Documente Academic

Documente Profesional

Documente Cultură

Calibration of Chronometers

Încărcat de

Gustavo SánchezDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Calibration of Chronometers

Încărcat de

Gustavo SánchezDrepturi de autor:

Formate disponibile

ITTC Recommended Procedures

Sample Work Instructions Calibration of Chronometers with Digital Indication

7.6-02-07 Page 1 of 13

Effective Date 2002 Revision 00

CONTENTS

PURPOSE WORK INSTRUCTION 1. 2. Introduction Technical Requirements 2.1 Interior Crystal Oscillator 2.2 Time Interval Measuring 3. Calibration Conditions 3.1 Environmental Conditions 3.2 Standard equipment for calibration 4. Subject and method of calibration 4.1 Examination of the exterior and during normal working 4.2 Calibration of the interior crystal oscillation 4.3 Calibration of the measuring error

5. Treatment of the calibration results and calibration period 5.1 Treatment of Calibration Results. 5.2 Calibration period APPENDICES Appendix 1 Contents and format of the calibration certificate Appendix 2 Calibration of the crystal oscillator standard if the chronometer does not have an output of the crystal oscillator frequency Appendix 3 The calibration of the crystal-oscillator stopwatch

Source: Verification regulation of time interval measuring instrument with digital indication (trial usage) [Issued on May 31, 1995 and put into effect since May 1, 1996 by National Technical Bureau - JJG 23895, National Measuring Verification Regulation of Peoples Republic of China]

Prepared by Quality Systems Group of 23rd ITTC Date

Approved 23rd ITTC 2002 Date

ITTC Recommended Procedures

Sample Work Instructions Calibration of Chronometers with Digital Indication

7.6-02-07 Page 2 of 13

Effective Date 2002 Revision 00

Calibration of Chronometers with Digital Indication

PURPOSE This working instruction can be applied to the calibration of a time interval-measuring instrument with digital indication with a measuring range larger than 10 ns on new products, also for products in the use and after repair. WORK INSTRUCTION 1. Introduction Chronometer with digital indication means a time interval measuring instrument with numbers for indicating the time interval measuring value. The fundamental principle of these chronometers is that the unit time (time base), the accuracy of which is known, is used to measure the time interval. The measuring results are recorded and displayed by an electronic counter. The selected time base is generated by division or doubling of the frequency of a quartz crystal oscillator . The principle block-diagram is shown in Fig. 1.

Crystal oscillator

Frequency doubling/ Frequency division

Electric gate

Counting display

Signal A Signal B Fig. 1

Filter A Filter B

controller

Fundamental diagram of the time interval measuring instrument with digital indication

These chronometers are used for the following measurements: time interval between two electronic pulses (rising or falling edge) time of one single electronic pulse time interval between closing and (or)

opening of two mechanical contacts duration of closing or opening for a single mechanical contact time interval between the actions of a single electronic pulse and a single mechanical contact

ITTC Recommended Procedures

Sample Work Instructions Calibration of Chronometers with Digital Indication

7.6-02-07 Page 3 of 13

Effective Date 2002 Revision 00

2. Technical Requirements 2.1 Interior Crystal Oscillator Frequency fluctuation: 10-6 ~ 10-10 Accuracy of frequency: 10-5 ~ 10 -9 2.2 Time Interval Measuring Time base: 10ns ~ 100ms Measuring range: 10ns ~1d The measuring error may be calculated by the following formula Measuring error = T accuracy of the frequency of crystal oscillation + trigger error +0 Where: T measured time interval 0 selected time base during measuring

3.2 Standard equipment for calibration 3.2.1 Standard time interval generator 3.2.1.1 It has two outputs. The signal pattern should be: The interval of two positive and (or) negative electronic pulses single positive or negative electric pulse width the interval between the open circuit and (or) the short circuit of two output terminals the duration of the open circuit or the short circuit of the single output terminal 3.2.1.2 The rise or fall time of the pulse must be less than one-fifth of the minimum resolution of the calibrated chronometer. 3.2.1.3 The range of the output time interval should meet the measuring requirements of the calibrated chronometers. 3.2.1.4 The error of the output time interval should be less than or equal to one-tenth of the measuring error of the calibrated chronometers. 3.2.2 Reference frequency standard This can be a highly stable crystal oscillator or an atomic frequency standard. The frequency fluctuation and the frequency accuracy must be ten times higher than the relevant indexes of the calibrated chronometer. 3.2.3 Frequency Standard Comparator Able to compare the functions and the technical indexes for realizing the calibration of the crystal oscillation index of the calibrated chronometer. 3.2.4 Electronic counter Able to measure the frequency in the range from 1 Hz to 10 MHz.

