Documente Academic

Documente Profesional

Documente Cultură

TC 1419 Mcnally

Încărcat de

mtlhwhTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

TC 1419 Mcnally

Încărcat de

mtlhwhDrepturi de autor:

Formate disponibile

Works:Chhendipara Road,SH- 63 P O Nisha Angul(Orissa)-759 130 INDIA Email:qclab.pm@angul.jspl.com Registered Office:Post box No.

6 ,O P Jindal Marg ,Hisar (Haryana) Corporate Office :Jindal Center,12 Bhikaji Cama Palace, New Delhi -110066 INDIA Phone No.:-(07762) 227001-227010; Fax :-07762 -227021-227022 :Gram PIG IRON

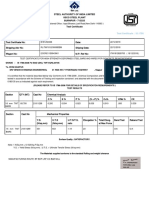

JINDAL STEEL & POWER LIMITED

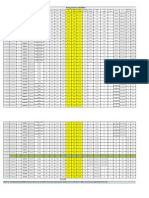

TEST CERTIFICATE FOR HOT ROLLED MEDIUM AND HIGH TENSILE STRUCTURAL STEEL

Test Method :Tensile:IS 1608:Bend:IS 1599; Impact:IS 1757; Chemical :ASTM E 415/IS 8811

Test Certificate No. 0000001419 To, M/s MCNALLY BHARAT ENGINEERING CO.LIMIT ANGUL

We Certify that the material described below fully conforms to IS 2062 : 2011. Chemical composition and mechanical properties of the product as tested in accordance with the Scheme of testing and inspection contained in the BIS certification marks licence No. CM/L-5639985 are as indicated below against each Heat Number. (PLEASE REFER TO IS 2062:2011 FOR DETAILS OF SPECIFICATION REQUIREMENT)

Date : 16.02.2013

Page 1 of 2

TEST RESULTS

Process of Manufacture : EAF->LRF->CCM->RHF->Hot rolling

(EAF - Electric Arc Furnace / LRF: Ladle Refining Furnace / VD : Vaccum Degassing / CCM : Continuous Casting Machine/ RHF : Re-Heating Furnace)

Supply Condition:AS ROLLED Deoxidation : Killed

Heat No Plate No.of Wt. MT No Pcs.

Material Grade : IS2062 E250 BR Plate Dimension -Thickness x Width x Length : 25.00mm x 2500mm x 10.000m Chemical Analysis

L/P %C 0.18 %Mn %S %P %Si %Al %Cu %V %Nb %Ti %Mo %Ni %B %Cr N2 ppm 62 CE 0.31 YS Mpa 280 285 UTS Mpa 465 460

Mechanical Properties

%EL* Bend Test Mand Dia. 27 OK(2.0 T) 26 OK(2.0 T) I II Impact Value at(J) III Avg Temp 0C Orien

3203418 EB0 3203418 EB0

4.926 L

0.80 0.008 0.013 0.10 0.029 0.005 0.010 0.003 0.002 0.002 0.003 0.0003 0.010

Sub Total 1 4.926 Material Grade : IS2062 E250 BR Plate Dimension -Thickness x Width x Length : 25.00mm x 2500mm x 11.000m Heat No Plate No.of Wt. MT Chemical Analysis

No Pcs.

L/P %C 0.17 0.17 %Mn %S %P %Si %Al %Cu %V %Nb %Ti %Mo %Ni %B %Cr N2 ppm 73 64 CE 0.31 0.30 YS Mpa 289 290 272 274 UTS Mpa 433 437 472 471

Mechanical Properties

%EL* Bend Test Mand Dia. 27 OK(2.0 T) 29 OK(2.0 T) 27 OK(2.0 T) 27 OK(2.0 T) I II Impact Value at(J) III Avg Temp 0C Orien

3203463 3203463 3203487 3203487

CB0 CB0 AB0 AB0

1 1 2

4.926 L 4.927 L 9.853

0.83 0.011 0.009 0.10 0.035 0.005 0.005 0.003 0.002 0.002 0.005 0.0003 0.006 0.80 0.009 0.012 0.09 0.035 0.005 0.005 0.003 0.002 0.002 0.004 0.0003 0.008

