Documente Academic

Documente Profesional

Documente Cultură

Compressor Trouble Shooting Guide 97-2003

Încărcat de

Vina SulistyaDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Compressor Trouble Shooting Guide 97-2003

Încărcat de

Vina SulistyaDrepturi de autor:

Formate disponibile

Compressor Trouble Shooting Guide

Here are some Compressor Trouble Shooting Tips to help you or anyone providing the regular maintenance for your compressor system. Below are listed several very common problems, their probable cause and some usual remedies for the trouble. Of course, there can be multiple problems and unique circumstances to every compressor issue. but these tend to solve the most common situations Provided below is a general list of common compressor problems, and a few quick fixes that may help solve your dilemma. this solution can be done alone. but if you have trouble, is expected to be fixed to the experience people. There are many problems and solution for troubleshooting compressor. Problem Cause 1. No electrical power. 2. Low oil level. 3. Pressure switch not making contact. 4. Pressure in the tank is below the cut-in pressure. Solution Turn on power. Push the reset button. Check oil level. Replace your oil if necessary See pressure switch adjustment. See pressure switch adjustment. Replace pressure switch to one that has a lower cut-in PSI Tighten any loose ends. Check for possible damage to bearings Replenish the oil level. Remove the compressor cylinder head and inspect for foreign matter on top of the piston. Add a new gasket and reassemble the head. Tighten the bolts on the air compressor. It may also be a good idea to replace your vibration pads. Repair or replace. Adjust and shim properly. Replace bearings. Replace rod.

Compressor will not operate.

1. Loose pulley, flywheel, belt, belt guard, cooler, clamps or accessories 2. Lack of oil in crankcase. 3. Piston hitting the valve plate. Excessive noise in operation. 4. Compressor floor mounting loose 5. Defective crankcase. 6. Excessive crank end play. 1. Main bearings. 2. Connecting rod bearings.

Knock - same cycle as R.P.M.

Knock occurs while compressor is loading.

3. Loose flywheel. 1. Connecting rod bearings. 2. Wrist pins, wrist pin bearings. 3. Loose connecting rod nut. 1. Water entering oil reservoir due to compressor operating in high humidity environment.

Tighten. Replace rod. Replace piston assembly. Tighten. a. Pipe air intake to less humid air source. b. Service unit (change oil, clean or replace air cleaner element, more often, at least every 45 days or 500 operating hours for oil changes. c. Drain tank daily. Clean or replace air filter. Tighten bolts or replace gasket. Replace rings. Drain oil, refill with oil of proper viscosity Level compressor. Vibration pads may help with this. Replace cylinder. Clean or replace your air filters. Replace rings. Drain down to full mark on sight gauge. Check viscosity. Replace crankshaft. Tighten. Level compressor so that all feet touch the floor before tightening down. Realign. Tighten belts. Replace crankshaft. Replace valve plate assembly. Check for leaks or restriction in hose or piping. Repair. Clean or replace air filter element. Tighten belts. Replace with larger hose. Limit air usage to compressor capacity by using fewer or smaller tools.

Milky oil in oil reservoir.

Excessive oil consumption.

Oil in discharge air.

1. Restricted air intake. 2. Oil leaks. 3. Worn piston rings. 4. Wrong oil viscosity. 5. Compressor tilted too much 6. Scored cylinder. 1. Compressor air intake restricted 2. Worn piston rings. 3. Excessive oil in compressor. 4. Wrong oil viscosity. 5. Piston rings installed up-side down 1. Mounting bolts loose. 2. Compressor not properly mounted

Compressor vibrates.

Air blowing out of inlet.

Insufficient pressure at point of use.

3. Pulley and flywheel misaligned. 4. Belts loose. 5. Bent crankshaft. 1. Broken first stage inlet valve. 1. Leaks or restriction. 2. Restricted air intake. 3. Slipping belts. 4. Service hose too small. 5. Excessive air requirement.

Receiver does not hold pressure when compressor is unloaded.

1. Faulty check valve. 1. Pulley out of alignment. 2. Belts too tight. 3. Belts too loose. 4. Pulley or flywheel wobble.

Excessive belt wear.

