Documente Academic

Documente Profesional

Documente Cultură

Research Designs & Standards Organization: 1. Amendment History

Încărcat de

Mark HinesTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Research Designs & Standards Organization: 1. Amendment History

Încărcat de

Mark HinesDrepturi de autor:

Formate disponibile

ISO9001:2008 Document No: QM-F-7.

1-17/A Document Title: Wagon Quality Score Sheet(Open Wagon BOXN Type)

Version No: 1.0

Date Effective: 01.02.2012

RESEARCH DESIGNS & STANDARDS ORGANIZATION

Manak Nagar, Lucknow 226011 QM-F-7.1-17/A

Wagon Quality Score Sheet (Open Wagon BOXN Type)

1. Amendment History:

S. No. 1 Amendment Date 01.02.2012 Version 1.0 Reasons for Amendment Fresh issue

SIO/QA(Mech) Prepared By:

Director/ QA(Mech) Issued By:

Printed: 01/02./2012 Page 1 of 2

ISO9001:2008 Document No: QM-F-7.1-17/A Document Title: Wagon Quality Score Sheet(Open Wagon BOXN Type)

Version No: 1.0

Date Effective: 01.02.2012

2. Purpose:

To calculate wagon quality score to be prepared as per the the requirement of the Railway Boards Wagon contract.

3. Scope of Application:

Applicable for open wagon- BOXN Type.

4. Procedure / Details:

Wagon Quality Score (Format QM-F-7.17/A) for open wagon Type BOXNHL is annexed. While using the form print and use only the Format/Annexure pages.

5. Referenced Documents

None

6. Referenced Documents of External Origin

None

7. Associated Records

None

8. Responsibility and Authority

Activity Creation, maintenance of this document Requirement of deviation from this form template. Responsible AIE/SIO, I&L/LKO Approver Supporting Director/I&L/ SE/SSE, LKO QA (Mech) Director/I&L/ LKO AIE/SIO, I&L Consulted Informed ED/QA(Mech) All Zonal office of QA (Mech) Dte.

AIE/SIO, I&L/LKO

ED/QA(Mech

All Zonal office of QA (Mech) Dte.

9. Abbreviations:

QA(Mech) RDSO I&L ED/QA (Mech) AIE SIO MR QMS STR M&P/T&P Quality Assurance(Mechanical) Directorate Research Designs & Standards Organization Inspection and Lisening Executive Director/ Quality Assurance (Mechanical) Assistant Inspecting Officer Senior inspecting Office Management Representative QA Mech. Schedule of Tech. requirements Schedule of Tech. requirements Machinery and Plant/ testing and Plant

SIO/QA(Mech) Prepared By:

Director/ QA(Mech) Issued By:

Printed: 01/02./2012 Page 2 of 2

ISO9001:2008 Document No: QM-F-7.1-17/A Document Title: Wagon Quality Score Sheet (BOXN Type)

Version No: 1.0

Date Effective: 01/02.2012

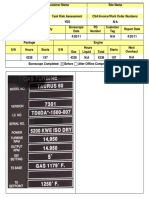

Wagon Quality Score Sheet

(Open Wagon BOXN Type)

Name of Wagon Builder & location Type of wagon and wagon no. Date of assessment Total score Score obtained 100

QM-F-7.1-17/A

Score sheets

S.N. 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. Items Cambering of under frame in final wagon Distance between bolster bogie centre Overall width Overall height Coupler height from RL Dimension of doors Air brake testing Welding of under-slung brackets/Clamp/safety strap/cross members i) Very good 4 ii) Acceptable 3 Welding of under-frame and its sub-assemblies. i) Very good 4 ii) Acceptable 3 Welding of end wall/side wall i) Very good 4 ii) Acceptable 3 Floor plate welding i) Very good 4 (With use of hydraulic press arrangement) ii) Acceptable 3 Use of MIG welding in maximum locations i) Above 90% 3 ii) Less than 90 % 2 Overall welding quality i) Very Good 4 ii) Acceptable 3 Edge preparation i) Very Good 4 ii) Acceptable 3 Provision of APD as stipulated for brake system and bogie assembly. i) Very Good 3 ii) Acceptable 2 Centre Pivot assembled height from bolster Side bearer set up height from bolster Painting as stipulated and paint thickness Lettering and marking as stipulated Total score 3 3 3 3 3 3 3 4 4 4 Actual obtained

11.

