Documente Academic

Documente Profesional

Documente Cultură

CNC Programs For Practice1

Încărcat de

Guillermo RamirezDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

CNC Programs For Practice1

Încărcat de

Guillermo RamirezDrepturi de autor:

Formate disponibile

St.

JohnCollegeofEngineeringTechnology,Palghar (DepartmentofInformationTechnology)

PROGRAM NO. 05007

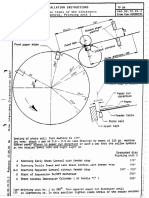

Q. Write a CNC Part Program for the figure shown

For side milling, take speed 1200 rpm & feed 100 mm/min For drilling holes, take speed 1200rpm & feed 80mm/min For slot milling, take speed 1200rpm & feed 120mm/min Take hole diameter as 15mm Use absolute coordinate system. Solution: 1 2 3 4 5 6 7 8 9 10 11 12 Sequence of operation: Set ref point, cordinate system, tool, give feed & speed value Set cutter for radius compensation left offset set tool at A, start spindle & give down feed (-Z direction) proceed further cutting of side milling and stop spindle at A Move tool at ref point & set the tool for slot cutting Move tool to P, start the spindle & give down feed Proceed further cutting of slot milling and stop spindle at S Move tool at ref point & set the tool for drilling Move tool to P, start the spindle & give full depth cut Move tool up & stop the spindle. Bring back tool at refrence point. End of the program

CNC Codes 05007

N001 N002 N003 N004 N005 N006 N007 N008 N009 G71 G92 G41 G01 G01 G02 G01 G01 G01 G90 X-15.0 G00 Z-15.0 X0.0 X10.0 X75.0 X100.0 Y92.0 Y10.0 Y-15.0 X0.0 M03 Y110.0 Y120.0 R10.0 Z0.0 Y0.0 T01 Z2.0 F100

Description

Program No.

Set dimension type mm, set absolute co-ordinate system S1200 Set reference point at 'O' (-15, -15, 0). Use tool T01(here side milling tool. Set Feed 100mm/rev, set spindle speed 1200 rpm Cutter radius compensation - left ON, move the tool at A & give clearance of 2mm before starting spindle rotation Start the spindle. Move tool down i.e. at Z direction for cut with feed (here M03 will execute first) Go to B linearly Go to C with clockwise circular interpolation with radius = 10 Go to D linearly Go to E linearly Go to F linearly

1

NotesBy:PrashantJadhav(Lecturer,DeptofMechanicalEngineering)

St.JohnCollegeofEngineeringTechnology,Palghar (DepartmentofInformationTechnology)

CNC Codes

N010 N011 N012 N013 N014 N015 N016 N017 N018 N019 N020 N021 N022 N023 N024 N024 N025 N026 G02 G01 Z2.0 G40 M06 G00 G01 Y80.0 X85.0 Y80.0 Z2.0 G00 M06 G00 G01 Z2.0 G00 M30 M05 X-15.0 T03 X50.0 Z-20.0 M05 X-15.0 Y-15.0 Y-15.0 F80 Y25.0 M03 X90.0 X0.0 M05 G00 T02 X15.0 Z-5.0 X-15.0 F120 Y55.0 M03 Y-15.0 Y0.0 R10.0

Description

Go to G with clockwise circular interpolation with radius = 10 Go to A linearly Go up 2mm in Z direction for clearance. Stop spindle rotation (here M05 will execute last). Cutter radius compensation OFF. Move tool to reference set point. Change the tool & use tool T02 (here for slot mill tool with dia 6mm). Set feed as 120mm/rev. Move tool to 'P' rapidly. Start the spindle. Move tool 5mm down i.e. at Z direction for cut with feed (here M03 will execute first) Go to Q linearly. Go to R linearly. Go to S linearly. Go up 2mm in Z direction for clearance. Stop spindle rotation (here M05 will execute last). Move tool to reference set point. Change the tool & use tool T03 (here for drill bit with dia 15mm). Set feed as 80mm/rev. Move tool to 'T' Go down 20mm for assuring full depth of hole. Go up rotation ( (here M05 will execute last). p 2mm in Z direction for clearance. Stop p spindle p ) Move tool to reference set point. Stop the program

NotesBy:PrashantJadhav(Lecturer,DeptofMechanicalEngineering)

