Documente Academic

Documente Profesional

Documente Cultură

P&I Diagram

Încărcat de

Mohamed AminDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

P&I Diagram

Încărcat de

Mohamed AminDrepturi de autor:

Formate disponibile

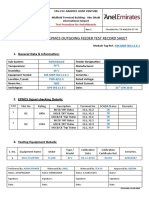

1.

3 Process & Instrumentation Diagram

An important means for engineering communication in the process industry is the so

called Process & Instrumentation (P&I) diagram. Figure 1.5 shows the P&I diagram of a

typical industrial heat exchanger. Heat exchanger is a process unit in which steam is used

to heat up a liquid material. The material ( called feedstock) is pumped at a specific flow

rate into the pipes passing through the heat exchanger chamber where heat is transferred

from steam to the material in the pipe. It is usually desired to regulate the temperature of

the outlet flow irrespective of the change in the demand (flow rate) of the feedstock or

change in the inlet temperature of the feedstock. The regulation of the outlet temperature

is achieved by automatic control of the steam flow rate to the heat exchanger. The P&I

diagram utilizes certain standard symbols to represent the process units, the

instrumentation, and the process flow.

A Process & Instrumentation diagram consists of:

1- A pictorial representation of the major pieces of equipment required with major lines

of flow to and from each piece.

2- All other equipment items with design temperatures, pressures, flow, etc..

3- All interconnecting piping with size, material and fabrication specifications

indicated.

4. All major instrument devices.

FIGURE 1.5

P&I Diagram of a Heat Exchanger

A partial list of the symbols and abbreviations are given in the tables in Appendix 1.A at

the end of this chapter. A comprehensive coverage may be found in the ISA standard in

reference [1]. Instruments are shown on the P&I diagram by circles, usually called

“balloons”. The balloons contain alphanumeric which reflect the function of the

instrument and its tag number. For example, TT102 means Temperature Transmitter

number 2 in the process unit (or area ) number 1. The number 102 is called tag number.

Each Temperature Transmitter (TT) must have a unique tag number in the plant. Tag

numbering may be different from one user to the other. P&I diagrams provide a valuable

reference for proper project installation. The instrument engineer uses it as a source for

many documents which must be prepared.

Another type of diagrams is known as Process flow Sheet. Process flow sheets consist

also of a pictorial representation of the major pieces of equipment required with major

lines of flow to and from each piece. However, additional information often given

includes operating conditions at various stages of the process (flows, pressures,

temperatures, viscosity, etc.), material balance, equipment size and configuration and, in

some cases, utility requirements. On the other hand, instrumentation on process flow

sheets may or may not be essentially complete.

A third type of diagrams is called Loop Wiring Diagrams. Electrical loop wiring

diagrams are electrical schematic drawings which are prepared for individual (or typical)

electrical loops. The simplest loop is one that contains only a transmitter and a receiver.

Other loops may contain many items such as; transmitters. recorders. controllers, alarm

units, control valves, transducers, integrators, and perhaps other items. Loop wiring

Diagrams are intended to show the location of the instruments, their identification

numbers and termination of interconnecting wiring. Cable routing, wire size intermediate

terminal points and other pertinent information are necessarily shown in other drawings.

However, knowledge of these diagrams is not required to understand the material of this

book. Understanding the basic P& I examples shown in this book can easily be achieved

following the heat exchanger example. The reader should consult Appendix 1.A to

verify and understand the following instruments list of the heat exchanger P&I diagram.

Instrument Description

FIC-101 Flow Indicator and Controller.0 to 50 m3/Hr, (normal reading 30

T/Hr).

This instrument controls the flow of cold feedstock entering the tube

side of the heat exchanger by positioning a valve on the cold

feedstock flow path.

FR-103 Flow Recorder, 0 to 10 Ton/Hr, (2.14 T/Hr).

This instrument records the steam flow rate.

HS-101 Hand Switch, ON/OFF (ON).

This switch turns on/off cold feedstock pump P-101. When the

switch is in the ON condition, the pump is running. When the

switch is in the OFF condition, the pump is not running.

