Documente Academic

Documente Profesional

Documente Cultură

Asset Requirements Planning (ARP) : Extending ERP's Reach To The

Încărcat de

worldtelemetry0 evaluări0% au considerat acest document util (0 voturi)

481 vizualizări1 paginăAn Asset Requirements Planning system is a

valuable addition to an existing ERP system

within organizations dealing with wet stock

inventory. ARP optimizes a company’s value

chain from the asset (tank) level all the way to

the execution engine.

Titlu original

Asset Requirements Planning (ARP): Extending ERP’s Reach to the

Drepturi de autor

© Attribution Non-Commercial (BY-NC)

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentAn Asset Requirements Planning system is a

valuable addition to an existing ERP system

within organizations dealing with wet stock

inventory. ARP optimizes a company’s value

chain from the asset (tank) level all the way to

the execution engine.

Drepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

481 vizualizări1 paginăAsset Requirements Planning (ARP) : Extending ERP's Reach To The

Încărcat de

worldtelemetryAn Asset Requirements Planning system is a

valuable addition to an existing ERP system

within organizations dealing with wet stock

inventory. ARP optimizes a company’s value

chain from the asset (tank) level all the way to

the execution engine.

Drepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 1

WorldTelemetry

ASSET REQUIREMENTS PLANNING

OVERVIEW M A N A G E M E N T C O N C E P T

Asset Requirements Planning (ARP):

An Asset Requirements Planning system is a

valuable addition to an existing ERP system

Asset Requirements Planning:

within organizations dealing with wet stock

inventory. ARP optimizes a company’s value Extending ERP’s Reach to the

chain from the asset (tank) level all the way to

the execution engine. Edge of the Supply Chain

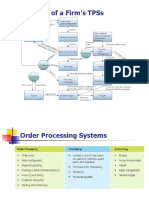

WHAT ERP IS MISSING nent of wet stock inventory management, particularly in VMI

situations, can be performed in different ways. In many com-

While an existing ERP system may have the capability to fore- panies, analysts manually study aggregated inventory data

cast supply requirements for dry stock inventories by applying and decide what ordering decisions to make based on the

statistical techniques, critical data needed to accurately fore- information available as well as personal experience. Compa-

cast wet stock inventory requirements is not available to these nies can improve this process by implementing an automatic

systems. ERP systems focus on planning at the overall product decision support tool. This type of software automatically

and customer level, while an ARP system focuses on planning analyzes the aggregated inventory data and creates sugges-

at the asset level and its unique constraints. For example, in a tions for supply chain decisions based on forecasted upcom-

wet-stock inventory situation, ARP focuses on asset constraints ing usage. These forecasts, based on historical and empirical

of each individual on-site storage tank, such as tank capac- data, are designed to keep enough inventory on-hand for the

ity, average daily usage rates, tank ullage, geometry, heel, anticipated demand, without keeping any unnecessary inven-

overfill and optimal levels, necessary bottom safety stock, and tory on-site.

delivery detection. These constraints are not only crucially 4) Integration to an execution engine / back office / ERP

important to optimal management; they can also change daily system - The execution of the supply chain decision is man-

depending on pump rates and usage. aged through the vendor’s back office system, often an ERP

The data necessary to optimize an ERP system’s outputs for application. The necessary products are ordered, delivered

wet stock inventory management is made available through and invoiced. This is another process that might be manual or

the implementation of an Asset Requirements Planning might have some portions that have been enhanced by tech-

system. This provides the necessary decision support for a nology, but full automation would be optimal. With the right

cost-saving, efficient wet-stock inventory control process that decision support tool, this would simply mean accepting the

extends to the asset level. software’s suggested orders.

