Documente Academic

Documente Profesional

Documente Cultură

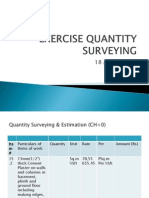

Estimation and Costing

Încărcat de

js kalyana ramaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Estimation and Costing

Încărcat de

js kalyana ramaDrepturi de autor:

Formate disponibile

Cost Estimating 1 Dr.

Emad Elbeltagi

CHAPTER 1

INTRODUCTION

Cost is a major factor in most decisions regarding construction, and cost estimates are

prepared throughout the planning, design, and construction phases of a construction

project, different types of cost estimating from preliminary to detailed are conducted for

different purposes. All of these estimates are important because they invariably influence

the expenditure of major sums. However, estimates made in the early phases of a project

are particularly important because they affect the most basic decisions about a project. In

most cases, the final cost (or cost projections during construction) has been significantly

higher than the cost estimates prepared and released during initial planning, preliminary

engineering, final design, or even at the start of construction.

1.1 The Construction Project

A project is defined, whether it is in construction or not, by the following characteristics:

- A defined goal or objective.

- Specific tasks to be performed.

- A defined beginning and end.

- Resources being consumed.

The goal of construction project is to build something. What differentiate the construction

industry from other industries is that its projects are large, built on-site, and generally

unique. Time, money, labor, equipment, and, materials are all examples of the kinds of

resources that are consumed by the project.

Cost Estimating 2 Dr. Emad Elbeltagi

Projects begin with a stated goal established by the owner and accomplished by the

project team. As the team begins to design, estimate, and plan out the project, the

members learn more about the project than was known when the goal was first

established. This often leads to a redefinition of the stated project goals.

1.2 Project Life-Cycle

The acquisition of a constructed facility usually represents a major capital investment,

whether its owner happens to be an individual, a private corporation or a public agency.

Since the commitment of resources for such an investment is motivated by market

demands or perceived needs, the facility is expected to satisfy certain objectives within

the constraints specified by the owner and relevant regulations.

From the perspective of an owner, the project life cycle for a constructed facility may be

illustrated schematically in Figure 1.1. A project is expected to meet market demands or

needs in a timely fashion. Various possibilities may be considered in the conceptual

planning stage, and the technological and economic feasibility of each alternative will be

assessed and compared in order to select the best possible project. The financing schemes

for the proposed alternatives must also be examined, and the project will be programmed

with respect to the timing for its completion and for available cash flows. After the scope

of the project is clearly defined, detailed engineering design will provide the blueprint for

construction, and the definitive cost estimate will serve as the baseline for cost control. In

the procurement and construction stage, the delivery of materials and the erection of the

project on site must be carefully planned and controlled. After the construction is

completed, there is usually a brief period of start-up of the constructed facility when it is

first occupied. Finally, the management of the facility is turned over to the owner for full

occupancy until the facility lives out its useful life and is designated for demolition or

conversion.

Of course, the stages of development in Figure 1.1 may not be strictly sequential. Some

of the stages require iteration, and others may be carried out in parallel or with

overlapping time frames, depending on the nature, size and urgency of the project.

Cost Estimating 3 Dr. Emad Elbeltagi

Furthermore, an owner may have in-house capacities to handle the work in every stage of

the entire process. By examining the project life cycle from an owner's perspective we

can focus on the proper roles of various activities and participants in all stages regardless

of the contractual arrangements for different types of work.

Figure 1.1: Project life cycle

The project life cycle may be viewed as a process through which a project is

implemented from beginning to end. This process is often very complex; however, it can

be decomposed into several stages as indicated by the general outline in Figure 1.1. The

solutions at various stages are then integrated to obtain the final outcome. Although each

stage requires different expertise, it usually includes both technical and managerial

activities in the knowledge domain of the specialist. The owner may choose to

decompose the entire process into more or less stages based on the size and nature of the

Cost Estimating 4 Dr. Emad Elbeltagi

project. Very often, the owner retains direct control of work in the planning stages, but

increasingly outside planners and financial experts are used as consultants because of the

complexities of projects. Since operation and maintenance of a facility will go on long

after the completion and acceptance of a project, it is usually treated as a separate

problem except in the consideration of the life cycle cost of a facility. All stages from

conceptual planning and feasibility studies to the acceptance of a facility for occupancy

may be broadly lumped together and referred to as the Design/Construct process, while

the procurement and construction alone are traditionally regarded as the province of the

construction industry.

There is no single best approach in organizing project management throughout a project's

life cycle. All organizational approaches have advantages and disadvantages, depending

on the knowledge of the owner in construction management as well as the type, size and

location of the project. It is important for the owner to be aware of the approach which is

most appropriate and beneficial for a particular project. In making choices, owners should

be concerned with the life cycle costs of constructed facilities rather than simply the

initial construction costs. Saving small amounts of money during construction may not be

worthwhile if the result is much larger operating costs or not meeting the functional

requirements for the new facility satisfactorily. Thus, owners must be very concerned

with the quality of the finished product as well as the cost of construction itself. Since

facility operation and maintenance is a part of the project life cycle, the owners'

expectation to satisfy investment objectives during the project life cycle will require

consideration of the cost of operation and maintenance. Therefore, the facility's operating

management should also be considered as early as possible, just as the construction

process should be kept in mind at the early stages of planning and programming.

1.3 Types of Contracts

There are many types of contracts that may be used in the construction industry.

Construction contracts are classified according to different aspects. They may be

classified according to the method of payment to the contractor. When payment is based

on prices which submitted by the contractor in his tender, they are called cost-based

Cost Estimating 5 Dr. Emad Elbeltagi

contracts. Examples are cost-reimbursable and target cost contracts. Contracts may be

classified in the point of view of the risk involved. The range of risk runs from a fixed-

price contract to a totally non-risk cost-reimbursable contract at the other end (Figure

1.2).

Figure 1.2: Contracts classification

1.2.1 Lump-sum contract

A single tendered price is given for the completion of specified work to the satisfaction of

the client by a certain date. Payment may be staged at intervals on the completion. The

contract has a very limited flexibility for design changes. The tendered price may include

high level of financing and high risk contingency. Where considerable risk has been

places with the contractor, this contract may lead to cost cutting, trivia claims, or

bankruptcy. Contract final price is known at tender. A lump-sum contract would seem to

prevent risks for the client where in fact it just changes them. An important risk to the

client is that of not receiving competitive bids from desirable contractors who may avoid

a high-risk lump-sum contract. This contract may be used for a turnkey construction. It is

appropriate when work is defined in detail, limited variations are expected, level of risk is

low and quantifiable, and client does not wish to be involved in the management of his

project.

1.2.2 Admeasurement contract

In this type of contracting, items of work are specified in Bills of Quantities or Schedule

of Rates. The contractor then specifies rates against each item. The rates include risk

contingency. Payment is paid monthly for all work completed during the month. The

Cost Estimating 6 Dr. Emad Elbeltagi

contract offers a facility for the client to introduce changes in the work defined in the

tender documents. The contractor can claim additional payment for any changes in the

work content of the contract. Claims resolution is very difficult because the client has no

knowledge of actual cost or hidden contingency. Tender price is usually increased by

variations and claims. Two forms of admeasurement contract are usually used: bill of

quantities and schedule of rates.

The admeasurement contract is well understood and widely used. It can be used when

little or no changes are expected, level of risk is low and quantifiable, and when design

and construction need to be overlapped.