HV-102 Hand Valve, OPEN/CLOSED, (OPEN).

This switch opens/closes the steam block valve through which steam

is routed from the header to the shell side of the heat exchanger.

When the switch is in the OPEN condition the block valve is open.

When the switch is in the CLOSED condition, the block valve is

closed.

PAL-103 Pressure Alarm Low, (Normal).

This alarm fires should the steam header pressure be less than 6

kg/cm.sqr.

PI-100 Pressure Indicator, 0 to 15 kg/cm.sqr , (3.18 Kg/cm2).

This instrument displays the steam pressure at the shell side of the

heat exchanger.

PI-103 Pressure Indicator, 0 to 15 kg/cm.sqr, (10.55 Kg/cm2).

This instrument displays the steam header pressure.

TAH/L-102 Temperature Alarm High/Low, (Normal).

This alarm fires should the temperature of the feedstock at the

exchanger outlet exceed 85 °C or be less than 71°C.

TI-103 Temperature Indicator, 0 to 200°C, (186 °C).

This instrument displays the temperature of the steam entering the

shell side of the heat exchanger.

TIRC-102 Temperature Indicator, Recorder, and Controller, 0 to 200°C, (80

°C).

This instrument controls the temperature of the feedstock at the

exchanger outlet by positioning the valve that regulates the steam

flow to the exchanger.

TR-101 Temperature Recorder, 0 to 200°C, (38 °C).

This instrument displays the temperature of the feedstock entering

the exchanger.

APPENDIX 1.A

Process & Instrumentation Diagram

FIGURE 1.A-1

Line Symbols of the P&I Diagrams.

Table 1.A-1. Meanings of Identification Letters

First Succeeding letters

Letter

A Analysis Alarm

B Burner flame

C Conductivity Control

D Density or specific gravity

E Voltage Primary element

F Flow rate

H Hand (manually initiated) High

Current Indicate

Power

K Time or time schedule Control station

L Level Light or low

M Moisture or humidity Middle or intermediate

O Orifice

P Pressure or vacuum Point

Q Quantity or event

R Radioactivity or ratio Record or print

S Speed or frequency Switch

T Temperature Transmit

V Viscosity Valve, damper, or louver

W Weight or force Well

Y Relay or compute

Z Position Drive

FIGURE 1.A-2

Summary of common symbols used in P&I diagrams.

S-ar putea să vă placă și

- VC-6000 Monitoring SystemDocument8 paginiVC-6000 Monitoring Systemahwaz89Încă nu există evaluări

- Basic InstrumentionDocument25 paginiBasic InstrumentionVijay SharmaÎncă nu există evaluări

- T&CDocument13 paginiT&CAbdurRahmanFÎncă nu există evaluări

- Power Transformer - For SwitchayrdDocument20 paginiPower Transformer - For SwitchayrdSindhuKumarÎncă nu există evaluări

- Circuit Breaker - For SwitchayrdDocument9 paginiCircuit Breaker - For SwitchayrdSindhuKumarÎncă nu există evaluări

- Winding Resistance Test: Main StatorDocument4 paginiWinding Resistance Test: Main Statorworkshop Ega SbyÎncă nu există evaluări

- Supervisor de Actuador PDFDocument2 paginiSupervisor de Actuador PDFAob AprilÎncă nu există evaluări

- Maintenance Manual - TD-TSP-0004-2A PDFDocument19 paginiMaintenance Manual - TD-TSP-0004-2A PDFSidhartha MallickÎncă nu există evaluări

- Avr Trouble ShootingDocument2 paginiAvr Trouble ShootingJAYKUMAR SINGHÎncă nu există evaluări

- Oil BDV Test ReportDocument1 paginăOil BDV Test ReportMani kalaiÎncă nu există evaluări

- JFR Instruction Manual AVRDocument28 paginiJFR Instruction Manual AVRSugar RayÎncă nu există evaluări

- Specification of Distribution Transformer 33 KV Cap. 100 KVADocument16 paginiSpecification of Distribution Transformer 33 KV Cap. 100 KVAzulryÎncă nu există evaluări