S-ar putea să vă placă și

- Cogs Recessing Uygulama FormuDocument4 paginiCogs Recessing Uygulama Formusamad behnodfarÎncă nu există evaluări

- Assignment 1 INDU411 w2017Document3 paginiAssignment 1 INDU411 w2017ThomasMannÎncă nu există evaluări

- TNC 370Document333 paginiTNC 370Олександр СапаровÎncă nu există evaluări

- Fantasy Machine User's Manual GuideDocument21 paginiFantasy Machine User's Manual GuideTibor TiborÎncă nu există evaluări

- Work Instructions For Generator Alignment at Site Rev 02-S88Document14 paginiWork Instructions For Generator Alignment at Site Rev 02-S88gregoriojunior100% (1)

- Guarantee TimeDocument12 paginiGuarantee TimeRene CamaraÎncă nu există evaluări

- Chamfer Canned Cycle: Always Prepare For Stopping Cycle in Case Tool Interference!Document1 paginăChamfer Canned Cycle: Always Prepare For Stopping Cycle in Case Tool Interference!TuanÎncă nu există evaluări

- CNC Milling: 2, Setting The DatumDocument14 paginiCNC Milling: 2, Setting The DatumGundhi AsmoroÎncă nu există evaluări

- CNC Cutter Diameter Compensation GuideDocument12 paginiCNC Cutter Diameter Compensation GuideSankaralingam ShankarÎncă nu există evaluări

- Technical Manual: Code: DCD01/ - Mtec 060/9610A1Document8 paginiTechnical Manual: Code: DCD01/ - Mtec 060/9610A1kijijiÎncă nu există evaluări

- ATP Alignment Test CalibrationDocument14 paginiATP Alignment Test Calibrationomar macielÎncă nu există evaluări

- Broaching Operations Guide for Rotary BroachingDocument2 paginiBroaching Operations Guide for Rotary BroachingpeterÎncă nu există evaluări

- Heritage Institute of Technology: Department of Mechanical EngineeringDocument8 paginiHeritage Institute of Technology: Department of Mechanical EngineeringSwapnil DeyÎncă nu există evaluări

- Fast & Fluid Management: Punch Installation Manual HA480/HA680Document8 paginiFast & Fluid Management: Punch Installation Manual HA480/HA680Ray PutraÎncă nu există evaluări

- T21 Thermal Differential Switch: General InstructionsDocument12 paginiT21 Thermal Differential Switch: General InstructionsJims Poma VilcahuamanÎncă nu există evaluări

- QuickstartguidewebDocument2 paginiQuickstartguidewebapi-452427194Încă nu există evaluări

- Elec Ns U ManualDocument35 paginiElec Ns U ManualSenares ArdoÎncă nu există evaluări

- CNC Milling: 3, Tool SetupDocument16 paginiCNC Milling: 3, Tool SetupGundhi AsmoroÎncă nu există evaluări

- CNC Tool Nose Radius CompensationDocument11 paginiCNC Tool Nose Radius CompensationManjunatha Gr100% (1)

- Rigid Tapping Turning ProcedureDocument2 paginiRigid Tapping Turning ProcedureBalaji SahÎncă nu există evaluări

- CNC Machines and Control Programming FundamentalsDocument29 paginiCNC Machines and Control Programming FundamentalsAyush JaiswalÎncă nu există evaluări

- Dial Indicators and Digital Indicators: Mounting A Dial IndicatorDocument1 paginăDial Indicators and Digital Indicators: Mounting A Dial IndicatorozanÎncă nu există evaluări

- Ahe58/59 Ac Servo System: Safely InstructionDocument8 paginiAhe58/59 Ac Servo System: Safely InstructionDinh Nguyen100% (1)

- Mechanical Planimeter PDFDocument12 paginiMechanical Planimeter PDFchristianvanÎncă nu există evaluări

- JIH 455 Part3Document61 paginiJIH 455 Part3Michał JabłońskiÎncă nu există evaluări

- Pressure Gauges: Armaturenbau GMBH Manotherm Beierfeld GMBHDocument8 paginiPressure Gauges: Armaturenbau GMBH Manotherm Beierfeld GMBHVladimirÎncă nu există evaluări

