Documente Academic

Documente Profesional

Documente Cultură

Use of Waste Plastic in Construction of Bituminous Road

Încărcat de

Tanmay SethiTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Use of Waste Plastic in Construction of Bituminous Road

Încărcat de

Tanmay SethiDrepturi de autor:

Formate disponibile

Mrs.Vidula Swami et al.

/ International Journal of Engineering Science and Technology (IJEST)

Use of waste plastic in construction of bituminous road

Mrs.Vidula Swami1, Abhijeet Jirge2, Karan patil2, Suhas patil2, Sushil patil2,Karan salokhe2

1.Associate Prof.,Civil Engg. Dept.,KITs College of Engg. Kolhapur,Maharashtra 2.Final Year Students, Civil Engg. Dept.,KITs College of Engg. Kolhapur,Maharashtra

ABSTRACT:

Bottles, containers and packing strips etc. is increasing day by day. As a result amount of waste plastic also increases. This leads to various environmental problems. Many of the wastes produced today will remain in the environment for many years leading to various environmental concerns. Therefore it is necessary to utilize the wastes effectively with technical development in each field. Many by-products are being produced using the plastic wastes. Our present work is helping to take care of these aspects. Plastic waste, consisting of carry bags, cups and other utilized plastic can be used as a coating over aggregate and this coated stone can be used for road construction. The mix polymer coated aggregate and tyre modified bitumen have shown higher strength. Use of this mix for road construction helps to use plastics waste. Once the plastic waste is separated from municipal solid waste, the organic matter can be converted into manure and used. Our paper will discuss in detail the process and its successful applications. INTRODUCTION: Now-a-days disposal of different wastes produced from different Industries is a great problem. These materials pose environmental pollution in the nearby locality because many of them are non-biodegradable. Traditionally soil, stone aggregates, sand, bitumen, cement etc. are used for road construction. Natural materials being exhaustible in nature, its quantity is declining gradually. Also, cost of extracting good quality of natural material is increasing. Concerned about this, the scientists are looking for alternative materials for highway construction, and industrial wastes product is one such category. If these materials can be suitably utilized in highway construction, the pollution and disposal problems may be partly reduced. In the absence of other outlets, these solid wastes have occupied several acres of land around plants throughout the country. Keeping in mind the need for bulk use of these solid wastes in India, it was thought expedient to test these materials and to develop specifications to enhance the use of these industrial wastes in road making, in which higher economic returns may be possible. The possible use of these materials should be developed for construction of lowvolume roads in different parts of our country. The necessary specifications should be formulated and attempts are to be made to maximize the use of solid wastes in different layers of the road pavement. Post construction pavement performance studies are to be done for these waste materials for construction of low volume roads with two-fold benefits: (a) it will help clear valuable land of huge dumps of wastes; (b) it will also help to preserve the natural reserves of aggregates, thus protecting the environment. Plastics are user friendly but not eco-friendly as they are non-biodegradable generally, it is disposed by way of land filling or incineration of materials which are hazardous. Plastic is versatile material and a friend to common man becomes a problem to the environment after its use. The better binding property of plastics in its molten state has helped in finding out a method of safe disposal of waste plastics. Road surface with neat bitumen can cause bleeding in hot climate, may develop cracks in cold climate, possess fewer loads bearing capacity and can cause serious damages because of higher axle load in present conditions due to rapid infrastructure development. Useful life of bituminous overlays has reportedly declined 78 from average life of 5-6 years in the past to about 3-4 years at present as compared to average pavement life (5-6 years) in abroad. India has to raise transportation system to a higher level both in terms of length and quality. This study presents the use of waste in hot bituminous mixes to enhance pavement performance, protect environment and provide low cost roads. Polymer and plastic modified bitumen, often abbreviated as modified bitumen is obtained with the incorporation of selected thermoplastics and shredded plastic from discarded waste, natural plastic or any other suitable elastomers in bitumen.