- Technical Specification of LT Panel (Switchboard) : To Be Found in The One-Line DiagramDocument13 paginiTechnical Specification of LT Panel (Switchboard) : To Be Found in The One-Line DiagramSharath CherryÎncă nu există evaluări

- BUET TEST REPORT OF 3x95 RM N2xSEYFGbY PDFDocument5 paginiBUET TEST REPORT OF 3x95 RM N2xSEYFGbY PDFjamilÎncă nu există evaluări

- Cpr-3 - Catalouge Rele RubberDocument2 paginiCpr-3 - Catalouge Rele Rubbermanuel100% (1)

- DNV Earthing Rule Pag.36Document1 paginăDNV Earthing Rule Pag.36CHOCAMAN1Încă nu există evaluări

- Dissolved Gas Analysis of Transformer: Cellulose Insulation Carbon OxidesDocument2 paginiDissolved Gas Analysis of Transformer: Cellulose Insulation Carbon OxidesheroÎncă nu există evaluări

- Experiment 2: Level Transmitter CalibrationDocument13 paginiExperiment 2: Level Transmitter CalibrationMuhammad FawwazÎncă nu există evaluări

- Pressure Gauge TerminologyDocument2 paginiPressure Gauge TerminologySaeed VuÎncă nu există evaluări

- Jamal Ali Ramadan DofanDocument41 paginiJamal Ali Ramadan DofanJai GosarÎncă nu există evaluări

- Testing of Power and Distribution TransformerDocument82 paginiTesting of Power and Distribution Transformeramulya sÎncă nu există evaluări

- Calculation of Minimum Levels of Short-Circuit Current - Electrical Installation GuideDocument8 paginiCalculation of Minimum Levels of Short-Circuit Current - Electrical Installation Guideambadi.ma1955Încă nu există evaluări

- TDX 5000Document12 paginiTDX 5000RAJESH KUMARÎncă nu există evaluări

- ATEX Ex-EDocument10 paginiATEX Ex-EBrajan's B.Încă nu există evaluări

- Aplicacion Autotransformador 7ut613Document3 paginiAplicacion Autotransformador 7ut613santiagoramosÎncă nu există evaluări

- Saudi Aramco Test Report: LV Panelboard - Pre-Energized and Functional Testing SATR-P-3825 3-Jul-18 ElectDocument7 paginiSaudi Aramco Test Report: LV Panelboard - Pre-Energized and Functional Testing SATR-P-3825 3-Jul-18 Electkarthi51289Încă nu există evaluări

- Test de RadiadorDocument10 paginiTest de RadiadorOmar Reinoso TigreÎncă nu există evaluări

- Notes Instrumenation All UnitsDocument164 paginiNotes Instrumenation All Unitsabhigna thotaÎncă nu există evaluări

- 15 - Test Format For SCADA Test (OUTGOING)Document1 pagină15 - Test Format For SCADA Test (OUTGOING)Gajendran SriramÎncă nu există evaluări

- And Reactance of Is Connected To The Generating Station Bus-Bars Through 5 MVA Step-Up Transformer Having ADocument7 paginiAnd Reactance of Is Connected To The Generating Station Bus-Bars Through 5 MVA Step-Up Transformer Having AJames SantosÎncă nu există evaluări

- Maintenance of TransformerDocument8 paginiMaintenance of TransformeranilsinghteslaÎncă nu există evaluări

- Technical Bid T - 3560: (Note: Photo Copy of SSI / NSIC Certificate Is Not Acceptable)Document12 paginiTechnical Bid T - 3560: (Note: Photo Copy of SSI / NSIC Certificate Is Not Acceptable)SeresdfrtÎncă nu există evaluări

- Permit To Work Self Assesment ChecklistDocument3 paginiPermit To Work Self Assesment Checklistஹரிஹரசுதன்Încă nu există evaluări

- Motor Protection PrinciplesDocument35 paginiMotor Protection PrinciplesTrầnThanhTrungÎncă nu există evaluări