- E-COMPACT Installation Manual: A Table of ContentsDocument10 paginiE-COMPACT Installation Manual: A Table of ContentsCaptvik VikÎncă nu există evaluări

- Massive MIMO AAU V2 - Installation Guidance and Standard (20-Nov-2020)Document12 paginiMassive MIMO AAU V2 - Installation Guidance and Standard (20-Nov-2020)Kyaw Kyaw WinÎncă nu există evaluări

- Board Layout: Sequence of Operation Safety PrecautionsDocument1 paginăBoard Layout: Sequence of Operation Safety PrecautionsNaveed AliÎncă nu există evaluări

- Touch ProbesDocument40 paginiTouch ProbesmarchmtetÎncă nu există evaluări

- Consew CSM1000 InstructionsDocument2 paginiConsew CSM1000 InstructionsJose Eduardo Vargas AngaritaÎncă nu există evaluări

- Total Station ZTS-720 Series Instruction ManualDocument10 paginiTotal Station ZTS-720 Series Instruction ManualRENE BRIONESÎncă nu există evaluări

- Ponchadora PDFDocument2 paginiPonchadora PDFmarco antoniomegreteÎncă nu există evaluări

- Veeco SPM Sop 07112018Document11 paginiVeeco SPM Sop 07112018AleksandarKarajićÎncă nu există evaluări

- Winmax Probe Training: Part Probe Setup and Conversational CalibrationDocument35 paginiWinmax Probe Training: Part Probe Setup and Conversational CalibrationNikolat84Încă nu există evaluări

- Eumig Projector Mark 610D Mark 607D User ManualDocument13 paginiEumig Projector Mark 610D Mark 607D User ManualHarald Melbye75% (4)

- Operation Manual enDocument12 paginiOperation Manual enRikiAndikaPersistentsÎncă nu există evaluări

- Installation Instructions for TP 94 Electronic Sheet CounterDocument4 paginiInstallation Instructions for TP 94 Electronic Sheet CounterNimesh SilvaÎncă nu există evaluări

- Toplok Adapter: Adapter and Pin Installation Instructions For The T410/T417-70SV2 SeriesDocument12 paginiToplok Adapter: Adapter and Pin Installation Instructions For The T410/T417-70SV2 SeriesAndree Ayma NuñezÎncă nu există evaluări

- R9说明书2019 10 11增加下挂Document21 paginiR9说明书2019 10 11增加下挂Tsu Min YiÎncă nu există evaluări

- Veeder-Root: Series S628 DC ProcessDocument16 paginiVeeder-Root: Series S628 DC ProcessjpierreÎncă nu există evaluări

- Gears: Mechanical Engineering DeptDocument20 paginiGears: Mechanical Engineering DeptAtikah AbdallaÎncă nu există evaluări

- Technote #34 Rotalign: Rotalign Ment of Cardan Shafts Using Cardan Bracket Ali 2.893setDocument5 paginiTechnote #34 Rotalign: Rotalign Ment of Cardan Shafts Using Cardan Bracket Ali 2.893setCarlos M100% (1)

- Dc645perf InstallDocument18 paginiDc645perf InstallLars NotlevÎncă nu există evaluări

- Pan Calibration in The Field - Revised FINALDocument10 paginiPan Calibration in The Field - Revised FINALkirk urreaÎncă nu există evaluări

- Info Max S - enDocument6 paginiInfo Max S - enbuidinhtien18051Încă nu există evaluări

- STRUCTURE ANALYSIS DRILLING PROCESSDocument21 paginiSTRUCTURE ANALYSIS DRILLING PROCESSDhananjay PatilÎncă nu există evaluări

- WheelTool 1Document18 paginiWheelTool 1M Mostafa MasalmaÎncă nu există evaluări

- Lathe MachineDocument91 paginiLathe MachineHrithik LakhaniÎncă nu există evaluări

- Unit 2 - 2 MarkDocument2 paginiUnit 2 - 2 MarkRUPILAA V MÎncă nu există evaluări

- Manually Set MRZP For TR Using A C ConfigurationDocument3 paginiManually Set MRZP For TR Using A C Configurationomar macielÎncă nu există evaluări

- M7E01 TechData 01Document10 paginiM7E01 TechData 01lexeberu100% (1)

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreDe la EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreEvaluare: 4.5 din 5 stele4.5/5 (11)