ISSN : 0975-5462

Vol. 4 No.05 May 2012

2351

Mrs.Vidula Swami et al. / International Journal of Engineering Science and Technology (IJEST)

Literature review: Prof.C.E.G. Justo States that addition of 8.0 % by weight of processed plastic for the preparation of modified bitumen results in a saving of 0.4 % bitumen by weight of the mix or about 9.6 kg bitumen per cubic meter (m 3) of BC mix. Modified Bitumen improves the stability or strength, life and other desirable properties of bituminous concrete mix. Dr. R. Vasudevan states that the polymer bitumen blend is a better binder compared to plain bitumen. Blend has increased Softening point and decreased Penetration value with a suitable ductility. When it used for road construction it can withstand higher temperature and load. The coating of plastics reduces the porosity, absorption of moisture and improves soundness. The polymer coated aggregate bitumen mix forms better material for flexible pavement construction as the mix shows higher Marshall Stability value and suitable Marshall Coefficient. Hence the use of waste plastics for flexible pavement is one of the best methods for easy disposal of waste plastics. Use of plastic bags in road help in many ways like Easy disposal of waste, better road and prevention of pollution and so on. According to V.S. Punith, (2001), Some encouraging results were reported in this study that there is possibility to improve the performance of bituminous mixes of road pavements. Waste plastics (polythene carry bags, etc.) on heating soften at around 130C. Thermo gravimetric analysis has shown that there is no gas evolution in the temperature range of 130-180C. Softened plastics have a binding property. Hence, it can be used as a binder for road construction.Sundaram & Rojasay (2008) studied the Effective blending technique for the use of plastic waste into bitumen for road laying and Polymer-bitumen mixtures of different compositions were prepared and used for carrying out various tests.Verma S.S. (2008). concluded that Plastics will increase the melting point of the bitumen. This technology not only strengthened the road construction but also increased the road life. Dr. R.Vasudevan and S. Rajasekaran, (2007) stated that the polymer bitumen blend is a better binder compared to plain bitumen.Blend has increased Softening point and decreased Penetration value with a suitable ductility. Mohd. Imtiyaz (2002) concluded that the mix prepared with modifiers shows:-Higher resistance to permanent deformation at higher temperature. Sabina et al (2001) studied the comparative performance of properties of bituminous mixes containing plastic/polymer (PP) (8% and 15% by wt of bitumen) with conventional bituminous concrete mix (prepared with 60/70 penetration grade bitumen). Improvement in properties like Marshall Stability, retained stability, indirect tensile strength and rutting was observed in Plastic modified bituminous concrete mixes. The laboratory studies conducted by CRRI in utilization of waste plastic bags in bituminous concrete mixes have proved that these enhance the properties of mix in addition to solving disposal problems. The results indicated that there was an improvement in strength properties when compared to a conventional mix. Therefore, the life of pavement surfacing using the waste plastic is expected to increase substantially in comparison to the use of conventional bituminous mix. METHODOLOGY: Waste plastic bags were collected from roads, garbage trucks, dumpsites and compost plants, ragpickers, waste-buyers at Rs 5-6 per kg.Household plastic was also collected for the project work, like empty milk bags, used plastic bags etc.The collected Plastic waste was sorted as per the required thickness.Generally, polyethylene of 60 micron or below is used for the further process. Less micron plastic is easily mixable in the bitumen at higher temperature (160c-170c).It is clean by de-dusting or washing if required. Collected Plastic was cut into fine pieces as far as possible.The plastic pieces were sieved through 4.75mm sieve and retaining at 2.36mm sieve was collected.Firstly, Bitumen was heated up to the temperature about 160c-170c which is its melting temp. Pieces were added slowly to the hot bitumen of temperature around 160-170c.The mixture was stirred manually for about 20-30 minutes. In that time period temperature was kept constant about 160-170c. Polymer-bitumen mixtures of different compositions were prepared and used for carrying out tests i.e.Penetration test,Ductility test,Flash point test & Fire point test,Stripping test,Ring and ball test and Marshall Stability value test. RESULTS: The increase in percentage of polymer decreased the penetration value. This shows that the addition of polymer increases the hardness of the bitumen.The penetration values of the blends are decreasing depending upon the percentage of polymers and the type of polymer added.The ductility decreased by the addition of plastic waste to bitumen. The decrease in the ductility value may be due to interlocking of polymer molecules with bitumen. Flash and fire point increased with the increase in the percentage of polymer .The polymer bitumen blend road surfaces are less affected by fire hazards. This shows that the

