Documente Academic

Documente Profesional

Documente Cultură

APCS Deatails

Încărcat de

DandamanDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

APCS Deatails

Încărcat de

DandamanDrepturi de autor:

Formate disponibile

APCS 1A epoxy coating system for atmospheric service (inorganic zinc primer) severe atmospheric exposure, particularly for

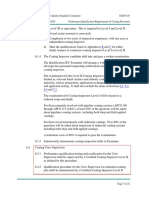

or offshore construction. APCS 1B epoxy coating system for atmospheric service (epoxy primer) severe atmospheric exposure including exposure to many acid and alkalis. APCS 1C epoxy coating system for atmospheric service (zinc rich epoxy primer) maintenance painting for severe atmospheric exposure. APCS 1D epoxy/polyurethanes coating system for atmospheric service (inorganic zinc primer) severe atmospheric exposure, when added gloss retention, color retention and abrasion resistance are required (usually outdoors) APCS 1E epoxy/polyurethanes coating system for atmospheric service (epoxy primer) severe atmospheric exposure including exposure to many acid and alkalis, when added gloss retention, color retention and abrasion resistance are required (usually outdoors) APCS 1F epoxy/polyurethanes coating system for atmospheric service (zinc rich epoxy primer) maintenance painting for severe atmospheric exposure when added gloss retention and abrasion resistance are required. (usually outdoors) APCS 2A epoxy coating system for general immersion service (self priming) immersion service particularly for raw or treated waters for GOSP traps handling hot crude oil/brine solutions. Not for potable water. APCS 2B epoxy coating system for potable water immersion service (self priming) immersion service for potable water. APCS 2C epoxy coating system for immersion service, at temperature up to 120C immersion service for demineralized water and boiler skim tanks. APCS 2D epoxy coating system for interior of steel aviation fuel storage tanks and piping. immersion service for aviation fuel, turbine fuel and kerosene. APCS 3 - coal tar epoxy coating system for immersion services (self priming) immersion service in tankage containing hydrocarbons, seawater, fresh water ang most alkalis; intermittent contact with acids and solvents. APCS 4 - aluminum pigmented coating system. Structural steelwork, tanks, vessels, pipes and equipment subject to moderate industrial atmospheres including H 2S fumes and high humidity. Not generally recommended for shop applications or when handling is required after coating. APCS 4 - alkyd enamel coating system Structural steels, machinery and equipment in marine and industrial environments including intermittent exposure to H 2S fumes and high humidity. Not recommended for shop application or when handling is required after coating. (See APCS - 26/26T). APCS 7 - Rust Conversion Primer/Alkyd Topcoat System for Use on Slightly Rusted Steel Maintenance coating system for APCS - 4 and APCS - 6. Applied directly to bare, slightly rusted steel surfaces. Not intended as an intermediate or tie coat over sound coatings. APCS 9 - Chlorinated Rubber Coating System Metallic and concrete surfaces exposed to salts, high humidity, and spillage of acids and alkalis.

APCS 10 - Metallic and c Bituminous Paint for Moderate Temperature, Buried or Immersion Service (Self-Priming) Buried and immersed steel. Resistant to water and acidic fumes.

APCS 11A - High Temperature Coating System for Atmospheric Service between 150C-400C (with Inorganic Zinc Primer) Steel in atmospheric service at elevated temperature. APCS 11B - Very High Temperature Coating System for Atmospheric Service Between 400C and 540C Steel in atmospheric service at elevated temperatures. APCS 12 - Nonskid Epoxy Coating System for Floors and Decks

