Documente Academic

Documente Profesional

Documente Cultură

Letter of Concern

Încărcat de

tamal mukherjeeDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Letter of Concern

Încărcat de

tamal mukherjeeDrepturi de autor:

Formate disponibile

`

Indus Business Academy

(Arihant Education & Research Foundation) Plot No- 44, Knowledge Park- III, Greater Noida- 201308 (UP) India Tel: +91-120-3921000(25 Lines) +91-120-2323641-644 Fax: +91-120-3921099 URL: www.ibainternational.org

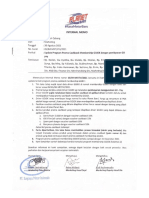

TO WHOMSOEVER IT MAY CONCERN

This is to certify that the Summer Internship Project Report, titled Operation Processing Standard of press parts packing in transportation trolleys submitted by Mr.Tamal mukherjee (FPG/1012/025) as partial fulfillment of requirement of the two years PGDM course and it is a bonafide work carried out by the student at our institute. This Summer Internship Project Report is his original work & has not been submitted to any other University/Instititute.

Dated:

Dr. Debabrata Das

(Director, Prof. Operations Management)

HONDA SIEL CARS INDIA LTD.

Dated:

TO WHOMSOEVER IT MAY CONCERN

This is to certify that Mr. tamal mukherje, PGDM Student of Indus Business Academy, Greater Noida has successfully completed the project on Operation Processing Standard of press parts packing in transportation trolleys as a part of Project training under the guidance of our Parts Logistics & Control Department at our organisation from 02/05/2011 to 30/06/2011. During the above period he has evinced keen interest in the subject matter of project and we found his conduct to be good. Aditya Shina Manager- HR

HONDA SIEL CARS INDIA LTD.

ACKNOWLEDGEMENT I take this opportunity to convey my hearty thanks to our CEO, Mr. Ritesh Jain, and our placement in charge Dr. Ekta Saxena for providing me a wonderful opportunity with the necessary infrastructure, thereby giving me the freedom to carry out the summer internship work in my area of interest. A special thanks to Mr. Aditya Shina (Manager-HR) for allowing me to do the project in the esteemed organization. I extend my gratitude to Mr. R.K.Paul (HOD, PLC Dept.), Mr. Vinod Kumar (Asst. Manager, PLC Dept.), for their continuous support throughout the project. Also I extend my gratitude to Mr. Bhaskar Kaushik (Sr. Executive, PLC Dept.) & Mr. Nishant Agrawal (Executive, PLC Dept.) for acting as the organizational guide throughout my project. I register my gratitude and indebtedness to all the HELI & KALINGA associates for their immense help & support which enable me to accomplish the project within stipulated period. Lastly, I would like to thank all the teaching & non-teaching staff and friends of Indus Business Academy, Greater Noida for giving me the moral support to complete the project successfully. Tamal Mukherjee (Indus Business Acadamy)

HONDA SIEL CARS INDIA LTD.

OBJECTIVE OF THE PROJECT

To categorize the trolleys used in HSCI, TKR Plant for the dispatch of press parts To study the transportation trolleys used with respect to its parts specifically for three HONDA models CITY , JAZZ & BRIO To find out the shortcomings in each trolley for each part particularly for three models CITY, JAZZ & BRIO in three stages a) Observing the trolley in dismantled condition without having any press parts in it b) Observing the trolley in assembled condition while parts of the trolleys are attached to it c) Observing the trolley while the press parts are loaded into it for the dispatch To establish the checking items for each transportation trolley used for dispatch of press parts for two model CITY, JAZZ & BRIO

Significance of the topic

HSCIs first state-of-the-art manufacturing unit was set up at Greater Noida, U.P in 1997. The annual capacity of this facility is 100,000 units. The companys p roduct range includes Honda Jazz, Honda City, Honda Civic and Honda Accord which are produced at the Greater Noida facility with an indigenization level of 77%, 76%, 74% and 28% respectively. The CR-V is imported from Japan as Completely Built Units. The companys second manufacturing facility is in Tapukara, Rajasthan which was inaugurated in 2008. This facility is spread over 600 acres and will have an initial production capacity of 60,000 units per annum, where I have undergone the opportunity to accomplish my project in Parts & Logistics Control (PLC) Dept. Basically the press parts & power transmission parts are manufactured in TKR plant, Rajasthan & dispatched to GNU for the final assembly plying over 200 km distance. The sole purpose of the TKR plant is to dispatch the parts packed in the transportation trolleys to GNU without having any damages in the parts during transportation. With respect to that I am supposed to establish the checking items in each of the transportation trolley used in three HONDA models CITY, JAZZ & BRIO before the final dispatch of press parts to GNU to avoid the flange bend, dents, scratches or any other damages in the parts during transportation.