ISSN : 0975-5462

Vol. 4 No.05 May 2012

2352

Mrs.Vidula Swami et al. / International Journal of Engineering Science and Technology (IJEST)

blend has better resistance towards water. This may be due to better binding property of the polymerbitumen blend.The softening point increased by the addition of plastic waste to the bitumen. Higher the percentage of plastic waste added, higher is the softening point. The influence over the softening point may be due to the chemical nature of polymers added. The increase in the softening point shows that there will be less bleeding during summer. Bleeding accounts, on one side, increased friction for the moving vehicles and on the other side, if it rains the bleedings accounts for the slippery condition. Both these adverse conditions are much reduced by polymer-bitumen blend. SUMMARY OF MARSHALL STABILITY TEST : Mix design for bitumen: The Marshall Quotient is also within the range of tolerance, thus showing that the plastic waste (polyethylene) blended bitumen mix is better and more suitable for flexible pavement construction.

Stability (KN) Bitumen Content Plain bitumen 4.5 Percent 5.0 Percent 5.5 Percent 6.0 Percent SUMMARY OF FLOW: Flow (mm) Bitumen Content Plain bitumen 4.5 Percent 5.0 Percent 5.5 Percent 6.0 Percent 4.08 4.23 4.40 5.10 10 % bitumen replaced by plastic waste 4.57 4.82 5.05 5.15 17.03 17.18 17.68 17.61 10 % bitumen replaced by plastic waste 20.28 21.15 22.43 21.81

ISSN : 0975-5462

Vol. 4 No.05 May 2012

2353

Mrs.Vidula Swami et al. / International Journal of Engineering Science and Technology (IJEST)

FLOW IN mm

FINDINGS: Test results Sr.no 1. 2. 3. 4. 5. 6. Tests conducted Plain bitumen Penetration test Ductility Flash point Fire point Stripping value 68mm 83mm 235c 251c Modified bitumen (10% plastic replaced) 58mm 52mm 260c 295c

0.4% 0.0% Temp.inc Time in sec Temp.inc Time in sec Softening point 53 334 64 550 Comparison between plain bitumen and modified bitumen (10% plastic waste)

Material cost comparision for 1km road:

Description

Unit

Rate/unit

For control mix quantity Amount(Rs) 325400.88 1112300

For modified sample quantity 495.65 28.85 2.885 Amount(Rs) 295903.05 1009750 17310 1322963.05

material Aggregate Bitumen Plastic waste Ton Ton Ton 597 35000 6000 1437700.88 545.06 31.78

Total material cost Total material cost reduction=7.99%

ISSN : 0975-5462

Vol. 4 No.05 May 2012

2354

Mrs.Vidula Swami et al. / International Journal of Engineering Science and Technology (IJEST)

SIGNIFICANCES: The polymer bitumen blend is a better binder compared to plain bitumen. The blend has increased Softening Point and decreased Penetration Value with a suitable ductility. When used for road construction it can withstand higher temperature. Hence it is suitable for tropical regions. It has decreased Penetration Value. Hence its load carrying capacity is increased. The blend with aggregate has no Stripping Value. So it can resist the effect of water.The Marshall Stability Value is high. The bitumen required can be reduced depending upon the % of polymer added. It is a good saving too. No toxic gas is produced. Disposal of waste plastic will no longer be a problem. The binding properties of polymer also improve the strength of mastic flooring. The use of waste plastics on the road has helps to provide better place for burying the plastic waste without causing disposal problem. At the same time, a better road is also constructed. It also helps to avoid the general disposal technique of waste plastics namely land-filling and the incineration, which have certain burden on ecology. CONCLUSION: The addition of waste plastic modifies the properties of bitumen. The modified bitumen shows good result when compared to standard results. The optimum content of waste plastic to be used is between the range of 5% to 10%. The problems like bleeding are reduce in hot temperature region. Plastic has property of absorbing sound, which also help in reducing the sound pollution of heavy traffic. The waste plastics thus can be put to use and it ultimately improves the quality and performance of road. Total material cost of the project is reduced by 7.99%