3. Calibration Conditions 3.1 Environmental Conditions 3.1.1 Environmental temperature: can be between 10 ~30 . The temperature variation should not exceed 2 during the calibration. 3.1.2 Relative humidity: (6515)% 3.1.3 Power supply: ~Voltage(110%)V 3.1.4 No strong electro-magnetic interference

ITTC Recommended Procedures

Sample Work Instructions Calibration of Chronometers with Digital Indication

7.6-02-07 Page 4 of 13

Effective Date 2002 Revision 00

4. Subject and method of the calibration 4.1 Examination of the exterior and during normal working 4.1.1 The calibrated chronometer should not have any mechanical damages, which could affect the normal use of the instrument. All the control switches should work easily and reliably. 4.1.2 Switch the current on. A standard time

interval is deliberately given by a standard time interval generator for checking the variety of functions in the measuring range of the calibrated chronometer. 4.2 Calibration of the interior crystal oscillation The connection of the instruments is shown in Fig. 2.

Calibrated nometer

chrocomparator Reference frequency standard

(a)

Calibrated nometer chrocounter Reference frequency standard

(b) Fig. 2 Connection diagram of the instruments for calibrating the interior crystal oscillation

If the accuracy of the frequency measurement can meet the calibration requirement when the gate time of the electronic counter is 10s, the version shown in Fig. 2 (b) may be selected for the calibration. The reference frequency standard can be used as the input of the external standard for the electronic counter. 4.2.1 Calibration of the frequency fluctuation After the chronometer has been warmed up according to its specification the measurements can be started. One meas-

urement per hour, totally N times (N = 4, 8 or 24). The measuring sample time can be taken as 10s. Three values each time. The frequency fluctuation value can be calculated the formulae (1) or (2).

S=

f max f min f0

(1)

f =

1 3 fi 3 i =1

ITTC Recommended Procedures

Sample Work Instructions Calibration of Chronometers with Digital Indication

7.6-02-07 Page 5 of 13

Effective Date 2002 Revision 00

where: fi measured value of each sample by use of the electronic counter. f0 nominal value of the output frequency for the calibrated crystal oscillation. Or:

y ( ) =

A=

f f0 f0

(4)

S = ymax ( ) - ymin ( ) 1 3 yi ( ) 3 i =1

(2)

where: yi() average relative frequency deviation directly measured using a comparator of the frequency standard. Alignment of the frequency accuracy 4.2.2 To ensure the reliability of the calibration result during the process the accuracy of the crystal oscillation must be restricted to a value less than one-tenth of the frequency fluctuation value. The frequency accuracy may be calculated by formula (3) using the data of the frequency fluctuation calibration.

A= f f0 f0

max

The crystal oscillation frequency must be aligned to the same order as that of the frequency fluctuation. However, the accuracy ought to be noted on the the calibration certificate. If the calibrated chronometer does not have an output of the crystal oscillation, the calibration of the crystal oscillation norm can be carried out on the basis of the method given in the Appendix 2. 4.3 Calibration of the measuring error 4.3.1 Selection of the calibration values and the error calculation. The measurement begins at the minimum value, followed by a series of values ten times greater each time and then ends with the maximum value. If the measuring range of the chronometer is divided into sub-ranges, the calibration value at the lowest sub-range can be selected according to the above mentioned method. For the calibration only the maximum values of the other sub-ranges need to be taken. The measurement must be done three times for each calibration value. The arithmetic mean value will be taken as the measuring value. The measuring error can be calculated by formula (5):

(3)

If the result of the calculation is better than the required accuracy, the crystal oscillating frequency need not be adjusted. Otherwise it must be aligned. When being adjusted the sampling time can be taken as 10s and only one measurement is sufficient. The frequency accuracy may be calculated by formula (4):

ITTC Recommended Procedures

Sample Work Instructions Calibration of Chronometers with Digital Indication

7.6-02-07 Page 6 of 13

Effective Date 2002 Revision 00

T = Ti T0

(5)

Ti =

1 3 Ti 3 i =1

where: Ti value which is measured every time. T0 given value of the standard time interval generator. 4.3.2 Measuring of the time interval of the electronic pulse

Time interval generator

The connection of the instruments is shown in Fig. 3. 4.3.2.1 Pulse Width Measurement of the Positive Pulse The single positive electronic pulse signal is given by the time interval generator and at the same time is sent to the A and B input terminals of the calibrated chronometer. The trigger slope of A channel (start-up channel) is set to be positive; the trigger slope of B channel (stop channel) is set to be negative.