- L04 Discrete-State Process ControlDocument44 paginiL04 Discrete-State Process Controlseraj sersawiÎncă nu există evaluări

- Electrical Testing Method Statement PDFDocument1 paginăElectrical Testing Method Statement PDFKamal LatifÎncă nu există evaluări

- Three Phase Appliance ProtectorDocument40 paginiThree Phase Appliance ProtectorJeevan PreethuÎncă nu există evaluări

- Pre-Commissioning Test Report For Numerical Relay: ProjectDocument3 paginiPre-Commissioning Test Report For Numerical Relay: ProjectHari haranÎncă nu există evaluări

- Sinha Power Plant QuestionDocument14 paginiSinha Power Plant QuestionRaihanÎncă nu există evaluări

- 50v 25A RectifierDocument20 pagini50v 25A RectifierSuarezÎncă nu există evaluări

- Sop-35 Calibration of Vacuum Pressure TransmitterDocument3 paginiSop-35 Calibration of Vacuum Pressure TransmitterOSAMAÎncă nu există evaluări

- CSRH-Y Water Cooled Chiller - R134aDocument20 paginiCSRH-Y Water Cooled Chiller - R134antt_121987Încă nu există evaluări

- Notes On Tripping RelaysDocument7 paginiNotes On Tripping RelaysSenthil KumarÎncă nu există evaluări

- DCS Grounding - LinkedInDocument8 paginiDCS Grounding - LinkedInmaryamÎncă nu există evaluări

- AF Technical - Testing & Commisioning 11-KV Sub-StationDocument6 paginiAF Technical - Testing & Commisioning 11-KV Sub-StationankurÎncă nu există evaluări

- Aarti Steel WHR PDDDocument34 paginiAarti Steel WHR PDDKvvPrasadÎncă nu există evaluări

- Feeder ProtectionDocument36 paginiFeeder ProtectionKoushik MaityÎncă nu există evaluări

- 06 Portfolio Siemens Protection enDocument28 pagini06 Portfolio Siemens Protection enErsat Wennur RonaldiÎncă nu există evaluări

- R6121e Mopn 0102Document14 paginiR6121e Mopn 0102zain shafiqÎncă nu există evaluări

- Aux Transformer TestDocument4 paginiAux Transformer TestEngr Fahimuddin QureshiÎncă nu există evaluări

- Method Statement Insulation Resistance of Motors GeneratorsDocument5 paginiMethod Statement Insulation Resistance of Motors Generatorssite.eng1100% (1)

- P225 PDFDocument12 paginiP225 PDFdave chaudhuryÎncă nu există evaluări

- Generator Earthing and Stator Earth Fault Protection - EEPDocument13 paginiGenerator Earthing and Stator Earth Fault Protection - EEPABHINAV SAURAVÎncă nu există evaluări

- Static and Dynamic Characteristics ofDocument7 paginiStatic and Dynamic Characteristics ofAman SinghÎncă nu există evaluări

- DC Faultr Location FinderDocument26 paginiDC Faultr Location Findergaurang1111Încă nu există evaluări

- On Instrumentation DiagramsDocument9 paginiOn Instrumentation DiagramsAanu OlumuyiwaÎncă nu există evaluări

- Piping and Instrumentation DiagramsTutorials IDocument3 paginiPiping and Instrumentation DiagramsTutorials Inishant9999100% (1)

- Pid SymbolsDocument20 paginiPid Symbolsyogacruise67% (3)

- Common P&ID SymbolsxDocument26 paginiCommon P&ID SymbolsxMuhammad Fahrul Fauzi100% (2)

- Installing Hyperledger Fabric and Composer: Ser/latest/installing/development-To Ols - HTMLDocument13 paginiInstalling Hyperledger Fabric and Composer: Ser/latest/installing/development-To Ols - HTMLVidhi jainÎncă nu există evaluări

- WWW Creativebloq Com Infographic Tools 2131971Document20 paginiWWW Creativebloq Com Infographic Tools 2131971Martin_Arrieta_GÎncă nu există evaluări

- Why Do Climates Change ?: Climate Changes Over The Last MillenniumDocument44 paginiWhy Do Climates Change ?: Climate Changes Over The Last Millenniumshaira alliah de castroÎncă nu există evaluări

- Ealpha - Week 4 - Half A Day - ForeshadowingDocument2 paginiEalpha - Week 4 - Half A Day - ForeshadowingaalshehabÎncă nu există evaluări

- Emcee Script For CompetitionDocument2 paginiEmcee Script For CompetitionArdini Izzati100% (3)

- Cry, The Beloved CountryDocument36 paginiCry, The Beloved CountryMariela RomeroÎncă nu există evaluări

- Implementasi Fault Management (Manajemen Kesalahan) Pada Network Management System (NMS) Berbasis SNMPDocument11 paginiImplementasi Fault Management (Manajemen Kesalahan) Pada Network Management System (NMS) Berbasis SNMPIwoncl AsranÎncă nu există evaluări

- Pico Power: A Boon For Rural Electrification: Rajat KapoorDocument8 paginiPico Power: A Boon For Rural Electrification: Rajat KapoorBamÎncă nu există evaluări

- Project Proposal Environmental Protection Program-DeNRDocument57 paginiProject Proposal Environmental Protection Program-DeNRLGU PadadaÎncă nu există evaluări

- ABC LTD ProposalDocument4 paginiABC LTD ProposalAbhishek JurianiÎncă nu există evaluări

- Region XiDocument2 paginiRegion XiGarcia, Rafael Rico O.Încă nu există evaluări

- Tamang GrammarDocument12 paginiTamang Grammarsoftdina100% (1)

- Program 2019 MTAPTL Annual Convention PDFDocument3 paginiProgram 2019 MTAPTL Annual Convention PDFrichardlfigueroaÎncă nu există evaluări

- STD 12 Accountancy1Document264 paginiSTD 12 Accountancy1Chetan KhonaÎncă nu există evaluări

- Neighbor'S Plot - : Sheet No Rev No R0Document1 paginăNeighbor'S Plot - : Sheet No Rev No R0jibeesh cmÎncă nu există evaluări

- Wavoo Wajeeha Women's College - Annual Report - 2013-14Document29 paginiWavoo Wajeeha Women's College - Annual Report - 2013-14kayalonthewebÎncă nu există evaluări

- Settlement Geography: Unit No-1&2Document11 paginiSettlement Geography: Unit No-1&2Arindam RoulÎncă nu există evaluări

- Chapter 1Document38 paginiChapter 1Kurt dela Torre100% (1)

- E9d30c8 4837smartDocument1 paginăE9d30c8 4837smartSantoshÎncă nu există evaluări

- This I BeleiveDocument3 paginiThis I Beleiveapi-708902979Încă nu există evaluări

- Individual Ability in SoftwareDocument9 paginiIndividual Ability in Softwaredhana0809100% (4)

- Pale ExamDocument4 paginiPale ExamPatrick Tan100% (1)

- Coca Cola FSDocument3 paginiCoca Cola FSManan MunshiÎncă nu există evaluări

- Intro To Semiology Reading NotesDocument6 paginiIntro To Semiology Reading NotesRyan DrakeÎncă nu există evaluări

- Strength of Materials Aug 5 2017Document16 paginiStrength of Materials Aug 5 2017MikaellaTeniolaÎncă nu există evaluări

- Bob Dylan Diskografija Prevodi PesamaDocument175 paginiBob Dylan Diskografija Prevodi PesamaJolanda NešovićÎncă nu există evaluări

- Priya - Rachna Kumari PrasadDocument17 paginiPriya - Rachna Kumari PrasadSumant priyadarshiÎncă nu există evaluări

- English ExercisesDocument2 paginiEnglish ExercisesLiceth HuertasÎncă nu există evaluări

- Enzyme Kinetics Principles and MethodsDocument268 paginiEnzyme Kinetics Principles and MethodsCarlos Carinelli100% (4)

- 5 Manifestos Da ArteDocument3 pagini5 Manifestos Da ArteCinthia MendonçaÎncă nu există evaluări