Nonskid surface on interior and exterior floors and walkways. APCS - 1A APCS - 1B APCS - 1C APCS - 1D APCS - 1E APCS - 1F APCS - 2A APCS - 2B APCS - 2C APCS - 2D APCS - 3 APCS - 4 APCS - 6 APCS - 7 APCS - 9 APCS - 10 APCS - 11A APCS - 11B APCS - 12 APCS - 17A APCS - 17B APCS - 19A APCS - 19B APCS - 20A APCS - 20B APCS - 22 APCS - 23 APCS - 26 APCS - 26T Epoxy Coating System for Atmospheric Service (with Inorganic Zinc Primer) Epoxy Coating System for Atmospheric Service (with Epoxy Primer) Epoxy Coating System for Atmospheric Service (with Zinc-Rich Epoxy Primer) Epoxy/Polyurethane Coating System for Atmospheric Service (with Inorganic Zinc Primer) Epoxy/Polyurethane Coating System for Atmospheric Service (with Epoxy Primer) Epoxy/Polyurethane Coating System for Atmospheric Service (with Zinc-Rich Epoxy Primer) Epoxy Coating System for General Immersion Service (Self-Priming) Epoxy Coating System for Potable Water Immersion Service (Self-Priming) Epoxy Coating System for Immersion Service, at temperatures up to 120C Epoxy Coating System for Interior of Steel Aviation Fuel Storage Tanks and Piping Coal Tar Epoxy Coating System for Immersion Service (Self-Priming) Aluminum-Pigmented Alkyd Coating System Alkyd Enamel Coating System Rust Conversion Primer/Alkyd Topcoat System for Use on Slightly Rusted Steel Chlorinated Rubber Coating System Bituminous Paint for Moderate Temperature, Buried or Immersion Service (Self-Priming) High Temperature Coating System for Atmospheric Service Between 150C - 400C Very High Temperature Coating System for Atmospheric Service Between 400C - 540C Nonskid Epoxy Coating System for Floors and Decks Inorganic Zinc Primer, Solvent Based Inorganic Zinc Primer, Water Based Splash Zone Compound, Hand Applied Splash Zone Compound, Spray Applied Fiberglass Reinforced Coatings, Hand Lay-Up Chopped Fiberglass Reinforced Epoxy Coatings, Spray Applied Epoxy Coating for Application onto Damp Steel Surfaces High Temperature Mastic Paint for Buried or Immersion Service (Self-Priming) Epoxy Mastic Coating (Self-Priming) Epoxy Mastic/Polyurethane Coating System

S-ar putea să vă placă și

- APCS DeatailsDocument3 paginiAPCS DeatailsnasirÎncă nu există evaluări

- Apcs 113a Rev 3 Pid ApprovalDocument19 paginiApcs 113a Rev 3 Pid ApprovalMedel Cay De Castro50% (2)

- Aramco Painting SpecificationDocument6 paginiAramco Painting Specificationvicky100% (1)

- Saudi Aramco Painting Project APCSDocument104 paginiSaudi Aramco Painting Project APCSsmart_onyx1792% (13)

- CBT 3Document9 paginiCBT 3SUNIL RAJPUT100% (1)

- Apcs 113a-87550Document2 paginiApcs 113a-87550jojo_32350% (6)

- Apcs & Ses - PCS - NewDocument44 paginiApcs & Ses - PCS - Newnasir100% (1)

- Approved Sigma Paint System Apcs 1 BDocument1 paginăApproved Sigma Paint System Apcs 1 BChiller jnglÎncă nu există evaluări

- SATIP-H-100-01 Rev 8Document4 paginiSATIP-H-100-01 Rev 8SajjadPervaiz100% (2)

- Coating Crew SupervisorDocument4 paginiCoating Crew Supervisorimtiaz100% (1)

- Gas QCP Pac 003 Apcs 113 CDocument18 paginiGas QCP Pac 003 Apcs 113 Cfawad ali0% (1)

- 09 Samss 060Document4 pagini09 Samss 060asimazami69Încă nu există evaluări

- Coating Inspector Interview QuestionsDocument14 paginiCoating Inspector Interview Questionshabib80% (15)

- Aramco Apcs 1bDocument55 paginiAramco Apcs 1bSadek Sad100% (2)

- Coating Inspector Interview QuestionsDocument11 paginiCoating Inspector Interview Questionshabib100% (3)

- Civil CBTDocument3 paginiCivil CBTAris BulaongÎncă nu există evaluări

- 12 Samss 007 PDFDocument30 pagini12 Samss 007 PDFMohammadAseef100% (1)

- CBT 06.02.2020Document3 paginiCBT 06.02.2020Nidhin Joseph100% (1)

- Aramco Painting Q ADocument31 paginiAramco Painting Q Aravi ajith88% (16)

- Saep 316Document20 paginiSaep 316brecht1980100% (18)

- Saep 1200Document9 paginiSaep 1200Anonymous 4IpmN7On100% (1)

- Satr H 1003Document2 paginiSatr H 1003Thouseef MaÎncă nu există evaluări

- Saes H 102Document10 paginiSaes H 102HaleemUrRashidBangash100% (1)

- SAIC-H-2032 Rev 7Document4 paginiSAIC-H-2032 Rev 7Satheesh Rama SamyÎncă nu există evaluări

- Aramco Abrasive and Samss#Document2 paginiAramco Abrasive and Samss#Sivaratnam Navatharan100% (1)

- S.No. Questions AnswerDocument248 paginiS.No. Questions AnswerSyed Munawar Ali100% (2)

- Saes H 101VDocument83 paginiSaes H 101Vacolombel100% (2)

- Aramco Test 400 QDocument20 paginiAramco Test 400 QAtif Khan100% (5)