1.2.3 Cost-reimbursable contract (cost-plus contract)

The contractor is reimbursed for actual cost plus a special fee for head office overheads

and profit, no special payment for risk. Payment may be made monthly in advance. The

contract involves a high level of flexibility for design changes. Final price depends on

changes and extent to which risks materialize. The contractor must make all his records

and accounts available for inspection by the client or by some agreed third party. The fee

may be a fixed amount or a percentage of actual costs. This contract has no direct

financial incentives for the contractor to perform efficiently. It may be used when it is

desirable for design to proceed concurrently with construction and when the client wishes

to be involved in contract management.

1.2.4 Target cost contract

Cost targets may be introduced into cost-reimbursable contracts. In addition to the

reimbursement of actual cost plus percentage fee, the contractor will be paid a share for

any saving between target and actual cost, while the fee will be reduced if actual cost

exceeds the target. The target figure should be realistic and the incentive must be

sufficient to generate the desired motivation. Specified risk' can be excluded from the

tendered target cost. When these occur, the target cost is adjusted accordingly and the

client pays the actual cost incurred by the contractor. The target may also b' adjusted for

Cost Estimating 7 Dr. Emad Elbeltagi

major changes in work and cost inflation. This contract can be used in the same

circumstances as the cost-plus contract.

1.4 Estimating

Estimating is not an exact science. Knowledge of construction, common sense and

judgment are required. Estimating material costs can be accomplished with a relatively

high degree of accuracy. However, accurate estimating of labor and equipment costs is

considerably more difficult to accomplish. Estimating material costs is a relatively simple

and easy task. The quantity of materials for a particular job can be accurately calculated

from the dimensions on the drawings for that particular job. After the quantity of material

is calculated and knowing the unit prices, the cost could be estimated by multiplying the

quantity by the unit prices. Estimating labor and equipment costs is more difficult than

estimating material costs. The cost of labor and material depends on productivity rates,

which can vary substantially from one job to another. The skill of the labor, job

conditions and many other factors affect the productivity of labor.

Estimating plays important roles in forecasting future events in construction process. It

consists of two distinct tasks: determining the probable cost and determining the probable

time to build a project

Cost estimate has been defined in different ways. For example:

Estimating is the compilation of all the costs of the elements of a project or effort

included within an agreed upon project scope. To a contractor, this is the cost that

will most likely be incurred to complete the project as defined in the contract

documents and to turn it over to the owner. In another definition, it is the production

of a statement of the approximate quantity of materials, time and costs to perform

construction decisions. Cost estimating is, also defined as, the process of analyzing a

specific scope of work and predicting the cost of performing the work. The basic

challenges the construction contractor faces are to estimate the cost of constructing a

project, schedule the specific construction activities, and then build the project within

the estimated cost and schedule.

Cost Estimating 8 Dr. Emad Elbeltagi

Cost estimating is the process of analyzing a specific scope of work and predicting the

cost of performing the work. The basic challenges the construction contractor faces are to

estimate the cost of constructing a project, schedule the specific construction activities,

and then build the project within the estimated cost and schedule. The objective of cost

estimate is to produce an accurate, cost effective prediction of what a project will most

likely cost and it needs to be done in different manners at different stages. Cost

Estimating is a complex process involving collection of available and pertinent

Information relating to the scope of a project, expected resource consumption and future

changes in resource costs. At the beginning of a project, the estimate cannot be expected

to carry a high degree of accuracy since little information is known. As the design

progresses more information is known and accuracy should improve (Figure 1.3).

Required information: Detailed plans, specifications, available site data, available

resource data (labor, material, & equipment), contract documents, resource cost

information, pertinent government regulations, applicable owner requirements. Various

names have been given to estimates by several organizations. However, there is no

industry standard that has been established for defining estimates.

Figure 1.3: Cost estimate stages

Cost Estimating 9 Dr. Emad Elbeltagi

1.5 An Estimator

The estimator (or quantity surveyor, or cost engineer) is the person who prepares

estimates in the planning, design, and perhaps construction stages. An estimator is always

involved for studies requiring thorough understanding of the principles and methods of

engineering economics. He or she must often work closely with managers, accountants,

financial analysts, and engineers to forecast the cash or borrowing needs for the project.

As major decision is made from information contained in the conceptual or preliminary

estimate, this places a responsibility and liability on the estimator. He or she will risk

reputation when insufficiently accurate estimate is prepared for a bid but the owner or the

contractor will risk money.

A good estimator must conceptualize the complete building before it is fully designed. He

or she must be able to think, and perceive the details of the project. The estimator must

also have the ability to anticipate design decisions and communicate those assumptions

made during the conceptual estimating process. He or she must also be knowledgeable of

the expected life of construction materials, accounting, taxation, law, economics, and

awareness of engineering design. Qualifications for a good estimator include: patience of

detail; technical knowledge; good memory; knowledge of construction process; able to

plan the works; have an idea of relative costs and good judgment. An estimator must not

spend so much time and effort to analyze unnecessary details in determining the costs of

insignificant items as the estimating will take time and be expensive. In a bill of

quantities for civil engineering project, 80% of the costs can be attributed to 20% of the

items, and vice versa.

1.6 Purpose of Estimating

The purpose of estimating is to determine the forecast costs required to complete a

project in accordance with the contract plans and specifications. For any given project,

the estimator can determine with reasonable accuracy the direct costs for materials, labor,

and equipment. The bid price can then be determined by adding to the direct cost the

costs for overhead (indirect costs required to build the project), contingencies (costs for

Cost Estimating 10 Dr. Emad Elbeltagi

any potential unforeseen work), and profit (cost for compensation for performing the

work). The bid price of a project should be high enough to enable the contractor to

complete the project with a reasonable profit, yet low enough to be within the owner's

budget.

There are two distinct tasks in estimating: determining the probable cost and determining

the probable time to build a project. With an increased emphasis on project planning and

scheduling, the estimator is often requested to provide production rates, crew sizes,

equipment spreads, and the estimated time required to perform individual work items.

This information, combined with costs, allows an integration of the estimating and

scheduling functions of construction project management. Because construction estimates

are prepared before a project is constructed, the estimate is, at best, a dose approximation

of the actual costs. The true cost of the project will not be known until the project has

been completed and all costs have been recorded.

1.7 Construction Project Costs

The principal components of a contractor's costs and expenses result from the use of

labors, materials, equipment, and subcontractors. Additional general overhead cost

components include taxes, premiums on bonds and insurance, and interest on loans. The

sum of a project's direct costs and its allocated indirect costs is termed the project cost.

The costs that spent on a specific activity or project can be classified as;

- Fixed cost: costs that spent once at specific point of time (e.g., the cost of

purchasing equipment, etc.)

- Time-related cost: costs spent along the activity duration (e.g., labor wages,

equipment rental costs, etc.)

- Quantity-proportional cost: costs changes with the quantities (e.g., material cost)

Project direct costs

The costs and expenses that are incurred for a specific activity are termed direct costs.

These costs are estimates based on detailed analysis of contract activities, the site

Cost Estimating 11 Dr. Emad Elbeltagi

conditions, resources productivity data, and the method of construction being used for

each activity. A breakdown of direct costs includes labor costs, material costs, equipment

costs, and subcontractor costs.

Project indirect costs

Other costs such as the overhead costs are termed indirect costs. Part of the companys

indirect costs is allocated to each of the company's projects. The indirect costs always

classified to: project (site) overhead; and General (head-office) overhead.