12. 13. 14.

3 4 4

15. 16. 17. 18. 19.

3 3 3 3 3

Quality Assurance (Mechanical) Directorate/RDSO

Format/Annexure Page 1 of 3

ISO9001:2008 Document No: QM-F-7.1-17/A Document Title: Wagon Quality Score Sheet(Open Wagon BOXN Type)

Version No: 1.0

Date Effective: 01.02.2012

S.N. 20.

21.

22.

23.

24.

25. 26. 27. 28. 29.

30.

31.

32.

33.

34.

Items Overall finish of wagon i) Very Good 4 ii) Acceptable 3 Lock bolting of CP top i) Very Good (With Use of hydraulic press) 4 ii) Acceptable 3 Lock bolting of side wall/end wall/stanchion i) Very Good 3 ii) Acceptable 2 Lock bolting of striker casting, Anchor plates, YPSP, YSP, back stop and other components i) Very Good 3 ii) Acceptable 2 Internal inspections and their records i) Fully available 3 ii) Not fully available 2 Tare weight of wagon i) With printing facility 2 ii) Without printing facility 1 Proper door locking arrangement Operation of knuckle with operating handle and Articulation of coupler body Hand brake operation Deployment of qualified welders and certification through 3rd Party i) System for regular certification and training exist 2 ii) Partially available 1 Validation of jigs and fixtures/other tools as specified in QAP i) System for regular validation is available 2 ii) System for regular validation is partially available 1 Use of hydraulic/Pneumatic clamp in fixtures i) Available for under-frame & other major subassemblies 2 ii) Partially available/Conventional clamping available 1 Use of CNC plasma machine i) Used for all application 2 ii) Not used for all application 1 Use of inverter based/pulse synergic MIG welding machine i) Available for all application 2 ii) Not available for all application 1 Automatic/auto grit recovery semi-automatic shot blasting machine i) Auto recovery of grit available 2 ii) Auto recovery of grit is not available 1

Total score 4

Actual obtained

2 2 2 2 2

Signature of Inspecting Official with name and date

Quality Assurance (Mechanical) Directorate/RDSO

Format/Annexure Page 2 of 3

ISO9001:2008 Document No: QM-F-7.1-17/A Document Title: Wagon Quality Score Sheet(Open Wagon BOXN Type)

Version No: 1.0

Date Effective: 01.02.2012

Annexure

Name of Wagon Builder: Date of Inspection: Check-sheet for inspection of lock Bolting i) ii) iii) iv) v) vi) 1 2 3 4 5 6 7

Works: Wagon No.

Location of Lock Bolt (As applicable) Remarks (defects observed, if any, to be mentioned) Centre pivot top Side stanchion End stanchion Corner stanchion Backstop Striker casting Lock bolting to be checked for following defects, as applicable Swaging of collar done properly or not(min. collar dia, max. collar length and profile as prescribed or not) Any scoring marks on collar Swaging done properly or not(collar diameter and length to be as prescribed) Projection of shank form collar(to be as prescribed) Pin tail cut off or not Collar straight or not Any sign of enlargement of hole

Check-sheet for inspection of welding joints Location of Joint Remarks (defects observed, if any, to be mentioned) i) Two Side Stanchions ii) One end stanchion iii) Two cross bars iv) One bolster v) One side top coping vi One floor plate joint Welding joints to be checked for following defects, as applicable Non-uniformity, Blowholes/Porosity, Cracks, Spatter, Sealing of ends of joints done or not, Undercut, Overlap, Scalloping proper or not, Proper gap maintained or not, Convexity within specified limits, Ground flush done or not(if specified in WPS), Leg length within specified limits, Throat within specified limits, Excessive convexity

Signature of Inspecting Official with name and date

Quality Assurance (Mechanical) Directorate/RDSO

Format/Annexure Page 3 of 3

S-ar putea să vă placă și

- A Practical Guide to Piping and Valves for the Oil and Gas IndustryDe la EverandA Practical Guide to Piping and Valves for the Oil and Gas IndustryEvaluare: 5 din 5 stele5/5 (3)

- Derrick Inspection Report TemplateDocument28 paginiDerrick Inspection Report TemplatesalgadofilhaÎncă nu există evaluări

