Documente Academic

Documente Profesional

Documente Cultură

Sec-I 133

Încărcat de

Panchal ShaileshDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Sec-I 133

Încărcat de

Panchal ShaileshDrepturi de autor:

Formate disponibile

2007 SECTION I

TABLE PW-39 MANDATORY REQUIREMENTS FOR POSTWELD HEAT TREATMENT OF PRESSURE PARTS MID ATTACHMENTS (CONT'D)

Minimum Holding Temperature, of Material P-No. SA Group No.1 and P-No. S8 Group No.1

(OC)

07

Minimum Holding Time at Normal Temperature for Weld Thickness (Nominal) Up to 2 in. (50 mm) 1 hr/in. (2 min/mm), IS min minimum Over 2 in. (50 mm) to 5 in. <125 mm) 1 hr/in. (2 min/mm) Over 5 in. <125 mm) S hr plus IS min for each additional inch (2S mm) over Sin. (I2S mm)

GENERAL NOTES: (a) Postweld heat treatment is not mandatory under the following conditions: (I) for circumferential butt welds in pressure parts with all of the following conditions: (a) a maximum specified chromium content of 3.0% (b) a nominal base metal thickness of %in. (I6 mm) or less at the weld (c) a maximum specified carbon content (SA material specification carbon content, except when further limited by the Purchaser to a value within the specification limits) of not more than O.lS% (d) a minimum preheat of 300F (ISOC) (2) for fillet welds used on socket welding fittings conforming to the rules of PW-41, when the following conditions are met: (a) a maximum specified chromium content of 3.0% (b) a fillet weld throat thickness of ~ in. (13 mm) or less, regardless of base metal thickness (c) a maximum specified carbon content (SA material specification carbon content, except when further limited by the Purchaser to a value within the specification limits) of not more than O.lS% (d) a minimum preheat of 300F (ISOC) (3) for pipe and tube materials meeting the requirements of (I)(a) through (I)(c) above having fillet welds attaching nonpressure parts to them, provided the fillet weld has a throat thickness of ~ in. (I3 mm) or less and the material is preheated to 300F (ISOC) minimum; or combination groove and fillet welds attaching nonpressure parts to pressure parts, with a weld thickness of ~ in. (13 mm) or less, and the material is preheated to a minimum of 300F (ISOC); or heat-absorbing surfaces and non-load-carrying studs attached to them, provided the material is preheated to 300F (ISOC) minimum. A lower preheating temperature may be used, provided specifically controlled procedures necessary to produce sound joints are used. Such procedures shall include but shall not be I imited to the following: (a) the maximum throat thickness of fillet welds shall be ~ in. (13 mm) (b) the maximum continuous length of fillet welds shall be not over 4 in. (IOO mm) (c) electrodes or filler metal shall be dry and shall provide a low-hydrogen weld deposit. Chromium-molybdenum filler metals shall have a maximum specified chromium content of not more than 2.S0% and a maximum specified carbon content of not more than O.OS% (d) the thickness of the test plate used in making the welding procedure qualification of Section IX shall not be less than that of the material to be welded (4) for tubes or pressure retaining handhole and inspection plugs or fittings with a specified maximum chromium content of 6% that are secured by physical means (rolling, shoulder construction, machine threads, etc.> and seal welded, provided the seal weld has a throat thickness of \ in. (IO mm) or less, and preheat to a minimum temperature of 300F (ISOC) is applied when the thickness of either in. (I6 mm) part exceeds (S) for welds attaching non load-carrying studs or insulation attachment pins not exceeding ~ in. (I3 mm) in diameter when using an automatic arc stud welding or automatic resistance stud welding process (6) for corrosion-resistant weld metal overlay of P-No. SA pipe or tube, provided the following conditions are met: (a) a minimum preheat of 300F (ISOC) is applied when the thickness exceeds ~ in. (I3 mm) (b) overlay is applied using GTAW or GMAW with a 360 deg spiral deposition technique in. (3 mm) (c) overlay cladding thickness does not exceed (d) the tube or pipe material does not exceed NPS S <ON 12S) and is not used as a drum or shell (b) Postweld heat treatment is not mandatory for electric resistance welds used to attach extended heat-absorbing fins to pipe and tube materials, provided the following requirements are met: (I) a maximum pipe or tube size of NPS 4 <ON 100) (2) a maximum specified carbon content (SA material specification carbon content, except when further limited by the Purchaser to a value within the specification limits) of not more than O.lS% in. (3 mm) (3) a maximum fin thickness of (4) prior to using the welding procedure, the Manufacturer shall demonstrate that the heat-affected zone does not encroach upon the minimum wall thickness (c) General Note (a) does not apply to welds using the inertia and continuous drive friction welding processes. Postweld heat treatment is mandatory for all thicknesses of materials welded using inertia and continuous drive friction welding.