Project overhead

Project overhead are site-related costs and includes the cost of items that cannot be

directly charged to a specific work element and it can be a fixed or time-related

costs. These include the costs of site utilities, supervisors, housing and feeding of

project staff, parking facilities, offices, workshops, stores, and first aid facility. Also,

it includes plants required to support working crews in different activities.

A detailed analysis of the particular elements of site-related costs is required to

arrive at an accurate estimate of these costs. However, companies used to develop

their own forms and checklists for estimating these costs. Sit overhead costs are

estimated to be between 5% - 15% of project total direct cost.

General overhead

The costs that cannot be directly attributed a specific project called general

overhead. These are the costs that used to support the overall company activities.

They represent the cost of the head-office expenses, mangers, directors, design

engineers, schedulers, etc. Continuous observations of the company expenses will

give a good idea of estimating reasonable values for the general overhead expenses.

Generally, the general overhead for a specific contract can be estimated to be

between 2% - 5% of the contract direct cost. The amount of the general overhead

that should be allocated to a specific project equals:

Project direct cost x general overhead of the company in a year

Expected sum of direct costs of all projects during the year

Cost Estimating 12 Dr. Emad Elbeltagi

Having defined the direct costs, indirect costs, then the project total cost equals the sum

of both direct and indirect costs.

1.8 Types of Cost Estimating

There are many types of cost estimates that can be performed on a project, each type

having different levels of accuracy. The estimating process becomes increasingly more

expensive as more detailed and accurate techniques are applied. Estimating can be

categorized into several classes according to purposes, budget, limitation, time, and

accuracy. Generally, the nature and characteristics of estimating can be summarized as

follow: accuracy improves with the development of the project such that the distribution

of errors narrows from feasibility to settlement; underestimates are more likely than

overestimates and the final cost of a project cannot be established until the settlement of

project accounts.

For example, cost estimates is divided into seven types: 1- Preliminary or rough cost or

approximate estimate is prepared to decide the financial aspect and accompanied by

detailed report, brief specifications, layout plan showing the proposal in hand; and brief

idea of rates for different items; 2- Detailed estimate, is prepared in detail prior to inviting

of tenders; 3- Quantity estimate, is a complete estimate of quantities for all items of work

required to complete a project; 4- Revised estimate is also a detailed estimate and is

prepared afresh, when the original sanctioned detailed estimate exceeds by 5% or more;

5- Annual repair or maintenance prepared in order to keep the structures in proper

condition; 6- Supplementary estimate, when some additions are done in the original

work; and 7- Extension estimate, when some changes and extensions are required to be

made in old work.

Typically, cost estimates are divided into three major types: 1- Conceptual cost estimates

are developed using incomplete project documentation; 2- Semi-detailed cost estimates

are prepared when parts of the project have been completely designed; and 3- Detailed

cost estimates are prepared based on fully developed construction drawings and

Cost Estimating 13 Dr. Emad Elbeltagi

specifications. The accuracy of the estimate depends on the completeness of the contract

documents and the experience of an estimator. The typical accuracy of the various types

of cost estimates is shown in Table 1.1.

Table 1.1: Accuracy of different types of cost estimates

Type of Estimate Construction Document Development

Expected

Percent Error*

Conceptual

Schematic Design

0-30% Construction Documents

10-20 %

Semi-Detailed

Design Development

30-90% Construction Documents

5-10 %

Detailed 90-100% Plans and Specifications 2-4 %

* Percent error means the expected variation between cost estimate and actual cost

There are many types of cost estimates and re-estimates for a project based on the stage

of project development. Estimates are performed throughout the life of a project,

beginning with the first estimate and extending through the various phases of design and

into construction. Initial cost estimates form the basis to which all future estimates are

compared. Future estimates are often expected to agree with (i.e., be equal to or less than)

the initial estimates. However, too often the final project costs exceed the initial

estimates. Estimates are performed throughout the life of a project, beginning with the

first estimate and extending through the various phases of design and into construction, as

shown in Figure 1.4.

Traditionally, the different classifications of estimates conclude that there are three main

types of estimates:

1. Conceptual cost estimates.

2. Semi-detailed cost estimates.

3. Detailed cost estimates.

Cost Estimating 14 Dr. Emad Elbeltagi

Figure 1.4: Level of accuracy of cost estimates

1.8.1 Conceptual estimate

A conceptual estimate is also known as a top-down, order of magnitude, feasibility,

analogous, or preliminary estimate. It is the first serious effort made at attempting to

predict the cost of the project. A conceptual estimate is usually performed as part of the

project feasibility analysis at the beginning of the project. In this way, the estimate is

made with limited information on project scope, and is usually made without detailed

design and engineering data.

The conceptual estimate is also defined as approximate estimate and used to know the

budget for a project. Considerable experience and judgment are required to obtain a

dependable approximate estimate for the cost.

1.8.2 Semi-detailed estimate

Semi-detailed cost estimates are developed while basic design decisions are being made

to verify that the project can be constructed at its intended scope within the owner's

budget. Some aspects of the project may be completely designed. Detailed estimating

methods can be used to estimate the cost of project components that have been designed,

and conceptual estimating methods are used to estimate the cost of those components that

remain to be designed. This means that databases are used to estimate the cost of

components for which the design is not complete, and project data are used to estimate

Cost Estimating 15 Dr. Emad Elbeltagi

the cost of components for which the design is complete. Therefore, these estimates are

known as semi-detailed cost estimates.

1.8.3 Detailed estimate

A detailed estimate is also known as a bottom-up, fair-cost, or bid estimate. Detailed

estimates are prepared once the design has been completed and all construction

documents prepared. The estimator divides the project into individual elements of work

and estimates the quantities of work for each element. Next, the individual elements of

work are priced to determine an estimated cost for each one. The estimated costs are

summed, and overhead costs are added to cover the contractor's cost of managing the

work.

The breakdown of tender price is illustrated in Figure 1.5. The tender price consists of

two components, the construction cost estimate and mark-up (margin). The direct cost is

the combined costs of labor, equipment, material, and subcontractors costs. The addition

of site overheads and office overheads to the direct cost produces the construction cost

estimates. The second component of the tender price is the mark-up (margin) which

consists of the profit margin, risk allowance, and financial charge.

Figure 1.5: Schematic diagram of the structure of tender price

Cost Estimating 16 Dr. Emad Elbeltagi

The various estimates discussed above are carried out in sequence, the previous cost

estimate being the input to the next one. The estimates are successively refined,

incorporating new information and thus keeping a continuously updated estimate that

becomes the budget, available for control process. As the project progresses, the amount

of unknowns and uncertainties decreases, while the level of details and the project

information increases. In this way, the accuracy of the estimate improves as it moves

from conceptual to detailed estimate.

A detailed estimate is prepared by determining the costs of materials, labor, equipment

and subcontractor work. Detailed estimate is prepared from a complete set of contract

documents before the submission of a bid. It follows a systematic procedure begins with

a thorough review of the complete set of contract documents, drawing and technical

specification. A site visit should be done to observe factors that can influence the cost of

construction such as: available space for material storing, security, control of traffic and

existing underground utilities.

The estimator prepares a material quantity take-off of all materials from the drawings.

The quantity of material multiplied by the unit cost of the materials yields the material

cost. The quantity of work required of equipment is divided by the equipment production

rate and then multiplied by the unit cost of equipment to obtain the total cost of

equipment and similarly, the cost of labor are calculated.

