Documente Academic

Documente Profesional

Documente Cultură

Work Instructions For Direct Loading of Pigs in Truck

Încărcat de

Shiva Prakasam PernetiTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Work Instructions For Direct Loading of Pigs in Truck

Încărcat de

Shiva Prakasam PernetiDrepturi de autor:

Formate disponibile

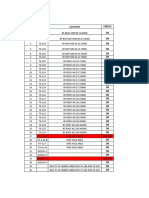

WORK INSTRUCTIONS FOR DIRECT LOADING OF PIGS IN TRUCK Criteria: To maintain Quality of Pig Iron by safe operation.

Responsibility: Bag House Staff/Pig shifting in charge

Identified Hazard 1. Contact with hot water 2. Contact with hot fumes. 3. Contact with Metal chips 4. Pig falling on person 5. Fall of a person 6. Truck catching fire

Significant aspect

1. Depletion of Natural resources

Procedure: 1. Unauthorized operation or repair of any equipment is a punishable offence 2. Person involved in this activity should wear Safety shoe, Helmet, spectacle, Hand

gloves, and Ear plugs.

3. .Pcm staff should ensure that truck availability and sufficient water is available in tank. 4. Truck for direct loading at discharge end to be placed by giving proper guidance to truck

driver with the help of whistle by standing towards driver side and both side visibility should be clear to the person giving direction. 5. During positioning /guiding of truck there should be no man movement in way of the moving truck. 6. After placing truck driver should get down from truck and put the stopper to the front tyre.

7. If only one side truck is placed ensure that diverting chute is towards the truck. 8. After placing truck and ensuring the diverter chute is appropriately placed, pig shifting in

charge should give clearance to pourer to start the pouring. 9. Start all the water sprays above truck before falling of pigs into trucks for proper cooling of pigs and avoid damage of truck lift. 10. PCM in charge should ensure hot metal sampling is done immediately after start of pouring to avoid delay of trucks. 10. Once the truck is full approximately 20t which is to be monitored physically divert the chute in other side truck. 11. Pig shifting in charge should ensure pigs are sufficiently cooled before the dispatch of the truck and ensure that water has been drained fully. 12. If Second truck is not available in time due to some reason pig shifting in charge should ask pourer to stop the pouring /PCM till second truck is made available.

13. Once pouring is over, PCM to be cleaned of stickers immediately and truck to be released. 14. Truck placement area to be cleaned of chipping once in shift to avoid tyre puncture by ensuring diverter chute is in the opposite direction to the place which requires cleaning. Ensure loose pigs from chute are removed with help of lancing pipe to avoid accidental fall of pigs. 15. In case of accidental fire, pouring should be immediately stopped and fire extinguishing apparatus to be activated to extinguish the fire. 16. In case of accidental fire enroute, the truck driver should use his portable fire extinguisher or should stop at any near fire hydrant point and extinguish the fire. 17. Beside the safety devices truck should be checked for effective self starting, no truck truck should be deployed effective self starting system. 18. The truck can be towed away by using proper safe tow lines in case of failure of self starting system, this should be done under the supervision of the concerned area in charge.

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- ID Risk Assessment TemplateDocument51 paginiID Risk Assessment TemplateCORAL ALONSOÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- M.P. Jain Administrative Law - Simran Sabharwal PDFDocument2.247 paginiM.P. Jain Administrative Law - Simran Sabharwal PDFAyush Pandey94% (17)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Sex For BeginnersDocument106 paginiSex For Beginnersmathan_20100% (4)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- David Carreras - A Cunnilinguist's Guide To Mind-Blowing Oral SexDocument6 paginiDavid Carreras - A Cunnilinguist's Guide To Mind-Blowing Oral SexKostyaÎncă nu există evaluări

- List of ISO Standards PDFDocument20 paginiList of ISO Standards PDFKristal Newton80% (5)

- (SAMPLE THESIS) Research and Analysis Project (Obu)Document66 pagini(SAMPLE THESIS) Research and Analysis Project (Obu)Murtaza Mansoor77% (35)

- Work Experience SheetDocument2 paginiWork Experience SheetAko Si Gilsboy100% (1)

- Rca SopDocument4 paginiRca SopShiva Prakasam PernetiÎncă nu există evaluări

- MNT CancerDocument62 paginiMNT CancerSaufi ZakariaÎncă nu există evaluări

- Fmea - Main Air CompressorDocument78 paginiFmea - Main Air CompressorShiva Prakasam Perneti100% (1)

- Plant Microsoft Office Word DocumentDocument2 paginiPlant Microsoft Office Word DocumentShiva Prakasam PernetiÎncă nu există evaluări

- MCK Appointment LetterDocument1 paginăMCK Appointment LetterShiva Prakasam PernetiÎncă nu există evaluări

- AC SparesDocument2 paginiAC SparesShiva Prakasam PernetiÎncă nu există evaluări

- Sivaprakasam ReDocument3 paginiSivaprakasam ReShiva Prakasam PernetiÎncă nu există evaluări

- Linto RDocument3 paginiLinto RShiva Prakasam PernetiÎncă nu există evaluări

- Equipment Tuning Procedure For BoilersDocument8 paginiEquipment Tuning Procedure For BoilersShiva Prakasam PernetiÎncă nu există evaluări

- Elamax ReportDocument2 paginiElamax ReportShiva Prakasam PernetiÎncă nu există evaluări

- BF Proper ThermocouplesDocument2 paginiBF Proper ThermocouplesShiva Prakasam PernetiÎncă nu există evaluări

- 11 Failure Mode AnalysisDocument2 pagini11 Failure Mode Analysisஎன் கருத்துÎncă nu există evaluări

- BF Top ValvesDocument1 paginăBF Top ValvesShiva Prakasam PernetiÎncă nu există evaluări

- Online Co MonitorDocument1 paginăOnline Co MonitorShiva Prakasam PernetiÎncă nu există evaluări

- SH Ded InputDocument1 paginăSH Ded InputShiva Prakasam PernetiÎncă nu există evaluări

- R F Admittance Point Level Switch ' Rfa'.: Instruction & Maintenance Manual FORDocument4 paginiR F Admittance Point Level Switch ' Rfa'.: Instruction & Maintenance Manual FORShiva Prakasam PernetiÎncă nu există evaluări

- BF Proper Thermocouple HistoryDocument67 paginiBF Proper Thermocouple HistoryShiva Prakasam PernetiÎncă nu există evaluări

- Cable Used For Redundency SupplyDocument2 paginiCable Used For Redundency SupplyShiva Prakasam PernetiÎncă nu există evaluări

- BFRV and Chute Operation/Troubleshooting Method I. Servo Drive Start Up Procedure After Power FailureDocument5 paginiBFRV and Chute Operation/Troubleshooting Method I. Servo Drive Start Up Procedure After Power FailureShiva Prakasam PernetiÎncă nu există evaluări

- BF Inst Mis Report December 2016Document30 paginiBF Inst Mis Report December 2016Shiva Prakasam PernetiÎncă nu există evaluări

- GCP Level Switch ReportDocument18 paginiGCP Level Switch ReportShiva Prakasam PernetiÎncă nu există evaluări

- BF Hydraulic Do DetailsDocument5 paginiBF Hydraulic Do DetailsShiva Prakasam PernetiÎncă nu există evaluări

- BF Proper ThermocouplesDocument2 paginiBF Proper ThermocouplesShiva Prakasam PernetiÎncă nu există evaluări

- GST P-9910B Handheld ProgrammerDocument15 paginiGST P-9910B Handheld ProgrammeretchegarayfÎncă nu există evaluări

- AMIE Section B Electrical SyllabusVVVVVDocument17 paginiAMIE Section B Electrical SyllabusVVVVVShiva Prakasam PernetiÎncă nu există evaluări

- Rules AMIE ExaminationDocument6 paginiRules AMIE ExaminationAjesh kumarÎncă nu există evaluări

- Cable List For CranesDocument2 paginiCable List For CranesShiva Prakasam PernetiÎncă nu există evaluări

- Temperature Viscosity Viscosity Temperature ViscosityDocument12 paginiTemperature Viscosity Viscosity Temperature ViscosityShiva Prakasam PernetiÎncă nu există evaluări

- Electrical 1Document1 paginăElectrical 1Shiva Prakasam PernetiÎncă nu există evaluări

- Electrical 1Document1 paginăElectrical 1Shiva Prakasam PernetiÎncă nu există evaluări

- SOP For Cleaning of Ultrasound Probes in Trust Imaging Departments PDFDocument2 paginiSOP For Cleaning of Ultrasound Probes in Trust Imaging Departments PDFShinta Vivoy21Încă nu există evaluări

- ID Pengaruh Self Selected Individual MusicDocument12 paginiID Pengaruh Self Selected Individual MusicNur AiniÎncă nu există evaluări

- Gangguan Mood - KuliahDocument57 paginiGangguan Mood - KuliahElRealManicheWemayÎncă nu există evaluări

- HDR 2015 Statistical AnnexDocument73 paginiHDR 2015 Statistical AnnexsssshekharÎncă nu există evaluări

- 03 - Hazards Identification, Risk Assessment and ControlDocument39 pagini03 - Hazards Identification, Risk Assessment and ControlDEO SALVACIONÎncă nu există evaluări

- S9 Q4 M1 Transport and Excretion and Respiration and Energy Exchange QuizDocument3 paginiS9 Q4 M1 Transport and Excretion and Respiration and Energy Exchange QuizJermae DizonÎncă nu există evaluări

- Buchholz Holland SF SchoolsDocument43 paginiBuchholz Holland SF SchoolsMirela Cojocaru StetcoÎncă nu există evaluări

- Antenatal CareDocument6 paginiAntenatal CareFancy DisouzaÎncă nu există evaluări

- How The Red Cross Raised Half A Billion Dollars For Haiti - and Built Six Homes - ProPublicaDocument15 paginiHow The Red Cross Raised Half A Billion Dollars For Haiti - and Built Six Homes - ProPublicaGina PistolÎncă nu există evaluări

- Life - Line ECMO Sell - Sheet ECMO FEB22 1 WebDocument2 paginiLife - Line ECMO Sell - Sheet ECMO FEB22 1 WebJavier Dario Cifuentes SandovalÎncă nu există evaluări

- Industrial Counseling HWDocument3 paginiIndustrial Counseling HWJoyce SisonÎncă nu există evaluări

- Britannia Industry LTD in India: Eat Healthy Think BetterDocument12 paginiBritannia Industry LTD in India: Eat Healthy Think BetterMayank ParasharÎncă nu există evaluări

- The Demand For, and Impact Of, Learning HIV StatusDocument36 paginiThe Demand For, and Impact Of, Learning HIV StatusWilson LancherosÎncă nu există evaluări

- Division of Blood Transfusion Services: Ministry of Health and Family WelfareDocument40 paginiDivision of Blood Transfusion Services: Ministry of Health and Family WelfareKirandragonÎncă nu există evaluări

- Developmental Screening Tools: Michelle M. Macias, MD D-PIP Training Workshop June 16, 2006Document39 paginiDevelopmental Screening Tools: Michelle M. Macias, MD D-PIP Training Workshop June 16, 2006psy22Încă nu există evaluări

- Test Cls 12 SNDocument1 paginăTest Cls 12 SNAntonia AntoÎncă nu există evaluări

- Telescopium) EXTRACTS: West Visayas State University College of MedicineDocument5 paginiTelescopium) EXTRACTS: West Visayas State University College of MedicineMark FuerteÎncă nu există evaluări

- Topic 13Document23 paginiTopic 13hasvinÎncă nu există evaluări

- List of Shelters in The Lower Mainland, June 2007Document2 paginiList of Shelters in The Lower Mainland, June 2007Union Gospel Mission100% (1)

- Biology Class 10 Syllabus Break Up AY 2022-23Document8 paginiBiology Class 10 Syllabus Break Up AY 2022-23alfredo pastaÎncă nu există evaluări

- NFPA Codes & Standards - 10Document1 paginăNFPA Codes & Standards - 10karpanaiÎncă nu există evaluări

- Full Download Essentials of Psychiatric Mental Health Nursing 7th Edition Test Bank PDF Full ChapterDocument36 paginiFull Download Essentials of Psychiatric Mental Health Nursing 7th Edition Test Bank PDF Full Chapterdiodontmetacism.0jw2al100% (16)

- Amber Sewell: Professional SummaryDocument4 paginiAmber Sewell: Professional Summaryapi-383979726Încă nu există evaluări