REFERENCES:

Indicative Operational Guidelines on Construction Polymer Bitumen road Central Pollution Control Board, Ministry of Environment and Forests. Probes/101/2005-2006 [2] Unevenness / Roughness ; Source IRC:SP:16-2004 [3] Skid Resistance/ Skid Number; Standardized in UK under BS:812-1967 [4] Sand Texture Depth; BS 598 part 105 (1990) [5] Rebound Deflection / Benkelman Beam; IRC: 81-1997 [6] Justo C.E.G. and A. veeraragavan, (2002) [7] V.S. Punith, (2001) Study of the Effect of Plastic Modifier on Bituminous Mix Properties [8] Mohd. Imtiyaz (2002)Adhesion Characteristics Study on Waste Plastics Modified Bitumen [9] Dr. R.Vasudevan and S. Rajasekaran, (2007). Utilization of Waste Plastics in Construction of Flexible Pavements (Reuse of waste plastics a path breaking initiative) [10] Verma S.S. (I.C.J.), (2008). Roads from plastic waste [11] Sundaram & Roja, (2008) The use of recycled material in highway construction [1]

ISSN : 0975-5462

Vol. 4 No.05 May 2012

2355

S-ar putea să vă placă și

- Eco-efficient Rendering Mortars: Use of Recycled MaterialsDe la EverandEco-efficient Rendering Mortars: Use of Recycled MaterialsÎncă nu există evaluări

- Use of Waste Plastic in Construction ofDocument10 paginiUse of Waste Plastic in Construction ofAnjali chilakalaÎncă nu există evaluări

- The Sustainable Solution: Plastic Granulate Production in Action: Money from trashDe la EverandThe Sustainable Solution: Plastic Granulate Production in Action: Money from trashÎncă nu există evaluări

- Penetration DecreaseDocument5 paginiPenetration DecreaseBeatrice KunguÎncă nu există evaluări

- Recycled Polyester: Manufacturing, Properties, Test Methods, and IdentificationDe la EverandRecycled Polyester: Manufacturing, Properties, Test Methods, and IdentificationÎncă nu există evaluări

- Seminar Report Plastic Road PDFDocument13 paginiSeminar Report Plastic Road PDFAbhinav YadavÎncă nu există evaluări

- PROJECT b11Document17 paginiPROJECT b11mohammadnawab098Încă nu există evaluări

- Use of Plastic Waste in Bituminous Road ConstructionDocument5 paginiUse of Plastic Waste in Bituminous Road ConstructionIJSTE100% (1)

- A Major ProjectDocument16 paginiA Major ProjectRajuÎncă nu există evaluări

- Plastic RoadsDocument30 paginiPlastic RoadsNigam Meher100% (14)

- Paper On Plastic To RoadDocument6 paginiPaper On Plastic To RoadSumskrutha Kosgi ShroffÎncă nu există evaluări

- 321-Article Text-520-1-10-20190425Document12 pagini321-Article Text-520-1-10-20190425Ahmed khushalÎncă nu există evaluări

- Category.:-: Company Name.:-. Problem Code.:-. Team Leader Name:-. College Code.Document7 paginiCategory.:-: Company Name.:-. Problem Code.:-. Team Leader Name:-. College Code.Karthepan visionsÎncă nu există evaluări

- Assessment of Suitability of Plastic Waste in Bituminous Pavement ConstructionDocument6 paginiAssessment of Suitability of Plastic Waste in Bituminous Pavement ConstructionSMALLETÎncă nu există evaluări

- Potential Reuse of Plastic Waste in Road ConstructionDocument8 paginiPotential Reuse of Plastic Waste in Road Constructionsourabh_gupta_54Încă nu există evaluări

- Thesis ProposalDocument7 paginiThesis ProposalMEHIDE HASANÎncă nu există evaluări