5. Nick in belt groove of pulley or flywheel. 1. Dirty cooling surfaces. Excessive discharge air temperature. 2. Poor ventilation. 3. Blown head gasket. 4. Restricted air intake. 5. Worn valves. 1. Safety relief valve not functioning properly. 2. Leaky gasket - High pressure inlet valve. 1. Dirty air filter. 2. Blown cylinder head gasket. 3. Worn or broken low pressure intake or discharge valves. 4. Air leaks. 5. Loose belts. 6. Speed too slow. 1. Excessive water in receiver. 2. Speed too fast. 1. Motor overload. 2. Malfunction or improperly adjusted 3. High ambient temperature. 1. Wrong fuse size.

Air leaking from inter stage safety relief valve when compressor is pumping.

Bleed tank! Disassemble check valve assembly, clean or replace faulty parts. Realign motor pulley with compressor flywheel. Adjust tension. Adjust tension. Check for worn worn crankshaft, keyway or pulley bore, resulting from running with loose pulleys. Check for bent crankshaft File smooth. Clean cooling surfaces of cylinder, intercooler and discharge tube. Improve ventilation or relocate compressor. Replace head gasket. Clean or replace air filter element. Replace valve plate assembly. Remove and install new safety relief valve. If new safety valve leaks remove cylinder head, inspect and clean reed valve assembly. Replace gasket. Clean or replace filter element. Install new gasket. Install new valve plate. Tighten joints. Tighten or replace belts. Check speed. Drain receiver/tank. Check speed. Shut down immediately to avoid damage. Adjust or replace. Provide ventilation. Check to make sure that fuses are of proper ampere rating.

Receiver pressure builds up slowly.

Receiver pressure builds up quickly on compressor. Reset mechanism cuts out repeatedly; fuses of proper size blow.

Fuses blow repeatedly.

Compressor will not operate.

1. No electrical power. 2. Pressure switch not making contact. 1. Loose pulley, flywheel belt, belt guard, clamps or accessories. 2. Lack of oil in crankcase. 3. Piston hitting the valve plate. 4. Compressor floor mounting loose. 5. Defective crankcase. 1. Main bearings. 2. Connecting rod bearings. 3. Loose flywheel. 1. Connecting rod bearings. 2. Wrist pins, wrist pin bearings. 3. Loose connecting rod bolt. 4. Loose flywheel. 1. Water entering oil reservoir due to compressor operating in high humidity environment. 1. Restricted air intake. 2. Oil leaks. 3. Worn piston rings. 4. Wrong oil viscosity. 5. Compressor tilted too much. 6. Scored cylinder. 1. Compressor air intake restricted.

Turn on power, check fuse, breaker, or motor overload Replace or repair. Tighten. Check for possible damage to bearings, replenish oil Remove the compressor cylinder head and inspect for foreign matter on top of the piston, clean, add a new gasket, and reassemble the head. Tighten. Repair Replace bearings. Replace rod. Tighten. Replace rod. Replace complete piston assembly. Tighten bolt. Tighten setscrew. Pipe air intake to less humid air source. Clean or replace air filter. Tighten bolts or replace gasket. Replace rings. Drain oil, refill with oil of proper viscosity. Level compressor. Replace cylinder. Clean air filter element and check for other restrictions in the intake system. Replace rings. Drain down to bottom of threads. Check viscosity and change oil if necessary Install rings in proper position. Clean or replace.

Excessive noise in operation.

Knock-same cycle as RPM.

Knock occurs while compressor is loading.

Milky oil in crankcase.

Excessive oil consumption.

Oil in discharge air.

2. Worn piston rings. 3. Excessive oil in compressor. 4. Wrong oil viscosity. 5. Piston rings installed up-side down. 6. Plugged crankcase breather

Compressor vibrates. Receiver does not hold pressure when compressor shuts off

1. Mounting bolts loose. 1. Faulty check valve. 1. Pulley out of alignment. 2. Belts too tight 3. Belts too loose.

Excessive belt wear.