A B

calibrated chronometer

Reference of frequency Standard

(a) for single pulse measurement

Time interval generator

A B

calibrated chronometer

Reference of frequency Standard

(b) for twin pulse measurement Fig. 3 The instruments connection diagram of the time interval measure for the electric pulses

ITTC Recommended Procedures

Sample Work Instructions Calibration of Chronometers with Digital Indication

7.6-02-07 Page 7 of 13

Effective Date 2002 Revision 00

Pulse Width Measurement of the 4.3.2.2 Negative Pulse The time interval generator gives a single negative pulse signal. The trigger slopes of A and B input channels of the calibrated chronometer are set to be negative and positive respectively. 4.3.2.3 Time interval measurement of two positive electronic pulses The time interval generator gives a single positive pulse signal in two traces. The start-up signal is put on A channel of the calibrated chronometer. The stop signal is put on B channel. The trigger slopes of both channels are set to be positive . 4.3.2.4 Time interval measurement of two negative electronic pulses The time interval generator gives a single negative pulse signal in two lines. The start-up signal is put on A channel of the

Time interval generator

calibrated chronometer. The stop signal is put on B channel. The trigger slopes of both channels are set to be negative. 4.3.3 Action Time Measurement of the mechanical contacts The connection of the instruments is shown in Fig. 4. 4.3.3.1 Duration Measurement of the closing for one contact A single start signal (short circuit) given by the time interval generator, connected to the relevant measurement input terminal of the chronometer. 4.3.3.2 Duration of the opening for a single contact The single turn-off signal (open circuit) given by the time interval generator is put onto the relevant measurement input terminal of the chronometer.

Calibrated chronometer

Reference of frequency standard

(a) for single contact

Time interval generator calibrated chronometer

Reference of frequency standard

(b) for two contacts Fig. 4 The instruments connection diagram of the action time measurement of the mechanical contacts

ITTC Recommended Procedures

Sample Work Instructions Calibration of Chronometers with Digital Indication

7.6-02-07 Page 8 of 13

Effective Date 2002 Revision 00

4.3.3.3 Measurement of the time interval for closing between two contacts The time interval generator gives single start signals as two outputs, one is the start-up signal and the other is the stop signal. Both of them are connected to the relevant measurement input terminals of the chronometer respectively. 4.3.3.4 Measurement of the time interval for the turn-off of two contacts Single turn-off signals given by the time interval generator one after another are connected to the relevant measurement input terminals of the chronometer respectively.

5. Treatment of the calibration results and calibration period

5.1 Treatment of Calibration Results. For chronometers which meet the requirement of this working instruction, a calibration certificate will be supplied: For the ones which do not meet the requirement, an advice note of the calibration result should be supplied with the items which do not comply being pointed out. 5.2 Calibration period The calibration period of the chronometer is one year

ITTC Recommended Procedures

Sample Work Instructions Calibration of Chronometers with Digital Indication

7.6-02-07 Page 9 of 13

Effective Date 2002 Revision 00

APPENDICES

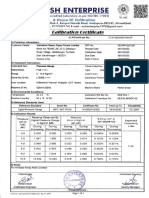

Appendix 1 Contents and format of the calibration certificate

A. Calibration of the internal crystal oscillation 1. Frequency fluctuation 2. Accuracy of frequency B. Calibration of the time interval measurement 1. Pulse width measurement of the positive pulse 2. Pulse width measurement of the negative pulse 3. Time interval measurement between two

positive pulses 4. Time interval measurement between two negative pulses 5. Duration measurement for closing mechanical contacts 6. Duration measurement for opening of mechanical contacts 7. Time interval measurement for closing of two contacts 8. The time interval measurement for opening of two contacts Each item of the calibrated data is given on the basis of the following table.

Standard value T0

Measured value Ti

Error T

ITTC Recommended Procedures

Sample Work Instructions Calibration of Chronometers with Digital Indication

7.6-02-07 Page 10 of 13

Effective Date 2002 Revision 00

Appendix 2 Calibration of the crystal oscillator standard if the chronometer does not have an output of the crystal oscillator frequency

The connection of the instruments is shown in the following Fig.

Time interval generator

Calibrated chronometer

Reference frequency standard

The functions of the chronometer are measured by use of the electronic pulse. The time interval generator gives the pulse width of the single pulse or the interval between two single pulses. The given time interval may be supposed to be T0. The time unit corresponding to the minimum display position of the chronometer is 0. Then the value of T0 must meet the following formula:

taken per hour, in total N times (N = 4, 8 or 24). The frequency fluctuation value can be calculated by use of formulae (1): S = (yi)max (yi)min (1) yi =

Ti T0 T0

where: Ti measured value every time. 2. Alignment of the frequency accuracy If the result of the calculation using the data from the frequency fluctuation measurements satisfies the following formula, the alignment of the crystal oscillator frequency is not needed.

10 S yi

max

1 v T0 10

where: v frequency fluctuation of the internal crystal oscillator of the chronometer. 1. Calibration of the frequency fluctuation After the chronometer has warmed up according to the working instruction the measurement can be started. One measurement is

(2)

else: open the cover of the chronometer, adjust the frequency of the crystal oscillation till it meets the requirement of formula (2). This time the value of |yi|max need only be calcu-

ITTC Recommended Procedures

Sample Work Instructions Calibration of Chronometers with Digital Indication

7.6-02-07 Page 11 of 13

Effective Date 2002 Revision 00

lated for one measured value after the alignment. If the crystal oscillator frequency cannot be adjusted or although it can be adjusted but the requirement of formula (2) cannot be met,

|yi|max must be stated in the calibration report as the frequency accuracy.

ITTC Recommended Procedures

Sample Work Instructions Calibration of Chronometers with Digital Indication

7.6-02-07 Page 12 of 13

Effective Date 2002 Revision 00

Appendix 3 The calibration of the crystal-oscillator stopwatch

use of an electromagnetic pulse should be used in the standard calibration equipment. The standard time interval generator must possess the corresponding function or a calibrator for this special use may be used. If the crystal-oscillator stopwatch does not have an output of the crystal oscillator frequency, the interior crystal oscillator need not be calibrated. Only the measuring error of the time interval and the daily difference should be calibrated. The connection of the instruments is shown in the following Figure:

A crystal-oscillator stopwatch belongs to the type of instruments for the time interval measuring with digital indication based on its working principle and display. Owing to the particularity and uniqueness of its measuring principle, the general-purpose items in the main body of this working instruction cannot completely meet the requirements for the calibration of the crystaloscillator stopwatch. For this reason a stopwatch fixture i.e. a mechanical hand that starts and stops the stopwatch by

Time interval generator Or Stopwatch calibrator

Stopwatch fixture

Stopwatch fixture

working instruction.

1. Calibration of the measuring error 2. Calibration of the daily difference

The calibration values are selected as 1s, 10s, 1min and 1h. Three measurements should be carried out for the first three measuring values. The arithmetic mean of their measurement values may be taken. For the last case, two measurements can be performed. Take the arithmetic mean value of its measurement value. The measuring error can be calculated by use of the formula (5) in the main body of this

The daily difference means the measuring error when the time interval is taken as one day. For the normal stopwatch no one will measure such a long time interval. But the crystal-oscillator stopwatch also posses the display function of hour, minute and second. So the requirement of the index of the travel-time daily difference similar as watch and crystal clock is required.

ITTC Recommended Procedures

Sample Work Instructions Calibration of Chronometers with Digital Indication

7.6-02-07 Page 13 of 13

Effective Date 2002 Revision 00

The calibration of the daily difference is the same as that of the calibration of the measuring error. The crystal-oscillator stopwatch measures the time interval, the standard time interval generator gives only one time. The calculation of the error is the same as above. The daily difference can also be calibrated by use of an instantaneous measuring device for the daily difference.

3. Format of the calibration certificate for crystal-oscillator stopwatch

See the table below.