HONDA SIEL CARS INDIA LTD.

TABLE OF CONTENTS Chapter 1: Industrial Profile ................................................. (1-8) 1.1 Overview of the automobile industry in India . 1 1.2 Evolution of automobile industry ... 2 1.3 Segment wise share in the automobile industry. 5 1.4 Contribution of automobile industry to the Economy ..6 1.5 Growth of automobile industry ..7 Chapter 2: Company profile .......................................... (9-11) 2.1 About the company ... 9 2.2 Product lines of HSCI 10 2.3 Environment policy... 11 Chapter 3: Vision & Mission- Honda Siel Cars India Ltd (12-15)

Chapter 4: HONDA & Technology ................................... 16 4.1 ASIMO... 16 4.2 JET 16 4.3 FCX 16 Chapter 5: Process flow chart associated with press parts ..17 18

Chapter 6: Problem statement

Chapter 7: Parts & Logistics Control (PLC) initiative ....... (19-23) 7.1 Team involved ...19 7.2 Methodology ...........................................................21 7.3 Press parts identification .........................................21

HONDA SIEL CARS INDIA LTD.

Chapter 8: Research methodology .......................... (24-62) 8.1 Trolley Introduction ................................................ 24 8.2 Transportation trolley nomenclature....................... 35 8.3 Checking items in transportation trolleys in two stages ...................................................................... 61 Chapter 9: Project premise .............................. (63-89) 9.1 Findings .................................................................. 63 9.2 Establishing the check points during packing of press parts before the dispatch ........................................ 64 9.3 Result ..................................................................... 89 9.4 Learning............................................................. (90-91)

Chapter 10: Conclusion

.................................................................. 92 93

REFERENCES ..............

HONDA SIEL CARS INDIA LTD.

PROJECT INSIGHT Purpose Operation Processing Standard (OPS) of the transportation trolleys used for the dispatch of press parts is an initiative implemented by Parts & Logistics Control (PLC) team to ensure the quality product and to achieve ideal delivery organism. This project focus on checking items in each of the transportation trolley for HONDA CITY, JAZZ & BRIO in three stages while finalizing the dispatch of press parts. Scope Scope of the project includes the rigorous study on transportation trolleys used by PLC team with respect to its each & every parts, subparts with necessary dimensions. It also includes finding out the loopholes in the transportation trolleys and arriving at the recommendations part with respective loopholes. Methodology A very prudent observation method has been followed with primary & secondary data analysis to study the operation processing standards of the transportation trolleys and eventually establishing check points during packing to avoid the scratches, dent, flange bend or any other damages in the press parts while finalizing the dispatch.

HONDA SIEL CARS INDIA LTD.

HONDA SIEL CARS INDIA LTD.

S-ar putea să vă placă și

- Satisfaction Level at Different CFS and Rail OperationsDocument67 paginiSatisfaction Level at Different CFS and Rail OperationsMythili MuthappaÎncă nu există evaluări

- Final Report Done1111Document63 paginiFinal Report Done1111shivamÎncă nu există evaluări

- Amity University Rajasthan: " Rico Auto Industries PVT Ltd. "Document21 paginiAmity University Rajasthan: " Rico Auto Industries PVT Ltd. "Aman SinhaÎncă nu există evaluări

- Training on Mahindra Tractor AssemblyDocument53 paginiTraining on Mahindra Tractor AssemblyDhruv Dholariya100% (1)

- 6 Week Internship Report ArvindDocument22 pagini6 Week Internship Report ArvindThe Bhavuk's Channel100% (1)

- Final Project Report in 1Document91 paginiFinal Project Report in 1MKamranDanish100% (1)

- Project Report Brahmdeep SinghDocument69 paginiProject Report Brahmdeep Singharush GargÎncă nu există evaluări

- Summer Internship ReportDocument41 paginiSummer Internship ReportRajveer deepÎncă nu există evaluări