WET STOCK INVENTORY MANAGEMENT ASSET REQUIREMENTS PLANNING (ARP)

Optimal management of wet-stock inventory requires four An Asset Requirements Planning (ARP) system encompasses

integral parts: all four necessary components of optimal wet-stock inven-

1) Automated data collection – Data collection is the tory management. Because it performs all of these required

gathering of information about current inventory levels. For processes effectively and automatically, it decreases operating

many companies, this is still a manual process. That means an costs, especially those associated with providing VMI services

appointed employee travels throughout a site, taking mea- to customers, while increasing the value of an existing ERP

surements or reading gauges on storage tanks to collect the system.

inventory data. Some companies have implemented automat-

ic monitoring equipment to achieve this goal more efficiently

BENEFITS OF ARP

and with less human error. Increased value of existing ERP systems

2) Automated data aggregation – Data aggregation in- Lowered operational expenses

volves centralizing all of the information gathered and making

it accessible for analysis. Many companies utilize spreadsheets Lower cost involved with offering VMI services

to accomplish this task, while a few have aggregation software Decreased inventory carry costs

in place to make the data centralized and visible. Optimized logistics / distribution

3) Automated data analysis - Data analysis, a key compo-

www.worldtelemetry.com

S-ar putea să vă placă și

- 1 s2.0 S2212827115012019 MainDocument5 pagini1 s2.0 S2212827115012019 MainHadi P.Încă nu există evaluări

- "Erp Uses in Management and Supply Chain": Project Report OnDocument19 pagini"Erp Uses in Management and Supply Chain": Project Report OnAman KumarÎncă nu există evaluări

- Erp-Boon To Supply Chain Management - Sastra UniversityDocument14 paginiErp-Boon To Supply Chain Management - Sastra UniversityPradeesh Kumar.AÎncă nu există evaluări

- ERP ANALYSIS OF RMG SECTORDocument14 paginiERP ANALYSIS OF RMG SECTORdev bijoyÎncă nu există evaluări

- Erp in RMG Sector PDFDocument22 paginiErp in RMG Sector PDFdev bijoyÎncă nu există evaluări

- Implementing IT in Supply Chain ManagementDocument49 paginiImplementing IT in Supply Chain ManagementpdraiÎncă nu există evaluări

- Unit - 1 Erp ConceptsDocument36 paginiUnit - 1 Erp ConceptsgbsshravanthyÎncă nu există evaluări

- Information Technology and Supply Chain Management: SCM 614 Dr. Huei Lee Eastern Michigan UniversityDocument60 paginiInformation Technology and Supply Chain Management: SCM 614 Dr. Huei Lee Eastern Michigan UniversityDeepesh PathakÎncă nu există evaluări

- Adding Enterprise Analytics: To Your ERPDocument7 paginiAdding Enterprise Analytics: To Your ERPpartho143Încă nu există evaluări

- Role of IT in SCM-notesDocument63 paginiRole of IT in SCM-notespiyushsithaÎncă nu există evaluări

- Chapter 11 ENTERPRISE RESOURCE PLANNING SYSTEMSDocument43 paginiChapter 11 ENTERPRISE RESOURCE PLANNING SYSTEMSisaiah menesesÎncă nu există evaluări

- SCM & ErpDocument31 paginiSCM & ErpVrinda MadhuÎncă nu există evaluări

- An Overview of ERPDocument42 paginiAn Overview of ERPBelajar MO100% (1)

- What Is An ERP System?: Prepare By: Dr. Usman Tariq 17 January 2020Document31 paginiWhat Is An ERP System?: Prepare By: Dr. Usman Tariq 17 January 2020Faisal AlharbiÎncă nu există evaluări

- Mba PFM 6105 PDFDocument22 paginiMba PFM 6105 PDFdev bijoyÎncă nu există evaluări

- ERPDocument30 paginiERPsbr11Încă nu există evaluări

- Enterprise Resource Planning SystemDocument4 paginiEnterprise Resource Planning SystemWendelyn TutorÎncă nu există evaluări

- Unit-I Introduction To Erp Enterprise Resource Planning (ERP) Is An Integrated Computer-Based SystemDocument51 paginiUnit-I Introduction To Erp Enterprise Resource Planning (ERP) Is An Integrated Computer-Based Systemchandru5g100% (4)

- Why ERP Enhances Profitability Through Increased Sales & Reduced CostsDocument61 paginiWhy ERP Enhances Profitability Through Increased Sales & Reduced CostsVidya VenkatesanÎncă nu există evaluări

- MRP An ImplementationDocument13 paginiMRP An ImplementationmishrarÎncă nu există evaluări

- The Evolution of ERP from MRP to Web-Based SystemsDocument27 paginiThe Evolution of ERP from MRP to Web-Based SystemsSumit Gupta50% (2)

- An Overview of Enterprise Resource Planning (Erp)Document13 paginiAn Overview of Enterprise Resource Planning (Erp)sunnygangisettiÎncă nu există evaluări

- ERP ConceptsDocument27 paginiERP ConceptsPranav JainÎncă nu există evaluări

- ERP ConceptsDocument27 paginiERP ConceptsLaxmi PaiÎncă nu există evaluări

- Energy Aware ERPDocument7 paginiEnergy Aware ERPJOHAN GERARDO GONZALEZ GILÎncă nu există evaluări

- Role of ASCPDocument8 paginiRole of ASCPPrabhu DevÎncă nu există evaluări

- Erp - 6 Sim - 1Document51 paginiErp - 6 Sim - 1Scroll with deepriyaÎncă nu există evaluări

- ERP Guide: Benefits and Evolution of Enterprise Resource PlanningDocument91 paginiERP Guide: Benefits and Evolution of Enterprise Resource PlanningScroll with deepriyaÎncă nu există evaluări

- ERP Systems vs WMS for Warehouse ManagementDocument11 paginiERP Systems vs WMS for Warehouse ManagementLucija PetrićÎncă nu există evaluări

- LectraDocument38 paginiLectraNiharika SinhaÎncă nu există evaluări

- Chapter 11 Enterprise Resource Planning Systems Reporter 23 - CHAPTER 11 - Enterprise Resource Planning Systems 545Document6 paginiChapter 11 Enterprise Resource Planning Systems Reporter 23 - CHAPTER 11 - Enterprise Resource Planning Systems 545Nazee Mohammad IsaÎncă nu există evaluări

- Assignment: Mohammad Ali Jinnah UniversityDocument4 paginiAssignment: Mohammad Ali Jinnah UniversityAbdullah KhanÎncă nu există evaluări

- Enterprise Resource Planning - ErpDocument26 paginiEnterprise Resource Planning - ErpNerish PlazaÎncă nu există evaluări

- ISCMDocument3 paginiISCMSyed Jawwad ul hasanÎncă nu există evaluări

- IT's Role in Walmart's Efficient SCMDocument43 paginiIT's Role in Walmart's Efficient SCMAman AgarwalÎncă nu există evaluări

- Ais ErpDocument11 paginiAis ErpmikamiiÎncă nu există evaluări

- New Microsoft Word DocumentDocument6 paginiNew Microsoft Word DocumentRahul BangaÎncă nu există evaluări

- EPI Enterprise Resource Planning: Computerized Maintenance Management SystemDocument8 paginiEPI Enterprise Resource Planning: Computerized Maintenance Management SystemAlfa MirzaÎncă nu există evaluări

- Erp AssignmentDocument15 paginiErp AssignmentAfrah Abdul AzeezÎncă nu există evaluări

- Lecture 2C TPS Processing 1Document27 paginiLecture 2C TPS Processing 1harpal05Încă nu există evaluări

- Relational Database System: Selected LinksDocument10 paginiRelational Database System: Selected Linksapi-251145380Încă nu există evaluări

- ERP Unit 12 Benefits of ERPDocument14 paginiERP Unit 12 Benefits of ERPAnonymous bTh744z7E60% (1)

- Enterprise Resource Planning: Erp Modules and Their Applications 1/30/2012Document41 paginiEnterprise Resource Planning: Erp Modules and Their Applications 1/30/2012Richa Sharma100% (1)

- Technology and Safety in Warehouse ManagementDocument7 paginiTechnology and Safety in Warehouse ManagementAbigail SalasÎncă nu există evaluări

- Manufacturing Resource Planning (MRP Ii) : Dr. Parneeta ThakurDocument17 paginiManufacturing Resource Planning (MRP Ii) : Dr. Parneeta ThakurParneeta ThakurÎncă nu există evaluări

- A Study On E Nterprise R Esource P LanningDocument15 paginiA Study On E Nterprise R Esource P LanningKrishnaKumar BrahmarouthuÎncă nu există evaluări

- Inventory MNGDocument7 paginiInventory MNGshyamÎncă nu există evaluări

- Rolls RoyceDocument17 paginiRolls Roycegaurav1590Încă nu există evaluări

- Error: Reference Source Not FoundDocument6 paginiError: Reference Source Not Foundpriya08lumbaÎncă nu există evaluări

- Basic Introduction About SAP ERP ECC and FICODocument12 paginiBasic Introduction About SAP ERP ECC and FICOsurnis4onkarÎncă nu există evaluări

- ERP Helps Productivity at Northern Digital IncDocument10 paginiERP Helps Productivity at Northern Digital IncImeldaÎncă nu există evaluări

- ERPgDocument24 paginiERPgLokesh ShewaniÎncă nu există evaluări

- DHL Logbook - ERPDocument3 paginiDHL Logbook - ERPThomas TaylorÎncă nu există evaluări

- Weaknesses of MRP: Name: Atreyee Sarma ROLL: 008Document8 paginiWeaknesses of MRP: Name: Atreyee Sarma ROLL: 008Atreyee SarmaÎncă nu există evaluări

- Software System Enables Effective Flow-Assurance Management: The ChallengeDocument3 paginiSoftware System Enables Effective Flow-Assurance Management: The ChallengeCarlos Alfredo Viloria RivasÎncă nu există evaluări

- Literature Review On Enterprise Resource Planning (ERP)Document6 paginiLiterature Review On Enterprise Resource Planning (ERP)Sheel ShahÎncă nu există evaluări

- Enterprise Resource Planning (Erp) the Great Gamble: An Executive’S Guide to Understanding an Erp ProjectDe la EverandEnterprise Resource Planning (Erp) the Great Gamble: An Executive’S Guide to Understanding an Erp ProjectEvaluare: 4.5 din 5 stele4.5/5 (5)

- The Official Supply Chain Dictionary: 8000 Researched Definitions for Industry Best-Practice GloballyDe la EverandThe Official Supply Chain Dictionary: 8000 Researched Definitions for Industry Best-Practice GloballyEvaluare: 4 din 5 stele4/5 (4)

- Business Visibility with Enterprise Resource PlanningDe la EverandBusiness Visibility with Enterprise Resource PlanningÎncă nu există evaluări

- Vendor Managed Inventory: Using Trust, Information & Relationships To Improve Operational EfficiencyDocument5 paginiVendor Managed Inventory: Using Trust, Information & Relationships To Improve Operational EfficiencyworldtelemetryÎncă nu există evaluări

- Intrinsic Safety and GPRS: Wireless, Safe and Convenient Liquid Asset Monitoring SolutionsDocument4 paginiIntrinsic Safety and GPRS: Wireless, Safe and Convenient Liquid Asset Monitoring SolutionsworldtelemetryÎncă nu există evaluări

- Calculating The Return On Investment For Automated Remote Data Acquisition and Aggregation SystemsDocument3 paginiCalculating The Return On Investment For Automated Remote Data Acquisition and Aggregation SystemsworldtelemetryÎncă nu există evaluări

- Achieving Predictable ROI With An End-To-End Wet Stock Inventory Monitoring SolutionDocument3 paginiAchieving Predictable ROI With An End-To-End Wet Stock Inventory Monitoring SolutionworldtelemetryÎncă nu există evaluări

- Business Intelligence For Wet Stock Inventory ManagementDocument3 paginiBusiness Intelligence For Wet Stock Inventory ManagementworldtelemetryÎncă nu există evaluări

- San Jose Police Department - Joe Gomez IncriminationDocument2 paginiSan Jose Police Department - Joe Gomez Incriminationchase manuelÎncă nu există evaluări

- Anomaly Sell Out Remap December 2019 S SUMATRA & JAMBIDocument143 paginiAnomaly Sell Out Remap December 2019 S SUMATRA & JAMBITeteh Nha' DwieÎncă nu există evaluări

- Afar Partnerships Ms. Ellery D. de Leon: True or FalseDocument6 paginiAfar Partnerships Ms. Ellery D. de Leon: True or FalsePat DrezaÎncă nu există evaluări

- Personal InsuranceDocument11 paginiPersonal InsuranceSumit Kumar SharmaÎncă nu există evaluări