Standard value T0 1s 10s 1min 1h

Measuring value Ti

Error T = Ti T0

S-ar putea să vă placă și

- SOP 24 Standard Operating Procedure For Calibration of Stopwatches and Timing DevicesDocument10 paginiSOP 24 Standard Operating Procedure For Calibration of Stopwatches and Timing DevicesAli RizviÎncă nu există evaluări

- 54-Pressure Gauge OIT Calibration CartificateDocument1 pagină54-Pressure Gauge OIT Calibration CartificateCustomer Support100% (1)

- EURAMET-cg-08 V 2.1 ChangesDocument18 paginiEURAMET-cg-08 V 2.1 ChangesGilberto Andrés JuradoÎncă nu există evaluări

- X-Series Manual: Including X-50, X-100, X-200, X-300 Model Handheld X-Ray Fluorescence AnalyzersDocument34 paginiX-Series Manual: Including X-50, X-100, X-200, X-300 Model Handheld X-Ray Fluorescence AnalyzersRahul DubeyÎncă nu există evaluări

- Digital Display Voltmeter (Ammeter) Anual Operational Instruction MDocument4 paginiDigital Display Voltmeter (Ammeter) Anual Operational Instruction MCaterine CrespoÎncă nu există evaluări

- Analytical Balance SOPDocument2 paginiAnalytical Balance SOPdivine productionÎncă nu există evaluări

- Technical Guide 8 Calibration of Stop-Watches: Measurement Standards LaboratoryDocument2 paginiTechnical Guide 8 Calibration of Stop-Watches: Measurement Standards Laboratoryloukas_pÎncă nu există evaluări

- Comparison Method Calibration For HydrometerDocument12 paginiComparison Method Calibration For HydrometerHi Tech Calibration ServicesÎncă nu există evaluări

- PROC-TC-012 Procedure For Calibration Flask, Cylinder SOP (PROC - C)Document19 paginiPROC-TC-012 Procedure For Calibration Flask, Cylinder SOP (PROC - C)Ban ZanganaÎncă nu există evaluări

- Procedure For Calibration and Installation of InstrumentsDocument62 paginiProcedure For Calibration and Installation of InstrumentsAbdul SammadÎncă nu există evaluări

- Calibration Procedure of Metal Detection MachineDocument1 paginăCalibration Procedure of Metal Detection MachineJobaer0% (1)

- Sanas TR 79-03Document9 paginiSanas TR 79-03Hi Tech Calibration ServicesÎncă nu există evaluări

- Lab3 Temperature and Calibration - FINALrrDocument6 paginiLab3 Temperature and Calibration - FINALrrDerrick SheeÎncă nu există evaluări

- 29-Stop Watch Calibration CartificateDocument1 pagină29-Stop Watch Calibration CartificateCustomer SupportÎncă nu există evaluări

- Theoretical Uncertainty of Orifice Flow Measurement 172KBDocument7 paginiTheoretical Uncertainty of Orifice Flow Measurement 172KBSatya Sai Babu YeletiÎncă nu există evaluări

- SASSCO Intermediate Check Instruction SheetDocument4 paginiSASSCO Intermediate Check Instruction SheetStudent ForeignÎncă nu există evaluări

- Kosaka Lab Scope CC 2611Document50 paginiKosaka Lab Scope CC 2611kumarÎncă nu există evaluări

- Theoretical Uncertainty of Orifice Flow Measurement TechWpaperDocument8 paginiTheoretical Uncertainty of Orifice Flow Measurement TechWpaperFikri AchdanÎncă nu există evaluări

- NIST Stopwatch & Timer Calibrations 2009Document82 paginiNIST Stopwatch & Timer Calibrations 2009ririmonir100% (1)

- Calibration: Procedures, Standard and MethodologiesDocument25 paginiCalibration: Procedures, Standard and MethodologiesUgochukwu FidelisÎncă nu există evaluări

- 2012 Calibrations in Process Control and AutomationDocument11 pagini2012 Calibrations in Process Control and AutomationLALIT RAAZPOOTÎncă nu există evaluări

- Microphone and Sound Level Meter Calibration in FR PDFDocument7 paginiMicrophone and Sound Level Meter Calibration in FR PDFumair2kplus492Încă nu există evaluări

- ULR: CC226721000004771F: Plot No.B-202, MIDC, Butibori, NagpurDocument2 paginiULR: CC226721000004771F: Plot No.B-202, MIDC, Butibori, NagpurKiranÎncă nu există evaluări

- Height Gauge Calibration Procedure: 1.0 Standards and EquipmentDocument2 paginiHeight Gauge Calibration Procedure: 1.0 Standards and EquipmentKiranÎncă nu există evaluări

