Documente Academic

Documente Profesional

Documente Cultură

Effects of Metakaolin on Strength Properties of Concrete

Încărcat de

Lokesh MechDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Effects of Metakaolin on Strength Properties of Concrete

Încărcat de

Lokesh MechDrepturi de autor:

Formate disponibile

STUDY PROPERTIES OF CONCRETE WITH METAKAOLIN AS PARTIAL REPLACEMENT OF CEMENT

Hemalatha.C and G. Murali Second year student, Department of Civil Engineering, Vel Tech High Tech Dr.Rangarajan Dr.Sakunthala Engineering College, Avadi, Chennai-62 #2 Assistant Professor, Vel Tech High Tech Dr.Rangarajan Dr.Sakunthala Engineering Colleges, Chennai 600062, 9944224485, murali_22984@yahoo.com

#1

ABSTRACT Metakaolin is a cementitious material used as an admixture to produce high strength concrete and is used for maintaining the consistency of concrete. In the case where insufficient or poor curing concrete structures like the seashore, underground structures which undergo severe loss of compressive strength and permeability interconnected durability, use of metakaolin proves to be very useful to modify the properties of concrete. This paper deals with the properties of concrete with varying percentage replacement of metakaolin. The mix M1, M2, M3 and M4 were obtained by replacing 0, 5, 7.5 and 10 percent Mass of Cement by Metakolin. Finally, required specimens were tested to investigate the behaviour such as compressive strength, flexural strength and split tensile strength. The test results indicated that the admixture metakaolin when used at optimum quantity tend to increase the strength of the concrete mix when compared with conventional concrete 1. INTRODUCTION Concrete is one of the most widely used man-made construction material in the world. Metakaolin is a cementitious material used as an admixture to produce high strength concrete. Optimal quantity of Metakaolin for M20 and M35 grade concrete has been worked out, which can replace the cement in order to get better strength and durability. And also identification of the dry shrinkage and permeability characteristics of blended cement has been done. Jiping Bai [1] studied that when metakaolin is used as a partial replacement for Portland cement, tends to improve both the mechanical properties and the durability of concrete. Friars and Cabrera [2] investigated the relationship between the pore size distribution and degree of hydration of metakaolin based cement pastes. They reported that metakaolin showed the best improvement on the mechanical properties of concrete. Palomo [3] investigated the chemical stability of metakaolin based cement composites. 2. EXPERIMENTAL PROGRAM 2.1 Materials Cement: In this experimental investigation ordinary Portland cement of 53 grade was used. Fine aggregate: Locally available river sand free from impurities was used. The size of it is less than 4.75mm. The specific gravity and fineness modulus of the fine aggregate were found to be 2.67 and 2.56 respectively. The percentage of passing is within the limits as per IS383-1970 [4]. Coarse aggregate: The coarse aggregate used is 12.5mm in size, crushed, angular in shape and free from dust. The specific gravity and fineness modulus were found to be

2.82 and 7.03 respectively. The percentage of passing is within the limits as per IS3831970 [4]. Water: Potable water free from injurious salt was used for mixing and curing. Admixture : The properties of metakolin as shown in table 1and 2. Table 1 physical properties Specific Gravity: 2.60 D10 <2.0um Physical Form: Powder D50 <4.5um Color: Off-White D90 <25um Brightness: 80-82 Hunter L Bulk Density (lbs/ft3): 20-25 BET: 15M2/gram Bulk Density (g/cm3): 0.4 Table 2 Chemical properties Chemical Composition, Wt.: SiO2 51-53% Al2O3 42-44% Fe2 O3 <2.20% TiO2 <3.0% SO4 <0.5% CaO MgO Na2O K2O L.O.I. <0.20% <0.10% <0.05% <0.40% <0.50%