- BUSN7054 Take Home Final Exam S1 2020Document14 paginiBUSN7054 Take Home Final Exam S1 2020Li XiangÎncă nu există evaluări

- Frequency Meter by C Programming of AVR MicrocontrDocument3 paginiFrequency Meter by C Programming of AVR MicrocontrRajesh DhavaleÎncă nu există evaluări

- VB 2Document11 paginiVB 2Sudhir IkkeÎncă nu există evaluări

- VSP-12Way - Is Rev.03Document55 paginiVSP-12Way - Is Rev.03Marcelo AlmeidaÎncă nu există evaluări

- ProkonDocument57 paginiProkonSelvasatha0% (1)

- Exam Venue For Monday Sep 25, 2023 - 12-00 To 01-00Document7 paginiExam Venue For Monday Sep 25, 2023 - 12-00 To 01-00naveed hassanÎncă nu există evaluări

- Anthony Flagg's Complaint Against Eddie LongDocument23 paginiAnthony Flagg's Complaint Against Eddie LongRod McCullom100% (1)

- Broadband BillDocument1 paginăBroadband BillKushi GowdaÎncă nu există evaluări

- Coupled Mode TheoryDocument5 paginiCoupled Mode TheoryRahul RoyÎncă nu există evaluări

- Converting An XML File With Many Hierarchy Levels To ABAP FormatDocument8 paginiConverting An XML File With Many Hierarchy Levels To ABAP FormatGisele Cristina Betencourt de OliveiraÎncă nu există evaluări

- Synopsis: A Study On Customer Satisfaction AT Nerolac Paints LTD., KadapaDocument5 paginiSynopsis: A Study On Customer Satisfaction AT Nerolac Paints LTD., KadapaAnu GraphicsÎncă nu există evaluări

- A Dream Takes FlightDocument3 paginiA Dream Takes FlightHafiq AmsyarÎncă nu există evaluări

- Proprietar Utilizator Nr. Crt. Numar Inmatriculare Functie Utilizator Categorie AutovehiculDocument3 paginiProprietar Utilizator Nr. Crt. Numar Inmatriculare Functie Utilizator Categorie Autovehicultranspol2023Încă nu există evaluări

- Fall Protection ANSIDocument5 paginiFall Protection ANSIsejudavisÎncă nu există evaluări

- Statement of PurposeDocument2 paginiStatement of Purposearmaan kaurÎncă nu există evaluări

- Chapter 1 - Introduction To Computer NetworksDocument32 paginiChapter 1 - Introduction To Computer NetworksHuluÎncă nu există evaluări

- Activate Adobe Photoshop CS5 Free Using Serial KeyDocument3 paginiActivate Adobe Photoshop CS5 Free Using Serial KeyLukmanto68% (28)

- Method Statement of Static Equipment ErectionDocument20 paginiMethod Statement of Static Equipment Erectionsarsan nedumkuzhi mani100% (4)

- 【4DI+4DO】MA01+-AXCX4040 UserManual EN v1.1Document36 pagini【4DI+4DO】MA01+-AXCX4040 UserManual EN v1.1RioNorte LojaÎncă nu există evaluări

- A - Bahasa Inggris-DikonversiDocument96 paginiA - Bahasa Inggris-DikonversiArie PurnamaÎncă nu există evaluări

- Forecasting AssignmentDocument1 paginăForecasting AssignmentVarun Singh100% (1)

- Lesson 3 - Materials That Undergo DecayDocument14 paginiLesson 3 - Materials That Undergo DecayFUMIKO SOPHIA67% (6)

- Rtlo 18918B 1202Document42 paginiRtlo 18918B 1202gustavomosqueraalbornozÎncă nu există evaluări

- Safety of High-Rise BuildingsDocument14 paginiSafety of High-Rise BuildingsHananeel Sandhi100% (2)

- Wheat as an alternative to reduce corn feed costsDocument4 paginiWheat as an alternative to reduce corn feed costsYuariza Winanda IstyanÎncă nu există evaluări

- (EMERSON) Loop CheckingDocument29 pagini(EMERSON) Loop CheckingDavid Chagas80% (5)