The direct cost of a project includes material, labor, equipment, and subcontractor costs.

Upon the completion of the estimate of direct costs, the estimator must determine the

indirect costs of taxes, bonds, insurance and overhead required to complete the project. A

risk analysis of uncertainties is required to determine an appropriate contingency to be

added to the base estimate to account for the unforeseen work that develops during

construction. Upon calculation of the direct and indirect costs, analysis of risk and

assignment of contingency, a profit is added to the estimate to establish the bid price. The

amount of profit can vary considerably, depending on numerous factors such as the size

and complexity of the project, amount of work in progress by the contractor, accuracy

Cost Estimating 17 Dr. Emad Elbeltagi

and completeness of the bid documents, competition for work. The steps for preparing a

detailed estimate are listed in Table 1.2.

Table 1.2: Steps for preparing a detailed cost estimate

1

Review the scope of project. Consider the effect of location, security, traffic,

available storage space, underground utilities, etc. on costs.

2 Determine quantities. Perform a material quantity takeoff for all work items.

3 Obtain suppliers bids.

4 Price material. Material cost = quantity x unit price.

5 Price labor based on their probable production rate.

6 Price equipment based on their probable production rates.

7 Obtain specialty contractors bids.

8 Calculate taxes, bonds, insurance and overhead.

9 Contingency and markup. Add costs for potential unforeseen work.

10 Profit. Add costs for compensation for performing the work.

1.9 Quantity Takeoff

To prepare an estimate, the estimator reviews the plans and specifications and performs a

quantity takeoff to determine the type and amount of work required to build the project.

The quantity of material in a project can be accurately determined from the drawings.

The estimator must review each sheet of the drawings, calculate the quantity of material

and record the amount and unit of measure. The unit cost of different materials should be

obtained from material suppliers and used as the basis of estimating the costs of materials

for the project. If the costs of the materials do not include delivery, the estimator must

include appropriate costs for transporting materials to the project.

Each estimator must develop a system of quantity takeoff that ensures that a quantity is

not omitted or calculated twice. A well-organized check-list of work will help reduce the

chances of omitting an item. The estimator must, also, add an appropriate percentage for

waste for those items where waste is likely to occur during construction. The material

quantity takeoff is extremely important for cost estimating because it often establishes the

quantity and unit of measure for the costs of labor and contractors equipment.

Cost Estimating 18 Dr. Emad Elbeltagi

1.10 Production Rates

To determine the time required to perform a given quantity of work, it is necessary to

estimate the probable rates of production of the equipment or labor. These rates are

subject considerable variation, depending on the difficulty of the work, skill of the labor,

management conditions and the condition of the equipment.

A production rate is the number of units of work produced by a unit of equipment or a

person in a specified unit of time. The time is usually one hour or one day. The rate could

be determined during an interval when production is processing at the maximum possible

speed. However, delays or interruptions may hinder the work at any time and reduce the

average production rate to less than the ideal rates. So, the production rate is always

lowered by a factor to account for such interruptions.

For example, a backhoe with 1 m

3

bucket may be capable of handling 3 bucket-loads per

minute under ideal conditions. However, on a given job, the average volume per bucket

may be only 0.8 m

3

and the backhoe may be actually operating only 45 min/hr. for these

operating conditions, the average output can be calculated as follows:

The ideal output: 3 m

3

/min x 60 min/hr = 180 m

3

/hr

The bucket factor = 0.8

The efficiency factor = 45/60 = 0.75

The combined operating factor = 0.8 x 0.75 = 0.6

The average output = 0.6 x 180 = 108 m

3

/hr

The average output should be used in computing the time required to complete a job.

1.11 Exercises

1. State if True (T) or False (F):

Cost Estimating 19 Dr. Emad Elbeltagi

a. Contract changes are more likely to occur on a single fixed price contract than

on a cost plus a fee contract.

b. In lump sum contracts, it is allowed to change in the quantity of work

performed within a limit of 25%.

c. In the admeasurement contracts, the item description, quantity, unit of

measure, unit cost and the total cost in the B.O.Q should be cleared.

d. The owner has the ability to know the contractor profit in the unit price

contracts.

e. The direct costs are the summation of the cost of the labor, equipment,

materials, and subcontractors.

f. Overheads include the cost of items which cannot be directly charged to a

specific work element.

g. The construction project must have a defined goal or objective.

h. The construction project must have a defined beginning and end.

2. What are the main types of construction contracts?

3. Explain what is meant by the two terms: Price-based Contracts and Cost-based

Contracts.

4. Compare the following types of contracts from the point of view of flexibility for

design changes and variations:

- Lump Sum.

- Admeasurement.

- Target cost.

5. Compare the lump sum, admeasurements, and cost plus contracts from the

following point of view:

- Early start to construction.

- Risk sharing.

6. Select the right answer:

I. Site selection and financing would be the responsibility of which project

member.

a. Owner b. Designer

c. Construction project manager d. Subcontractor

Cost Estimating 20 Dr. Emad Elbeltagi

II. Which of the following is not a characteristic of a project?

a. Having a specific goal b. Having a defined beginning and end

c. Resources being consumed d. usually being performed only once

e. Never being found outside the construction field

III. The advertising for contractors and review of contractors bids occurs during

which project phase.

a. Procurement b. Design

c. Construction d. Conceptual planning

IV. As-built drawings, warranties, and operation manuals are all provided to the

owner during which project phase.

a. Design b. Conceptual planning

c. Construction d. Project closeout

V. As project moves on in time, the ability to change the project

becomesdifficult andexpensive.

a. more, less b. less, less

c. more, more d. less, more

7. Briefly describe the project life cycle.

8. Explain how the cost could be transferred to a tender price?

9. Give three examples of direct and indirect costs.

10. The cost spent of a given activity could be classified into ., .. and

11. What are the different types of cost estimate and when each one is used?

Cost Estimating 21 Dr. Emad Elbeltagi

CHAPTER 2

QUANTITY TAKE-OFF

The quantity takeoff is an important part of the cost estimate. It must be as accurate as

possible and should be based on all available engineering and design data. Use of

appropriate automation tools is highly recommended. Accuracy and completeness are

critical factors in all cost estimates. An accurate and complete estimate establishes

accountability and credibility of the cost engineer, therefore, providing greater confidence

in the cost estimate. The estimate contingencies for programming purposes reflect the

estimate confidence.

2.1 Importance of Quantity Takeoff and Required Documents

The quantity of material in a project can be accurately determined from the drawings.

The estimator must review each sheet of the drawings, calculate the quantity of material

and record the amount and unit of measure. Each estimator must develop a system of

quantity takeoff that ensures that a quantity is not omitted or calculated twice. A well-

organized check-list of work will help reduce the chances of omitting an item. The

estimator must, also, add an appropriate percentage for waste for those items where waste

is likely to occur during construction. The material quantity takeoff is extremely

important for cost estimating because it often establishes the quantity and unit of measure

for the costs of labor and contractors equipment.

2.1.1 Contract documents

The contract is defined by the contract documents, which are developed from the tender

documents. In a logical order, these documents refer to the following subjects:

Cost Estimating 22 Dr. Emad Elbeltagi

Input from the client (task description).

Output of the contract (specifications, results to be achieved).

Prices for the contractor's contribution.

Responsibilities and procedures (liability, resources provided, time schedule,

payment conditions, changes procedures, etc).

Contract documents are usually arranged according to the following sequence:

General (for any project).