- Mahindra CIE Project ReportDocument33 paginiMahindra CIE Project ReportManoj KuchipudiÎncă nu există evaluări

- Ricco Summer Training ReportDocument57 paginiRicco Summer Training Reportaarti bhardwajÎncă nu există evaluări

- Maharashtra State Board of Technical Educationpage 1Document49 paginiMaharashtra State Board of Technical Educationpage 1Nitin DudhavadeÎncă nu există evaluări

- Internship 02 06 09 17 PDFDocument33 paginiInternship 02 06 09 17 PDFDîñ Êsh Chä ÛhâñÎncă nu există evaluări

- Komatsu India PVT KiplDocument26 paginiKomatsu India PVT Kiplsubash sekar100% (1)

- Industrial Training ReportDocument41 paginiIndustrial Training ReportRohit PrasadÎncă nu există evaluări

- Industrial Training Project Report2Document51 paginiIndustrial Training Project Report2mandeepÎncă nu există evaluări

- Milling Injection MouldingDocument50 paginiMilling Injection MouldingNitish Kumar SinghÎncă nu există evaluări

- Maharashtra State Board of Technical EducationpageDocument63 paginiMaharashtra State Board of Technical EducationpageNitin DudhavadeÎncă nu există evaluări

- Training Report RACDocument33 paginiTraining Report RACTarun RaghavÎncă nu există evaluări

- Indus Motor Company Limited Final Project ReportDocument23 paginiIndus Motor Company Limited Final Project ReportZeeshan MazharÎncă nu există evaluări

- Working Capital ManagementDocument70 paginiWorking Capital ManagementjyotiÎncă nu există evaluări

- Swaraj ReportDocument77 paginiSwaraj ReportShivali KumariÎncă nu există evaluări

- PT3 Report FinalDocument38 paginiPT3 Report Finalhamidu athumaniÎncă nu există evaluări

- Final Toyota ReportDocument90 paginiFinal Toyota ReportGenious GeniousÎncă nu există evaluări

- CAD and FEM Analysis of a DESL UnderframeDocument43 paginiCAD and FEM Analysis of a DESL UnderframeAnubhav Tyagi100% (1)

- Mannu HindalcoDocument77 paginiMannu HindalcoAshish RaiÎncă nu există evaluări

- Suyash GAIL Summer Training ReportDocument35 paginiSuyash GAIL Summer Training ReportSuyash PatelÎncă nu există evaluări

- King NARZARY BBA PROJECT 6Document80 paginiKing NARZARY BBA PROJECT 6Sunny SinghÎncă nu există evaluări

- Project ReportDocument45 paginiProject Reportadityaintouch40% (5)

- HyandaiDocument67 paginiHyandaimonika_richaÎncă nu există evaluări

- PDFDocument86 paginiPDFabiÎncă nu există evaluări

- PDFDocument86 paginiPDFabiÎncă nu există evaluări

- Research Paper On MOSTDocument3 paginiResearch Paper On MOSTSagar ShidurkarÎncă nu există evaluări

- Design and Manufacturing of Automatic Multipoint Spanner For Maruti 800Document61 paginiDesign and Manufacturing of Automatic Multipoint Spanner For Maruti 800Rajput PratiksinghÎncă nu există evaluări

- Ashish TrainingDocument28 paginiAshish TrainingAniket Saini005 -MEÎncă nu există evaluări

- Amit NagarDocument53 paginiAmit NagarakashÎncă nu există evaluări

- Bhupinder SinghDocument70 paginiBhupinder SinghAndrew MeyerÎncă nu există evaluări

- Assembly of Gearbox No.4028, 1613Document33 paginiAssembly of Gearbox No.4028, 1613Ahil KhanÎncă nu există evaluări

- Bishal Shrestha Final ReportDocument74 paginiBishal Shrestha Final ReportPaOneÎncă nu există evaluări

- Vocational Training Report: Mahindra Yuvraj 215 Panchnath Auto PVT - Ltd. Shapar, Rajkot-GujaratDocument50 paginiVocational Training Report: Mahindra Yuvraj 215 Panchnath Auto PVT - Ltd. Shapar, Rajkot-GujaratDhruv DholariyaÎncă nu există evaluări

- Internship Report 1Document30 paginiInternship Report 1Sayanth SunilÎncă nu există evaluări

