Documente Academic

Documente Profesional

Documente Cultură

Stepper Motors 1

Încărcat de

ngt881Descriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Stepper Motors 1

Încărcat de

ngt881Drepturi de autor:

Formate disponibile

By Jeram Chamberlain of Nippon Pulse America JChamberlain@Nipponpulse.com http://www.nipponpulse.com/main.

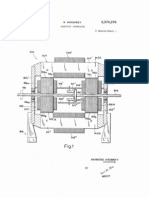

html Have you ever picked up a motor and discovered it had a few more wires then you were expecting? It could have been a stepper motor. Stepper motors are very commonly used in a number of products you might use every day. You can find them in everything from wrist watches to printers, IV pumps to gas pumps, stepper motors are also FIGURE 1 popular in machine tools, process control systems, tape and disk drive systems, and programmable controllers. Most technicians while in school learned about motors, but as common as stepper motors are it is amazing, how few technicians know, or still reminder, how stepper motors work, and how to troubleshoot and test them. There is much confusion about the differences between Unipolar and Bipolar types of stepper motors. There is confusion about how Constant Current and Constant Voltage types of stepper motor drives work. Why do I use a 5V motor when I have a 24V supply? But dont feel bad. There are a number of engineers who do not understand either. This is a 2 part series were we will cover the most important steps of troubleshooting any stepper motor system. This article will cover an overview of stepper motors what they are and how they work. Then we will discuss how to troubleshoot them. In the second article will also cover the electronics needed to make a stepper motor run. And discuss how to troubleshoot them.1 Stepper motors what they are and how they work A stepper or stepping motor converts electronic pulses into mechanical movement. Each electronic pulse step causes the shaft to rotate a certain number of degrees (step angle). Thus, a stepper motor can be operated in an open loop application, which means it can be told to go a certain distance at a certain speed without the need for any type of feedback. Figure 1 illustrates a simple application for a stepper motor each time the controller receives an input signal, the paper is driven a certain incremental distance. Another important characteristic of the stepper motor is that it can maintain the holding torque indefinitely when the rotor is stopped with out burning up the motor windings. When a stepper motor has a steady DC signal applied to one stator winding, the rotor will overcome the residual torque and line up with that stator field. The holding torque is defined as the amount of torque required to move the rotor one full

Stepper Motors Part 1 Motors

FIGURE 2 step with the stator energized. When no power is applied to the windings, a small magnetic force is developed between the permanent magnet and the stator. This magnetic force is called the residual, or detent torque. The detent torque can be noticed by turning a stepper motor by hand and is generally about one-tenth of the holding torque. How does a stepper motor work? Figure 2 illustrates a typical

1 While a lot of formulas may help you design a new stepper motor, what we will try to do in these articles is give a general overview of stepper motors. If you would like to get deeper into stepper motors, like a lot of formulas I suggest two books: Industrial Electronics by Colin D. Simpson , published by Prentice Hall PTR. Copyright 1996, and Stepping Motors and their Microprocessor Controls by Takashi Kenjo and Akira Sugawara, published by Oxford Science Publications Copyright 1994. (Both were used as references for this article.)

one phase step sequence for a two phase motor. In Step 1, phase A of a two-phase stator is energized. This magnetically locks the rotor in the position shown, since unlike poles attract. When phase A is turned off and phase B is turned on, the rotor rotates 90 clockwise. In Step 3, phase B is turned off and phase A is turned on but with the polarity reversed from Step 1. This causes another 90 rotation. In Step 4, phase A is turned off and phase B is turned on, with polarity reversed from Step 2. Repeating this sequence causes the rotor to rotate clockwise in 90 steps. There are three main types of stepper motors: permanent-magnet (PM), variable reluctance (VR) and Hybrid. The permanent-magnet (PM) stepper motor operates on the reaction between a permanentmagnet rotor and an electromagnetic field. One of the most common PM motors are of the Tin Can or claw-tooth type See Figure 3.

Figure 3 In these tin can steppers, the rotor shaft is surrounded by a magnet with radially opposing poles. It has no teeth. The stator is a series of poles with wound wire coils. Because of the magnet, the rotor will resist movement even when the motor is not energized. Permanent magnet step motors are used in low-cost, low-power applications, the bill feeder inside vending machines is driven by a permanent magnet step motor.

The variable-reluctance (VR) are misaligned with each other by a stepper motor differs from the PM half-tooth pitch. Torque is created stepper in that it has no in the hybrid motor by the permanent-magnet rotor and no interaction of the magnetic field of residual torque to hold the rotor at the permanent magnet and the one position when turned off. This magnetic field produced by the type of motor operates on the stator. Most hybrid steppers are principle of minimizing the NEMA size motors See Figure 5. reluctance along the path of the applied magnetic field. One of the first uses for Variable-reluctance stepper motors was to move the direction indicator of torpedo tubes and guns on British warships in the 1920s. Shortly thereafter they were employed by the US Navy for a similar purpose. The hybrid step motor consists of two pieces of soft iron, as well as Figure 5 an axially magnetized, round rotor. The term hybrid is derived from the The windings for steppers come fact that the motor is operated in two types Bipolar and Unipolar. under the combined principles of There are a number of advantages the permanent magnet and to each type of winding. variable-reluctance stepper motors. Bipolar see Figure 6. The stator core structure of a hybrid motor is essentially the same as its VR counterpart. The main difference is that in the VR motor, only one of the two coils of one phase is wound on one pole, while a typical hybrid motor will have coils of two different phases wound on the same pole. The two coils at a pole are wound in a configuration known as a bifilar connection. Each pole of a hybrid motor is covered with Figure 6 uniformly spaced teeth made of The two-phase stepping soft steel See Figure 4. The teeth sequence described earlier utilizes on the two sections of each pole a bipolar coil winding. Each phase consists of a single winding. This is referred to as a bipolar winding because the current flow, on the coils is reversed. By reversing the current in the windings, electromagnetic polarity is reversed.

Figure 4

Unipolar see Figure 7

2. The brushes go bad. There are no brushes in a stepper motor. Therefore, this will never be a cause of failure.

Figure 7 Another common winding is the unipolar winding some times called four-phase steppers. This consists of two windings on a pole connected in such a way that when one winding is energized a magnetic north pole is created; when the other winding is energized, a south pole is created. This is referred to as a unipolar winding because the electrical polarity, i.e. current flow, from the drive to the coils is never reversed. Testing Stepper motors Typically there are four things that can go wrong with a motor in general. 1. They burn up. 2. The brushes go bad. 3. The bearings go bad. 4. The technician breaks them. Lets look at each of these in respect to the stepper motor. 1. They burn up. An important characteristic of the stepper motor is that it can maintain the holding torque indefinitely when the rotor is stopped. If a stepper motor stalls out it will not typically burn up as with most AC and DC motors. If the motor does burn up it typically indicates a driver problem. We will get more in why this is the case in the next article. Just replacing the motor will cause the motor to burn up again. This is a very uncommon problem with stepper motors unless there is a bad driver causing it.

Bipolar or Unipolar motor. Figure 8 A Bipolar will always have 4 leads. A Unipolar will have 5 or 6 leads. If 5 leads, the two common wires are connected. A few motors you run into will have 8 leads, these can be wired as either a Unipolar or Bipolar See Figure 9. Using the Ohmmeter, you can check the resistance of the windings. On a Bipolar the resistance for both winding should be the same in both directions Figure 10. In a unipolar

Figure 8 3. The bearings go bad. The cooler the motor stays the longer the bearings will last. But at times the bearings will go bad. Still this is not a very common problem. The bearings in most cheap motors are rated at 3K hours or more, and most high-end quality motors are rated at 90K to 100K hours. 4. The technician breaks them. OK, this is the most common cause of failure for stepper motors. When working with stepper motors be careful with them. They do not need to be handled like fine china but you cannot fix one with a hammer. Most cheap motors only use glue to hold the shaft to the rotor, and most quality steppers will use grooving along with adhesive. Testing. You want to test the motor. First us an ohm meter. It will help you tell if a winding is burnt up and what type of stepper motor you have. Most likely you will have a

Figure 10 winding the resistance from each phase to com should be the same in both directions Figure 11. After you have checked the motor with the ohmmeter, you can use a 9V battery to step the motor through its paces. This will confirm the

Figure 11 motor windings are good. You can

use the charts in Figure 9 to assist with this. Also turn the motor by hand while listening for bad bearings. All PM and hybrid stepper motors will have some detent torque. PM will have more than the hybrid steppers. If the leads of the stepper motor are touching the detent torque will be greatly exaggerated. Be careful! Some technicians have falsely linked this to bad bearings. If the bearings are bad, there will usually be extra axial play in the motor. If possible check against a known good motor. When replacing a motor many technicians wonder what the color code for the wires is. Remember the windings make up an electromagnet. So as long as you have the windings grouped correctly (Phase 1 and 3 together and Phase 2 and 4 together) the worst that will happen when you go to run the motor is that it will run backwards. If it does just swap one set of phases (1 and 3 or 2 and 4). Next time we will get more in to electronics of stepper motors. We will get more into the differences between Bipolar vs. Unipolar windings and how Constant Current and Constant Voltage types of stepper motor drives work. We will finally answer the question, why do I use a 5V motor when I have a 24V supply?

Figure 9

S-ar putea să vă placă și

- March 19, 1968 - R, Kromrey I 3,374,376: Electric GeneratorDocument8 paginiMarch 19, 1968 - R, Kromrey I 3,374,376: Electric GeneratorVlad AdrianÎncă nu există evaluări

- Laser spectroscopy IXDe la EverandLaser spectroscopy IXMichael FeldÎncă nu există evaluări

- Altra Scienza Rivista Free Energy N 03 Nikola TeslaDocument90 paginiAltra Scienza Rivista Free Energy N 03 Nikola TeslaxxxrainbowxxxÎncă nu există evaluări

- Materials Analysis by Ion Channeling: Submicron CrystallographyDe la EverandMaterials Analysis by Ion Channeling: Submicron CrystallographyÎncă nu există evaluări

- Andrey Melnichenko 19 AugDocument3 paginiAndrey Melnichenko 19 AugJaroslav KnopÎncă nu există evaluări

- Fundamentals of Electric Propulsion: Ion and Hall ThrustersDe la EverandFundamentals of Electric Propulsion: Ion and Hall ThrustersÎncă nu există evaluări

- DC Power SupplyDocument14 paginiDC Power Supplyrjjain07Încă nu există evaluări

- Handbook of Power Systems Engineering with Power Electronics ApplicationsDe la EverandHandbook of Power Systems Engineering with Power Electronics ApplicationsÎncă nu există evaluări

- PhysicsDocument16 paginiPhysicslordbravorious100% (1)

- Solid State Relay Backemf - Recoil Recovery Circuit - AlternativeWorld EnergyDocument2 paginiSolid State Relay Backemf - Recoil Recovery Circuit - AlternativeWorld Energyfsilassie8012Încă nu există evaluări

- Experiment 6Document10 paginiExperiment 6Nfa Noorfadzilah MdisaÎncă nu există evaluări

- Majorana Fermions in Condensed Matter Physics: The 1D Nanowire CaseDocument6 paginiMajorana Fermions in Condensed Matter Physics: The 1D Nanowire CaseOscar BohórquezÎncă nu există evaluări

- US20140111054A1-Generator Cu Bobine Îmbunătățite Pentru Ai Spori Proprietățile electrodinamice-US20140111054ADocument21 paginiUS20140111054A1-Generator Cu Bobine Îmbunătățite Pentru Ai Spori Proprietățile electrodinamice-US20140111054AbluesurviverÎncă nu există evaluări

- Parallel Magnetic Path TechnologyDocument16 paginiParallel Magnetic Path TechnologyMohammed FaizanÎncă nu există evaluări

- Tesla Coil Project: V1 Cprobe 15p CP 9.3p L1 19.5m R1 1megDocument9 paginiTesla Coil Project: V1 Cprobe 15p CP 9.3p L1 19.5m R1 1megNISHANT KumarÎncă nu există evaluări

- Switz Russian SEG ReportDocument32 paginiSwitz Russian SEG ReportBoris MitovÎncă nu există evaluări

- Electric Motor: Your Activity MaterialDocument6 paginiElectric Motor: Your Activity MaterialJoel Varghese ThomasÎncă nu există evaluări

- Stepper MotorDocument59 paginiStepper Motorya zool / يا زولÎncă nu există evaluări

- Power Generation by Foot Step Method - Rack and PinionDocument13 paginiPower Generation by Foot Step Method - Rack and Pinionprem53100% (2)

- Free Energy1Document20 paginiFree Energy11tektron1Încă nu există evaluări

- MELNICENKO Patent WO2007069936A1 enDocument12 paginiMELNICENKO Patent WO2007069936A1 enMihai DanielÎncă nu există evaluări

- Electrolysis Using Nano-Pulse Power SupplyDocument4 paginiElectrolysis Using Nano-Pulse Power SupplyKaryadi DjayaÎncă nu există evaluări

- Ic Crystal Oscillator CircuitsDocument4 paginiIc Crystal Oscillator Circuitsipa76100% (2)

- HPT (Ieee, 2005)Document7 paginiHPT (Ieee, 2005)Muhammad Hadi MustajabÎncă nu există evaluări

- "Servomotor Controlled by PWM": Experiment 6Document2 pagini"Servomotor Controlled by PWM": Experiment 6edsonÎncă nu există evaluări

- Tesla TurbinesDocument16 paginiTesla Turbinesrajeev murugadasÎncă nu există evaluări

- 220V DC To 220V AC: DIY Inverter Part 2: InstructablesDocument10 pagini220V DC To 220V AC: DIY Inverter Part 2: InstructablesTnT ElektricÎncă nu există evaluări

- Step Recovery DIODEDocument9 paginiStep Recovery DIODEwoyaoxiaxiaÎncă nu există evaluări

- Dave Lawton Replica of MeyeDocument6 paginiDave Lawton Replica of MeyeVlad AdrianÎncă nu există evaluări

- Hybrid Tech Eat On Fuel CellDocument13 paginiHybrid Tech Eat On Fuel CellhhojonÎncă nu există evaluări

- Slip Ring and Split RingDocument5 paginiSlip Ring and Split RingboltuÎncă nu există evaluări

- Ni Sbrio-9651: Getting Started With The Sbrio-9651 Som Development KitDocument2 paginiNi Sbrio-9651: Getting Started With The Sbrio-9651 Som Development Kitkhin600Încă nu există evaluări

- LV Steho enDocument7 paginiLV Steho enKeresztúri FerencÎncă nu există evaluări

- Diagnostic Sales Evening Component TestingDocument124 paginiDiagnostic Sales Evening Component TestingbibÎncă nu există evaluări

- Bedini SG: The Complete, Beginner's HandbookDocument8 paginiBedini SG: The Complete, Beginner's HandbookAhmad AriesandyÎncă nu există evaluări

- 0102 - Forever Flasher PDFDocument3 pagini0102 - Forever Flasher PDFMuhammadAsifÎncă nu există evaluări

- Electret Amplifier Application NoteDocument14 paginiElectret Amplifier Application NoterobkosaÎncă nu există evaluări

- Sources of Radiant EnergyDocument1 paginăSources of Radiant EnergyRjvm Net Ca Fe100% (1)

- Andrei Melnichenko InventionsDocument7 paginiAndrei Melnichenko InventionsPopescu George BogdanÎncă nu există evaluări

- Acoustic Horn On BoilersDocument1 paginăAcoustic Horn On BoilersjomoltÎncă nu există evaluări

- 2016 04 22 17 09 16Document8 pagini2016 04 22 17 09 16shubhamÎncă nu există evaluări

- Bio BatteryDocument29 paginiBio BatteryDileepChowdary100% (1)

- Resonant Inverter OrCADDocument13 paginiResonant Inverter OrCADCh ChristianÎncă nu există evaluări

- Les Banki Circuit Updated Version August 16Document12 paginiLes Banki Circuit Updated Version August 16petar2009100% (2)

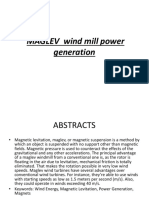

- MAGLEV Wind Mill Power GenerationDocument16 paginiMAGLEV Wind Mill Power GenerationNagabhushanaÎncă nu există evaluări

- MelnichenkoDocument5 paginiMelnichenkomitza22Încă nu există evaluări

- Samsung CL29K3W Chassis KS3ADocument92 paginiSamsung CL29K3W Chassis KS3AHernan Ortiz EnamoradoÎncă nu există evaluări

- How To Build Johann BesslerDocument13 paginiHow To Build Johann BesslerixCxlÎncă nu există evaluări

- Bsse Knowledge How - The - Stan - Meyer - Tech - Works 2 July 2018Document120 paginiBsse Knowledge How - The - Stan - Meyer - Tech - Works 2 July 2018Jumpman OutletÎncă nu există evaluări

- GB Patent 2130431Document6 paginiGB Patent 2130431chadj1060Încă nu există evaluări

- Numerical Study Ofa Tesla TurbineDocument8 paginiNumerical Study Ofa Tesla TurbineRavi ScoobyÎncă nu există evaluări

- EMS Lab Manual Ver 1.0 (Fall 2016)Document69 paginiEMS Lab Manual Ver 1.0 (Fall 2016)Fahad MahmoodÎncă nu există evaluări

- Stephanov Patent TransformerDocument6 paginiStephanov Patent TransformerPopescu George BogdanÎncă nu există evaluări

- 500 Watt DCDocument9 pagini500 Watt DCTariq AliÎncă nu există evaluări

- Is Einstein Theory of Relativity CorrecDocument3 paginiIs Einstein Theory of Relativity CorrecJose PecinaÎncă nu există evaluări

- Two eFlexPWM Module SynchronizationDocument10 paginiTwo eFlexPWM Module SynchronizationDinesh Dhiman100% (1)

- Brown Stove Works Gas - ManualDocument32 paginiBrown Stove Works Gas - ManualChuck StoneÎncă nu există evaluări

- Free Energy From PendulumDocument12 paginiFree Energy From PendulumpbonuttoÎncă nu există evaluări

- Performance Enhancements On Vertical Axis Wind Turbines Using Flow Augmentation Systems A Review 2017 Renewable and Sustainable Energy ReviewsDocument18 paginiPerformance Enhancements On Vertical Axis Wind Turbines Using Flow Augmentation Systems A Review 2017 Renewable and Sustainable Energy ReviewsCleyson GomesÎncă nu există evaluări

- MilsDocument1 paginăMilsngt881Încă nu există evaluări

- What Is Neutral in ElectricityDocument6 paginiWhat Is Neutral in Electricityngt881Încă nu există evaluări

- Poool ElecDocument1 paginăPoool Elecngt881Încă nu există evaluări

- Physics of ResonanceDocument5 paginiPhysics of Resonancengt881Încă nu există evaluări

- Nickelmetalhydride AppmanDocument36 paginiNickelmetalhydride Appmanngt881Încă nu există evaluări

- Radioshack Charger InstructionsDocument4 paginiRadioshack Charger Instructionsngt881Încă nu există evaluări

- BatteriesDocument12 paginiBatteriesngt881Încă nu există evaluări

- Lead-Acid Battery InfoDocument16 paginiLead-Acid Battery Infongt881Încă nu există evaluări

- Rev ProtectionDocument1 paginăRev Protectionngt881Încă nu există evaluări

- About Nicd BatteriesDocument9 paginiAbout Nicd Batteriesngt881Încă nu există evaluări

- Ship Store Code PracticeDocument2 paginiShip Store Code Practicengt881Încă nu există evaluări

- Paper59 TCXO ComparisonDocument5 paginiPaper59 TCXO Comparisonngt881Încă nu există evaluări

- Typical Characteristics PDFDocument4 paginiTypical Characteristics PDFngt881Încă nu există evaluări

- W3000Document1 paginăW3000ngt881Încă nu există evaluări

- C HDCDocument1 paginăC HDCngt881Încă nu există evaluări

- SoundwavesDocument6 paginiSoundwavesngt881Încă nu există evaluări

- Non Rechargeable FAQDocument3 paginiNon Rechargeable FAQngt881Încă nu există evaluări

- Design and Safety ConsiderationsDocument4 paginiDesign and Safety Considerationsngt881Încă nu există evaluări

- Series vs. Parallel Configurations: GuidelinesDocument1 paginăSeries vs. Parallel Configurations: Guidelinesngt881Încă nu există evaluări

- Crystal Resonator Basic TheoryDocument4 paginiCrystal Resonator Basic Theoryngt881Încă nu există evaluări

- Energizer Point-of-Sale Battery Testers - Loaded Volt MetersDocument1 paginăEnergizer Point-of-Sale Battery Testers - Loaded Volt Metersngt881Încă nu există evaluări

- Temper atDocument9 paginiTemper atngt881Încă nu există evaluări

- Energizer Chm39: Product DatasheetDocument1 paginăEnergizer Chm39: Product Datasheetngt881Încă nu există evaluări

- Transistor - Limiting Base Current To BJT - Electrical Engineering - Stack ExchangeDocument3 paginiTransistor - Limiting Base Current To BJT - Electrical Engineering - Stack Exchangengt881Încă nu există evaluări

- Driver RelayDocument2 paginiDriver Relaysandi sukma100% (1)

- The 555 Timer ICDocument4 paginiThe 555 Timer ICngt881Încă nu există evaluări

- PICkit 2 User Guide - 51553DDocument58 paginiPICkit 2 User Guide - 51553Dmontri_lpk1728Încă nu există evaluări

- Transistor SwitchesDocument5 paginiTransistor SwitchesplisdÎncă nu există evaluări

- Driver RelayDocument2 paginiDriver Relaysandi sukma100% (1)

- Microstep Driver Manual: Version 6/13/2006Document12 paginiMicrostep Driver Manual: Version 6/13/2006sandeshrai49Încă nu există evaluări

- 2 - Compass NotesDocument30 pagini2 - Compass NotesAeshwarya AgrawalÎncă nu există evaluări

- Electro Dynamometer TypeDocument5 paginiElectro Dynamometer Typeanuj1166Încă nu există evaluări

- Armature Reaction: The Effect of Magnetic Field Set Up by Armature Current OnDocument3 paginiArmature Reaction: The Effect of Magnetic Field Set Up by Armature Current OnYash VarunÎncă nu există evaluări

- Feeder Details & GTP AETLDocument14 paginiFeeder Details & GTP AETLViswa BhuvanÎncă nu există evaluări

- T2W9C Maxwell - S EquationDocument7 paginiT2W9C Maxwell - S EquationNoof YousefÎncă nu există evaluări

- Geophysics: Lecture-3 T.Ahmed Abdelraouf Al Neelain University Hydrogeology DepartmentDocument21 paginiGeophysics: Lecture-3 T.Ahmed Abdelraouf Al Neelain University Hydrogeology Departmentahmed abassÎncă nu există evaluări

- Frantz OperationDocument48 paginiFrantz OperationrizkipraÎncă nu există evaluări

- Magnetoplastic Effect in Nonmagnetic MaterialsDocument8 paginiMagnetoplastic Effect in Nonmagnetic MaterialsSeindahNyaÎncă nu există evaluări

- 04alt PDFDocument9 pagini04alt PDFGUESSOUMAÎncă nu există evaluări

- TRB Circuit Theory Test 1Document6 paginiTRB Circuit Theory Test 1Ragunathan NarayananÎncă nu există evaluări

- SSD Course PlanDocument5 paginiSSD Course PlanDhamu DharanÎncă nu există evaluări

- Hargreaves, 12 (3 Year)Document228 paginiHargreaves, 12 (3 Year)Maycon Maran0% (1)

- Nvis 6108 - UpdatedDocument24 paginiNvis 6108 - UpdatedAnanya PulgamÎncă nu există evaluări

- MAGNETISM AND MATTER NotesDocument9 paginiMAGNETISM AND MATTER NotesWill The WiseÎncă nu există evaluări

- Physics of Mri PDFDocument17 paginiPhysics of Mri PDFBushra HafizÎncă nu există evaluări

- Experiment 12 The Universal Motor ObjectiveDocument5 paginiExperiment 12 The Universal Motor ObjectiveFahad IbrarÎncă nu există evaluări

- C-01 Solid States-2Document25 paginiC-01 Solid States-2Abhishek KukretiÎncă nu există evaluări

- Magnet TherapyDocument5 paginiMagnet TherapyFilip Ilic100% (1)

- Phase: SemisterDocument5 paginiPhase: SemisterMuhammad TausiqueÎncă nu există evaluări

- Physics ProjectDocument19 paginiPhysics Projectnandish guptaÎncă nu există evaluări

- N48H Grade Neodymium Magnets DataDocument1 paginăN48H Grade Neodymium Magnets DataSteve HsuÎncă nu există evaluări

- CBSE Class-12 Physics Quick Revision Notes Chapter-05: Magnetism and MatterDocument2 paginiCBSE Class-12 Physics Quick Revision Notes Chapter-05: Magnetism and Matter8D Audio TuneÎncă nu există evaluări

- 4 Electricity and Magnetism Revision 4.1 Simple Phenomena of Magnetism - IGCSE Physics - Chris Gozzard PhysicsDocument2 pagini4 Electricity and Magnetism Revision 4.1 Simple Phenomena of Magnetism - IGCSE Physics - Chris Gozzard Physicsjayashree krishnaÎncă nu există evaluări

- Snist Et Question PaperDocument2 paginiSnist Et Question PaperAzharÎncă nu există evaluări

- Induced EmfDocument5 paginiInduced Emftajju_121Încă nu există evaluări

- Seminar Report On Brushless DC MotorDocument13 paginiSeminar Report On Brushless DC MotorDev Kumar50% (2)

- EE311 Electric Drives & Control For AutomationDocument2 paginiEE311 Electric Drives & Control For AutomationMathews P RejiÎncă nu există evaluări

- Grade 10 STE Electronics Robotics Q4 Module 3 Wk3 ADMDocument28 paginiGrade 10 STE Electronics Robotics Q4 Module 3 Wk3 ADMPorferio Abanggan100% (1)

- Apho2018 Experiment SolutionDocument13 paginiApho2018 Experiment SolutionmpecthÎncă nu există evaluări

- Magnetic Properties: Rianne Alipio Juvy Joyce Gonzales Trina LoriaDocument70 paginiMagnetic Properties: Rianne Alipio Juvy Joyce Gonzales Trina LoriaMhark Louie T. SardañaÎncă nu există evaluări

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeDe la EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeEvaluare: 4.5 din 5 stele4.5/5 (10)

- INCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesDe la EverandINCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesEvaluare: 5 din 5 stele5/5 (1)

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tDe la EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tEvaluare: 4.5 din 5 stele4.5/5 (27)

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionDe la EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionEvaluare: 4.5 din 5 stele4.5/5 (543)

- Digital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosDe la EverandDigital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosEvaluare: 5 din 5 stele5/5 (1)

- Hacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsDe la EverandHacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsEvaluare: 3.5 din 5 stele3.5/5 (2)

- Practical Electrical Wiring: Residential, Farm, Commercial, and IndustrialDe la EverandPractical Electrical Wiring: Residential, Farm, Commercial, and IndustrialEvaluare: 3.5 din 5 stele3.5/5 (3)

- Retro Gaming with Raspberry Pi: Nearly 200 Pages of Video Game ProjectsDe la EverandRetro Gaming with Raspberry Pi: Nearly 200 Pages of Video Game ProjectsÎncă nu există evaluări

- Programming the Raspberry Pi, Third Edition: Getting Started with PythonDe la EverandProgramming the Raspberry Pi, Third Edition: Getting Started with PythonEvaluare: 5 din 5 stele5/5 (2)

- 2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersDe la Everand2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersEvaluare: 5 din 5 stele5/5 (1)

- Analog Design and Simulation Using OrCAD Capture and PSpiceDe la EverandAnalog Design and Simulation Using OrCAD Capture and PSpiceÎncă nu există evaluări

- Current Interruption Transients CalculationDe la EverandCurrent Interruption Transients CalculationEvaluare: 4 din 5 stele4/5 (1)

- Build Your Own Electronics WorkshopDe la EverandBuild Your Own Electronics WorkshopEvaluare: 3.5 din 5 stele3.5/5 (3)

- A Mind at Play: How Claude Shannon Invented the Information AgeDe la EverandA Mind at Play: How Claude Shannon Invented the Information AgeEvaluare: 4 din 5 stele4/5 (53)

- Beginner's Guide to Reading Schematics, Third EditionDe la EverandBeginner's Guide to Reading Schematics, Third EditionÎncă nu există evaluări

- Heat Transfer Engineering: Fundamentals and TechniquesDe la EverandHeat Transfer Engineering: Fundamentals and TechniquesEvaluare: 4 din 5 stele4/5 (1)

- Teach Yourself Electricity and Electronics, 6th EditionDe la EverandTeach Yourself Electricity and Electronics, 6th EditionEvaluare: 3.5 din 5 stele3.5/5 (15)

- Power Electronics Diploma Interview Q&A: Career GuideDe la EverandPower Electronics Diploma Interview Q&A: Career GuideÎncă nu există evaluări