- Tank Farm Field Construction Work Progress Measurement System - Sample Template For Practical UseDocument7 paginiTank Farm Field Construction Work Progress Measurement System - Sample Template For Practical UseMd Izzuddin OmarÎncă nu există evaluări

- Inspection and Test Procedure and Plan Rev 0 Commented by HDECDocument16 paginiInspection and Test Procedure and Plan Rev 0 Commented by HDECarchalys4u100% (4)

- Boroscopeo Turbina PDFDocument9 paginiBoroscopeo Turbina PDFegr00Încă nu există evaluări

- Work Instruction On Tube ExpansionDocument40 paginiWork Instruction On Tube Expansionjayaarnav100% (1)

- ITP For Field Erected Tank Rev ADocument9 paginiITP For Field Erected Tank Rev AHoang Tuan Kiet100% (1)

- 2004 A Piping DesignDocument76 pagini2004 A Piping DesignRudy SuryaÎncă nu există evaluări

- Works Instruction For Piping Welding InspectionDocument5 paginiWorks Instruction For Piping Welding InspectionAbg SepulÎncă nu există evaluări

- Method Statement For Trial LoadingDocument5 paginiMethod Statement For Trial LoadingPunithan PunithanÎncă nu există evaluări

- Steel Girder Fabrication RequirementsDocument11 paginiSteel Girder Fabrication RequirementsAnkur Tayal100% (1)

- System ValvesDocument18 paginiSystem ValvesSumit SinghÎncă nu există evaluări

- 030-QCP For UG GRP PIPING PDFDocument12 pagini030-QCP For UG GRP PIPING PDFKöksal Patan100% (1)

- Quality Assurance For MS PipeDocument54 paginiQuality Assurance For MS PipeRam Narendra Nath100% (2)

- SAIC-D-2022 Rev 2Document5 paginiSAIC-D-2022 Rev 2ரமேஷ் பாலக்காடுÎncă nu există evaluări

- 40 Ton Crane Tender DocumentDocument12 pagini40 Ton Crane Tender DocumentJaay VelÎncă nu există evaluări

- 00-014 v. 09 - 2010Document34 pagini00-014 v. 09 - 2010opreamihÎncă nu există evaluări

- Development Road Specification and Construction Amended February 2009Document162 paginiDevelopment Road Specification and Construction Amended February 2009wopshistosÎncă nu există evaluări

- 2.6 - SAT - C1574 - SAT Procedure PDFDocument7 pagini2.6 - SAT - C1574 - SAT Procedure PDFGeorge JhonsonÎncă nu există evaluări

- Six Sigma: Modification of Qa Procedure of FRP Shelter' Against Op Task Orders For Issue of Inspection NoteDocument47 paginiSix Sigma: Modification of Qa Procedure of FRP Shelter' Against Op Task Orders For Issue of Inspection Notevikrambakshi67Încă nu există evaluări

- Chrysler GAGE StandardDocument97 paginiChrysler GAGE StandardAli Hernandez100% (2)

- How To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-3)Document15 paginiHow To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-3)Mohamed Atef100% (1)

- Spec. no.C-9202-R2 - Oct 08Document32 paginiSpec. no.C-9202-R2 - Oct 08Sumit ShyamalÎncă nu există evaluări

- QCS 2010 Part 07 Vehicle Crash BarriersDocument13 paginiQCS 2010 Part 07 Vehicle Crash BarriersRotsapNayrbÎncă nu există evaluări

- Technical Specification for Higher Carrying Capacity (HCC) EMU/DMU BogieDocument24 paginiTechnical Specification for Higher Carrying Capacity (HCC) EMU/DMU BogiePremchand BeuraÎncă nu există evaluări

- 00 Common StandardsDocument21 pagini00 Common StandardsBrand StrÎncă nu există evaluări

- 01-GENERAL Aging AirplanesDocument129 pagini01-GENERAL Aging Airplanesherculesp51Încă nu există evaluări

- Shellliftingspecsops0055rev1 4Document125 paginiShellliftingspecsops0055rev1 4Marcos TadsioÎncă nu există evaluări

- Major Structures Steel Erection InspectionDocument4 paginiMajor Structures Steel Erection InspectionYohannes GebreÎncă nu există evaluări

- Asme Sec Viii Div-2Document31 paginiAsme Sec Viii Div-2Yash Rami100% (3)