MIX PROPORTIONS 2.1 Grade of concrete The mix proportion of this investigation was 1:2.4:4.9 as per [5 6] and M20 grade of concrete was adopted 2.2 Preparation of specimens The strength characteristics of concrete with varying percentage of metakaolin were studied by casting cubes, cylinders and prisms. The constituents of the concrete viz, cement, fine aggregate and coarse aggregate were mixed to appropriate proportion by adding water. Metakaolin is added to the different mixes in varying proportions as a partial replacement for cement. Moulds for cubes of size (100X100X100mm), cylinders with dimensions of (100mm diameter X 200mm height) and prisms of size (500X100X100mm) were prepared and concrete was poured in to the mould layer by layer and vibrated thoroughly. The specimens were removed from the moulds after 24 hours and then the specimens were cured with water for 28days. 3. Testing Concrete specimens were taken out of curing chamber after 28days. Cubes were tested for compressive strength using a compression testing machine, cylinders were tested for their split tensile strength using a compression testing machine and prisms were tested for their flexural strength using flexural testing machine as shown in figure 4. 4. Results and discussions It was found from the experimental results that the compressive strength, split tensile strength and flexural strength has increased for the specimens with varying percentage of metakaolin as replacement for cement when compared with the conventional concrete. The test results obtained are presented in table.3, 4 and 5.

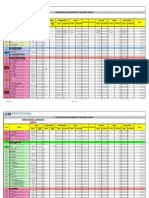

Mix M1 M2 M3 M4 Mix M1 M2 M3 M4 Mix M1 M2 M3 M4

Table 3. Compressive strength % of 7 days 14 days Metakaolin (Mpa) (Mpa) 0 18.1 20.6 5 19.2 21 7.5 19.8 21.5 10 18.5 20.9

28 days (Mpa) 26 28.4 29.7 28.3

Table 4. Split Tensile strength % of Metakaolin 28 days (Mpa) 0 2.76 5 2.86 7.5 2.98 10 2.81 Table 4. Flexural Strength % of Metakaolin 28 days (Mpa) 0 3.56 5 3.75 7.5 3.89 10 3.6

It is obvious from the test results that 7.5% replacement of cement with metakaolin increased the compressive strength of concrete by 14.2%, split tensile strength by 7.9% and flexural strength by 9.3%. The other percentage of metakaolin such as 5 and 10 percentages also showed considerable increase in strength characteristics of the concrete when compared with the conventional concrete. The comparison of compressive strength, split tensile strength and flexural strength for different mixes with varying metakaolin proportion are shown in figure 1, 2 and 3 respectively. 2 )

30 28 26 24

/ N ( h g n t v i s e r p m o c

0%

5%

7.50%

10%

%of meta k a olin

Figure 1. Variation of compressive strength

3 2.9 2.8 2.7 2.6 0% 5% 7.50% 10%

h g r s n e t i l p S

m / N (

2 )

%of m eta k a olin

Figure 2. Variation of split tensile strength 2 )

4 3.8 3.6 3.4 3.2 0%

m / N ( h g n t s a r u x e l F

5%

7.50%

10%

%of meta k a olin

Figure 3. Variation of flexural strength

Figure 4. Testing of specimens CONCLUSION The admixture metakaolin when used at optimum quantity tend to increase the strength of the concrete mix when compared with conventional concrete.

7.5% of metakaolin increased the compressive strength, split tensile strength and flexural strength of concrete by 14.2%, 7.9% and 9.3% respectively. 5% of metakaolin increased the compressive strength, split tensile strength and flexural strength of concrete by 9.2%, 3.6% and 5.3% respectively. 10% of metakaolin also showed considerable increase in compressive strength, split tensile strength and flexural strength of concrete by 8.8%, 1.8% and 1.1% respectively.

REFERENCES [1] Jiping Bai, Albinas Gailius, Consistancy of Fly-ash and Metakaolin Concrete, Journal of Civil Engineering and Management, pp. 131-135, (2009). [2] Frias, Moises and Cabrera, JoshepPore Size Distribution and Degree of Hydration of Metakaolin-Cement Pastes. Cement and Concrete Research, 30 (4), pp. 561-569, (2000). [3] Palomo, A., Blanco-Varela, M. T., Granizo, M. L., Vazquez, T. and Grutzeck, M. W. Chemical Stability of Cementitious Materials based on Metakaolin. Cement and Concrete Research, 20 (7), pp. 997-1004. (1999): [4]. IS 383-1970 Specification for fine and coarse aggregate from natural sources for concrete (Second revision) [5] IS 456-2000, Plain and Rein forced concrete code of practice, Bureau Indian standards, New Delhi, India. [6]. IS 10262-2009 Recommended guidelines for concrete mix design, BIS, New Delhi, India, 2009.

S-ar putea să vă placă și

- Specifications: 1.write The Detail Technical Specification For Earthwork Excavation in Hard SoilDocument5 paginiSpecifications: 1.write The Detail Technical Specification For Earthwork Excavation in Hard SoilAnusha ChikmathÎncă nu există evaluări

- Companywise Plant ListDocument9 paginiCompanywise Plant ListSabyasachi BangalÎncă nu există evaluări

- Procurement Tracking ChartDocument5 paginiProcurement Tracking ChartjayÎncă nu există evaluări

- DSR ProjectDocument17 paginiDSR ProjectPankaj Zudpe87% (15)

- Project:: Use of Metakaoline and Alccofine As A Admixture in ConcreteDocument52 paginiProject:: Use of Metakaoline and Alccofine As A Admixture in ConcreteAnonymous wlbOBqQWDÎncă nu există evaluări

- Role of Admixture in ConcreteDocument69 paginiRole of Admixture in Concretesateeshsingh100% (4)

- S.No. Questions AnswerDocument248 paginiS.No. Questions AnswerSyed Munawar Ali100% (2)

- Oilwell Cementing PracticesDocument16 paginiOilwell Cementing Practicessdb158Încă nu există evaluări

- Pages From Sor PWD WBDocument12 paginiPages From Sor PWD WBUTTAL RAYÎncă nu există evaluări

- Building Materials: Cement Manufacturing ProcessDocument120 paginiBuilding Materials: Cement Manufacturing ProcessAdhyyan JoshiÎncă nu există evaluări

- Effect of Metakaolin Content On The Properties of High Strength ConcreteDocument9 paginiEffect of Metakaolin Content On The Properties of High Strength ConcreteElango PaulchamyÎncă nu există evaluări

- Study On The Performance of Concrete Usi PDFDocument4 paginiStudy On The Performance of Concrete Usi PDFBenharzallah KrobbaÎncă nu există evaluări

- Mechanical Properties For Cement Replacement by Metakaolin Based ConcreteDocument5 paginiMechanical Properties For Cement Replacement by Metakaolin Based ConcreteerpublicationÎncă nu există evaluări

- Effect of Lathe Waste Review 1Document22 paginiEffect of Lathe Waste Review 1dreamboy87Încă nu există evaluări

- Literature Review: Nova John (2013) Examined The Strength Properties of Metakaolin Admixed Concrete. HeDocument9 paginiLiterature Review: Nova John (2013) Examined The Strength Properties of Metakaolin Admixed Concrete. Henutan acharyaÎncă nu există evaluări

- A Review On Use of Metakaolin in Concrete: AbstractDocument6 paginiA Review On Use of Metakaolin in Concrete: AbstractjumahjessiÎncă nu există evaluări

- Metakaolin A ReviewDocument5 paginiMetakaolin A ReviewSairam VenkatÎncă nu există evaluări

- Development of High Strength High Performance Concrete Using Indian MetakaolinDocument10 paginiDevelopment of High Strength High Performance Concrete Using Indian Metakaolindigvijay singhÎncă nu există evaluări

- Manuscript Info: Metakaolin - The Best Material For Replacement of Cement in ConcreteDocument7 paginiManuscript Info: Metakaolin - The Best Material For Replacement of Cement in ConcreteAkashÎncă nu există evaluări

- Plagerissm MetakaolinDocument28 paginiPlagerissm Metakaolinsiva 17Încă nu există evaluări

- Master's Research ProposalDocument7 paginiMaster's Research ProposalPeter OkitoiÎncă nu există evaluări

- Research PaperDocument5 paginiResearch PapergvijaymÎncă nu există evaluări

- Mechanical Properties of Concrete Using Flyash With Addition of Polypropylene FibresDocument39 paginiMechanical Properties of Concrete Using Flyash With Addition of Polypropylene FibresMohammed AzharuddinÎncă nu există evaluări

- E Ect of Metakaolin On Creep and Shrinkage of Concrete: J.J. Brooks, M.A. Megat JohariDocument8 paginiE Ect of Metakaolin On Creep and Shrinkage of Concrete: J.J. Brooks, M.A. Megat Johariit does not exist for the [mpossibleÎncă nu există evaluări

- 14 - 5 - 5 NewDocument13 pagini14 - 5 - 5 NewSalima MimaÎncă nu există evaluări

- Paper After Corrections 1 FinalllDocument14 paginiPaper After Corrections 1 Finalllsiva 17Încă nu există evaluări

- Effect of Recycled Aggregate and Glass Fiber on ConcreteDocument22 paginiEffect of Recycled Aggregate and Glass Fiber on ConcreteSuresh KomurajuÎncă nu există evaluări

- Effect of Wollastonite on Strength and Durability of ConcreteDocument4 paginiEffect of Wollastonite on Strength and Durability of ConcreteChidananda GÎncă nu există evaluări

- Bio Based Mortar For Concrete RepairDocument8 paginiBio Based Mortar For Concrete RepairAnonymous rx6OafUpgXÎncă nu există evaluări

- Effect of Metakaolin Content On The Properties of High Strength ConcreteDocument9 paginiEffect of Metakaolin Content On The Properties of High Strength ConcreteZhwan Anwar Noori MuhamadÎncă nu există evaluări

- Behaviour of Concrete Partially Replacement of Cement by Steatite and Polypropylene FibreDocument4 paginiBehaviour of Concrete Partially Replacement of Cement by Steatite and Polypropylene FibreijaertÎncă nu există evaluări

- Ijciet: International Journal of Civil Engineering and Technology (Ijciet)Document8 paginiIjciet: International Journal of Civil Engineering and Technology (Ijciet)IAEME PublicationÎncă nu există evaluări

- Full Paper - ID 9112Document6 paginiFull Paper - ID 9112effÎncă nu există evaluări

- Experimental Investigation On Flexural Strength of RC Beam Using Sisal Fiber and Comparing With Conventional ConcreteDocument7 paginiExperimental Investigation On Flexural Strength of RC Beam Using Sisal Fiber and Comparing With Conventional ConcretereenaÎncă nu există evaluări

- Mechanical Properties of Carbon Fiber Reinforced ConcreteDocument44 paginiMechanical Properties of Carbon Fiber Reinforced Concretecien18111051 KFUEITÎncă nu există evaluări

- Mechanical Properties of Cement Mortar With Al O NanoparticlesDocument4 paginiMechanical Properties of Cement Mortar With Al O NanoparticlesSridhar DineshÎncă nu există evaluări

- Sathyan 2018 IOP Conf. Ser. Mater. Sci. Eng. 310 012036Document11 paginiSathyan 2018 IOP Conf. Ser. Mater. Sci. Eng. 310 012036henryÎncă nu există evaluări

- RRLDocument13 paginiRRLAngelineAlinsodÎncă nu există evaluări

- Effect of Cement Content and Size of Coarse Aggregate On The Strength of Brick Aggregate ConcreteDocument5 paginiEffect of Cement Content and Size of Coarse Aggregate On The Strength of Brick Aggregate ConcreteVikash TiwariÎncă nu există evaluări

- In Uence of Coarse Aggregate On The Permeation, Durability and The Microstructure Characteristics of Ordinary Portland Cement ConcreteDocument9 paginiIn Uence of Coarse Aggregate On The Permeation, Durability and The Microstructure Characteristics of Ordinary Portland Cement ConcreteA M Yasin ArmanÎncă nu există evaluări

- Utilization of E-Waste in Concrete by Partial Repl PDFDocument9 paginiUtilization of E-Waste in Concrete by Partial Repl PDFHemantJohariÎncă nu există evaluări

- Research ArticleDocument9 paginiResearch ArticleAmine RezaeiÎncă nu există evaluări

- PCX - Performance of Cement Mortar Containing Micro and Ultrafine Metakaolin BindersDocument12 paginiPCX - Performance of Cement Mortar Containing Micro and Ultrafine Metakaolin Binderscibif40663Încă nu există evaluări

- CONCLUSIONSDocument1 paginăCONCLUSIONSUmer FarooqÎncă nu există evaluări

- 2.6. - Effects of Titanium Dioxide Nanopowder On Rheological Properties of Self Compacting ConcreteDocument4 pagini2.6. - Effects of Titanium Dioxide Nanopowder On Rheological Properties of Self Compacting ConcreteCARLOS ALEJANDRO CABALLA OLIVARESÎncă nu există evaluări

- Strength and Duriabilty Properties of Concrete With Partial Replacement of Cement With Metakaolin and Marble Dust IJERTV4IS070881Document4 paginiStrength and Duriabilty Properties of Concrete With Partial Replacement of Cement With Metakaolin and Marble Dust IJERTV4IS070881اسد راجÎncă nu există evaluări

- Fly Ash Concrete PDFDocument5 paginiFly Ash Concrete PDFVishal PanchalÎncă nu există evaluări

- Las Relaciones Entre Tensión y Deformación para Hormigón de Alto Rendimiento Con MetacaolínDocument5 paginiLas Relaciones Entre Tensión y Deformación para Hormigón de Alto Rendimiento Con Metacaolínerika yajaira leonÎncă nu există evaluări

- Polymer CementDocument15 paginiPolymer CementfaheemqcÎncă nu există evaluări

- Usage of Sugarcane Bagasse Ash in Concrete: AbstractDocument7 paginiUsage of Sugarcane Bagasse Ash in Concrete: AbstractRadix CitizenÎncă nu există evaluări

- IJCRT1892221Document6 paginiIJCRT1892221Niva R ChandraÎncă nu există evaluări

- Study On The Effect of Coir Fibre in The Bituminous Concrete MixDocument5 paginiStudy On The Effect of Coir Fibre in The Bituminous Concrete MixIJSTEÎncă nu există evaluări

- Department of Civil Engineering GM Institute of Technology, DAVANAGERE-577006Document23 paginiDepartment of Civil Engineering GM Institute of Technology, DAVANAGERE-577006Basavaraju SÎncă nu există evaluări

- Study On Properties of Polymer Modified Mortars Used As Repair MaterialsDocument6 paginiStudy On Properties of Polymer Modified Mortars Used As Repair MaterialsIJSTE100% (1)

- Submited by Raj Kumar Reddy (U14CE510) Vamsi G (U14CE511) Raghu Varma N (U14CE130) Bharath Reddy (U14CE034) Guided by Anitha - KDocument38 paginiSubmited by Raj Kumar Reddy (U14CE510) Vamsi G (U14CE511) Raghu Varma N (U14CE130) Bharath Reddy (U14CE034) Guided by Anitha - KsrikanthÎncă nu există evaluări

- ASIF 04 MS Thesis Presentation (Update)Document27 paginiASIF 04 MS Thesis Presentation (Update)tanvir_austÎncă nu există evaluări

- Effect of Aggregate Type On Compressive Strength of ConcreteDocument10 paginiEffect of Aggregate Type On Compressive Strength of ConcreteamelialoritaÎncă nu există evaluări

- Combined Effect of Ground Granulated Blast Furnace Slag and Metakaolin On Mechanical Properties of Self Compacting ConcreteDocument7 paginiCombined Effect of Ground Granulated Blast Furnace Slag and Metakaolin On Mechanical Properties of Self Compacting ConcreteinventionjournalsÎncă nu există evaluări

- Comparative Study On Durability Properties of Engineered Cementitious Composites With Polypropylene Fiber and Glass FiberDocument19 paginiComparative Study On Durability Properties of Engineered Cementitious Composites With Polypropylene Fiber and Glass Fiberci_balaÎncă nu există evaluări

- Sample TemplateDocument3 paginiSample TemplatepraveenÎncă nu există evaluări

- 4N5 Ijeset0202520 PDFDocument8 pagini4N5 Ijeset0202520 PDFBia MughalÎncă nu există evaluări

- Ehab, Debaiky, RedaDocument8 paginiEhab, Debaiky, RedaAhmed S DebaikyÎncă nu există evaluări

- K.H.Kabbur Institute of EngineeringDocument32 paginiK.H.Kabbur Institute of EngineeringTanushÎncă nu există evaluări

- Mechanism and Strengthening Effects of Carbon Fiber On Mechanical Properties of Cement MortarDocument6 paginiMechanism and Strengthening Effects of Carbon Fiber On Mechanical Properties of Cement MortarIJAERS JOURNALÎncă nu există evaluări