- An Overview of Use of Waste Plastic in Road Construction: April 2018Document4 paginiAn Overview of Use of Waste Plastic in Road Construction: April 2018Manohar SimhadriÎncă nu există evaluări

- Civil Engineering: Khammam Institute of Technology and SciencesDocument31 paginiCivil Engineering: Khammam Institute of Technology and Sciencesramesh ankathiÎncă nu există evaluări

- Use of Plastic Waste in Pavement: Riya M. Patekar Prof. S. P. Mahajan Prof. Ashish R. BijweDocument3 paginiUse of Plastic Waste in Pavement: Riya M. Patekar Prof. S. P. Mahajan Prof. Ashish R. BijweriyaÎncă nu există evaluări

- Civil39 PDFDocument5 paginiCivil39 PDFch umairÎncă nu există evaluări

- Use of Plastic Waste in Flexible Pavements: Volume 2, Issue 4, April 2013Document13 paginiUse of Plastic Waste in Flexible Pavements: Volume 2, Issue 4, April 2013International Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- J0704047981 PDFDocument3 paginiJ0704047981 PDFShuddhashil GhoshÎncă nu există evaluări

- 321 ArticleText 520 1 10 201904251Document13 pagini321 ArticleText 520 1 10 201904251Ebenezer EffisahÎncă nu există evaluări

- Chapter - 1: 1.1 GeneralDocument57 paginiChapter - 1: 1.1 GeneralMAHEN DRANÎncă nu există evaluări

- Report Black BookDocument54 paginiReport Black BookSanket ChaudhariÎncă nu există evaluări

- Plastic Roads: Presented By-Akash Chakole (First Year MBBS, GMC Nagpur)Document27 paginiPlastic Roads: Presented By-Akash Chakole (First Year MBBS, GMC Nagpur)Chandu CKÎncă nu există evaluări

- Plastic Roads - Akashchakole PDFDocument27 paginiPlastic Roads - Akashchakole PDFAnn CruzÎncă nu există evaluări

- Minor Project Synopsis Civil FinalDocument9 paginiMinor Project Synopsis Civil FinalAceÎncă nu există evaluări

- Plasticroads 140415203620 Phpapp02Document27 paginiPlasticroads 140415203620 Phpapp02Piyush KumarÎncă nu există evaluări

- Experimental Study of Bituminous Concrete Mix by Using Waste PlasticDocument6 paginiExperimental Study of Bituminous Concrete Mix by Using Waste PlasticIJSTEÎncă nu există evaluări

- Chapter One: 1.1. Problem StatementDocument11 paginiChapter One: 1.1. Problem StatementetayhailuÎncă nu există evaluări

- Studies On The Improvement of Characteristics of Bitumen With Use of Waste PlasticDocument6 paginiStudies On The Improvement of Characteristics of Bitumen With Use of Waste PlasticAnurag TiwariÎncă nu există evaluări

- Waste Plastic GoooodDocument12 paginiWaste Plastic GoooodAngel AngelÎncă nu există evaluări

- 804 811V10N8CTDocument9 pagini804 811V10N8CTDIVIN KURUPÎncă nu există evaluări

- Use of Plastic Waste in Bituminous Pavement: International Journal of Chemtech Research January 2017Document9 paginiUse of Plastic Waste in Bituminous Pavement: International Journal of Chemtech Research January 2017sulemanÎncă nu există evaluări

- SL No. Chapters Pg. No.: Use of Waste Plastic For Road ConstructionDocument11 paginiSL No. Chapters Pg. No.: Use of Waste Plastic For Road Constructionvinay kumar h sÎncă nu există evaluări

- Utilization of Plastic Waste in Bituminous RoadsDocument9 paginiUtilization of Plastic Waste in Bituminous RoadsDeepankar DaburÎncă nu există evaluări

- CTRG2015 Submission 452Document10 paginiCTRG2015 Submission 452Sri RamyaÎncă nu există evaluări

- PROJECT PPT (New)Document41 paginiPROJECT PPT (New)Mitali Parkhiya83% (6)