Special (for a specialty area of the project).

Supplementary (unique to a given project).

Additional (during bidding or negotiation).

Agreement form (for singing very important and particular clauses).

Modifications (during contract fulfillment).

The complete contract agreement usually consists of the following documents:

Conditions (general, special, supplementary).

Drawing and specifications.

Addenda.

Agreement form.

Modifications.

The most important document from the legal point of view is the agreement. It is

sometimes called the contract. Since so many documents are included as contract

documents, the agreement is the better term for this particular one. The form of the

agreement can be standardized and used for many projects, or a unique document can be

prepared for each project. The standard form of agreement prescribed by the American

Institute of Architects has proved to be satisfactory and has been used on many building

projects with good results. The form followed for non-building projects is often more

varied. Man: agencies have own standard forms, which are used on all their projects.

Cost Estimating 23 Dr. Emad Elbeltagi

Information usually included in the agreement of three parts. The first part is a short

introductory paragraph which defines the parties, gives the date of the agreement, and

state that each party agrees to what follows. The second part contains the elements of

contract and defines the work to be undertaken. The final paragraph confirms the

agreement and provides space for signatures of the parties. Thus, the agreement usually

composed of the following articles:

1. A short introductory paragraph.

2. Scope of the work.

3. Time of completion.

4. Contract documents.

5. Performance bond.

6. Contractor's insurance.

7. Owner's insurance.

8. Laws, regulations and permits.

9. Payments.

10. Extensions of time.

11. Changes in the work.

12. Owner's right to terminate the work.

13. Contractor's right to terminate the work.

14. Confirmation and signatures.

2.1.2 Quantity take-off: Why?

Owner perspective:

- Initial (preliminary) estimate of the project costs at the different stages of the

project.

- Preparing the BOQ as a requirement of the contract documents.

- Estimating the work done for issuing the contractor payments.

Contractor perspective:

Cost Estimating 24 Dr. Emad Elbeltagi

- Pricing different work items.

- Identifying the needed resources (Labor, Equipment, etc.).

- Project schedule.

- Preparing invoices for work done.

- Subcontractors payments.

- Review and control of crews production rates.

2.2 Quantity Development

After the scope has been analyzed and broken down into construction tasks, each task

must be quantified prior to pricing. Equal emphasis should be placed on both accurate

quantity calculation and accurate pricing. Quantities should be shown in standard units

of measure and should be consistent with design units. Assistance for preparing

takeoffs may be provided by others within the organization in support of cost

engineering; however, the responsibility for the accuracy of the quantities remains with

the cost engineer. Distinction should be made between net quantities without waste

versus quantities that include waste or loss. This is necessary to ensure duplication does

not occur within the estimate.

The detail to which the quantities are prepared for each task is dependent on the level of

design detail. Quantity calculations beyond design details are often necessary to

determine a reasonable price to complete the overall scope of work for the cost estimate.

A simple example would be fabrication waste material that is a material cost to the

project. Project notes will be added at the appropriate level in the estimate to explain the

basis for the quantity calculations, to clearly show assumed quantity allowances or

quantity contingencies, and to record quantities determined by cost engineering judgment

that will be reconciled upon design refinement. Use the following recommended

guidelines in quantity development:

- Coordinate the quantity takeoff process and plan with the estimator.

- Ensure full project scope is reflected within the estimate.

- Include a list of materials in quantity takeoffs.

Cost Estimating 25 Dr. Emad Elbeltagi

- Utilize a process that easily records the quantity development, i.e., document

source and date, estimator name and date, location within the project,

demonstrated calculations and additions such as waste or loss.

- Use a systematic approach similar to the construction methodology required.

- Check scales and dimensions on each drawing sheet.

- Highlight or mark drawing areas where quantities have been determined to ensure

all scope is captured but not double counted.

- Consider items that have no material but still require cost, e.g., job office

overhead (JOOH), task setup, training and certifications, and labor preparation.

- Develop quantities within a reasonable range for the work using decimals where

critical.

- Add a certain amount of waste, loss, drop off, or length related to the material

purchases for a bulk order. Ensure this addition is separate from the original

quantity measured.

- Select a natural stopping point during work interruptions.

- Coordinate with designers if the design appears in error, if a better approach is

discovered, or a value engineering process is warranted.

2.3 Bill of Quantities

The Bill of Quantities (BOQ) is defined as a list of brief descriptions and estimated

quantities. The quantities are defined as estimated because they are subject to

admeasurement and are not expected to be totally accurate due to the unknown factors

which occur in civil engineering work. The objective of preparing the Bill of Quantities is

to assist estimators to produce an accurate tender efficiently and to assist the post-

contract administration to be carried out in an efficient and cost-effective manner. It

should be noted that the quality of the drawings plays a major part in achieving theses

aims by enabling the taker-off to produce an accurate bill and also by allowing the

estimator to make sound engineering judgments on methods of working. Figure 2.1

shows a sample of a bill of quantities.

Cost Estimating 26 Dr. Emad Elbeltagi

Fig. 2.1: Bill of quantities sample

Cost Estimating 27 Dr. Emad Elbeltagi

The bill of quantities, when completed, is traditionally presented in trade format; that is,

in a given order, for example:

- Demolition and alteration

- Groundwork

- Concrete work

- Masonry

- Etc.

Also, the bill of quantities is classified into the following work groups:

- Civil works which includes: Earth works (leveling, excavation, backfilling,

transportation of excavated soil); Foundation works (plain and reinforced

concrete, piling foundations); Brick works (internal and external); Skelton

reinforce concrete (columns, beans, slabs and stairs); Water proofing; Staircases;

Plastering, Flooring; Painting; Metal works (windows, doors, accessories); etc.

- Sanitary works which includes: Water feeding systems; Internal and external

plumbing works; Finishes of plumbing works; etc.

- Electrical works which includes: Electrical cables; Wiring; Accessories; Internal

connections; etc.

- Mechanical works which includes: Air conditioning systems; Elevators; etc.

2.4 Measurement Practice

It is vitally important that measurement practice applied to buildings is both accurate and

consistent. There are a number of situations that require a quantity surveyor to measure

and record dimensions from both drawings as well as on site, depending on the stage of

the project. In order to standardize measurement rules and conventions, there are a

number of standard codes and methods of measurement that are available. These are

outlined below.

There are various approaches to measurement for bills of quantities and these are as

follows:

- Each (numbers): Piles, doors, Windows, Precast concrete, etc.

- Length (meter): Windows sills, Pipes, Skirts, stair steps, etc.

Cost Estimating 28 Dr. Emad Elbeltagi

- Area (Square meter): Flooring, painting, plastering, Brick walls (12 cm or less),

etc.

- Volume (Cubic meter): Brick walls (>12 cm thick), Excavation, Backfilling,

Reinforced Concrete, etc.

- Weight (Ton): Metallic works, Reinforcement steel, etc.

- Lump Sum: Some electrical and plumbing works, Manholes, etc.

- Effort (Man-day): Renting of equipment or labor, etc.

Figure 2.2 shows a sample of the quantity surveying table for quantity take-off.

Fig. 2.2: Quantity take-off table

2.4.1 Earth works

Earth works comprises site level, excavation, backfilling and transportation of excavated

materials.

Cost Estimating 29 Dr. Emad Elbeltagi

Excavation:

- Quantities are calculated based on the dimensions of the foundation in plans from

the owner perspective.

- Contractors should consider the excess of material excavated to all for safe

operations.

