYRx0% (1)

- Guillang V BedaniaDocument2 paginiGuillang V BedaniaTon RiveraÎncă nu există evaluări

- Administrative Action Tools: Discretion and Policy RuleDocument32 paginiAdministrative Action Tools: Discretion and Policy RuleSallSallyÎncă nu există evaluări

- Corp Law NotesDocument9 paginiCorp Law NotesPamela Jane I. TornoÎncă nu există evaluări

- Ronald Augustus Dipaola v. Walter Riddle, Superintendent, Virginia State Penitentiary, James D. Swinson, Sheriff, Fairfax County, William J. Powell, Sheriff, Sussex County, 581 F.2d 1111, 4th Cir. (1978)Document4 paginiRonald Augustus Dipaola v. Walter Riddle, Superintendent, Virginia State Penitentiary, James D. Swinson, Sheriff, Fairfax County, William J. Powell, Sheriff, Sussex County, 581 F.2d 1111, 4th Cir. (1978)Scribd Government DocsÎncă nu există evaluări

- 7.philippine Airlines vs. COADocument11 pagini7.philippine Airlines vs. COAGwyneth SantosÎncă nu există evaluări

- Evidentiary Issues in Will Contests: Anne C. Bederka, EsqDocument71 paginiEvidentiary Issues in Will Contests: Anne C. Bederka, EsqRosemary JuarezÎncă nu există evaluări

- SAMPLE MANUFACTURING COMPANY LIMITED FINANCIAL STATEMENTS FOR YEAR ENDED DEC 31, 2011Document36 paginiSAMPLE MANUFACTURING COMPANY LIMITED FINANCIAL STATEMENTS FOR YEAR ENDED DEC 31, 2011talhaadnanÎncă nu există evaluări

- Judicial Elaboration of the Constitution: Construction and SupremacyDocument1 paginăJudicial Elaboration of the Constitution: Construction and SupremacyA M I R AÎncă nu există evaluări

- Toribio vs. Bidin G.R. No. L-57821Document2 paginiToribio vs. Bidin G.R. No. L-57821Marianne AndresÎncă nu există evaluări

- CV Motion PacketDocument3 paginiCV Motion PacketshannonbutterfieldÎncă nu există evaluări

- Bureau of Internal RevenueDocument4 paginiBureau of Internal Revenuecrispyy turonÎncă nu există evaluări

- Model Law on Family Insolvency for Latin AmericaDocument18 paginiModel Law on Family Insolvency for Latin AmericaSergio Leonel CardonaÎncă nu există evaluări

- Fahar Edavana - Digital Answer SheetDocument2 paginiFahar Edavana - Digital Answer SheetAsmara Noor75% (8)

- Possible Crim QuestionDocument3 paginiPossible Crim Questionroselleyap20Încă nu există evaluări

- Republic V MarcopperDocument4 paginiRepublic V MarcopperYngwie EnriquezÎncă nu există evaluări

- RFBT-Securities Regulation Code PDFDocument22 paginiRFBT-Securities Regulation Code PDFKiana Fernandez100% (1)