- Wearing Surface Technology Individual Project: Recycling Plastic Into Hotmix AsphaltDocument10 paginiWearing Surface Technology Individual Project: Recycling Plastic Into Hotmix AsphaltOpaqueÎncă nu există evaluări

- Plastic PavementDocument20 paginiPlastic PavementRj RajatÎncă nu există evaluări

- Plastic Roads A Seminar Report SubmittedDocument18 paginiPlastic Roads A Seminar Report SubmittedritikÎncă nu există evaluări

- Partial Repacement of Plastic in BitumenDocument5 paginiPartial Repacement of Plastic in BitumenSri HariÎncă nu există evaluări

- Plastic Waste Recycling For Development of Bito-PlDocument14 paginiPlastic Waste Recycling For Development of Bito-PlmominspsÎncă nu există evaluări

- Guidelines For The Use of Plastic Waste in Rural Roads ConstructionDocument5 paginiGuidelines For The Use of Plastic Waste in Rural Roads ConstructionGanesh BhisteÎncă nu există evaluări

- Plastic Roads (Ang)Document17 paginiPlastic Roads (Ang)Feryani DoniaÎncă nu există evaluări

- Utilization of Waste Plastic Bags in Bituminous Mix For Improved Performance of RoadsDocument12 paginiUtilization of Waste Plastic Bags in Bituminous Mix For Improved Performance of RoadsFaheem AfzalÎncă nu există evaluări

- Disposal of Large Consumed Plastics Cause An Environmental Pollution As They Are Considered Non-Biodegradable MaterialsDocument18 paginiDisposal of Large Consumed Plastics Cause An Environmental Pollution As They Are Considered Non-Biodegradable MaterialsKanimozhi SÎncă nu există evaluări

- Literature ReviewDocument4 paginiLiterature Reviewmt22tre002Încă nu există evaluări

- Pavement Assignment PDFDocument4 paginiPavement Assignment PDFSyed AimanÎncă nu există evaluări

- Use of Waste Rubber Tyres in Construction of Bituminous Road - An OverviewDocument3 paginiUse of Waste Rubber Tyres in Construction of Bituminous Road - An OverviewInternational Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- Use of Waste Plastic in Flexible PavementDocument4 paginiUse of Waste Plastic in Flexible PavementEttaMahenderÎncă nu există evaluări

- 8.justo. and Veeraragavan. (2002)Document3 pagini8.justo. and Veeraragavan. (2002)Anurag TiwariÎncă nu există evaluări

- A Review Report On The Utilization of Plastic Wastes in Road ConstructionDocument9 paginiA Review Report On The Utilization of Plastic Wastes in Road ConstructionPoornima PÎncă nu există evaluări

- Review Paper On Use of Waste Plastic Waste RubberDocument5 paginiReview Paper On Use of Waste Plastic Waste RubberRahul KumarÎncă nu există evaluări

- New Proposal - 21-6-2018Document14 paginiNew Proposal - 21-6-2018Shivkumar HosamaniÎncă nu există evaluări

- Plastic Use in Roads ConstructionDocument6 paginiPlastic Use in Roads Constructionபுருஷோத்தமன் சரவணன்Încă nu există evaluări

- Effect of Natural Rubber On The Properties of Bitumen and Bituminious MixesDocument13 paginiEffect of Natural Rubber On The Properties of Bitumen and Bituminious MixesIAEME Publication100% (1)

- Use of Modified Bitumen in Highway Construction: Minakshi Singhal Yudhvir YadavDocument7 paginiUse of Modified Bitumen in Highway Construction: Minakshi Singhal Yudhvir Yadavnswain76Încă nu există evaluări

- Standard and Specifications Based On NSCP 2010 DeadloadsDocument7 paginiStandard and Specifications Based On NSCP 2010 DeadloadsIan Dave AdvinculaÎncă nu există evaluări

- Annexure - B Safety SOP ChecklistDocument4 paginiAnnexure - B Safety SOP ChecklistANUJ SHAHÎncă nu există evaluări

- Sheet LaminationDocument13 paginiSheet LaminationRishika JaiswalÎncă nu există evaluări

- Toilet: Layout Toilet With Tanggulan Layout Accesible Toilet With TanggulanDocument1 paginăToilet: Layout Toilet With Tanggulan Layout Accesible Toilet With TanggulanhendriÎncă nu există evaluări

- G1 - Construction Process of Retaining WallDocument1 paginăG1 - Construction Process of Retaining WallNur Azlin IdayuÎncă nu există evaluări

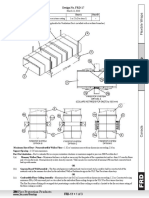

- FRD17Document3 paginiFRD17Raul FloresÎncă nu există evaluări

- Mechanical Assembly - Chapter 33Document67 paginiMechanical Assembly - Chapter 33xharpreetxÎncă nu există evaluări

- Europacable Cable Technology UpdateDocument13 paginiEuropacable Cable Technology UpdateA. HassanÎncă nu există evaluări

- DEUTZ FL912 Engine Overhaul Part ListDocument12 paginiDEUTZ FL912 Engine Overhaul Part ListTong Hai WangÎncă nu există evaluări

- FormulaeDocument10 paginiFormulaeCisum ErupÎncă nu există evaluări

- QSE Experiment No 2Document4 paginiQSE Experiment No 2Neeraj Kumar ThakurÎncă nu există evaluări

- Maintenance Management of Equipment in Coal MinesDocument39 paginiMaintenance Management of Equipment in Coal MinesDr-Narayan Acharya100% (1)

- Wet Abrasive Blasting System and MethodDocument13 paginiWet Abrasive Blasting System and MethodhainguyenbkvhvÎncă nu există evaluări

- 16Mncr5: Quality 16Mncr5 Case Hardening SteelDocument2 pagini16Mncr5: Quality 16Mncr5 Case Hardening SteelShubhangi ShindeÎncă nu există evaluări

- Ingenieria-Cema 300-Screw Conveyor StandardDocument33 paginiIngenieria-Cema 300-Screw Conveyor StandardVICTORÎncă nu există evaluări

- High Performance Concrete & High Strength Concrete: Presentation byDocument27 paginiHigh Performance Concrete & High Strength Concrete: Presentation byrexdindigulÎncă nu există evaluări

- Chemdur - 42 RHDocument3 paginiChemdur - 42 RHICPL-RWPÎncă nu există evaluări

- Spec Sheet - American StandardDocument2 paginiSpec Sheet - American StandardJohn Enrick ManuelÎncă nu există evaluări

- HB 3700Document2 paginiHB 3700Suehsner Jorge AlbertoÎncă nu există evaluări

- Structural Design of Composite Super-Columns For TDocument10 paginiStructural Design of Composite Super-Columns For TSameh LotfyÎncă nu există evaluări

- Lintels Problems - STEEL STRUCTURESDocument8 paginiLintels Problems - STEEL STRUCTURESDarya Memon100% (1)

- Chapter 4 Deflection and BucklingDocument64 paginiChapter 4 Deflection and BucklingHamlity SaintataÎncă nu există evaluări

- Zerowatt sx403Document16 paginiZerowatt sx403MaxÎncă nu există evaluări

- Plastic Design GuidelinesDocument241 paginiPlastic Design Guidelines2023ht30006Încă nu există evaluări

- Speech by Premier Job Mokgoro 2019Document37 paginiSpeech by Premier Job Mokgoro 2019Paras Kumar SinghÎncă nu există evaluări

- Slab With ReportsDocument36 paginiSlab With ReportsER Manish MakhijaÎncă nu există evaluări

- Phoenix Z10167Document2 paginiPhoenix Z10167Mohamed Sherif S MÎncă nu există evaluări

- Introduction To StairsDocument13 paginiIntroduction To StairsShilpa BhargavaÎncă nu există evaluări

- Embankment Dam PDFDocument106 paginiEmbankment Dam PDFAubel50% (2)

- Mulberry CatalogDocument168 paginiMulberry Catalogblue100% (1)