'le

'le

95

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- John Crane Seal Identification CodingDocument9 paginiJohn Crane Seal Identification CodingEloy Alejandro Justiniano Coimbra100% (1)

- Closed Book Practice QuestionsDocument10 paginiClosed Book Practice Questionsdgelvez100% (3)

- Table Pw-39 Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and Attachments (Conrd)Document1 paginăTable Pw-39 Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and Attachments (Conrd)Panchal ShaileshÎncă nu există evaluări

- Table Pw-39 Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and Attachments (Coiijt'D)Document1 paginăTable Pw-39 Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and Attachments (Coiijt'D)Panchal ShaileshÎncă nu există evaluări

- Table Pw-39 (Cont'D) Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and AttachmentsDocument1 paginăTable Pw-39 (Cont'D) Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and AttachmentsPanchal ShaileshÎncă nu există evaluări

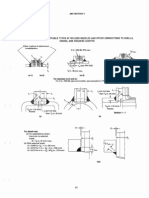

- FIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Cont'D)Document1 paginăFIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Cont'D)Panchal ShaileshÎncă nu există evaluări

- FIG. PW-19.4 (A) Some Acceptable Types of Diagonal Braces For Installation by WeldingDocument1 paginăFIG. PW-19.4 (A) Some Acceptable Types of Diagonal Braces For Installation by WeldingPanchal ShaileshÎncă nu există evaluări

- Sec-I 128Document1 paginăSec-I 128Panchal ShaileshÎncă nu există evaluări

- Sec-I 126Document1 paginăSec-I 126Panchal ShaileshÎncă nu există evaluări

- FIG. PW-15 Examples of Weld Strength Calculations: 2007 Section IDocument1 paginăFIG. PW-15 Examples of Weld Strength Calculations: 2007 Section IPanchal ShaileshÎncă nu există evaluări

- FIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Co NT'D)Document1 paginăFIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Co NT'D)Panchal ShaileshÎncă nu există evaluări

- FIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Cot/Inections To Shells, Drums, and HeadersDocument1 paginăFIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Cot/Inections To Shells, Drums, and HeadersPanchal ShaileshÎncă nu există evaluări

- Sec-I 121Document1 paginăSec-I 121Panchal ShaileshÎncă nu există evaluări

- FIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Cont'D)Document1 paginăFIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Cont'D)Panchal ShaileshÎncă nu există evaluări

- Design: FIG. PW-9.1 Butt Welding of Plates of Unequal Thici NessDocument1 paginăDesign: FIG. PW-9.1 Butt Welding of Plates of Unequal Thici NessPanchal ShaileshÎncă nu există evaluări

- Manufacturer'S Data Report Forms: 2007 Section IDocument1 paginăManufacturer'S Data Report Forms: 2007 Section IPanchal ShaileshÎncă nu există evaluări

- Openings and CompensationDocument1 paginăOpenings and CompensationPanchal ShaileshÎncă nu există evaluări

- Sec-I 10Document1 paginăSec-I 10Panchal ShaileshÎncă nu există evaluări

- PG-LL PG-13: Xvii Xix Xxxi Xxxiii XxxviDocument1 paginăPG-LL PG-13: Xvii Xix Xxxi Xxxiii XxxviPanchal ShaileshÎncă nu există evaluări

- Sec-I 14 PDFDocument1 paginăSec-I 14 PDFPanchal ShaileshÎncă nu există evaluări

- 2007 ASME Boiler Pressure Vessel Code: Rules For Construction of Power BoilersDocument1 pagină2007 ASME Boiler Pressure Vessel Code: Rules For Construction of Power BoilersPanchal ShaileshÎncă nu există evaluări

- 2007 ASME Boiler and Pressure Vessel Code: SectionsDocument1 pagină2007 ASME Boiler and Pressure Vessel Code: SectionsPanchal ShaileshÎncă nu există evaluări