- Ddaily Drift Calibration Procedure: 1. ScopeDocument1 paginăDdaily Drift Calibration Procedure: 1. ScopeJohn DolanÎncă nu există evaluări

- Calibration TerminologyDocument15 paginiCalibration TerminologyDavid GaryÎncă nu există evaluări

- Sidhi International Metalloys Pvt. LTD.: Customer Property RecordsDocument2 paginiSidhi International Metalloys Pvt. LTD.: Customer Property Recordspulkit gargÎncă nu există evaluări

- CALIBRATION OF Piston Pipette and Buritte PDFDocument98 paginiCALIBRATION OF Piston Pipette and Buritte PDFBan ZanganaÎncă nu există evaluări

- Stability and UniformityDocument6 paginiStability and UniformitymegacobÎncă nu există evaluări

- 003 Torque Wrench16486-2017Document22 pagini003 Torque Wrench16486-2017DiptiÎncă nu există evaluări

- Calibration Procedure FOR Calipers General: Technical ManualDocument8 paginiCalibration Procedure FOR Calipers General: Technical ManualrcmetrologyÎncă nu există evaluări

- Stop Watch-ID-23 - 24 To 25Document2 paginiStop Watch-ID-23 - 24 To 25monwar hosenÎncă nu există evaluări

- Calibration of AnemometerDocument4 paginiCalibration of AnemometerAhmet ŞenÎncă nu există evaluări

- 031-Conductivity MeterDocument4 pagini031-Conductivity MeterAjlan KhanÎncă nu există evaluări

- 1.SOP For Calibratioon of Pressure GaugesDocument3 pagini1.SOP For Calibratioon of Pressure Gaugesget_engineer05100% (1)

- Lead STD Cal 8Document3 paginiLead STD Cal 8John Dolan100% (1)

- 02-Calibration & Control of Measuring & Monitoring DevicesDocument1 pagină02-Calibration & Control of Measuring & Monitoring DeviceskitekÎncă nu există evaluări

- Std-Insp-0001 (Proceudre For Storage, Drying (Baking), Issue and Control of Welding Consumables)Document5 paginiStd-Insp-0001 (Proceudre For Storage, Drying (Baking), Issue and Control of Welding Consumables)airbroomÎncă nu există evaluări

- Uncertainty Budget TemplateDocument4 paginiUncertainty Budget TemplateshahazadÎncă nu există evaluări

- EIA - SyllabusDocument3 paginiEIA - SyllabussyamalaÎncă nu există evaluări

- Digltalmeasuringinstrumentsfor Measurementandcontrol: Indian StandardDocument14 paginiDigltalmeasuringinstrumentsfor Measurementandcontrol: Indian StandardSriniramu SriniramuÎncă nu există evaluări

- 8.4.4 Instron Tensile Tester SOPDocument1 pagină8.4.4 Instron Tensile Tester SOPDarby BrownÎncă nu există evaluări

- DLAB Scientific Brochure 2016Document97 paginiDLAB Scientific Brochure 2016ThanhSơnHồÎncă nu există evaluări

- ITTC - Recommended Procedures: Sample Work Instructions Calibration of A Liquid-in-Glass ThermometerDocument12 paginiITTC - Recommended Procedures: Sample Work Instructions Calibration of A Liquid-in-Glass ThermometertungluongÎncă nu există evaluări

- Transduction PrinciplesDocument14 paginiTransduction PrinciplesNavin KaranthÎncă nu există evaluări

- Final ReportDocument53 paginiFinal ReportmirelamanteamirelaÎncă nu există evaluări

- CP No.601-Hydraulic Type (Pressure) - RevDocument18 paginiCP No.601-Hydraulic Type (Pressure) - Revamelchan_tiqueÎncă nu există evaluări

- ISO 9000 2015 (En) Quality Management Systems - Fundamentals and VocabularyDocument23 paginiISO 9000 2015 (En) Quality Management Systems - Fundamentals and VocabularyPaulino MutomboÎncă nu există evaluări

- Digital Thermo Hygrometer (HTC-1)Document1 paginăDigital Thermo Hygrometer (HTC-1)darsunaddictedÎncă nu există evaluări

- 18.in House Calibration ProcedureDocument1 pagină18.in House Calibration ProcedureSAKTHIVEL AÎncă nu există evaluări