Sub Total

Remarks: Revised TC dated 08-03-2013

The Material supplied conforms to the tolerances as per IS:1852. UltraSonic Examination : All the above plates are ultrasonically tested as per ASTM A-435 and found ok Purchase Order No. & Date: 10024764 30.01.2013 Despatch Advice No: 61205821 Prepared by BSAHU Truck/Wagon No. OR05Z5785 Preparation Date :16.02.2013 12:31:21

* Gauge Length: 5.65(SO)1/2

Printing Date 08.03.2013 & Time 15:44:39

Authorised Signatory QA/QC PlateMill For, JINDAL STEEL & POWER LIMITED

Works:Chhendipara Road,SH- 63 P O Nisha Angul(Orissa)-759 130 INDIA Email:qclab.pm@angul.jspl.com Registered Office:Post box No. 6 ,O P Jindal Marg ,Hisar (Haryana) Corporate Office :Jindal Center,12 Bhikaji Cama Palace, New Delhi -110066 INDIA Phone No.:-(07762) 227001-227010; Fax :-07762 -227021-227022 :Gram PIG IRON

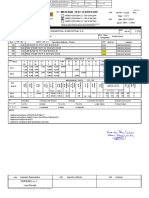

JINDAL STEEL & POWER LIMITED

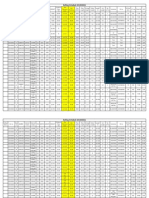

TEST CERTIFICATE FOR HOT ROLLED MEDIUM AND HIGH TENSILE STRUCTURAL STEEL

Test Method :Tensile:IS 1608:Bend:IS 1599; Impact:IS 1757; Chemical :ASTM E 415/IS 8811

Test Certificate No. 0000001419 To, M/s MCNALLY BHARAT ENGINEERING CO.LIMIT ANGUL

We Certify that the material described below fully conforms to IS 2062 : 2011. Chemical composition and mechanical properties of the product as tested in accordance with the Scheme of testing and inspection contained in the BIS certification marks licence No. CM/L-5639985 are as indicated below against each Heat Number. (PLEASE REFER TO IS 2062:2011 FOR DETAILS OF SPECIFICATION REQUIREMENT)

Date : 16.02.2013

Page 2 of 2

TEST RESULTS

Process of Manufacture : EAF->LRF->CCM->RHF->Hot rolling

(EAF - Electric Arc Furnace / LRF: Ladle Refining Furnace / VD : Vaccum Degassing / CCM : Continuous Casting Machine/ RHF : Re-Heating Furnace)

Supply Condition:AS ROLLED Deoxidation : Killed

Heat No Plate No.of Wt. MT No Pcs.

Material Grade : IS2062 E250 BR Plate Dimension -Thickness x Width x Length : 25.00mm x 2500mm x 11.500m Chemical Analysis

L/P %C 0.17 0.17 0.18 %Mn %S %P %Si %Al %Cu %V %Nb %Ti %Mo %Ni %B %Cr N2 ppm 73 64 65 CE 0.31 0.30 0.31 YS Mpa 289 290 272 274 280 285 UTS Mpa 433 437 472 471 460 465

Mechanical Properties

%EL* Bend Test Mand Dia. 27 OK(2.0 T) 29 OK(2.0 T) 27 OK(2.0 T) 27 OK(2.0 T) 27 OK(2.0 T) 26 OK(2.0 T) I II Impact Value at(J) III Avg Temp 0C Orien

3203463 3203463 3203487 3203487 3203635 3203635

CA0 CA0 AA0 AA0 FA0 FA0

1 1 1 3 6

6.158 L 6.158 L 6.025 L 18.341 33.120

0.83 0.011 0.009 0.10 0.035 0.005 0.005 0.003 0.002 0.002 0.005 0.0003 0.006 0.80 0.009 0.012 0.09 0.035 0.005 0.005 0.003 0.002 0.002 0.004 0.0003 0.008 0.79 0.004 0.012 0.11 0.022 0.005 0.008 0.003 0.002 0.008 0.0004 0.008

