Documente Academic

Documente Profesional

Documente Cultură

Circuit Breaker Duty Cycle

Încărcat de

Ravishankar.AzadDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Circuit Breaker Duty Cycle

Încărcat de

Ravishankar.AzadDrepturi de autor:

Formate disponibile

TechTopics

TechTopics Topic: Circuit Breaker Standard Duty Cycle

TechTopics No. 61 Revision 1 Date: Dec. 12, 2006

Recently, we have fielded many questions about the standard duty cycle from specifiers and users of medium-voltage circuit breakers in reclosing applications. The standard duty cycle for medium-voltage circuit breakers is specified in the ANSI/IEEE standards, and the specification of the standard duty cycle changed with the approval of the 1999 edition of the standards. The standard duty cycle has always been intended as the benchmark for circuit breaker application, and as the uniform operating cycle for use during the design (type) tests of the circuit breaker in the short-circuit laboratory. The standard duty cycle given in the various generations of standards is as follows: 1979 generation of standards: C37.04-1979, clause 5.6: Rated Standard Operating Duty (Standard Duty Cycle). The standard operating duty of a circuit breaker shall be two unit operations with 15s interval between operations (CO 15s CO). C37.09 specified the standard interrupting test (TD4) with a 15s interval between opening operations, and included reclosing duty tests (TD9 and TD10) with the interval between operations was equal to the minimum reclosing time in C37.06, 30 cycles for medium voltage circuit breakers. C37.04 DID NOT REQUIRE the standard duty cycle on the circuit breaker rating label. The application guide, C37.010, gave derating factors and formulas for interrupting capacity on reclosing cycles that differed from the standard duty cycle. 1999 generation of standards: C37.4-1999, clause 5.6: Rated standard operating duty (standard duty cycle). The standard operating duty of a circuit breaker is: O t CO t CO Where O = Open; CO = Close Open = 3 minutes t t = 15 seconds for circuit breakers not rated for rapid reclosing, and t = 0.3 seconds for circuit breakers rated for rapid reclosing C37.09 requires that the standard operating duty test (TD4) be conducted with the duty cycle as defined in C37.04, either non-reclosing or reclosing. Hence, the 1999 edition simplifies testing. It also specifies three interruptions in a sequence. C37.04 REQUIRES that the standard duty cycle be stated on the circuit breaker rating label. The application guide, C37.010, no longer indicates derating factors for vacuum circuit breakers for reclosing duty cycles that differ from the standard duty cycle. In essence, the basis of rating for the circuit breakers, and the basis of the design (type) tests, has not changed from the 1979 to the 1999 standards. Both the generations include a test duty cycle with a reclosing interval of a minimum time (0.3 seconds in the 1999 edition, 30 cycles or 0.5 seconds in the 1979

2006 Siemens Power Transmission & Distribution, Inc. PO Box 29503, Raleigh, NC 27626

TechTopics No. 61 Page 1

edition). The 1999 standard adds a requirement for a second CO operation (i.e., a third interruption) after the time interval t (3 minutes), which was not in the 1979 standards, and therefore, the testing performed in accordance with the 1999 standards is more severe than that required under the 1979 (and earlier) versions of the standards. We feel that the questions from users about the standard duty cycle arise from confusion between the reclosing duty cycle used in a particular application, and the standard duty cycle which is the basis of circuit breaker design, application, and design testing. The standard duty cycle establishes a uniform basis for the performance of circuit breakers. Also, it establishes a uniform basis for the short-circuit design tests conducted in the power laboratory. The short-circuit laboratories have limitations on the number of interruptions that they can perform in a single operating cycle. Most short-circuit laboratories use a short-circuit generator which is disconnected from the power system during an actual test, and the generator output is maintained by the inertia of the rotating machine during the test. Under this arrangement, the machine slows down during each short-circuit episode, and in turn, the recovery voltage imposed on the circuit breaker following interruption decreases. The short-circuit energy available for a subsequent short-circuit episode is also reduced and may not meet the current levels required during an interrupting test. Most laboratories cannot perform duty cycles in which there are more than two interruptions in a small space of time, as they need time to increase the speed of the machine after the second short-circuit. For this reason, the new standard duty cycle has a 3 minute interval between the second interruption and the third interruption, to allow the laboratory to connect the short-circuit generator to the power system for a sufficient time to bring its frequency back up to the 60 Hz area, and hence, to assure that recovery voltage and short-circuit current will meet the conditions required for a valid test. Thus, users need have no concern that the 1999 revision of the standard duty cycle somehow masks poorer product performance. The reverse is really true, as the 1999 standards added a third interruption to the standard duty cycle test. Users can apply circuit breakers tested to the new standard duty cycle in the 1999 standards without derating factors for reclosing duty cycles, in accordance with the guidelines in the C37.010 application guide.

T. W. (Ted) Olsen Manager, Technology

2006 Siemens Power Transmission & Distribution, Inc. PO Box 29503, Raleigh, NC 27626

TechTopics No. 61 Page 2

S-ar putea să vă placă și

- DATA SHEET EP 65-12 (New)Document3 paginiDATA SHEET EP 65-12 (New)Sudipto Ranjan DassÎncă nu există evaluări

- CBIP Limit For TandeltaDocument1 paginăCBIP Limit For TandeltaMEPL VadodaraÎncă nu există evaluări

- IRI PRO V3 CatalogueDocument14 paginiIRI PRO V3 CatalogueThomas Joseph100% (2)

- Is 8084 1976Document32 paginiIs 8084 1976Ramesh AnanthanarayananÎncă nu există evaluări

- Setting File of 630 KW FD FanDocument11 paginiSetting File of 630 KW FD FanAbhisek SurÎncă nu există evaluări

- Disclosure To Promote The Right To InformationDocument14 paginiDisclosure To Promote The Right To InformationSajjad PirzadaÎncă nu există evaluări

- Relay SettingsDocument1 paginăRelay SettingsrajÎncă nu există evaluări

- Cigre Paper On CT FailureDocument6 paginiCigre Paper On CT Failureahmadshoeb19Încă nu există evaluări

- 11kV SPBD General TechnicalDocument12 pagini11kV SPBD General TechnicalNihar SenapatiÎncă nu există evaluări

- KVPS RAO - Sub-Station Experience-23Document20 paginiKVPS RAO - Sub-Station Experience-23Hari HaranÎncă nu există evaluări

- Operating Mannual of Digital Automatic Voltage Regulator (Davr)Document31 paginiOperating Mannual of Digital Automatic Voltage Regulator (Davr)ArvindPrasadÎncă nu există evaluări

- Generator Protection StudyDocument14 paginiGenerator Protection Studyjimmy hartantoÎncă nu există evaluări

- Ieema Journal For Testing of Power TransformerDocument11 paginiIeema Journal For Testing of Power TransformerAnushree RoyÎncă nu există evaluări

- Spaj140c1 PDFDocument29 paginiSpaj140c1 PDFRihlesh ParlÎncă nu există evaluări

- Instrument Transformer.: Y. K. PandharipandeDocument19 paginiInstrument Transformer.: Y. K. Pandharipandeupt vadodaraÎncă nu există evaluări

- Unitrol 6080 Excitation Systems: Proven Flexible SolutionsDocument12 paginiUnitrol 6080 Excitation Systems: Proven Flexible SolutionsEkanit ChuaykoedÎncă nu există evaluări

- Installation and Service Instructions 12 ... 24 KV - 630 ... 4000 A - 16 ... 50 KaDocument88 paginiInstallation and Service Instructions 12 ... 24 KV - 630 ... 4000 A - 16 ... 50 KaPetre GabrielÎncă nu există evaluări

- 1986-0040-EL-SPE01-0001 RA Specification For Induction MotorsDocument14 pagini1986-0040-EL-SPE01-0001 RA Specification For Induction MotorsjmohammadrezaÎncă nu există evaluări

- CM OLTC Operating Instruction-HM0.460.301Document45 paginiCM OLTC Operating Instruction-HM0.460.301zakirul islamÎncă nu există evaluări

- Operation, Erection & Maintenance For Power TrafoDocument50 paginiOperation, Erection & Maintenance For Power TrafoJagdeep KumarÎncă nu există evaluări

- BR PR PartsDocument18 paginiBR PR PartsKrishna KumarÎncă nu există evaluări

- DVR STG ProtocolDocument8 paginiDVR STG Protocolprt24Încă nu există evaluări

- AC Motor Name Plate - Terms & MeaningsDocument2 paginiAC Motor Name Plate - Terms & Meaningsavandetq15Încă nu există evaluări

- Type 2 Co-Ordination Selection ChartsDocument48 paginiType 2 Co-Ordination Selection ChartsShashank GuptaÎncă nu există evaluări

- Type VTT 11, 12: Definite Time Delay RelayDocument6 paginiType VTT 11, 12: Definite Time Delay RelayArun KumarÎncă nu există evaluări

- CMA9 MOTOR DRIVE ManualDocument29 paginiCMA9 MOTOR DRIVE ManualAshraf NazifÎncă nu există evaluări

- Mrs. Shweta PatelDocument4 paginiMrs. Shweta PatelJAY PARIKHÎncă nu există evaluări

- Industrial Training Presentation ROHIT YADAVDocument15 paginiIndustrial Training Presentation ROHIT YADAVROHIT YADAVÎncă nu există evaluări

- Static Excitation SystemDocument44 paginiStatic Excitation Systemgigelu79Încă nu există evaluări

- Why We Need Power Supplies and Batteries for Telecom EquipmentDocument18 paginiWhy We Need Power Supplies and Batteries for Telecom Equipmentsamad_omidvar629250% (2)

- Gen ProtDocument41 paginiGen Protmithun46Încă nu există evaluări

- IEEMA Article On Over Current ProtectionDocument5 paginiIEEMA Article On Over Current ProtectionHari Krishna.MÎncă nu există evaluări

- Surge Impedance Loading Techniques and BenefitsDocument6 paginiSurge Impedance Loading Techniques and BenefitsMadiha ChÎncă nu există evaluări

- Bty Charger 5.6KWDocument12 paginiBty Charger 5.6KWPankaj TiwariÎncă nu există evaluări

- As The Name Suggests, Permit Tap Changing and Hence Voltage Regulation With The Transformer During On-LoadDocument41 paginiAs The Name Suggests, Permit Tap Changing and Hence Voltage Regulation With The Transformer During On-LoadDaniel Galabo RangcapanÎncă nu există evaluări

- LV and MV Switchgear 7Document36 paginiLV and MV Switchgear 7ahvaz1392bÎncă nu există evaluări

- ApparatusDocument85 paginiApparatusTap ToanÎncă nu există evaluări

- BHELDocument26 paginiBHELVishal ChoudharyÎncă nu există evaluări

- 35MW Generator Test ReportDocument10 pagini35MW Generator Test ReportAshok KumarÎncă nu există evaluări

- Standard Numbering For Small Wiring For Switch Gear and AssociatedDocument4 paginiStandard Numbering For Small Wiring For Switch Gear and AssociatedPaul JonesÎncă nu există evaluări

- Condition Monitoring of Transformers SAILDocument17 paginiCondition Monitoring of Transformers SAILavadiraja100% (1)

- Ehv Circuit BreakersDocument12 paginiEhv Circuit BreakersBoreda RahulÎncă nu există evaluări

- Report On Mejia Thermal Power Plant DVCDocument75 paginiReport On Mejia Thermal Power Plant DVCRahul Roy0% (1)

- Control TransformerDocument3 paginiControl TransformerlehuanÎncă nu există evaluări

- Guaranteed Technical Particulars of Vacuum Interrupter Type Vg4-02 Equivalent To V-207 GBDocument3 paginiGuaranteed Technical Particulars of Vacuum Interrupter Type Vg4-02 Equivalent To V-207 GBLalit SoniÎncă nu există evaluări

- Improved Reactive Power Capability With Grid Connected Doubly Fed Induction GeneratorDocument14 paginiImproved Reactive Power Capability With Grid Connected Doubly Fed Induction GeneratorUday Wankar100% (2)

- Limit-Torque BroucherDocument16 paginiLimit-Torque BroucherChakravarthi NagaÎncă nu există evaluări

- What Is Tap ChangerDocument42 paginiWhat Is Tap ChangerMatele de GilesÎncă nu există evaluări

- Figure 1: Voltage Injection Unit RXTTE4 With Its Main Internal ComponentsDocument15 paginiFigure 1: Voltage Injection Unit RXTTE4 With Its Main Internal ComponentsAlfonso Núñez SchorrÎncă nu există evaluări

- Generator ReactancesDocument3 paginiGenerator ReactancesLora BishopÎncă nu există evaluări

- Transformer Losses & EfficencyDocument8 paginiTransformer Losses & EfficencyMuhammad ZumyÎncă nu există evaluări

- Transformer BhelDocument17 paginiTransformer BhelAayushiÎncă nu există evaluări

- IOC Tr. Oil Test ReportDocument3 paginiIOC Tr. Oil Test ReportMalini VenkatesanÎncă nu există evaluări

- KKMurty Sir Tutorial On Differential Protn CKT - IEEMA Journal May'22Document6 paginiKKMurty Sir Tutorial On Differential Protn CKT - IEEMA Journal May'22Amit BiswasÎncă nu există evaluări

- Alm 36Document14 paginiAlm 36Meet Kumar KataraÎncă nu există evaluări

- Stator Earth Fault in 200MW Generator-A Case StudyDocument5 paginiStator Earth Fault in 200MW Generator-A Case StudylrpatraÎncă nu există evaluări

- ANSIDocument2 paginiANSIchauhanv4uÎncă nu există evaluări

- Cigre, 13 Years Test Experience With Short Circuit Withstand Capability of Large Power TransformersDocument7 paginiCigre, 13 Years Test Experience With Short Circuit Withstand Capability of Large Power TransformersAnonymous YBOliZYÎncă nu există evaluări

- Harmonic Analysis of Transformer LoadDocument2 paginiHarmonic Analysis of Transformer LoadRavishankar.AzadÎncă nu există evaluări

- Short CKT Force in IPBDocument5 paginiShort CKT Force in IPBRavishankar.AzadÎncă nu există evaluări

- Earthing Calculation - V - 0.2Document18 paginiEarthing Calculation - V - 0.2Ravishankar.AzadÎncă nu există evaluări

- Basics of Arc FlashDocument13 paginiBasics of Arc FlashRavishankar.AzadÎncă nu există evaluări

- CT GroundingDocument2 paginiCT GroundingRavishankar.AzadÎncă nu există evaluări

- Contactors PDFDocument264 paginiContactors PDFRavishankar.AzadÎncă nu există evaluări

- Microsoft PowerPoint - Motor Protection Principles 101308.Ppt - Motor Protection PrinciplesDocument35 paginiMicrosoft PowerPoint - Motor Protection Principles 101308.Ppt - Motor Protection PrinciplesPaneendra Kumar0% (1)

- Arc Flash Hazard Incident PDFDocument13 paginiArc Flash Hazard Incident PDFRaja Bharath DonthiÎncă nu există evaluări

- GCBDocument10 paginiGCBRavishankar.AzadÎncă nu există evaluări

- MCX912 913Document98 paginiMCX912 913Ravishankar.Azad100% (1)

- Circuit BreakersDocument88 paginiCircuit Breakersjhigz25Încă nu există evaluări

- 7PG15 TR Catalogue SheetDocument30 pagini7PG15 TR Catalogue SheetRavishankar.Azad0% (1)

- NEMA MotorsEnglish CGLDocument21 paginiNEMA MotorsEnglish CGLRavishankar.AzadÎncă nu există evaluări

- Distance Control of AC Relays and ContactorsDocument28 paginiDistance Control of AC Relays and ContactorsRavishankar.AzadÎncă nu există evaluări

- Microsoft PowerPoint - Motor Protection Principles 101308.Ppt - Motor Protection PrinciplesDocument35 paginiMicrosoft PowerPoint - Motor Protection Principles 101308.Ppt - Motor Protection PrinciplesPaneendra Kumar0% (1)

- DC Short CKT CalculationDocument5 paginiDC Short CKT CalculationRavishankar.AzadÎncă nu există evaluări

- CT DimensioningDocument12 paginiCT DimensioningwaelateaÎncă nu există evaluări

- ABB Solution to Harmonics and Capacitor ProductsDocument6 paginiABB Solution to Harmonics and Capacitor ProductsRavishankar.AzadÎncă nu există evaluări

- Comparison For Voltage Drop For DOL and Star-Delta StarterDocument3 paginiComparison For Voltage Drop For DOL and Star-Delta StarterRavishankar.Azad100% (1)

- Application Note - Co-Ordination of Protection DeviceDocument8 paginiApplication Note - Co-Ordination of Protection DeviceRavishankar.AzadÎncă nu există evaluări

- Contactor Control Motor Feeder Application GuideDocument14 paginiContactor Control Motor Feeder Application GuideRavishankar.AzadÎncă nu există evaluări

- Application Note - Co-Ordination of Protection DeviceDocument8 paginiApplication Note - Co-Ordination of Protection DeviceRavishankar.AzadÎncă nu există evaluări

- Benefits and Drawbacks of Geothermal Energy SystemsDocument1 paginăBenefits and Drawbacks of Geothermal Energy SystemszapÎncă nu există evaluări

- Enercon Technology Service EngDocument32 paginiEnercon Technology Service EnggeguzeÎncă nu există evaluări

- Civil Mech Process Electrical InstrumentDocument2 paginiCivil Mech Process Electrical InstrumentAbhishek JainÎncă nu există evaluări

- An Economic Dispatch Model Incorporating Wind PowerDocument9 paginiAn Economic Dispatch Model Incorporating Wind PowerBalajiÎncă nu există evaluări

- Technical Study of Electric Vehicles and Charging InfrastructureDocument455 paginiTechnical Study of Electric Vehicles and Charging InfrastructureRudra BarotÎncă nu există evaluări

- Install and operate packaged air conditioners safelyDocument10 paginiInstall and operate packaged air conditioners safelyWild AntÎncă nu există evaluări

- Analysis Calculation Performance Engine Turbofan Cfm56Document8 paginiAnalysis Calculation Performance Engine Turbofan Cfm56AswanTajuddin100% (1)

- Tabla de Factores de Conversión de UnidadesDocument2 paginiTabla de Factores de Conversión de UnidadesAnonymous mJNbkg1C0Încă nu există evaluări

- 0530 DWG BSC 40 007 - Grounding - Rev02Document1 pagină0530 DWG BSC 40 007 - Grounding - Rev02Luis Marín DíazÎncă nu există evaluări

- MNS MNS: Auto Transfert Switch UnitDocument2 paginiMNS MNS: Auto Transfert Switch Unitluat1983Încă nu există evaluări

- Navigating Out of The Static - On The Ultimate Stream of ConsciousnessDocument61 paginiNavigating Out of The Static - On The Ultimate Stream of Consciousnesstina_4979017820% (1)

- MB3746 ManualmainDocument12 paginiMB3746 ManualmainSarah Daphne FooÎncă nu există evaluări

- APS-6R: 6.0 Amp Auxilary Power SupplyDocument2 paginiAPS-6R: 6.0 Amp Auxilary Power SupplyDinaÎncă nu există evaluări

- Robot PetroleroDocument2 paginiRobot PetroleroMariannaÎncă nu există evaluări

- PS1800 C-SJ3-18: Solar Submersible Pump System For 4" WellsDocument2 paginiPS1800 C-SJ3-18: Solar Submersible Pump System For 4" WellsSYAHRULÎncă nu există evaluări

- Fusibles NH FEDERALDocument11 paginiFusibles NH FEDERALantonioÎncă nu există evaluări

- List of FINAL TOPICS 23-24 N-SBDocument9 paginiList of FINAL TOPICS 23-24 N-SBAkashdeep Sunil WaghmareÎncă nu există evaluări

- SEPAM Seria80Document324 paginiSEPAM Seria80Chiana PetreÎncă nu există evaluări

- Map of Nigeria Oil FieldDocument1 paginăMap of Nigeria Oil Fieldriddi12350% (10)

- Benefits of Paper RecyclingDocument5 paginiBenefits of Paper RecyclingArun KCÎncă nu există evaluări

- Earth Science Quarter 1 - Module 4Document3 paginiEarth Science Quarter 1 - Module 4Shelly Ryn SaligumbaÎncă nu există evaluări

- Air N2 Receiver Size EstimationDocument5 paginiAir N2 Receiver Size EstimationHenry WicaksanaÎncă nu există evaluări

- Seminar On Wireless Charging of Mobile DevicesDocument24 paginiSeminar On Wireless Charging of Mobile DevicesGourish Amonkar100% (1)

- Fans InPower PlantsDocument48 paginiFans InPower PlantsitsdilipÎncă nu există evaluări

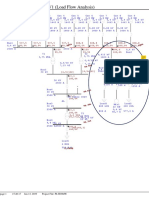

- OLV1 (Load Flow Analysis)Document1 paginăOLV1 (Load Flow Analysis)Alry PurwariyadiÎncă nu există evaluări

- Waste Management AerbDocument54 paginiWaste Management AerbSandesh AvadhaniÎncă nu există evaluări

- GENERATING ELECTRICITYDocument34 paginiGENERATING ELECTRICITYAdeniji OlusegunÎncă nu există evaluări

- Emmy SeminarDocument21 paginiEmmy SeminarEdul BrianÎncă nu există evaluări

- EAP1220.4B - Mai Thuy Dung - Summary&CritiqueDocument2 paginiEAP1220.4B - Mai Thuy Dung - Summary&CritiqueDung MaiÎncă nu există evaluări

- ECO80 - 1,67MW-2.0MW (Folleto)Document4 paginiECO80 - 1,67MW-2.0MW (Folleto)Ingenieria SydisÎncă nu există evaluări