- Prices differ based on the soil type, deep of excavation, ground water level, site

location, shoring system, Equipment used, etc.

- Unit of measurement is cubic meter (volume).

- Consider the following example (Figure 2.3).

Fig. 2.3: Plan and cross section of building foundation

The length of excavation = 5.4 2 + (4.4 2) 2 = 15.6 m

Depth of excavation = 1.8 m

Width of excavation = width of plain concrete footing = 1.0 m

Volume = 15.6 1.8 1.0 = 18.8 m

3

- Consider another example (Figure 2.4). Plain concrete dimensions (1.2 2.0 0.2

m), reinforced concrete footings dimensions (0.8 1.6 0.4 m); depth of

excavation 1.2 m and ground beams cross section is (0.25 0.4 m). Find the

Cost Estimating 30 Dr. Emad Elbeltagi

volume of the excavated material (see Figure 2.4). Distance between centerlines is

5 m.

Fig. 2.4: Footing foundation plan and cross section

Excavation for footings = 2 1.2 2.0 1.2 = 5.76 m

3

Excavation for smell = (5 2 1) 0.6 0.25 = 0.45 m

3

Volume = 5.76 + 0.45 = 6.21 m

3

Backfilling:

- Unit of measurement is cubic meter (volume)

- Backfilling = Excavation volume of all works inside the excavated pit (footings,

smells, column necks, brickwork, etc.) + amount above GL (or amount below

GL) as shown in Figure 2.5.

Fig. 2.5: Backfilling quantities calculations

Cost Estimating 31 Dr. Emad Elbeltagi

- Consider the example shown in Figure 2.4, the volume of backfilling could be

calculated as follow:

Volume of backfilling = excavation concrete brick

Volume of concrete = 15.6 1 0.4 = 6.24 m

3

Volume of brick = 15.6 0.4 1.4 = 8.736 m

3

Volume of backfilling = 18.8 (6.24 + 8.736) = 3.824 m

3

Site leveling:

- Measured in m

2

(area) if thickness less than 30 cm.

- Measured in m

3

(volume) if thickness more than 30 cm.

Soil transportation:

- Transported soil = vol. of exc. vol. of backfilling + additional soil at site

- Add swelling factor based on the soil type: 5% sandy soil. 15% clayey soil and

25% for demolition material. (owner or contractor)

2.4.2 Concrete works:

Concrete works comprises of both plain concrete (PC) and reinforced concrete (RC).

Plain concrete (PC):

- Measured in m

2

(area) if thickness < 20 cm.

- Measured in m

3

(volume) if thickness 20 cm.

- Average thickness should be mentioned when measurement is done by area.

Reinforced concrete (RC):

- All RC elements measured by volume (m3) except hollow block slabs measured

by area (m

2

).

- Domes, cylindrical roofs and shells measured by area in the horizontal projection.

2.4.3 Brick works:

Cost Estimating 32 Dr. Emad Elbeltagi

The rules and precautions that should be followed when measuring brick works are

(Figure 2.6):

- Measured in m

2

(by area) if thickness <25 cm.

- Measured m

3

(by volume) if thickness 25cm.

- Deduct all openings.

- Deduct half the area (volume) of arches.

- Deduct all Concrete elements.

- Facades are measured by area.

- Separate item for each brick type

Fig. 2.6: Cross section of brick walls

2.4.4 Plastering:

Plaster works are measured according to its location of being internal or external works.

Internal plaster work measured as it is (engineering measurement).

Cost Estimating 33 Dr. Emad Elbeltagi

Internal Plaster:

- Engineering measurement by area (m

2

).

- All openings are deducted.

- All openings sides are added.

- Inclined slabs are calculated based on their horizontal projection.

External plaster:

- Measured by area (m

2

).

- Openings with areas < 4 m2 are kept with deduction.

- Deduct half the area of the openings 4 m

2

.

- Openings with areas < 4 m

2

are kept with deduction.

- Cantilever slabs < 1 m projection not added.

- Add half the area of cantilever slabs 1 m.

2.5 Example Application: Substructure

As with most measurement exercises it is good practice to start with a taking-off list

containing all the items that have to be included on a Substructure taking-off list:

Site preparation Removing trees and shrubs

Lifting turf

Top soil/removing/preserving

Excavation Reduce levels/disposal of excavated material

Excavating trenches/disposal of excavated material

/filling/surface treatments

Earthwork support to sides of reduced level/sides of trenches

Concrete Foundations

Beds/formwork/damp-proof membrane

Masonry Brick walls/facings

Forming cavities

Filling to cavities

Damp-proof courses

Site levels

Cost Estimating 34 Dr. Emad Elbeltagi

Virgin sites will almost certainly be covered with a layer of vegetation that has to be

removed prior to excavation and stored separately or removed from site. Top soil cannot

be used for backfilling as it would, over time, cause damage to the substructure. The

usual default depth for topsoil is 150 mm although it could be more than this and a test pit

may be dug to accurately determine the actual depth. Figure 2.7 shows a 5 m grid of a

survey of levels taken on a proposed site.

Fig. 2.7: Grid survey of the proposed site

The site is required to be reduced to a level of 35.62 and in order to calculate the volume

of excavation required the average level of the site must be determined. This can be quite

easily done by calculating the average level:

Average site level = (35.90 5 + 35.86 3 + 35.89 2 + 35.92 + 35.84 2 +

35.88 2 + 35.85 + 35.87 2) / 18 = 35.87 m

Reduced site level = 35.62 m

Average excavation depth = 0.25 m

Total excavation volume = 0.25 25 10 = 62.5 m

3

Figure 2.7 shows the ground floor plan of the building with the external and internal

walls.

Cost Estimating 35 Dr. Emad Elbeltagi

Fig. 2.7: Ground floor plan showing external and internal walls

Figure 2.8 shows a cross-section through the trench and reduced level excavation

required for the external wall in the Example application. Note that the levels have been

reduced internally by 150 mm to allow for a 150 mm thick bed of hardcore. The top of

the hardcore bed when compacted will be covered or blinded with sand to prevent the

damp proof membrane, a layer of polythene sheet with a minimum thickness of 0.30 mm,

being perforated by the hardcore. It is important that the material used as hardcore is inert

and free from chemicals, vegetable or other deleterious matter. It is a requirement of the

Building Regulations that insulation is incorporated into the floor construction and in this

case 50 mm thick rigid insulation board has been used. The bottom of the trench

excavation when completed will be compacted prior to the concrete being poured, this is

to prevent the soil being incorporated into the concrete and weakening the mix. This is

particularly important when reinforced concrete is being used, where it is common to

blind the bottom of the excavation with a weak mix concrete before the reinforcement is

placed in position.

Cost Estimating 36 Dr. Emad Elbeltagi

Fig. 2.8: Cross sections of external and internal walls

Working space

Working space is to be measured in circumstances where workmen have to operate in

situations that require them to work in trenches below ground level, for example when

working with formwork, rendering, tanking or protection. It is measurable as a superficial

item where there is less than 600 mm between the face of the excavation and the work;

all additional earthwork support, disposal, backfilling and breaking out are deemed to be

Cost Estimating 37 Dr. Emad Elbeltagi

included with the working space item. This is another contractors risk item as he must

decide and price what space he thinks is required as illustrated in Figure 2.9.

Fig. 2.9: Work space allowance

The different quantities take-off is shown as presented below.