4. Pulley or flywheel wobble.

5. Nick in belt groove of pulley or flywheel. 1. Dirty cooling surfaces. Excessive discharge air temperature. 2. Poor ventilation. 3. Blown head gasket. 4. Worn valve. 1. Dirty air filter. 2. Blown cylinder head gasket. 3. Worn or broken low pressure intake or discharge valves. 4. Air leaks. 5. Loose belts. 6. Speed too slow. 1. Excessive water in receiver. 1. Motor overload. 2. Malfunction or improperly adjusted. 3. High ambient temperature. 1. Wrong fuse size. 2. Low voltage. 3. Defective unloader or check valve. 4. Belt to tight. 1. Bad unloader valve 2. Loss of power

Tighten. Consider installing vibration pads. Bleed tank! Disassemble check valve assembly, clean or replace faulty parts. Realign motor pulley with compressor flywheel. Adjust tension. Adjust tension. Check for worn crankshaft, keyway or pulley bore, resulting from running with loose pulleys. Check for bent crankshaft - if bent then replace. File smooth. Clean cooling surfaces of cylinder, intercooler and discharge tube. Improve ventilation or relocate compressor. Replace head gasket. Repair or replace valves. Clean or replace filter element. Install new gasket. Install new flapper valves and gaskets. Tighten joints. Tighten belt or replace belt. Check pulley size and belt tension. Drain receiver/tank. Shut down immediately to avoid damage. Adjust or replace. Provide ventilation. Check to make sure that fuses are of proper ampere rating. Replace or repair. Loosen belt. Replace the unloader valve. Plug compressor into a new power source

Receiver pressure builds up slowly.

Receiver pressure builds up rapidly. Reset mechanism cuts out repeatedly.

Fuses blow repeatedly.

Compressor suddenly stops working

S-ar putea să vă placă și

- Refrigeration System Problem and SolutionDocument29 paginiRefrigeration System Problem and SolutionAngel Rose AnongÎncă nu există evaluări

- Air Condition Refilling Automobile Ac SystamDocument11 paginiAir Condition Refilling Automobile Ac SystamMechanical DepartmentÎncă nu există evaluări

- Automatic protection ensures safe operation of refrigeration compressorsDocument50 paginiAutomatic protection ensures safe operation of refrigeration compressorsAhmed SalemÎncă nu există evaluări

- Refrigeration and Air Conditioning Lab: Mansoura University Faculty of Engineering Mechanical Power Department 4 YearDocument9 paginiRefrigeration and Air Conditioning Lab: Mansoura University Faculty of Engineering Mechanical Power Department 4 YearKhaled HakimÎncă nu există evaluări

- refrigerator common problemsDocument3 paginirefrigerator common problemsMateo, Dale Vincent A.Încă nu există evaluări

- CompressorDocument20 paginiCompressorS R Akhil KrishnanÎncă nu există evaluări

- Complete Guide To Room and Central Air Conditioners: Last Updated: July 2015Document26 paginiComplete Guide To Room and Central Air Conditioners: Last Updated: July 2015QOBITÎncă nu există evaluări

- 409 - 5 Refrigeration & Air ConditioningDocument104 pagini409 - 5 Refrigeration & Air Conditioningisrat jahanÎncă nu există evaluări

- MODULE 1 Introduction To Refrigeration SystemDocument9 paginiMODULE 1 Introduction To Refrigeration SystemBembem DelfinÎncă nu există evaluări

- Refrigerator: Prasad Murumkar Simran Jagtap Prasanna GramopadhyeDocument13 paginiRefrigerator: Prasad Murumkar Simran Jagtap Prasanna GramopadhyeSHREYAS JOSHIÎncă nu există evaluări

- Piping SolderingDocument33 paginiPiping SolderingKristian UretaÎncă nu există evaluări

- My Freezer Isn't Freezing - HomeServe USADocument9 paginiMy Freezer Isn't Freezing - HomeServe USAAla SamuelÎncă nu există evaluări

- Household Refrigerators and FreezersDocument12 paginiHousehold Refrigerators and FreezersLuis Carlos PardoÎncă nu există evaluări

- Basics of Refrig PDFDocument17 paginiBasics of Refrig PDFHoàngViệtAnhÎncă nu există evaluări

- Schematic Diagram of Cold Air Flow: EvaporatorDocument1 paginăSchematic Diagram of Cold Air Flow: EvaporatorMario FabrisÎncă nu există evaluări

- Bohler Welding in Tool MakingDocument24 paginiBohler Welding in Tool MakingcfcshakerÎncă nu există evaluări

- CH 1Document53 paginiCH 1huien ababuÎncă nu există evaluări

- Refrigeration 1Document13 paginiRefrigeration 1Vishwanathan RishanthÎncă nu există evaluări

- The Four Types of Refrigeration Systems You Need To KnowDocument2 paginiThe Four Types of Refrigeration Systems You Need To KnowtakayÎncă nu există evaluări

- Rac PPT1.Document22 paginiRac PPT1.andu gashuÎncă nu există evaluări

- RefrigeratorDocument12 paginiRefrigeratorVikram PorjeÎncă nu există evaluări

- Assignment Style GuideDocument7 paginiAssignment Style GuideAhmed Farazv SoomroÎncă nu există evaluări

- Refrigeration System Components: - Vishakh GaneshDocument34 paginiRefrigeration System Components: - Vishakh GaneshS R Akhil KrishnanÎncă nu există evaluări

- Vibration Monitoring Techniques (CMDocument28 paginiVibration Monitoring Techniques (CMAhmed SalemÎncă nu există evaluări

- Weldability TestDocument11 paginiWeldability TestRajan BhadoriyaÎncă nu există evaluări

- MODULE 3 RAC Servicing and MaintenanceDocument23 paginiMODULE 3 RAC Servicing and MaintenanceBembem DelfinÎncă nu există evaluări

- Guide to Welding ElectrodesDocument25 paginiGuide to Welding ElectrodesrajuÎncă nu există evaluări

- Lesson 6 & 7: Results and DiscussionDocument29 paginiLesson 6 & 7: Results and DiscussionJ i n100% (1)

- Refrigerant System Components and ControlsDocument16 paginiRefrigerant System Components and ControlssrybsantosÎncă nu există evaluări

- Introduction To Arc WeldingDocument36 paginiIntroduction To Arc WeldingcfcshakerÎncă nu există evaluări

- Refrigeration Compressor Failure: Cause & Cure - Part 1Document5 paginiRefrigeration Compressor Failure: Cause & Cure - Part 1ADARSH GADDAMÎncă nu există evaluări

- Kertas Penerangan 3Document23 paginiKertas Penerangan 3neddylalolaÎncă nu există evaluări

- Stainless Steel Welding Electrodes GuideDocument1 paginăStainless Steel Welding Electrodes GuideRajeev KhantwalÎncă nu există evaluări

- Essential Properties Required in A Refrigerant Are As FollowsDocument11 paginiEssential Properties Required in A Refrigerant Are As FollowssrybsantosÎncă nu există evaluări

- Welding Soldering BrazingDocument100 paginiWelding Soldering BrazingMore YashÎncă nu există evaluări

- Automatic Washer: Study Course (Belt Drive Models)Document24 paginiAutomatic Washer: Study Course (Belt Drive Models)plasmapeteÎncă nu există evaluări

- Compressed Air UsesDocument5 paginiCompressed Air Usesandy habibiÎncă nu există evaluări

- Engine Cooling Fan: 1991 Mitsubishi MonteroDocument9 paginiEngine Cooling Fan: 1991 Mitsubishi MonteroAnimemanuel MuñozÎncă nu există evaluări

- Documents - Pub - Advanced Welding TechnologyDocument60 paginiDocuments - Pub - Advanced Welding TechnologybalamuruganÎncă nu există evaluări

- ME362 Nozzle Flow AnalysisDocument6 paginiME362 Nozzle Flow Analysisদুর্জয় দুর্বারÎncă nu există evaluări

- Refrigeration and Air Conditioning Technology (RAC) Tool ListDocument1 paginăRefrigeration and Air Conditioning Technology (RAC) Tool ListAhmed AzadÎncă nu există evaluări

- Compressor, Main Parts, Types and Working Principle: PV NRT P TDocument6 paginiCompressor, Main Parts, Types and Working Principle: PV NRT P TMuhammad Arslan AfzalÎncă nu există evaluări

- Ultrasonic FlowmeterDocument6 paginiUltrasonic Flowmeterদুর্জয় দুর্বারÎncă nu există evaluări

- Vu 20978Document6 paginiVu 20978Hadz DeeÎncă nu există evaluări

- Commercial Refrigeration Systems ExplainedDocument11 paginiCommercial Refrigeration Systems ExplainedBenjie flor CalayegÎncă nu există evaluări

- Fridge ManualDocument24 paginiFridge ManualDylan NelsonÎncă nu există evaluări

- EPOS4 EtherCAT Card Hardware ReferenceDocument28 paginiEPOS4 EtherCAT Card Hardware ReferenceHoang ManhÎncă nu există evaluări

- Welding Symbols 3Document8 paginiWelding Symbols 3cfcshakerÎncă nu există evaluări

- Common Problems and Solutions for IronsDocument3 paginiCommon Problems and Solutions for IronsCik Miza MizzieyÎncă nu există evaluări

- Pipe Elements 1Document310 paginiPipe Elements 1Ryan Llona FernandezÎncă nu există evaluări

- Litar Siri Dan SelariDocument19 paginiLitar Siri Dan SelarineddylalolaÎncă nu există evaluări

- C - NH3 Compressor by OCA GDocument24 paginiC - NH3 Compressor by OCA GDionis DagumanÎncă nu există evaluări

- Refrigeration NotesDocument4 paginiRefrigeration NotesWai Phyo AungÎncă nu există evaluări

- Refrigerant Management to Prevent Compressor DamageDocument7 paginiRefrigerant Management to Prevent Compressor DamageSlavikNZÎncă nu există evaluări

- Stainless Steel Welding: A Subramanian/Lecturer/AWTI/ICFDocument62 paginiStainless Steel Welding: A Subramanian/Lecturer/AWTI/ICFaravindanÎncă nu există evaluări

- CompressorsDocument51 paginiCompressorsReza RahmanudinÎncă nu există evaluări

- #2 PDFDocument20 pagini#2 PDFplasmapeteÎncă nu există evaluări

- Air Compressor Trouble Shooting Problem CauseDocument10 paginiAir Compressor Trouble Shooting Problem CauseVisu SamyÎncă nu există evaluări

- Rotary Lift: Trouble Shooting Guide IndexDocument20 paginiRotary Lift: Trouble Shooting Guide IndexFarhsa Dhom Eemihahs DhomÎncă nu există evaluări

- Hydraulics21th SepDocument5 paginiHydraulics21th SepAnonymous m4e8KwH7Încă nu există evaluări

- RizkyDocument1 paginăRizkyVina SulistyaÎncă nu există evaluări

- Timing Belt Replacement GuideDocument76 paginiTiming Belt Replacement GuideVina SulistyaÎncă nu există evaluări

- WepaDocument1 paginăWepaVina SulistyaÎncă nu există evaluări

- QC Process Improvement Test QuestionsDocument3 paginiQC Process Improvement Test QuestionsVina SulistyaÎncă nu există evaluări

- E Belt PulleyDocument124 paginiE Belt PulleyVina SulistyaÎncă nu există evaluări

- Timing Belt Replacement GuideDocument76 paginiTiming Belt Replacement GuideVina SulistyaÎncă nu există evaluări

- The Application of Refrigeration: A FreezerDocument5 paginiThe Application of Refrigeration: A FreezerVina SulistyaÎncă nu există evaluări

- QC Process Improvement Test QuestionsDocument3 paginiQC Process Improvement Test QuestionsVina SulistyaÎncă nu există evaluări

- E Belt PulleyDocument124 paginiE Belt PulleyVina SulistyaÎncă nu există evaluări

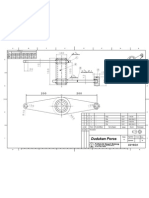

- Drawing A4 RamaDocument1 paginăDrawing A4 RamaVina SulistyaÎncă nu există evaluări

- Timing System Take OneDocument2 paginiTiming System Take OneVina SulistyaÎncă nu există evaluări

- Compressor BacaanDocument7 paginiCompressor BacaanVina SulistyaÎncă nu există evaluări

- DrawingA3 RizkyDocument1 paginăDrawingA3 RizkyVina SulistyaÎncă nu există evaluări

- Swing BracketDocument1 paginăSwing BracketVina SulistyaÎncă nu există evaluări

- CompressorDocument10 paginiCompressorVina SulistyaÎncă nu există evaluări

- Compressor BacaanDocument7 paginiCompressor BacaanVina SulistyaÎncă nu există evaluări

- Compressor Trouble Shooting Guide: Problem Cause SolutionDocument6 paginiCompressor Trouble Shooting Guide: Problem Cause SolutionVina SulistyaÎncă nu există evaluări