- Construction and Building Materials: Kazim TurkDocument9 paginiConstruction and Building Materials: Kazim TurkTarek ChikerÎncă nu există evaluări

- Effect of Size and Dosage of Mineral AdmixturesDocument8 paginiEffect of Size and Dosage of Mineral Admixturestianshanlang23Încă nu există evaluări

- A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessDe la EverandA Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessÎncă nu există evaluări

- Manganese Metal Composites Properties ExplorationDe la EverandManganese Metal Composites Properties ExplorationÎncă nu există evaluări

- Differences Between Gypsum and LimeDocument4 paginiDifferences Between Gypsum and LimeafsfsfÎncă nu există evaluări

- 1627-Article Text-4517-4-10-20220703Document10 pagini1627-Article Text-4517-4-10-20220703bakhtiar Al-BarzinjiÎncă nu există evaluări

- Libro Concreto Pca PDFDocument326 paginiLibro Concreto Pca PDFJavierAndrésMezaGilÎncă nu există evaluări

- Particular Region or Country": Is An Adjective Meaning, "Originating in and Characteristic of ADocument2 paginiParticular Region or Country": Is An Adjective Meaning, "Originating in and Characteristic of AMary Rose MinguilloÎncă nu există evaluări

- Stabilization of Expansive Belle Fourche Shale Clay With Different ChemicalDocument14 paginiStabilization of Expansive Belle Fourche Shale Clay With Different ChemicalGabrielly SouzaÎncă nu există evaluări

- High-Level Integrity Assessment of Abandoned Wells: M.D.C. Van Der Kuip, T. Benedictus, N. Wildgust, T. AikenDocument7 paginiHigh-Level Integrity Assessment of Abandoned Wells: M.D.C. Van Der Kuip, T. Benedictus, N. Wildgust, T. AikenLuis Eduardo SeguraÎncă nu există evaluări

- CeramicDocument14 paginiCeramicIrham SyahmiÎncă nu există evaluări

- History of Cement and its PropertiesDocument21 paginiHistory of Cement and its PropertiesShrikant N. Pawar-BadgujarÎncă nu există evaluări

- Autoclaved Aerated Concrete BricksDocument24 paginiAutoclaved Aerated Concrete BricksRazil RomÎncă nu există evaluări

- Chemical Shrinkage of Hydraulic Cement Paste: Standard Test Method ForDocument4 paginiChemical Shrinkage of Hydraulic Cement Paste: Standard Test Method ForAlejandroÎncă nu există evaluări

- Retaining Wall Cost EstimationDocument5 paginiRetaining Wall Cost EstimationtemesgenÎncă nu există evaluări

- TDS - Glenium Ace 340Document3 paginiTDS - Glenium Ace 340Alexi ALfred H. TagoÎncă nu există evaluări

- Cement Consistency and Setting Times Test ReportDocument5 paginiCement Consistency and Setting Times Test Reportvelmurug_balaÎncă nu există evaluări

- KUWS&DBoard SR 2018-19Document63 paginiKUWS&DBoard SR 2018-19Radhakrishna KPÎncă nu există evaluări

- Masteremaco s488 Ci TdsDocument3 paginiMasteremaco s488 Ci TdsShesh ManiÎncă nu există evaluări

- Haener Block Building Tips for Fast and Easy Masonry Wall ConstructionDocument13 paginiHaener Block Building Tips for Fast and Easy Masonry Wall ConstructionWaqas HanifÎncă nu există evaluări

- Flooring Procedure and Inspection PlanDocument4 paginiFlooring Procedure and Inspection PlanAkhilesh Kumar0% (1)

- Inv. Kamrieng 1 2023Document13 paginiInv. Kamrieng 1 2023Pitho ChanÎncă nu există evaluări

- 4: Job Job Costing Costing Questions QuestionsDocument49 pagini4: Job Job Costing Costing Questions QuestionsAtroeas KavovicÎncă nu există evaluări

- Cera Expan 250Document2 paginiCera Expan 250raviteja036Încă nu există evaluări

- BS-Wall and Floor TilingDocument82 paginiBS-Wall and Floor TilingTito GarciaÎncă nu există evaluări