- Tvs ReportDocument42 paginiTvs ReportGaurav Batra100% (2)

- Reports of Internship (Krishna)Document21 paginiReports of Internship (Krishna)Himanshu KalaÎncă nu există evaluări

- Vikrant ReportDocument40 paginiVikrant ReportHimanshu Joon100% (1)

- Industrial Training ReportsDocument13 paginiIndustrial Training Reportschildprogress23Încă nu există evaluări

- Project On TATA MotorsDocument140 paginiProject On TATA MotorsArun Guleria50% (2)

- Feasibility Study Report: Subros LimitedDocument139 paginiFeasibility Study Report: Subros Limitedmishra464100% (1)

- A Comparative Study On The Effect of Marketing Techniques of Volkswagen and ToyotaDocument92 paginiA Comparative Study On The Effect of Marketing Techniques of Volkswagen and ToyotaPranshu Sahni100% (3)

- Summer Internship Report: Indian Oil Corporation LimitedDocument34 paginiSummer Internship Report: Indian Oil Corporation Limitedshakti shanker0% (1)

- MahmuodDocument60 paginiMahmuodBirhanu AlemuÎncă nu există evaluări

- A Study of the Supply Chain and Financial Parameters of a Small Manufacturing BusinessDe la EverandA Study of the Supply Chain and Financial Parameters of a Small Manufacturing BusinessÎncă nu există evaluări

- The Toyota Way, Second Edition: 14 Management Principles from the World's Greatest ManufacturerDe la EverandThe Toyota Way, Second Edition: 14 Management Principles from the World's Greatest ManufacturerEvaluare: 4 din 5 stele4/5 (102)

- Training Facility Norms and Standard Equipment Lists: Volume 1---Precision Engineering or MachiningDe la EverandTraining Facility Norms and Standard Equipment Lists: Volume 1---Precision Engineering or MachiningÎncă nu există evaluări

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successDe la EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successEvaluare: 4.5 din 5 stele4.5/5 (3)

- Leveraging on India: Best Practices Related to Manufacturing, Engineering, and ItDe la EverandLeveraging on India: Best Practices Related to Manufacturing, Engineering, and ItÎncă nu există evaluări

- A Study of the Supply Chain and Financial Parameters of a Small BusinessDe la EverandA Study of the Supply Chain and Financial Parameters of a Small BusinessÎncă nu există evaluări

- Advanced Work Packaging: Guide for Life Cycle ImplementationDe la EverandAdvanced Work Packaging: Guide for Life Cycle ImplementationÎncă nu există evaluări

- Takt Time: A Guide to the Very Basic Lean CalculationDe la EverandTakt Time: A Guide to the Very Basic Lean CalculationEvaluare: 5 din 5 stele5/5 (2)

- Inventory ClassificationDocument9 paginiInventory Classificationtamal mukherjeeÎncă nu există evaluări

- Cost & Lead Time of Each Category of Inbound Materials On The Fiscal Year 2011-12Document11 paginiCost & Lead Time of Each Category of Inbound Materials On The Fiscal Year 2011-12tamal mukherjeeÎncă nu există evaluări

- Presentation On OPS of Press Parts Packing of Transportation TrolleysDocument46 paginiPresentation On OPS of Press Parts Packing of Transportation Trolleystamal mukherjeeÎncă nu există evaluări

- Executive Summary of The ProjectDocument2 paginiExecutive Summary of The Projecttamal mukherjeeÎncă nu există evaluări

- 1.1: Overview of Automobile Industry in India: Chapter 1: Industrial ProfileDocument93 pagini1.1: Overview of Automobile Industry in India: Chapter 1: Industrial Profiletamal mukherjeeÎncă nu există evaluări

- Operation Processing Standards of Press Parts Packing in Transportation TrolleysDocument1 paginăOperation Processing Standards of Press Parts Packing in Transportation Trolleystamal mukherjeeÎncă nu există evaluări

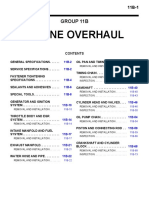

- Engine Overhaul: Group 11BDocument74 paginiEngine Overhaul: Group 11BToponari MedveÎncă nu există evaluări

- Study of Different EV ChargersDocument64 paginiStudy of Different EV Chargersvinod 7Încă nu există evaluări

- Case 527Document337 paginiCase 527Николай Некрасов100% (1)

- Design and Fabrication of Electric ForkliftDocument7 paginiDesign and Fabrication of Electric ForkliftIJRASETPublicationsÎncă nu există evaluări

- Hyva Moves Your World: Hyva International B.VDocument2 paginiHyva Moves Your World: Hyva International B.VDaniel SolomonÎncă nu există evaluări

- InsuranceDocument3 paginiInsuranceAnonymous jcCTbWMiÎncă nu există evaluări

- Product Features: Angie Paola Guevara SanchezDocument10 paginiProduct Features: Angie Paola Guevara SanchezAngy GuevaraÎncă nu există evaluări

- John Deere Service Manual JD S Tm1158Document14 paginiJohn Deere Service Manual JD S Tm1158p0t2g047Încă nu există evaluări

- List Equipment of H.039: Main Engine Port Side Starboard SideDocument4 paginiList Equipment of H.039: Main Engine Port Side Starboard SideSuseprianus PatumbaÎncă nu există evaluări

- Application For A Contract Carriage PermitDocument1 paginăApplication For A Contract Carriage Permitdev sharmaÎncă nu există evaluări

- DT Swiss Techbook 2016Document64 paginiDT Swiss Techbook 2016Josep A. TERUELÎncă nu există evaluări

- Amaze Petrol: Aan Honda Rajkot Price ListDocument1 paginăAmaze Petrol: Aan Honda Rajkot Price ListdoctorniravÎncă nu există evaluări

- 2.0 Body Work FrameDocument2 pagini2.0 Body Work FrameGarcia CruzÎncă nu există evaluări

- 085IM - Program Promo Membership GOJEK - Full Signed+lampiranDocument5 pagini085IM - Program Promo Membership GOJEK - Full Signed+lampiranRiskyArgaUmbaaraÎncă nu există evaluări

- MA00094R01HDocument3 paginiMA00094R01HvitrinetecnicaÎncă nu există evaluări

- HIRA Cage Ladder InstallationDocument9 paginiHIRA Cage Ladder InstallationR. Ayyanuperumal AyyanuperumalÎncă nu există evaluări

- 2 Engine With Mounting and Equipment PDFDocument99 pagini2 Engine With Mounting and Equipment PDFMichael BochoridisÎncă nu există evaluări

- DC1372A 365-449kWDocument2 paginiDC1372A 365-449kWBlas ViniciusÎncă nu există evaluări

- UP27BT2389Document2 paginiUP27BT2389Shubham guptaÎncă nu există evaluări

- Bearing For Industrial GearboxDocument32 paginiBearing For Industrial Gearboxabhipraya01Încă nu există evaluări

- QSK19 Natural Gas Engine FamiliarizationDocument91 paginiQSK19 Natural Gas Engine FamiliarizationGabriel LibensonÎncă nu există evaluări

- Slick Magnetos Refernecia LycomingDocument8 paginiSlick Magnetos Refernecia LycomingCristhian342Încă nu există evaluări

- Comparative ScheduleDocument6 paginiComparative ScheduleGustavo Adolfo De Haro GonzálezÎncă nu există evaluări

- Holsetpartnumbers 2008Document1 paginăHolsetpartnumbers 2008Marielis ContrerasÎncă nu există evaluări

- Segmentation: Targeting & PromotionDocument5 paginiSegmentation: Targeting & PromotionPuneet GargÎncă nu există evaluări

- Mercedes-Benz AtegoDocument7 paginiMercedes-Benz AtegoRoberto Ortega Micalizzi0% (1)

- Mid187 Ppid1442 Se4209Document2 paginiMid187 Ppid1442 Se4209AwanÎncă nu există evaluări

- SL, SM & SH 90, 110, 132, 150, 200, 250 & 300 (50Hz) L, H & HH 125, 150, 200, 250, 300, 350 & 400 (60Hz)Document74 paginiSL, SM & SH 90, 110, 132, 150, 200, 250 & 300 (50Hz) L, H & HH 125, 150, 200, 250, 300, 350 & 400 (60Hz)Barok AhÎncă nu există evaluări

- JCB EPC1Document3 paginiJCB EPC1chrideerÎncă nu există evaluări

- Esquema SSPDocument25 paginiEsquema SSPGabriel SilvaÎncă nu există evaluări