- Calibration of Pressure GaugeDocument3 paginiCalibration of Pressure Gauge047-Nidhi HingankarÎncă nu există evaluări

- 18.in House Calibration ProcedureDocument1 pagină18.in House Calibration ProcedureSAKTHIVEL AÎncă nu există evaluări

- Evaluation of Measurement Uncertainty - Core DocumentDocument9 paginiEvaluation of Measurement Uncertainty - Core DocumentHabib BerrandjiaÎncă nu există evaluări

- ITTC 7.6-02-07 Calibration of Chronometers With Digital Indication PDFDocument13 paginiITTC 7.6-02-07 Calibration of Chronometers With Digital Indication PDFfrancisco monsivaisÎncă nu există evaluări

- Time Difference MeterDocument8 paginiTime Difference MeterMike AndersonÎncă nu există evaluări

- Project Report KanojDocument17 paginiProject Report KanojKanoj Bsn100% (3)

- Identification of Torsional Vibration Features in Electrical Powered Rotating EquipmentDocument9 paginiIdentification of Torsional Vibration Features in Electrical Powered Rotating EquipmentHasan PashaÎncă nu există evaluări

- Frequency CounterDocument23 paginiFrequency CounterEng. Dr. Dennis N Mwighusa100% (2)

- Temperature Measurement CircuitsDocument22 paginiTemperature Measurement Circuitsestraj1954Încă nu există evaluări

- Anccscetisomer 0611 PDFDocument2 paginiAnccscetisomer 0611 PDFGustavo SánchezÎncă nu există evaluări

- BS en 60584-1-1996Document121 paginiBS en 60584-1-1996Gustavo Sánchez100% (1)

- Air Resistance of Paper (Gurley Method) t460Document19 paginiAir Resistance of Paper (Gurley Method) t460Gustavo Sánchez100% (1)

- THERMOMETER CALIBRATION USING CONTROLLED TEMPERATURE Baths Cal926 PDFDocument7 paginiTHERMOMETER CALIBRATION USING CONTROLLED TEMPERATURE Baths Cal926 PDFGustavo SánchezÎncă nu există evaluări

- NBS13Document196 paginiNBS13Gustavo SánchezÎncă nu există evaluări

- Triple Point CellsDocument48 paginiTriple Point CellsGustavo SánchezÎncă nu există evaluări

- Temperature HandbookDocument136 paginiTemperature HandbookGustavo SánchezÎncă nu există evaluări

- ISO 7027 Turbidity TechniqueDocument2 paginiISO 7027 Turbidity TechniqueGustavo Sánchez0% (1)

- Guía para El Uso de Fotografías en CB Report CTL-OP 107-Ed.1Document3 paginiGuía para El Uso de Fotografías en CB Report CTL-OP 107-Ed.1Gustavo SánchezÎncă nu există evaluări

- The Nist Industrial Thermometer Calibration LaboratoryDocument6 paginiThe Nist Industrial Thermometer Calibration LaboratoryGustavo SánchezÎncă nu există evaluări

- Agilent 6890 and UniChrom - EngDocument8 paginiAgilent 6890 and UniChrom - EngGustavo SánchezÎncă nu există evaluări

- Turbidity ScienceDocument26 paginiTurbidity ScienceGustavo SánchezÎncă nu există evaluări

- Finnigan LCQ - Training ManualDocument19 paginiFinnigan LCQ - Training ManualGustavo SánchezÎncă nu există evaluări

- Programming Data For Spectrophotometer and Spectroquant Test Kits Measured With A Reference SpectrophotometerDocument17 paginiProgramming Data For Spectrophotometer and Spectroquant Test Kits Measured With A Reference SpectrophotometerGustavo SánchezÎncă nu există evaluări

- Physics Final SolutionDocument5 paginiPhysics Final SolutionMushfiq Jahan Khan100% (1)

- Is 11717 2000Document40 paginiIs 11717 2000simplyneerajÎncă nu există evaluări

- Naval Sonar, NAVPERS 10884, 1953 Was Created A Few Years After WW II and IncorporatesDocument48 paginiNaval Sonar, NAVPERS 10884, 1953 Was Created A Few Years After WW II and IncorporatesHaerul ImamÎncă nu există evaluări

- Ftee 80 106Document3 paginiFtee 80 106Vinayaga Murthy GÎncă nu există evaluări

- Pump Control Fuji FrenicDocument36 paginiPump Control Fuji FrenicRamaÎncă nu există evaluări

- Science Second Quarter ReviewerDocument10 paginiScience Second Quarter ReviewercorinneÎncă nu există evaluări

- Chapter 21 Sound Wave REVISIONDocument4 paginiChapter 21 Sound Wave REVISIONYilea1111111Încă nu există evaluări

- Ground Vibrations Due To Pile and Sheet Pile DrivingDocument126 paginiGround Vibrations Due To Pile and Sheet Pile DrivingBassem MuhannaÎncă nu există evaluări

- Samsung 932BFDocument74 paginiSamsung 932BFstevebensonÎncă nu există evaluări

- SAAB 900 Alarm - ProgrammingDocument53 paginiSAAB 900 Alarm - ProgrammingUldis Markuss100% (3)

- Grand Summary IGCSE Physics (Black & White)Document56 paginiGrand Summary IGCSE Physics (Black & White)jun100% (1)

- GK 404 ReadoutDocument2 paginiGK 404 ReadoutamssanchezÎncă nu există evaluări

- 3RG6 Sonar-BERO Ultrasonic Proximity Switches: GeneralDocument22 pagini3RG6 Sonar-BERO Ultrasonic Proximity Switches: Generalyouri59490Încă nu există evaluări

- GLS614 - CHAPTER 2 - Underwater Acoustic and SonarDocument11 paginiGLS614 - CHAPTER 2 - Underwater Acoustic and SonarHarith HnryusanÎncă nu există evaluări

- Vibration Diagonistic ChartDocument1 paginăVibration Diagonistic Chartjawadhussain1100% (10)

- C.A 6115Document6 paginiC.A 6115Ini AtnÎncă nu există evaluări

- Physics Stage 3 FinalDocument45 paginiPhysics Stage 3 FinalAnandraj GovindarajÎncă nu există evaluări

- THE ORIGINAL - Science jm9000Document5 paginiTHE ORIGINAL - Science jm9000paiynmailÎncă nu există evaluări

- Full Download Test Bank For Radiographic Imaging and Exposure 4th Edition Fauber PDF Full ChapterDocument36 paginiFull Download Test Bank For Radiographic Imaging and Exposure 4th Edition Fauber PDF Full Chaptermaryrodriguezxsntrogkwd100% (17)

- Syllabus: Wave Analyzers: Frequency Selective Wave Analyzer, Heterodyne Wave Analyzer, DistortionDocument16 paginiSyllabus: Wave Analyzers: Frequency Selective Wave Analyzer, Heterodyne Wave Analyzer, DistortionVineela ThonduriÎncă nu există evaluări

- Grade 11 Waves and Sound Lesson PlanDocument4 paginiGrade 11 Waves and Sound Lesson Planapi-272399401100% (1)

- System Sensor SPSW Data SheetDocument4 paginiSystem Sensor SPSW Data SheetJMAC SupplyÎncă nu există evaluări

- ISO 8528-9 Diesel Generator Evaluation CriteriaDocument24 paginiISO 8528-9 Diesel Generator Evaluation CriteriachocoteteÎncă nu există evaluări

- O-Level-Physics-Formula-Sheet 1 PDFDocument3 paginiO-Level-Physics-Formula-Sheet 1 PDFGeofrey100% (4)

- Vibration Analysis Rotating EquipmentDocument161 paginiVibration Analysis Rotating Equipmentronfrend100% (17)

- Rolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 720000 - 4Document24 paginiRolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 720000 - 4anony8103Încă nu există evaluări

- Reviewer in Science For Ymca Key AnswerDocument13 paginiReviewer in Science For Ymca Key AnswerCamille ManlongatÎncă nu există evaluări

- SDOF - Free VibrationDocument12 paginiSDOF - Free VibrationPaul Bryan GuanÎncă nu există evaluări

- The Digital Oscilloscope and The Function Generator: Part I: Amplitude and Frequency MeasurementsDocument6 paginiThe Digital Oscilloscope and The Function Generator: Part I: Amplitude and Frequency MeasurementsNour ShamiÎncă nu există evaluări

- MFJ MFJ-269 Ant Analyser Calibration PDFDocument0 paginiMFJ MFJ-269 Ant Analyser Calibration PDFchaparalÎncă nu există evaluări