- Is.6452.b.1989 Specifications For HAC For Structural Use (High Alumina Cement) .Document19 paginiIs.6452.b.1989 Specifications For HAC For Structural Use (High Alumina Cement) .SAIKIRAN LÎncă nu există evaluări

- AAP S17 Gate Valves E2 S PDFDocument16 paginiAAP S17 Gate Valves E2 S PDFbugmenot-scribdÎncă nu există evaluări

- Flux Certificate - 234-ELİFLUX BBR-AG-Sample PDFDocument1 paginăFlux Certificate - 234-ELİFLUX BBR-AG-Sample PDFans44155Încă nu există evaluări

- Is 13095 1991 PDFDocument15 paginiIs 13095 1991 PDFRanganathan SekarÎncă nu există evaluări

- Detection and Analysis of Magnetic Particle Testing Defects On Heavy Truck Crankshaft Manufactured by Microalloyed Medium-Carbon Forging SteelDocument10 paginiDetection and Analysis of Magnetic Particle Testing Defects On Heavy Truck Crankshaft Manufactured by Microalloyed Medium-Carbon Forging SteelprabuÎncă nu există evaluări

- Tutorial 1Document46 paginiTutorial 1Mohamed SherifÎncă nu există evaluări

- Best Management PracticeDocument48 paginiBest Management PracticeCarlos MercadoÎncă nu există evaluări

- 20 Green Sand Casting Defects and Their Suggested RemediesDocument4 pagini20 Green Sand Casting Defects and Their Suggested RemediesPatil Amol PandurangÎncă nu există evaluări

- Cable-Gland-Catalogue CMPDocument1 paginăCable-Gland-Catalogue CMPKaustabha DasÎncă nu există evaluări

- Refractories T1 TheoryDocument12 paginiRefractories T1 TheoryslchemÎncă nu există evaluări

- May 2014-1Document412 paginiMay 2014-1Andi DumayÎncă nu există evaluări

- Ashish Industrial Training ReportDocument31 paginiAshish Industrial Training Reportprosperity facilitationÎncă nu există evaluări

- 12 Samss 007Document33 pagini12 Samss 007marghoobÎncă nu există evaluări

- Mosquito Net - SQ - FT Calculation Description Actual Breadth Length Nos Area Rate Amount Aluminium Frame Sl. NoDocument25 paginiMosquito Net - SQ - FT Calculation Description Actual Breadth Length Nos Area Rate Amount Aluminium Frame Sl. NoidiotfellowÎncă nu există evaluări

- Advanced High Strength Natural Fibre Composites in ConstructionDocument11 paginiAdvanced High Strength Natural Fibre Composites in ConstructionHani BarakatÎncă nu există evaluări

- Parts of The BuildingDocument16 paginiParts of The BuildingAkshaya Dheer MadugulaÎncă nu există evaluări

- Type Test Approvals: Powering The RegionDocument4 paginiType Test Approvals: Powering The RegionJean Pierre GoossensÎncă nu există evaluări

- BS IndexDocument11 paginiBS IndexShirleyLiuÎncă nu există evaluări

- Astm C270 10Document14 paginiAstm C270 10MustafaMahdi100% (2)

- Phoenix ValveDocument4 paginiPhoenix Valvespadafora77Încă nu există evaluări

- Traditional Timber (Compatibility Mode)Document13 paginiTraditional Timber (Compatibility Mode)Asish BarailiÎncă nu există evaluări

- Irc SP 63 - 2004Document48 paginiIrc SP 63 - 2004Anant86% (7)

- Epdm Sponge Rubber Seals08Document2 paginiEpdm Sponge Rubber Seals08Subodh KantÎncă nu există evaluări

- Arf SWGL 20mm.21Document1 paginăArf SWGL 20mm.21GS BOOMIKÎncă nu există evaluări

- VIN129 Polyethylene Pipe and Fittings SystemsDocument145 paginiVIN129 Polyethylene Pipe and Fittings SystemsKevin Tran0% (1)

- Building PlanDocument1 paginăBuilding Planshaik moizÎncă nu există evaluări

- REPORTTT (Repaired) PDFDocument161 paginiREPORTTT (Repaired) PDFHeartless GuitaristÎncă nu există evaluări

- 008 2015 en GL BW Bestseller WebDocument48 pagini008 2015 en GL BW Bestseller WebNaveen SolankiÎncă nu există evaluări