- MS 1005 R2 Surveying WorkDocument7 paginiMS 1005 R2 Surveying Workkaran976Încă nu există evaluări

- API 510 PREPARATION CLASSDocument162 paginiAPI 510 PREPARATION CLASSAli Ahmed100% (3)

- NullDocument20 paginiNullMichael OkwuwaÎncă nu există evaluări

- NullDocument9 paginiNullMichael OkwuwaÎncă nu există evaluări

- 3PS Gaw 002Document6 pagini3PS Gaw 002ravi00098Încă nu există evaluări

- Irst 19 2012Document65 paginiIrst 19 2012krischaever100% (1)

- Pipe Fabrication - ErectionDocument18 paginiPipe Fabrication - ErectionShrichand G. Bathv50% (2)

- Omc Clarification Sheet: Standard(s) (Incl. Year) Sub-Clause(s) For Secretariat Use OnlyDocument2 paginiOmc Clarification Sheet: Standard(s) (Incl. Year) Sub-Clause(s) For Secretariat Use OnlyBala JiÎncă nu există evaluări

- Abs Type Approval1 - TeamDocument5 paginiAbs Type Approval1 - TeamRogério FreitasÎncă nu există evaluări

- CPPP Self Assessment Spot Welding (QHB037G) 1Document28 paginiCPPP Self Assessment Spot Welding (QHB037G) 1broÎncă nu există evaluări

- Reasoned Document of EUI SystemDocument5 paginiReasoned Document of EUI Systemمصطفي الغنيمىÎncă nu există evaluări

- Storage Tank Inspection and Calibration Using Laser Scanning and Trimble RealworksDocument42 paginiStorage Tank Inspection and Calibration Using Laser Scanning and Trimble RealworksMahmoud GaberÎncă nu există evaluări

- Training New BuildingDocument88 paginiTraining New BuildingIrdhan Kabutono WunaÎncă nu există evaluări

- Ad 1Document10 paginiAd 1Mehul BarotÎncă nu există evaluări

- Submission of Method Statement For Prestressing Works For T-Girder (Rev-01) From Dynamic Prestress Projects & Services Pvt. LTDDocument50 paginiSubmission of Method Statement For Prestressing Works For T-Girder (Rev-01) From Dynamic Prestress Projects & Services Pvt. LTDDinesh ChoudharyÎncă nu există evaluări

- 030-Itp For Ug GRP Piping PDFDocument22 pagini030-Itp For Ug GRP Piping PDFKöksal Patan89% (9)

- Field Welding ProceduresDocument102 paginiField Welding Procedureslaz_k100% (2)

- API 510 Study MaterialDocument310 paginiAPI 510 Study MaterialPrashant Tiwari100% (1)

- Offshore Platform Structural Design CriteriaDocument51 paginiOffshore Platform Structural Design Criteriavhprao100% (3)

- SAIC-D-2007 Rev 2Document4 paginiSAIC-D-2007 Rev 2ரமேஷ் பாலக்காடுÎncă nu există evaluări

- Ac 193Document46 paginiAc 193Tiago Castelani100% (1)

- Checklist For Tank No 1Document2 paginiChecklist For Tank No 1sathi11189Încă nu există evaluări

- Quality Control of PilingDocument2 paginiQuality Control of PilingBudi Ariyadi100% (3)

- Machine Design Elements and AssembliesDe la EverandMachine Design Elements and AssembliesEvaluare: 3.5 din 5 stele3.5/5 (2)

- Total Quality Process Control for Injection MoldingDe la EverandTotal Quality Process Control for Injection MoldingEvaluare: 5 din 5 stele5/5 (1)

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionDe la EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionEvaluare: 4.5 din 5 stele4.5/5 (16)

- Sarthak WorksheetDocument15 paginiSarthak Worksheetcyber forensicÎncă nu există evaluări

- SM RSJ 420 800Document77 paginiSM RSJ 420 800elshan_asgarovÎncă nu există evaluări

- BIRADS Lexicon and Its Histopathological Corroboration in The Diagnosis of Breast LesionsDocument7 paginiBIRADS Lexicon and Its Histopathological Corroboration in The Diagnosis of Breast LesionsInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- HierbasDocument25 paginiHierbasrincón de la iohÎncă nu există evaluări

- PB PWR e R1 PDFDocument8 paginiPB PWR e R1 PDFnallinikanth sivalankaÎncă nu există evaluări