Cost Estimating 38 Dr. Emad Elbeltagi

Cost Estimating 39 Dr. Emad Elbeltagi

Cost Estimating 40 Dr. Emad Elbeltagi

Cost Estimating 41 Dr. Emad Elbeltagi

Cost Estimating 42 Dr. Emad Elbeltagi

Cost Estimating 43 Dr. Emad Elbeltagi

2.6 Exercises

1. Consider the following figure, it is required to prepare a quantity take-off for the

following types of work to be included on the bill of quantities:

a. Excavation.

b. . Backfilling

c. Plain concrete footing

d. Reinforced concrete footings and smells and column necks till the ground

level.

e. Insulation.

Cost Estimating 44 Dr. Emad Elbeltagi

2. Consider the following figure; find the same requirements as above.

Cost Estimating 45 Dr. Emad Elbeltagi

3. Perform quantity surveying for the different work items of the building shown

below.

Cost Estimating 46 Dr. Emad Elbeltagi

4. Consider the following figure; find the same requirements as above.

Cost Estimating 47 Dr. Emad Elbeltagi

CHAPTER 3

CONCEPTUAL COST ESTIMATING

At the beginning of a project by the owner, prior to any design, only limited information

is known about a project. However, the owner must know the approximate to evaluate the

economic feasibility of proceeding with the project. Thus, there is a need to determine the

approximate cost of a project during its conceptual phase.

A conceptual estimate is also known as a top-down, order of magnitude, feasibility,

analogous, or preliminary estimate. It is the first serious effort made to predict the cost of

the project. A conceptual estimate is usually performed as part of the project feasibility

analysis at the beginning of the project. In this way, the estimate is made with limited

information on project scope, and is usually made without detailed design and

engineering data. The conceptual estimate is also defined as approximate estimate and

used to know the budget for a project. Considerable experience and judgment are

required to obtain a dependable approximate estimate for the cost.

3.1 Conceptual Cost Estimating Basics

Conceptual cost estimating is an important pre-design planning process. The following

subsections present the conceptual cost estimating definitions, characteristics,

importance, preparation, process, and outputs.

3.1.1 Conceptual cost estimating definition

A conceptual estimate is an estimate prepared by using engineering concepts and

avoiding the counting of individual pieces. As the name implies, conceptual estimates are

Cost Estimating 48 Dr. Emad Elbeltagi

generally made in the early phases of a project, before construction drawings are

completed, often before they are hardly begin. The first function of a conceptual estimate

is to tell the owner about the anticipated cost, thus presenting useful information for the

owner in contemplating the project feasibility and further development. A conceptual

estimate is also used to set a preliminary construction budget, and to control construction

costs at the most critical stage, during the design. Conceptual cost estimating is defined as

the forecast of project costs that is performed before any significant amount of

information is available from detailed design and with incomplete work scope definition,

with the purpose of using it as the basis for important project decisions like go/no-go and

the appropriation of funds decisions.

3.1.2 Conceptual cost estimating characteristics

The first recognized characteristic of conceptual estimating, like all other estimating, is

the inexactness in the process. With the absence of data and with shortage of time, there

may be no other way to evaluate designs but to use opinion. Conceptual estimating is a

mixture of art and science; the science of estimating tells the cost of past work. The art is

in visualizing a project and the construction of each detail, selecting comparative costs

from past projects and adjusting them to new conditions.

The second characteristic of conceptual estimating is that its accuracy and validity are

highly related to the level of information provided by the project scope. The availability

of a good, complete scope definition is considered the most crucial factor for conceptual

estimating.

The third characteristic of conceptual estimating is that it is a resource restricted activity.

The main resources for conceptual estimating are information, time, and cost. Due to the

fact that conceptual estimating is performed in the early stages of the project, the scope

information available is usually restricted in detail as well as in precision. In addition, the

time and cost available for making the estimate is restricted. Conceptual estimating is

used to determine the feasibility of a project quickly or screen several alternative designs.

Therefore, the estimate, although important, cannot be given much time and resources.

Cost Estimating 49 Dr. Emad Elbeltagi

3.1.3 Importance of conceptual cost estimates

Preliminary estimate assists the overall cost-control program by serving as the first check

against the budget. It will indicate the cost overruns early enough for the project team to

review the design for possible alternates. Since preliminary estimate is made prior to the

completion of detailed design, the margin of error will be relatively large. Then, the

larger contingency should be applied. The contingency varies with the amount of design

information available and the extent of cost information obtainable from similar projects.

3.1.4 Preparation of conceptual cost estimates

A generic conceptual cost estimating preparations is shown in Figure 3.1, the

preparations begins with a request made by management to estimate the cost of a new

project. The most important part of the request is the project scope. The first task for the

estimator is to study and interpret the project scope and produce an estimating plan. The

next task is to collect historical data related to similar past projects. The selection and

usage of these data is crucial for the estimating preparations because inappropriate

information will negatively affect the estimate. The outputs from this stage are the project

conceptual cost estimate and a documented estimating basis used to develop this cost. It

is very important to describe in detail all the information, assumptions, adjustments, and

procedures considered in the estimate. The resulting conceptual cost estimate is then

submitted to management for decision-making.

To prepare an elemental cost plan the following information should be assembled:

A cost analysis of a previous similar building

Sketch plans and elevations of the proposed project

Outline specification/levels of services installation, etc. for the proposed project.

3.1.5 Conceptual Cost Estimating Output

The primary output of the cost estimating effort is the cost estimate. The estimate is

typically expressed in unit cost. Alternative units can be work quantities, material

quantities, or staff work hours. However, for majority of the highway construction

Cost Estimating 50 Dr. Emad Elbeltagi

projects, the unit cost are mostly applicable; therefore, they are frequently used.

Fig. 3.1: Conceptual cost estimating preparations

3.2 Broad Scope of Conceptual Estimates

Prior the design of a project, cost estimate could be prepared based on the cost

information based on previously completed projects similar to the proposed project. The

number of units or size of the project is the only available information. Although the

range of costs varies among projects, the estimator can develop unit costs to forecast the

cost of future projects.

The unit cost should be developed from weighting the data that emphasizes the average

value, yet it should account for the extreme maximum and minimum values. In that

regard Eq. (3.1) can be used for weighting cost data from previous projects.

UC = (A + 4B + C) / 6 (3.1)

Where: UC = forecast unit cost

A = minimum unit cost of previous projects

Request for Estimate

Report to Management

Study & Interpretation

of Information

Collect Additional Information

Conceptual Cost Estimating

Decision

Making

Not Approved

Approved

Preliminary

Budget

Cost Estimating 51 Dr. Emad Elbeltagi

B = average unit cost of previous project

C = maximum unit cost of previous projects

Example 3.1

Use the weighted unit cost to determine the conceptual cost estimate for a proposed

parking that is to contain 135 parked cars. Previous projects data are given in Table

3.1.

Table 3.1: Previous projects cost data

Project No. Cost (LE) No. of cars

1

2

3

4

5

6

7

8

466,580

290,304

525,096

349,920

259,290

657,206

291,718

711,414

150

80

120

90

60

220

70

180

Solution

The unit cost per car can be calculated as given in Table 3.2.

Table 3.2: Unit cost per car

Project No. Unit cost (LE/car)

1

2

3

4

5

6

7

8

3,110.4

3,628.8

4,375.8

3,888.0

4,321.5

2,978.3

4,167.4

3,952.3

Then, the average unit cost = 30,431.5 / 8 = LE3,803.94 / car

Using Eq. 3.1, the forecast unit cost = (2,987.3 + 4 3,803.94 + 4,375.8) / 6 =

3,763.14.