Sub Total G Total

Remarks: Revised TC dated 08-03-2013

The Material supplied conforms to the tolerances as per IS:1852. UltraSonic Examination : All the above plates are ultrasonically tested as per ASTM A-435 and found ok Purchase Order No. & Date: 10024764 30.01.2013 Despatch Advice No: 61205821 Prepared by BSAHU Truck/Wagon No. OR05Z5785 Preparation Date :16.02.2013 12:31:21

* Gauge Length: 5.65(SO)1/2

Printing Date 08.03.2013 & Time 15:44:39

Authorised Signatory QA/QC PlateMill For, JINDAL STEEL & POWER LIMITED

S-ar putea să vă placă și

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 paginăCustomer Specification Shipment/Delivery No.: GL 5.65 SOBilal Luhar100% (1)

- Test Certificate No.: 0000524871: Chemical Analysis Mechanical PropertiesDocument1 paginăTest Certificate No.: 0000524871: Chemical Analysis Mechanical PropertiesSuman Jana100% (1)

- R.K Steel Udyog PVT - LTD: Test Certificate For High Strength Deformed Steel Bars and Wires For Concrete ReinforcementDocument2 paginiR.K Steel Udyog PVT - LTD: Test Certificate For High Strength Deformed Steel Bars and Wires For Concrete Reinforcementnanda kishopre100% (4)

- Jindal Steel & Power Limited: Page 1 of 6Document1 paginăJindal Steel & Power Limited: Page 1 of 6pranesh kadam100% (2)

- Page 2 of 6: Test Certificate No. 0000052877Document1 paginăPage 2 of 6: Test Certificate No. 0000052877pranesh kadam100% (2)

- Test Method: Tensile: IS 1608 Bend: IS 1599 Impact: IS 1757 Chemical:ASTM E 415/ IS8811Document1 paginăTest Method: Tensile: IS 1608 Bend: IS 1599 Impact: IS 1757 Chemical:ASTM E 415/ IS8811akash_smhs0% (1)

- MTC Inv 053 PDFDocument1 paginăMTC Inv 053 PDFBeshnu Garanaik100% (1)

- Page 1 of 1: Test Certificate No. 0000141878Document1 paginăPage 1 of 1: Test Certificate No. 0000141878Vishwanathan NagarajanÎncă nu există evaluări

- Jindal Steel & Power Limited: Test Certificate No. 0000247591, Revision No. 000 Date: 03.09.2018Document1 paginăJindal Steel & Power Limited: Test Certificate No. 0000247591, Revision No. 000 Date: 03.09.2018Mohammad Adil50% (2)

- Page 1 of 6: Test Certificate No. 0000052877Document6 paginiPage 1 of 6: Test Certificate No. 0000052877panduranganraghurama78% (9)

- Test Certificate 16mmDocument1 paginăTest Certificate 16mmSabyasachi Bangal100% (2)

- Universal 1-2 Clase 6000 Tipo 316Document2 paginiUniversal 1-2 Clase 6000 Tipo 316comercial 3100% (1)

- SS304-1 2THK PDFDocument1 paginăSS304-1 2THK PDFrajÎncă nu există evaluări

- 622888Document1 pagină622888DeepakÎncă nu există evaluări

- MILL TEST CERTIFICATE FOR 304 STAINLESS STEELDocument1 paginăMILL TEST CERTIFICATE FOR 304 STAINLESS STEELMANIMARAN QC100% (1)

- 304 1.5MM PCDocument1 pagină304 1.5MM PCsabir hussain100% (1)

- 1jsl Ltd. TPI 3 (31803) MMDocument2 pagini1jsl Ltd. TPI 3 (31803) MMPratik KarekarÎncă nu există evaluări

- Global Aluminium Private Limited: M/S. Wonjin Autoparts India PVT LTD, ChennaiDocument1 paginăGlobal Aluminium Private Limited: M/S. Wonjin Autoparts India PVT LTD, ChennaiSonu Singh100% (1)

- HR 6MM X 2.5 X 6 Mtrs (5) - SHELLDocument1 paginăHR 6MM X 2.5 X 6 Mtrs (5) - SHELLGurumoorthy RajavijayanÎncă nu există evaluări

- T.T.I. - Tubacex Tubos Inoxidables, S.A.: Mill Test CertificateDocument3 paginiT.T.I. - Tubacex Tubos Inoxidables, S.A.: Mill Test CertificateMANUFACTURER OF FORGED FLANGES AND PIPE FITTINGSÎncă nu există evaluări

- Jindal Steel & Power LTD: Test CertificateDocument2 paginiJindal Steel & Power LTD: Test CertificateAmandeep Singh50% (2)

- MAHARASHTRA SEAMLESS LIMITED CERTIFICATE OF MANUFACTURE AND TEST FOR PIPESDocument1 paginăMAHARASHTRA SEAMLESS LIMITED CERTIFICATE OF MANUFACTURE AND TEST FOR PIPESPetroPower OilandgasÎncă nu există evaluări

- IS 10748_2004 Compliant HR Steel Coils CertificateDocument1 paginăIS 10748_2004 Compliant HR Steel Coils CertificateravigurajapuÎncă nu există evaluări

- QM-System: Certification As Per ISO 9001: (WWW - Dillinger.de/certificate)Document20 paginiQM-System: Certification As Per ISO 9001: (WWW - Dillinger.de/certificate)hemantmech099200Încă nu există evaluări

- Essar MTCDocument1 paginăEssar MTCGowtham Vishvakarma33% (3)

- Mill Test Certificate: Jindal Stainless (Hisar) LimitedDocument1 paginăMill Test Certificate: Jindal Stainless (Hisar) Limitedhemantmech099200Încă nu există evaluări

- Aluminium Rod Material Detail PDFDocument1 paginăAluminium Rod Material Detail PDFPradeep SÎncă nu există evaluări

- Tata Steel Hot Rolled Coils Test CertificateDocument1 paginăTata Steel Hot Rolled Coils Test CertificateMohd YaskeenÎncă nu există evaluări

- No. A-14-401751 Rev 00Document3 paginiNo. A-14-401751 Rev 00Adrian CeplinschiÎncă nu există evaluări

- 4.0X1500. 23920 E250a DoDocument1 pagină4.0X1500. 23920 E250a Dosatyaprakashgond100% (1)

- Flange 24 InchDocument2 paginiFlange 24 InchreniÎncă nu există evaluări

- MTC FITTINGSDocument5 paginiMTC FITTINGSAzee TitouÎncă nu există evaluări

- JSW Steel TMT Test CertificateDocument2 paginiJSW Steel TMT Test Certificatevenkata krishna reddy MorthlaÎncă nu există evaluări

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 paginăCustomer Specification Shipment/Delivery No.: GL 5.65 SOParesh MehtaÎncă nu există evaluări

- Mill Test Certificate: Jindal Stainless (Hisar) LimitedDocument1 paginăMill Test Certificate: Jindal Stainless (Hisar) Limitedhemantmech09920050% (2)

- 90mm 316l Peeled and PolishedDocument1 pagină90mm 316l Peeled and PolishedB.M Industrial WorksÎncă nu există evaluări

- Test Certificate: CM/L-NO:5200036277Document10 paginiTest Certificate: CM/L-NO:5200036277TARUNKUMARÎncă nu există evaluări

- MTC-SML (1) - 4500528257 I - Ii - Tubos GB - SCH 6MT - 210251 - 210291 - 210377Document3 paginiMTC-SML (1) - 4500528257 I - Ii - Tubos GB - SCH 6MT - 210251 - 210291 - 210377Saul Omar Fernandez RojasÎncă nu există evaluări

- Test Certificate: CM/L-NO:5530357Document10 paginiTest Certificate: CM/L-NO:5530357TARUNKUMARÎncă nu există evaluări

- CERTIFICATE OF QUALITY FOR STAINLESS STEEL SHEETDocument1 paginăCERTIFICATE OF QUALITY FOR STAINLESS STEEL SHEETCarlos RomeroÎncă nu există evaluări

- 300 C SailDocument2 pagini300 C Sailchandrabhushan kushwahaÎncă nu există evaluări

- 2.5 MM 1250....Document1 pagină2.5 MM 1250....Balaji Defence100% (1)

- Quantity and Quality Certificate (EN 10204/3.1) : PAGE:1/7Document1 paginăQuantity and Quality Certificate (EN 10204/3.1) : PAGE:1/7Nilton Santillan OrtegaÎncă nu există evaluări

- Mittal Corp Limited Test Certificate FinalDocument1 paginăMittal Corp Limited Test Certificate FinalMehmet SoysalÎncă nu există evaluări

- Test CertificateDocument2 paginiTest CertificatePRITESHÎncă nu există evaluări

- QUALITY MILL CERTIFICATE FOR HOT ROLLED STEEL ROUND, ANNEALED GRADE AISI4140Document1 paginăQUALITY MILL CERTIFICATE FOR HOT ROLLED STEEL ROUND, ANNEALED GRADE AISI4140Mohamed NabeilÎncă nu există evaluări

- SLA Mill Test Certificate for 316/316 Stainless Steel PlatesDocument4 paginiSLA Mill Test Certificate for 316/316 Stainless Steel PlatesSurajPandey33% (3)

- M12X50 HDG GR 8.8 ISO 4017 Hex Bolt 2019HD-261Document1 paginăM12X50 HDG GR 8.8 ISO 4017 Hex Bolt 2019HD-261Athul T.NÎncă nu există evaluări

- MTC 4500528257 Iii - 210209Document3 paginiMTC 4500528257 Iii - 210209Saul Omar Fernandez RojasÎncă nu există evaluări

- MTC 5Document1 paginăMTC 5Muthazhagan SaravananÎncă nu există evaluări

- T & C Fastener Co, LTD.: Certified Material Test ReportDocument1 paginăT & C Fastener Co, LTD.: Certified Material Test Reportlady romeroÎncă nu există evaluări

- 4140 Material For TubeDocument2 pagini4140 Material For Tubesharafudheen_sÎncă nu există evaluări

- MTC PDFDocument170 paginiMTC PDFShoukat Zaki0% (2)

- Material TCDocument1 paginăMaterial TCgmbakshiÎncă nu există evaluări

- JCOUSER03Document1 paginăJCOUSER03Neem LalÎncă nu există evaluări

- MTC 17 4PH Al20201127a174Document1 paginăMTC 17 4PH Al20201127a174Ajeng PratiwiÎncă nu există evaluări

- Al Jazeera Steel Mill Test ReportDocument1 paginăAl Jazeera Steel Mill Test Reportsnehalmdeshmukh100% (1)

- Page 1 of 9: Test Certificate No. 0000145263Document9 paginiPage 1 of 9: Test Certificate No. 0000145263Vishwanathan NagarajanÎncă nu există evaluări

- MS SHEETS MTCDocument6 paginiMS SHEETS MTCAmit Kumar OjhaÎncă nu există evaluări

- Tinita Engineering testing and material reportsDocument4 paginiTinita Engineering testing and material reportsalokbdasÎncă nu există evaluări

- After Rolling SCH No.201303011Document4 paginiAfter Rolling SCH No.201303011mtlhwhÎncă nu există evaluări

- Attendance DiscrepanciesDocument8 paginiAttendance DiscrepanciesmtlhwhÎncă nu există evaluări

- Cleared For Dispatch MANASDocument1 paginăCleared For Dispatch MANASmtlhwhÎncă nu există evaluări

- Rolling SCH 201303021Document5 paginiRolling SCH 201303021mtlhwhÎncă nu există evaluări

- 4561016807 (2)Document6 pagini4561016807 (2)mtlhwhÎncă nu există evaluări

- 201302009Document2 pagini201302009mtlhwhÎncă nu există evaluări

- Presentation1. AEC GeoTech LANDFILLDocument22 paginiPresentation1. AEC GeoTech LANDFILLAyan BorgohainÎncă nu există evaluări

- Low Temp Refrigeration Oil DataDocument1 paginăLow Temp Refrigeration Oil DataGeorgiana DumitruÎncă nu există evaluări

- CHEMISTRY LAB VIVA QuestionsDocument3 paginiCHEMISTRY LAB VIVA QuestionsUjjWal MahAjan55% (20)

- Astm 1351 1 REPLICADocument6 paginiAstm 1351 1 REPLICAmaheshÎncă nu există evaluări

- Sspc-Ab 1Document5 paginiSspc-Ab 1Anton Thomas Punzalan100% (3)

- Binary and TernaryDocument13 paginiBinary and TernaryRosemarie Degala LateÎncă nu există evaluări

- Lecture notes on basic inorganic chemistry IIDocument24 paginiLecture notes on basic inorganic chemistry IIRSLÎncă nu există evaluări

- Instruction Manual Instruction Manual: HDI 2D949-80Document30 paginiInstruction Manual Instruction Manual: HDI 2D949-80GeorgianaÎncă nu există evaluări

- Banana Peel Shoe PolishDocument11 paginiBanana Peel Shoe PolishGMae Lim100% (4)

- UNIT III TheoryDocument6 paginiUNIT III TheoryRanchuÎncă nu există evaluări

- Is 2986Document9 paginiIs 2986sreenathaÎncă nu există evaluări

- Ti OSO4Document4 paginiTi OSO4Liz AfanadorÎncă nu există evaluări

- 109 Sodium ChlorideDocument6 pagini109 Sodium Chlorideeng20072007Încă nu există evaluări

- RE - Unit 1Document84 paginiRE - Unit 1Faraj NabiyevÎncă nu există evaluări

- Final - Report Hydroelectric Power PlantDocument39 paginiFinal - Report Hydroelectric Power PlantnisarÎncă nu există evaluări

- Food Preservatives and Their Harmful EffDocument2 paginiFood Preservatives and Their Harmful EffJo ShuÎncă nu există evaluări

- Tube InstallationDocument49 paginiTube InstallationgshdavidÎncă nu există evaluări

- ConChem q1 m1Document28 paginiConChem q1 m1Leonora Alejo100% (1)

- Acid RainDocument35 paginiAcid RainAshish Deotale100% (4)

- Expwb3ans eDocument67 paginiExpwb3ans eOlivia LinÎncă nu există evaluări

- ArcelorMittal Projects Steel Pipe ProductionDocument20 paginiArcelorMittal Projects Steel Pipe Productionanil-kumar-singh-6674Încă nu există evaluări

- International Journal of Plasticity: Rolf Mahnken, Andreas Schneidt, Thomas AntretterDocument22 paginiInternational Journal of Plasticity: Rolf Mahnken, Andreas Schneidt, Thomas AntretterKhouloud GharbiÎncă nu există evaluări

- Rapid and Reliable HPLC Method For The Simultaneous Determination of Dihydroxyacetone, Methylglyoxal and 5-Hydroxymethylfurfural in Leptospermum HoneysDocument9 paginiRapid and Reliable HPLC Method For The Simultaneous Determination of Dihydroxyacetone, Methylglyoxal and 5-Hydroxymethylfurfural in Leptospermum Honeysasel ppÎncă nu există evaluări

- 02-04800 Painting SafetyDocument29 pagini02-04800 Painting SafetykumarÎncă nu există evaluări

- Synthesis and Discriminative Stimulus Properties of N(6)-Alkyl Norlysergic Acid DerivativesDocument4 paginiSynthesis and Discriminative Stimulus Properties of N(6)-Alkyl Norlysergic Acid Derivativesmik100% (1)

- Johnson Industrial Screens PDFDocument20 paginiJohnson Industrial Screens PDFjaime palenzuela rodriguezÎncă nu există evaluări

- General Characteristics of Bacteria and MollicutesDocument13 paginiGeneral Characteristics of Bacteria and MollicutesPrincess Mehra0% (1)

- Unit 1 - Part A-Water Supply IDocument24 paginiUnit 1 - Part A-Water Supply IIsha SinghÎncă nu există evaluări

- Ethanol Absolut (Ethyl Alcohol)Document6 paginiEthanol Absolut (Ethyl Alcohol)Fitra Isni RositaÎncă nu există evaluări

- 1010750-Steam Quality TestingDocument11 pagini1010750-Steam Quality TestingHendra Hadriansyah100% (1)