- Materials System SpecificationDocument6 paginiMaterials System SpecificationAjeetKumarÎncă nu există evaluări

- Saes H 101Document77 paginiSaes H 101Henry Ocbina Luares100% (6)

- Saic H 1003Document2 paginiSaic H 1003Hussain Nasser Al- NowiesserÎncă nu există evaluări

- Materials System SpecificationDocument7 paginiMaterials System SpecificationAjeetKumarÎncă nu există evaluări

- SATIP SAIC SATR IndexDocument87 paginiSATIP SAIC SATR Indexlhanx2100% (8)

- Process Industry Practices Insulation: PIP INTG1000 Insulation Inspection ChecklistDocument7 paginiProcess Industry Practices Insulation: PIP INTG1000 Insulation Inspection ChecklistCristian Jhair PerezÎncă nu există evaluări

- Saes H 004Document8 paginiSaes H 004kaleeswaran s100% (1)

- Abu Ali project-APCS 1D Using Hempel Paint REV.01 PDFDocument10 paginiAbu Ali project-APCS 1D Using Hempel Paint REV.01 PDFravi ajith100% (1)

- SAES-H-201 General Specification For Over-The-Ditch External & Internal ... 2017 VersionDocument13 paginiSAES-H-201 General Specification For Over-The-Ditch External & Internal ... 2017 VersiondanishÎncă nu există evaluări

- Saes Q 001 Saes-Q-006Document5 paginiSaes Q 001 Saes-Q-006Abdul Hannan100% (1)

- CBT 2Document2 paginiCBT 2SUNIL RAJPUT100% (1)

- COATING Aramco QuestionsDocument24 paginiCOATING Aramco QuestionsDavid Salguero100% (13)

- 1 SATIP-L-350-01 On-Plot Piping - Rev 01Document4 pagini1 SATIP-L-350-01 On-Plot Piping - Rev 01zooplado75% (4)

- CBT QuestionsDocument20 paginiCBT Questionsmohammed amjad ali100% (1)

- Typical Inspection Plan (TIP) Index: Project Inspection Division / IAGDocument6 paginiTypical Inspection Plan (TIP) Index: Project Inspection Division / IAGAbu BindongÎncă nu există evaluări

- Saes H 204Document34 paginiSaes H 204heartbreakkid132Încă nu există evaluări

- 09-SAMSS-071 - (2016) Qualification Requirements For Inorganic Zinc Primer (APCS-17A) and (APCS-17B)Document9 pagini09-SAMSS-071 - (2016) Qualification Requirements For Inorganic Zinc Primer (APCS-17A) and (APCS-17B)middlepermian100% (1)

- SATR-H-2006 Rev 8Document3 paginiSATR-H-2006 Rev 8ravi ajith100% (1)

- Hempadur XP 87550: DescriptionDocument2 paginiHempadur XP 87550: DescriptionEngTamer50% (4)

- Schedule Q Based QuestionsDocument11 paginiSchedule Q Based Questionschandu666creator100% (7)

- Saes-H-002 - ArmacoDocument29 paginiSaes-H-002 - ArmacoVenkat Gokila DT100% (1)

- TDS Nitomortar TC2000 Saudi ArabiaDocument3 paginiTDS Nitomortar TC2000 Saudi ArabiaHarry BawingÎncă nu există evaluări

- Marine Systemguide 0814Document8 paginiMarine Systemguide 0814Syaiful Arif WicaksonoÎncă nu există evaluări

- PPG CatalogDocument332 paginiPPG Catalogdancas01100% (1)

- Water Treatment ProcessesDocument7 paginiWater Treatment ProcessesgondeathÎncă nu există evaluări

- Coating Systems For Various StructuresDocument38 paginiCoating Systems For Various StructuresgppsclÎncă nu există evaluări

- FHWA Bridge CoatingsDocument2 paginiFHWA Bridge CoatingsAnonymous V92ZmILyQTÎncă nu există evaluări

- Chemco Maintenance Repair Coating ShipDocument69 paginiChemco Maintenance Repair Coating ShipJorge Cipriano0% (1)

- Curing Mechanism of BindersDocument17 paginiCuring Mechanism of BindersSajan MittalÎncă nu există evaluări

- Kanatpaints PipelineDocument16 paginiKanatpaints PipelineMekineÎncă nu există evaluări

- Duplex Stainless Steels in Chemical IndustryDocument8 paginiDuplex Stainless Steels in Chemical IndustryCarlos Ortega JonesÎncă nu există evaluări

- Chemistry Part Three Dictionary: Grow Your Vocabulary, #30De la EverandChemistry Part Three Dictionary: Grow Your Vocabulary, #30Încă nu există evaluări

- Bgas PaintingDocument85 paginiBgas PaintingDandaman92% (12)

- INSULATIONDocument4 paginiINSULATIONDandaman0% (1)

- Surface CoatingDocument18 paginiSurface Coatingaaftab ahmed100% (1)

- Paints and PigmentsDocument19 paginiPaints and PigmentsbaanaadiÎncă nu există evaluări

- Alucobest Aluminum Composite Panel For Sign, Display and Digital PrintingDocument12 paginiAlucobest Aluminum Composite Panel For Sign, Display and Digital PrintingAli ZhangÎncă nu există evaluări

- Epoxy ResinsDocument16 paginiEpoxy ResinsreddyÎncă nu există evaluări

- Hempel Coating Reference Handbook GBDocument145 paginiHempel Coating Reference Handbook GBJerome100% (2)

- Premium 7130 To 7530 Diagn-Tm400019 PDFDocument5.433 paginiPremium 7130 To 7530 Diagn-Tm400019 PDFandis_a100% (7)

- CPAR Notes-Week 1-10Document14 paginiCPAR Notes-Week 1-10Chrystell JaneÎncă nu există evaluări

- JotunBitum Ballastic BlackDocument3 paginiJotunBitum Ballastic BlackMekhmanÎncă nu există evaluări

- Nuancier Hardcore 2Document6 paginiNuancier Hardcore 2cyrilÎncă nu există evaluări

- Marketing Strategies of Berger Paints Bangladesh LimitedDocument35 paginiMarketing Strategies of Berger Paints Bangladesh Limitedনিশীথিনী কুহুরানী0% (1)

- TL 260 Engl 20040501 PDFDocument4 paginiTL 260 Engl 20040501 PDFpaulojospin100% (2)

- Material 2Document10 paginiMaterial 2Tori SmallÎncă nu există evaluări

- PC 0458Document2 paginiPC 0458Sanjay YadavÎncă nu există evaluări

- TDS 00000476 1 Go en PDFDocument2 paginiTDS 00000476 1 Go en PDFColin HessionÎncă nu există evaluări

- South Horr Police StationDocument18 paginiSouth Horr Police Stationcliff machukaÎncă nu există evaluări

- Firetex M90: Product Technical DataDocument2 paginiFiretex M90: Product Technical DatalambtranÎncă nu există evaluări

- The Paint DetectiveDocument52 paginiThe Paint DetectivePatrick BatyÎncă nu există evaluări

- Homemade GessoDocument13 paginiHomemade GessoBettyÎncă nu există evaluări

- Bentone 38Document2 paginiBentone 38Kris SzongÎncă nu există evaluări

- Basic Miniature PaintingDocument6 paginiBasic Miniature PaintingThe Rude1Încă nu există evaluări

- Mooring - Do It Safely (2013) PDFDocument88 paginiMooring - Do It Safely (2013) PDFtyuÎncă nu există evaluări

- CLGB260 Service Manual 202305000-EnDocument442 paginiCLGB260 Service Manual 202305000-Enfranck.brokouaÎncă nu există evaluări

- Dynasylan® 40: Ethyl PolysilicateDocument3 paginiDynasylan® 40: Ethyl Polysilicatenarendra43100% (1)

- TKDN - PT Nipsea Paint and ChemicalsDocument6 paginiTKDN - PT Nipsea Paint and ChemicalsPrinanda IndaniÎncă nu există evaluări

- Estudio Antifouling PDFDocument12 paginiEstudio Antifouling PDFJuanIgnacioIzquierdoÎncă nu există evaluări

- 0901 B 8038091 CFC 5Document6 pagini0901 B 8038091 CFC 5ForeverÎncă nu există evaluări

- RepairProcedurePatchRepair TBDocument2 paginiRepairProcedurePatchRepair TBAleksandr TsymbalÎncă nu există evaluări

- Lifetime Prediction of Waterborne Acrylic PaintsDocument7 paginiLifetime Prediction of Waterborne Acrylic Paintsvarvara viÎncă nu există evaluări

- TDS 561 Jotun Thinner No. 7 Euk GBDocument2 paginiTDS 561 Jotun Thinner No. 7 Euk GBangelito bernalÎncă nu există evaluări

- Brand AQAGloss-Brochure - Product Overview Polymer Dispersions Architectural Coatings-EnglishDocument6 paginiBrand AQAGloss-Brochure - Product Overview Polymer Dispersions Architectural Coatings-Englishfrox123Încă nu există evaluări

- Royale LustreDocument2 paginiRoyale LustreZheng JiangÎncă nu există evaluări

- Repair Manual SWE080L StaxioDocument200 paginiRepair Manual SWE080L Staxiojose100% (1)