- AYUSHMAN BHARAT Operationalizing Health and Wellness CentresDocument34 paginiAYUSHMAN BHARAT Operationalizing Health and Wellness CentresDr. Sachendra Raj100% (1)

- History of The Stethoscope PDFDocument10 paginiHistory of The Stethoscope PDFjmad2427Încă nu există evaluări

- Rapid Cycling in Bipolar DisorderDocument1 paginăRapid Cycling in Bipolar Disorderdo leeÎncă nu există evaluări

- Nutrition During PregnancyDocument8 paginiNutrition During PregnancyHalliahÎncă nu există evaluări

- Cot 1 Vital SignsDocument22 paginiCot 1 Vital Signscristine g. magatÎncă nu există evaluări

- Affidavit of Consent For Shared Parental AuthorityDocument2 paginiAffidavit of Consent For Shared Parental AuthorityTet LegaspiÎncă nu există evaluări

- Neurons and Nerve Impulses: Nandika Arora and Risa Gaikwad (11 G2)Document17 paginiNeurons and Nerve Impulses: Nandika Arora and Risa Gaikwad (11 G2)RisaÎncă nu există evaluări

- Alternate Dialysis Platforms:: Sorbents SorbentsDocument17 paginiAlternate Dialysis Platforms:: Sorbents SorbentsJoe Single100% (2)

- Esaote MyLabX7Document12 paginiEsaote MyLabX7Neo BiosÎncă nu există evaluări

- Merit of RatingDocument1 paginăMerit of RatingRaidasÎncă nu există evaluări

- Nursing Care PlansDocument10 paginiNursing Care PlansGracie S. Vergara100% (1)

- Soal Upk B Inggris PKBM WinaDocument11 paginiSoal Upk B Inggris PKBM WinaCuman MitosÎncă nu există evaluări

- Very Easy Toeic Units 7 - 12 (Q1)Document39 paginiVery Easy Toeic Units 7 - 12 (Q1)Minh KhaiÎncă nu există evaluări

- Module A Specimen Questions January2020 PDFDocument5 paginiModule A Specimen Questions January2020 PDFShashi Bhusan SinghÎncă nu există evaluări

- How To Practice Self Care - WikiHowDocument7 paginiHow To Practice Self Care - WikiHowВасе АнѓелескиÎncă nu există evaluări

- Hinduism Today April May June 2015Document43 paginiHinduism Today April May June 2015jpmahadevÎncă nu există evaluări

- Ethamem-G1: Turn-Key Distillery Plant Enhancement With High Efficiency and Low Opex Ethamem TechonologyDocument25 paginiEthamem-G1: Turn-Key Distillery Plant Enhancement With High Efficiency and Low Opex Ethamem TechonologyNikhilÎncă nu există evaluări

- EEDMATH1 - Teaching Mathematics in The Primary Grades Beed 2E Learning Activity PlanDocument3 paginiEEDMATH1 - Teaching Mathematics in The Primary Grades Beed 2E Learning Activity PlanBELJUNE MARK GALANANÎncă nu există evaluări

- Manual Masina de Spalat Slim SamsungDocument1.020 paginiManual Masina de Spalat Slim SamsungPerfectreviewÎncă nu există evaluări

- How To Become A Coffee Aficionado: Tips & Tricks: Kate Macdonnell Brewing Updated: Feb 06 2023Document17 paginiHow To Become A Coffee Aficionado: Tips & Tricks: Kate Macdonnell Brewing Updated: Feb 06 2023sadenaikeÎncă nu există evaluări

- Maximizing Oredrive Development at Khoemacau MineDocument54 paginiMaximizing Oredrive Development at Khoemacau MineModisa SibungaÎncă nu există evaluări

- BCM Continuous ImprovementDocument22 paginiBCM Continuous ImprovementnikoÎncă nu există evaluări

- EO On Ban of Fireworks (Integrated)Document2 paginiEO On Ban of Fireworks (Integrated)Mario Roldan Jr.Încă nu există evaluări

- Q1 Tle 4 (Ict)Document34 paginiQ1 Tle 4 (Ict)Jake Role GusiÎncă nu există evaluări

- General Specifications: Detail ADocument1 paginăGeneral Specifications: Detail AJeniel PascualÎncă nu există evaluări