Accordingly, the cost estimate for 135-cars parking = 135 3,763.14 = LE508,023

Cost Estimating 52 Dr. Emad Elbeltagi

3.3 Conceptual Estimate Adjustment

It is necessary for the estimator to adjust the cost information from previously completed

projects for use in the preparation of a conceptual cost estimate for a proposed project.

There should be adjustment for time, location, and size.

3.3.1 Adjustment for time

The use of cost information from a previous project to forecast the cost of a proposed

project will not be reliable unless an adjustment is made proportional to the difference in

tine between the two projects. The adjustment should represent the relative inflation or

deflation of costs with respect to time due to factors such as labor rates, material costs,

interest rates, etc.

Measures of changes in items such as location, building costs or tender prices are

performed using index numbers. Index numbers are a means of expressing data relative to

a base year. For example, in the case of a building cost index, a selection of building

materials is identified, recorded and given the index number 100. Let us say for the sake

of argument that the cost of the materials included in the base index is LE70.00 in

January 2005. Every 3 months the costs are recorded for exactly the same materials and

any increase or decrease in cost is reflected in the index as follows: Building cost index

January 2005 = 100; Building cost index January 2009 = 135. This, therefore, represents

an increase of 35% in the cost of the selected materials and this information can be used

if, for example, data from a 2005 cost analysis was being used as the basis for calculating

costs for an estimate in January 2009.

Various organizations publish indices that show the economic trends of the construction

industry with respect to time. The estimator can use the change of value of an index

between any two years to adjust past cost records and to forecast future project costs.

Example 3.2

Cost Estimating 53 Dr. Emad Elbeltagi

Suppose the indices for building construction projects show these economic trends

(Table 3.3). It is required to use the cost of a LE843,500 project completed last year

to prepare a conceptual estimate for a project proposed for construction 3 years from

now.

Table 3.3: Construction economic trends

Year Index

3 years ago

2 years ago

1 year ago

Current year

358

359

367

378

Solution

The equivalent interest rate can be calculated based on the change in the cost index

during the 3-year period as follow:

(378/358) = (1 + i)

3

, then i = 1.83%

Accordingly, the cost of the project should be adjusted for time as follows:

Cost = LE843,500 (1 + 0.0183)

4

= LE906,960

3.3.2 Adjustment for location

Tender price levels vary according to the region of the country where the work is carried

out. Similarly, as stated previously in section 3.3.1, the use of cost information from a

previous project to forecast the cost of a proposed project will not be reliable unless an

adjustment is made proportional that represents the difference in cost between the

locations of the two projects. The adjustment should represent the relative difference in

costs material, equipment and labor of the two locations. Indices that show the relative

difference in construction costs with respect to geographical location is usually published

by many organizations.

Example 3.3

Suppose the indices for different location of construction costs are shown in Table

3.4. Suppose that the construction cost of a project completed at city A is LE387,200,

it is required to prepare a conceptual estimate for a similar project proposed in city D.

Cost Estimating 54 Dr. Emad Elbeltagi

Table 3.4: Locations cost indices

Location Index

City A

City B

City C

City D

City E

1.025

1.170

1.260

1.105

1.240

Solution

The cost of the proposed project could be adjusted for location as follows:

Cost = LE387,200 (1.105 / 1.025) = LE417,420

3.3.3 Adjustment for size

The use of cost information from a previous project to forecast the cost of a future project

will not be reliable unless an adjustment is made that represents the difference in size of

the two projects. In general, the cost of a project is directly proportional to its size. The

adjustment is generally a simple ratio of the size of the proposed project to the size of the

previous project from which the cost data are obtained.

3.3.4 Combined adjustment

The conceptual cost estimate for a proposed project is prepared from cost records of a

project completed at a different time and at a different location with a different size. The

estimator must adjust the previous cost information for the combination of time, location

and size.

Example 3.4

Use the time and location indices presented in Tables 3.3 and 3.4 to prepare the

conceptual cost estimate for a building with 62,700 m

2

of floor area. The building is

to be constructed 3 years from now in city B. A similar type of building that cost

Cost Estimating 55 Dr. Emad Elbeltagi

LE2,197,540 and contained 38,500 m

2

completed 2 years ago in city E. Estimate the

probable cost of the proposed building.

Solution

Proposed cost

= Previous cost Time adjustment Location adjustment Size adjustment

= LE2,179,540 (1 + 0.0183)

5

(1.17 / 1.24) (62,700 / 38,500)

= LE3,700,360

3.3.5 Unit-cost adjustment

Although the total cost of a project will increase with size, the cost per unit may decrease.

For example, the cost of an 1800 m

2

house may be LE535/m

2

where as the cost of a 2200

m

2

house of comparable construction maybe only LE487/m

2

. This is because certain

items such as furniture, garage, etc., are independent of the size of the project. Size

adjustment for a project is unique to the type of project. The estimator must obtain cost

records from previous projects and develop appropriate adjustments for his/her particular

project.

Example 3.5

Cost records from previous projects show this information (Table 3.5). Find the unit

cost as a function of the number of units.

.

Table 3.5: Previous projects cost data

Project No. Cost (LE) Size, no. of units

1

2

3

4

5

2,250

1,485

2,467

2,730

3,401

100

60

120

150

190

Solution

The unit costs are calculated as given in Table 3.6.

Cost Estimating 56 Dr. Emad Elbeltagi

Table 3.2: Unit cost

Project No. Unit cost (LE)

1

2

3

4

5

22.5

24.75

20.56

18.20

17.90

A plot of these points is shown in Figure 3.2. For the first order relationship, the

general equation for a straight line is: y = ax + b. The equation of the straight line can

be determined as:

y = [(17.9 24.75) / (190 60)] x + 24.75 = - 0.0526 x + 24.75

where 60 < x < 190, then y = 24.75 0.0526 (S 60)

where S the number if units in the proposed project.

Or by adding a trend line of linear type, thus yields the equation shown in Figure 3.1:

y = - 0.056 x + 27.81

Obtaining the unit cost for 170 units project size = - 0.056 170 + 27.81 = LE18.29

Fig. 3.2: Comparison of size and cost per unit

Cost Estimating 57 Dr. Emad Elbeltagi

As illustrated in the Example 3.5, the adjustment of unit costs based on the size of a

project is unique and can be obtained only from previous cost records. The cost data for

some types of projects could be nonlinear. Accordingly, a second order equation may

better fit the data for some types of projects. The estimator must evaluate his/her own

particular cost records and develop a unit cost-size relationship.

3.4 Conceptual Estimating Techniques

3.4.1 Interpolation

Interpolation is a technique used in the early stages of the design sequence when

information on the proposed project is in short supply. It requires a good deal of skill and

experience and is the process of adding in or deducting from the cost analysis to arrive at

a budget for a new project. Therefore in preparing a budget for a new project assume a

cost analysis has been chosen as the basis for the estimate. However, the cost analysis

will contain items that are not required for the new project and these must be deducted.

For example, in the new project the client wishes to exclude the installation of air

conditioning from the estimate and this will have to be deducted from the budget; but on

the other hand the client wishes to include CCTV throughout and the cost of providing

this must be calculated and added in. It is important, as described later, to adjust costs to

take account of differences in price levels. The process continues until all identified

differences have been accounted for. Other credible approaches to approximate

estimating that are available to the quantity surveyor are: