Documente Academic

Documente Profesional

Documente Cultură

Injector Valveadjustment

Încărcat de

jose_saugo2601Descriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Injector Valveadjustment

Încărcat de

jose_saugo2601Drepturi de autor:

Formate disponibile

.

FOREWORD

This

program for

is designed setting

model overhead the

to teach

you the theories

We've

and

used

procedures

an

~

injectors

to

and valves.

the two

NH/NT methods for

engine of

establish

most drscuss

curthe

rent

adjustment. differences

We'll between

process

rdentifyrng

PT (type

D) and

PT (type

D) Top

Stop injectors.

You'll

see how

to use the injector

justing method

type for determining

the correct

ad-

We hope

this

program

provides

you

with

a better

under-

standing

and

about

how overhead

settings

affect

engine

life

performance

~

Produced by:

J. E. Mobley Distribution Training

Copyright@ 1983 Cummins Engine

Company,

I nc

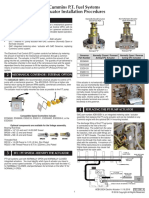

This program covers the most current injector and valve adjustment procedures for Cummins NH/NT engine models with PT (type D) Top Stop or non Top Stop injectors.

2.

~ 0,

Shown here lated parts. cam followers, and valves the overhead.

are specific valve train reThe injectors, push rods, rocker levers, crossheads are commonly referred to as

We'll discuss the theory and procedures for setting injector plunger travel using the dial indicator method (D.I.M. ).

4.

Included is the recommended procedure for checking and adjusting crossheads. We'll discuss the effects of crosshead adjustment related to valve operation.

This is a Top Stop adjustment fixture (3375160). It's required to set Top Stop plunger travel, and to torque the splined locknut to 55 ft.lbs. The plunger travel is set by preloading the injector spring with the weighted handle at a prescribed travel.

6.

Plunger travel for Top Stop injectors cannot be set in the engine. Always use the adjustment fixture (3375160) to set Top Stop injector plunger travel. Travel is changed by turning the adjusting nut. The upward travel stops when the sprin-g washer contacts the nut. The downward travel stop is the injector cup.

7.

This program uses an NH/NT right-hand-rotation engirie, firing order 1-5-3-6-2-4. We'll fi rst explain piston movement relative to cran kshaft rotation . Understanding the relationship of the crankshaft to firing order will help you identify injector and valve adjustment positions .

8.

Piston movement is actuated by the crankshaft connecting rod journals. The two upward strokes are compression and exhaust, the downward strokes are intake and power. In a 4 stroke cycle the two pistons traveling together in the same direction are called companion cylinders.

Crankshaft firing order positions are identified by the valve set marks. They are located on the accessory drive pulley. When it is rotated in the di rection of cran kshaft rotation, any "VS" mark A, B, or C may be aligned with the cast-in pointer on the gear cover. At any "VS" mark the pistons in the cylinders to be adjusted are moving upward. Note, when the "TC" or top-center mark is aligned, cylinders 1 and 6 are at top-dead-center.

f'

10. Valve set marks are geometrically spaced in accordance with the connecting rod journals. The journals and marks are spaced 120 apart. This spacing accounts for the relationship between crank angle degrees and piston travel locations .

11.

,,-.

The following slides will help you more thoroughly understand how the valve set marks relate to cran k and piston positions. When the accessory drive is positioned at the "A" mark, cylinders 1 and 6 have traveled 900 on their downward stroke. Remember, the two downward strokes are intake and power.

12. With the "A" mark still at the pointer, cylinders 2 and 5 are 300 before-topcenter in an upward stroke position . Notice the cran kshaft rod jou rnals for cylinders .2 and 5 relate to the "8" mark.

13.

The

" A ., mark

is still

aligned

with

the

pointer. At this time pistons 3 and 4 are positioned 1500 before-top-center. They have just passed bottom-dead-center beginning their upward strokes. The crankshaft rod journals for cylinders 3 and 4 relate to the "C" mark.

14.

Remember, the valve set marks, A, B, and C relate to the spacing of the crankshaft connecting rod jou rnals .Each set of cylinders A, B, and C are companion cylinders. When any "VS" mark is aligned, the pistons in the corresponding cylinders to be adjusted are moving upward.

15

This circle represents a crankshaft. It is spaced in degrees which relate to the 4 cycles of piston travel. It takes two revolutions of the cran kshaft, or 720, to complete a full fuel injection cycle. The circles are incremented to the 2 upward strokes, exhaust and compression and the 2 downward strokes, intake and power.

16.

The "Vs" adjustment marks also serve as point locators for the camshaft. The injector and valve camshaft lobes have definite surface positions. The lobe surfaces are:

INJECTOR .Inner Base .I njection Ramp .Cam Nose .Outer Base .Retraction Ramp VALVE .Closing Ramp .Base Ci rcle .Opening .Pea k Ramp Lift

17.

Like the relationship of the "V5" marks to the crankshaft rod journals, these marks relate in the same manner to the injector and valve lobes. It takes two crank revolutions to equal one camshaft revolution (3600). The marks on the accessory drive indicate the points on the cam lobes where the roller must be positioned to ensure correct overhead adjustments.

18. When properly aligned, the "VS" marks locate the correct camshaft position that is requi red for making injector and valve adjustments for all Cummins methods. Cummins NH/NT models produced prior to 1971, and small vees will require the torque method of overhead set ti ng . However, where the application permits, the D.I.M. camshaft positions are preferred for most models.

19

The torque method of adjustment requi res precise alignment of the "VS" marks. The torque adjustment point is located on the outer-base-circle of the injector lobe at 900 after-top-center during the power stroke. If the adjustment point is passed, the valve lobe roller will have started up the ramp and clearance will be loose because the exhaust valves will have started to open .

20.

The dial indicator method uses two separate adjustment points, both located on the inner base circle of the camshaft lobes. This method requires that the injector and valves be set on separate cylinders, the injector at the beginning of the compression stroke, the valves at the end of the same stroke on the corresponding cylinder.

21

Use this drawing to aquaint yourself with the injector "VS" adjustment point. The injector is metering; the plunger is positioned at rts uppermost travel in the cup. The piston is moving upward on the compression stroke at or near 1500 B.T.C. The roller is positioned on the inner base circle of the injector lobe.

22.

The exhaust lobe adjustment point occurs at or near 300 B.T.C. near the end of the compression stroke. At this position both the jntake and exhaust valves are closed, providihg lash in the valve train to ensu re correct clearance settings. If positioned past the adjustment point, the intake valves will start to open, causing loose clearance settings.

23

This slide highlights the injector and exhaust roller-to-lobe positions at the "A" valve set adjustment point. The injector lobe is positioned on the inner base circle, or 1500 B.T.C. The exhaust valve lobe is positioned prior to the opening ramp at 30 B.T.C.

24. This

valve lift graph shows the relationship between cam lobe positioning and crank stroke. The exhaust valve is directly related to the power and exhaust strokes. The exhaust valve is closed on the base circle and is fully open at peak lift. The arrows depict the di rection of cam roller travel.

25.

r---

This graph illustrates the approximate position of the exhaust valve adjustment point for any given cylinder. The "VS" point occurs during the compression stroke, when both the exhaust and intake valves are closed. The crosshatched section represents valve overlap. During valve overlap both valves are slightly open .

26 /""'

We've overlayed an injector profile to provide you a guide for seeing the relationship between intake valve and injector travel. Note the relationship between the "VS" adjustment points . The injector roller has just passed B.D.C. The exhaust lobe is nearing T. D. C. Du ring injection both sets of valves are closed.

27

1""'""

Before we get into setting valves and injectors, let's ask- ourselves a question . What determines the setting method? Recognizing the unique parts of the Top Stop will provide you the clues. The two methods are torquing to preload the Top Stop plunger link and setting the non Top Stop plunger travel with the dial indicator.

28. Top Stop injectors are easily identified by the splined locknut on top of the injector body. Top Stops are preloaded to produce a no-lash condition between the plunger link and the rocker lever.

-

r"

29.

Being able to identify the injector type will aid you in determining the correct overhead adjustment procedu res. With the Top Stop, the data plate reads T.S. Zero Lash.

30 This

injector and valve adjustment table will aid you in finding the two cylinders that are beginning and ending the compression stroke. The numbers represent the cylinders to be adjusted when the pointer is aligned with one of the "VS" marks. Adjustment procedures can be made starting at any "VS'I mark, then proceeding through the firing order. For example, if the pointer is at IIA II ,

check for closed valves on cylinders 5 and 2; the injector will be metering on 3 or 4.

31

Cummins recommends adjustment when the engine is cold (1400 because temperature variations cylinders can affect clearances.

be made or less); across

32.

Use this check to identify the closed valves. With your thumb and index finger, try to raise and lower the exhaust and intake rocker levers. When both levers move, the valves are free from spring tension. This condition indicates (1) the valves are closed, (2) the cylinder is on the compression stroke and (3) the companion cylinder valves are open .

f'

If you fail to locate the compression stroke using the rocker lever check, try this procedure: Loosen the intake and exhaust adjusting screws 1/2-1 turn; this introduces lash in the valve train . Once again, try the rocker lever check.

34. To

~

locate the compression stroke in an engine with newly-installed rocker boxes, follow these procedures: Check the torque on the rocker box capscrews to make sure it's within recommended specifications. Then, with the valve set mark " A II aligned, tu rn down the rocker lever adjusting screws on cylinders 2 and 5 to remove all valve lash. Note, any "VS" mark may be aligned and its corresponding adjusting screws tightened.

r'

To determine whether cylinder 2 or 5 is on the compression stroke, observe the height at which the intake and exhaust adjusting screws protrude above the locknut. The set of screws that protrudes at approximately the same height identifies the compression stroke. The exhaust stroke shows a slightly higher protrusion on the exhaust adjusting screw.

,..-,

To begin the adjusting procedures, rotate the accessory drive in a clockwise direction. Align the valve set mark "A" with the pointer. CAUTION, be sure when rotating from the accessory drive that it has a 3/4" flanged nut; otherwise, rotate from the cran kshaft because you may overtorque the old-style nut.

('

37

Once again by referencing our valve and injector adjustment table, we know to check for loose rocker levers on 5 and 2. By using the rocker lever test, we find the valves are closed on 5. Looking at ou r table we see plunger travel for the standard PT (type D) injector should be checked and set on cylinder number 3.

38.

To set plunger travel use service tool kit (3375842). Before setting the injector plunger travel, check the torque on the rocker box housing and injector hold-down capscrews. When necessary, retorque them to maintain tolerances.

39. To set up the

dial indicator, position it in the mounting bracket so that the gauge mounts flush and the extension moves freely. Securely tighten the hold down into place in the rocker box housing. Position the extension securely on top of the injector plunger flange. CAUTION, be sure the extension clears the rocker lever.

40.

Using the actuator, compress the rocker lever 2 or 3 times to completely seat the injector plunger. With the plunger seated, zero the indicator. Slowly release the rocker lever. Now, compare the indicator reading to the recommended plunger travel. If the travel is within plus or minus .001" of the specification, it is not necessary to re-set. CAUTION, injector plunger travel settings vary according to engine model.

41.

If injector plunger travel is out of specification limits, loosen the locknut on the injector adjusting screw. Compress the rocker lever until the plunger is seated to assure a zero indicator reading. Allow the plunger to rise, then tu rn the screw until plunger travel matches the specification.

42.

Hold the adjusting screw in place while you tighten the locknut, or plunger travel may be altered during torquing. If threads of adjusting screws are mutilated or galled, they may not hold or torque correctly, due to the increased friction between metal parts. If you find unacceptable wear conditions on the adjusting components, replace them.

43.

Torque the (54-61 N.m).

locknut

to

40-45

ft.lbs.

'"""'

44.

Note, Cummins service tool ST -669 torque wrench adapter can be used to simultaneously hold the adjusting screw and torque the locknut. CAUTION, when using the ST-669, torque values are lower. Torque the locknut to 35-40 ft.lbs. (47-54 N.m). Once you've completed th.e torquing procedu re, recheck the plunger travel reading. If you obtain an inaccurate reading, repeat the adjusting procedure.

45.

After setting injector plunger travel, check and set the crossheads and valve clearances on cylinder number 5. Always check the engine data plate and other cu rrent service publications for adjustment specifications .

46.

Before we adjust valves, let's take our present valve

the crossheads and a moment to reflect on set mark " A " location .

(1) The valves are closed on cylinder number 5, (2) The roller is positioned on the base circle, (3) The piston is traveling upward, positioned 300 beforetop-center on the compression stroke.

47.

To begin the crosshead and valve adjustment procedu res always check the crossheads first. The crossheads are exposed here to illustrate that one rocker lever operates two intake or two exhaust valves with equal tension. A misadjusted crosshead causes contact surface wear, thereby increasing stress on the valve train.

48.

To adjust the crossheads, back off the intake and exhaust valve locknuts and adjusting screws. Inspect the crosshead contact surfaces for wear. Hold the crosshead in place and lightly turn down the adjusting screw until you feel contact. Advance the screw slightly and lock it down .

49.

f"

Torque the locknut to 25-30 ft.lbs. (34-41 N.m). Be careful not to turn the screw; if its position changes, back off the locknut and screw, and readjust. NOTE: When using the ST -669 Torque Wrench adapter, torque the locknut to 22-26 ft.lbs (30-35 N.m).

50.

1"'"""

Valve clearance, or lash, is the space between the crosshead surface and the rocker lever. Incorrect clearances affect overall engine performance, emisson levels, and valve train wear. With the en~ine positioned at the valve set mark A", set the clearances on cylinder number 5.

51.

The intake and exhaust valve clearances differ. Check the data plate or shop manual for correct clearances.

52.

Now insert the feeler gauge between the rocker lever and the crosshead contact surface. With the feeler gauge in place, tighten the adjusting screw until you feel it contact. Advance the screw slightly and lock it down. This process prevents the loss of clearance during torquing, and helps to provide consistent clearance settings throughout the engine. When the gauge is moved you should feel a slight drag .

53.

Torque the locknut to 40-45 ft.lbs. (54-61 N.m). When removing the gauge, you should still feel a slight drag. If you do not, repeat the valve clearance procedure. Be sure to use the correct clearance specifications.

54.

Now rotate the accessory drive in the direction of engine rotation to valve set mark "8" and repeat the injector and valve adjustments. The "8" indicates the valves may be set on 3 and the injector on 6. Each valve set mark is used twice to set all 6 cylinders .

55

When preloading Top Stop injectors, use the D.I.M. adjustment points. At this time, let's take a moment to reflect on our present "Atf valve set mark position. The injector for cylinder number 3 is metering and the cam' roller is positioned on the inner base circle.

56.

Preloading Top Stop injectors helps to provide consistent injection timing for all 6 cylinders. The process consists of torquing the injector adjusting screw to preload the link between the plunger and the rocker lever. ~

57. To perform the adjusting procedure, first loosen the injector adjusting locknut and screw on cylinder number 3.

58.

~

Now tighten the injector adjusting screw until all the clearance is removed from the injector train. Turn the screw down one additional tu rn to squeeze excess oil from the contact surfaces. This procedure does not bottom the plunger in the cup., but partially compresses the spring.

59.

Now you are ready to set a 5-6 in.lb. preload on the injector train. To do this, back out the injector adjusting screw until you feel the spring washer contact the stop nut. The injector rocker lever is now unloaded.

I"'""

60.

Using service tool (3376592), torque the adjusting screw to 5-6 in.lbs. NOTE: If this service tool is not available, use a torque wrench with an in.lb. reading that does not exceed 12 in.lbs. CAUTION: An overtorqued setting on the injector adjusting screw will produce increased stress on the injector train.

61.

Hold the adjusting screw in place with a screwdriver and tighten the locknut. Note the position of the screw slot. Torque the locknut to 40-45 ft.lbs. (47-54 N.m) .CAUTION: If the screw position changed, repeat the procedu re.

62.

To adjust the crosshead and ances, refer to frames 45 clearance settin~ procedures. ber, each "VS' mark is to set all 6 cylinders.

valve clearthru 54 for Rememused twice

~, .v

63. Mechanical variable timed engines use Top Stop injectors. When making overhead adjustments, the actuator must be in a fully retarded mode. To retard, idle the engine and gently disconnect the electrical wire from the air solenoid. This action depresses the actuator.

~

64.

MVT models use a special camshaft design. This design requi res that a specia! bolt-on-pointer bracket be used to align the "VS" marks. The pointer is positioned 400 clockwise from the pre-cast pointer. CAUTION, do not use the "TC" marks in reference with the bolt-on-pointer.

65.

Correctly adjusted overheads impact on fuel economy, power, emission levels, engine life, and the reliability and durability of engine performance.

66. The

1"'"""

Top Stop design offers several advantages: (1) injector plunger travel is pre-set and does not require setting in the engine, (2) tests show that plunger travel remains calibrated longer because it improves train and joint lubrication, thereby, causing less wear on the camshaft and other related parts, and (3) offers improved emission levels .

67. Misadjusted plunger travel produces a noticeable difference in fuel consumption. Travel distances and time contribute to effective meteri ng at the fuel port. Fuel arriving late produces an incomplete burn, which leads to carboning and black smoke. /"""

68.

Improperly torqued preload and/or misadjusted plunger travel can also produce an excessive load on the cam. Other results are bent push rods, camshaft lobe wear due to roller contact fatigue, and higher particulate and smoke levels.

69.

Incorrect crosshead and valve adjustment affect engine performance and reliability. Tight valve clearances can cause burnt valves. Loose clearance settings can cause air restrictions, low power, black smoke, increased impact loading on the valve train, and increased overhead noise levels .

70.

Remember, always check overhead settings at the recommended scheduled maintenance intervals for optimum engine life. Use the prescribed methods per injector type and engine model. The injector type designates the method of overhead adjustment.

""""'

71

We have thoroughly discussed the theories and procedures for adjusting the PT (type D) Top Stop and non Top Stop injectors, as well as the crossheads and valves. We're confident that each of you has gained a better understanding of these procedures, not only HOW to set the overhead, but WHY it must be done this way.

"""'

S-ar putea să vă placă și

- Cummins STCDocument2 paginiCummins STCAnonymous 340A7vnwV1100% (10)

- STC Oil Control Valve Mechanical 006 007 K38 K50Document18 paginiSTC Oil Control Valve Mechanical 006 007 K38 K50SpectrumRaijin100% (10)

- STC system uses rail pressure to control engine timingDocument3 paginiSTC system uses rail pressure to control engine timingmanoj262400/295% (20)

- Cummins PT Engine Service ManualDocument8 paginiCummins PT Engine Service Manualعلي محمد المزيقر25% (8)

- Injection Timing Chart Using ST-593 or ST-840Document18 paginiInjection Timing Chart Using ST-593 or ST-840javier leyva100% (7)

- PT Fuel System Troubleshooting GuideDocument60 paginiPT Fuel System Troubleshooting GuideMuhammad Faridh Amroulloh100% (32)

- Cummins PT Fuel Systems Colleage TrainingDocument13 paginiCummins PT Fuel Systems Colleage Trainingjose_saugo260175% (4)

- SM NT 855Document693 paginiSM NT 855marco100% (37)

- Celect Injector Adjustment 01-05Document3 paginiCelect Injector Adjustment 01-055476492% (13)

- PT Pump CumminsDocument22 paginiPT Pump Cumminsyani100% (4)

- Cummins L10 Engine FamiliarisationDocument16 paginiCummins L10 Engine FamiliarisationTariqMaqsood100% (2)

- Injectors and Fuel Lines - OverviewDocument17 paginiInjectors and Fuel Lines - Overviewjose_saugo2601100% (1)

- Cummins PT Pump Adjust PDFDocument3 paginiCummins PT Pump Adjust PDFHugh O'Brien GwazeÎncă nu există evaluări

- Overhead Set (Travel Method)Document8 paginiOverhead Set (Travel Method)jengandxb100% (8)

- Vol3Document854 paginiVol3Giapy Phuc Tran100% (66)

- N NT855 FpartsDocument39 paginiN NT855 FpartsCenk- Aysel Ozfidan100% (11)

- Cummims Manuales de Servicio y Reparacion NT 855 PDFDocument693 paginiCummims Manuales de Servicio y Reparacion NT 855 PDFJames Scott Valderrama100% (7)

- Manual QSK19Document634 paginiManual QSK19Drillco98% (48)

- Cummins NTA855-C360 Parts CatalogueDocument58 paginiCummins NTA855-C360 Parts CatalogueGeorge Buitrago96% (24)

- Motor NTA 855Document252 paginiMotor NTA 855luisdeangeli88% (26)

- Cummins Sec 7Document28 paginiCummins Sec 7SpectrumRaijin0% (1)

- Advance Engine Timing with STCDocument28 paginiAdvance Engine Timing with STCLuisPupiales100% (1)

- Cummins NTC 400 SVC & Repair Vol 1Document280 paginiCummins NTC 400 SVC & Repair Vol 1FtFrancy95% (21)

- Kta19 Spare Parts BookDocument152 paginiKta19 Spare Parts BookGeorgios Logakis91% (11)

- Cummins KTA19 Engine Specs, Bolt Torques and ManualsDocument12 paginiCummins KTA19 Engine Specs, Bolt Torques and Manualsfaizal78% (9)

- Manual For N14Document16 paginiManual For N14Jechkong78% (9)

- Cummins Serie K Calibracion de ValvulasDocument63 paginiCummins Serie K Calibracion de Valvulasfrank_16100% (1)

- PIB1006 - A Cummins PT Fuel SystemDocument2 paginiPIB1006 - A Cummins PT Fuel SystemMauricio Guanella80% (5)

- K19 CumminsDocument148 paginiK19 CumminsAngel Jesús Agapito Cortez100% (5)

- QSK-19 Troubleshooting 3666098 PDFDocument690 paginiQSK-19 Troubleshooting 3666098 PDFMiguel Angel Garrido Cardenas100% (18)

- Cummins N855 BigCam Torque ValueDocument4 paginiCummins N855 BigCam Torque ValueCésar Pérez91% (11)

- N14 Parts Catalog PDFDocument114 paginiN14 Parts Catalog PDFManuais De Catálogos Jose Carlos100% (15)

- Cummins Nt855 Service ManualDocument82 paginiCummins Nt855 Service ManualAlenMazurek85% (13)

- Catalago Cummins - Nta855-GDocument45 paginiCatalago Cummins - Nta855-GAnonymous 9fCAFynM78% (9)

- KTA19-P600 Spec.& Scope of Supply With Gearbox HC400Document4 paginiKTA19-P600 Spec.& Scope of Supply With Gearbox HC400Romie Harie100% (4)

- Cummins NTA855 Engine Parts Catalog PC2282Document106 paginiCummins NTA855 Engine Parts Catalog PC2282MAYUR GENSET75% (4)

- OH Setting QSK23Document10 paginiOH Setting QSK23NikkikumarÎncă nu există evaluări

- Valve Adjustment E7Document16 paginiValve Adjustment E7malcolm stewartÎncă nu există evaluări

- Turbine AlignmentDocument3 paginiTurbine AlignmentParmasamy SubramaniÎncă nu există evaluări

- Checking The Gap Between The Coupling FacesDocument3 paginiChecking The Gap Between The Coupling Faceslinhcdt3100% (1)

- Fuel Injection Timing: Engine Setup and AdjustmentsDocument28 paginiFuel Injection Timing: Engine Setup and AdjustmentsDaniel PaisÎncă nu există evaluări

- Calibracion Serie 60 DetroitDocument15 paginiCalibracion Serie 60 DetroitCe Bayona100% (31)

- 05 - B - RTA 8 Series RTA 2 Series Fuel Pump UpdateDocument16 pagini05 - B - RTA 8 Series RTA 2 Series Fuel Pump UpdateGiovanniJara100% (1)

- Valve Adjustment 2001 Honda CivicDocument34 paginiValve Adjustment 2001 Honda Civicjohn macsterÎncă nu există evaluări

- CCW Two Cylinder ModelsDocument6 paginiCCW Two Cylinder ModelsPaul MartinÎncă nu există evaluări

- Detroit s60 Valve AdjustmentDocument12 paginiDetroit s60 Valve AdjustmentÑengo Flow Full Record50% (2)

- Preparatory Steps: Note: The Following Procedure Is Only To Be Used ForDocument9 paginiPreparatory Steps: Note: The Following Procedure Is Only To Be Used FordeedÎncă nu există evaluări

- Null MOTORDocument215 paginiNull MOTORAditya JoglekarÎncă nu există evaluări

- Detroit s60 Valve Adjustment PDFDocument12 paginiDetroit s60 Valve Adjustment PDFDiego Monroy50% (2)

- Adjust: Valve, Brake, and Injector Adjustment Values Injector Adjustment Is 8 N - M (70 In-Lb)Document9 paginiAdjust: Valve, Brake, and Injector Adjustment Values Injector Adjustment Is 8 N - M (70 In-Lb)Simon LagudÎncă nu există evaluări

- Ajuste Valvulas 9NZDocument5 paginiAjuste Valvulas 9NZLuis OcampoÎncă nu există evaluări

- Calibracion QSK23Document7 paginiCalibracion QSK23Kionss Kions50% (2)

- Ajuste de Valvulas PDFDocument8 paginiAjuste de Valvulas PDFRoberto Rincon RoblesÎncă nu există evaluări

- Ajuste Valvulas e Inyectores DetroitDocument6 paginiAjuste Valvulas e Inyectores DetroitGabriel Duarte100% (19)

- PerkinsDocument12 paginiPerkinsDalibor Sopina Duc100% (2)

- Bolens Models 1969 1972Document3 paginiBolens Models 1969 1972Paul MartinÎncă nu există evaluări

- 117101Document7 pagini117101alejanndrofroebelÎncă nu există evaluări

- Valve Lash AdjustmentsDocument13 paginiValve Lash AdjustmentsEnriqueÎncă nu există evaluări

- Maintenance Manual VCP Upto 80mmDocument16 paginiMaintenance Manual VCP Upto 80mmKaushik Chakraborty0% (1)

- Wartsila Fuel Pump - MaintenanceDocument15 paginiWartsila Fuel Pump - MaintenanceAbhishek Singh Chauhan0% (1)

- MAHLE Failures in Pistons, Rings, Liners, Bearings & Bushings ManualDocument68 paginiMAHLE Failures in Pistons, Rings, Liners, Bearings & Bushings Manualaakk7592% (12)

- Códigos de Falla MID 128Document48 paginiCódigos de Falla MID 128Omar Cantón LealÎncă nu există evaluări

- Injector ValveadjustmentDocument21 paginiInjector Valveadjustmentjose_saugo260191% (58)

- Injectors and Fuel Lines - OverviewDocument17 paginiInjectors and Fuel Lines - Overviewjose_saugo2601100% (1)

- Scope MeterDocument159 paginiScope MeterVishwanath GargÎncă nu există evaluări

- Cummins PT Fuel Systems Colleage TrainingDocument13 paginiCummins PT Fuel Systems Colleage Trainingjose_saugo260175% (4)

- Tricare IVSA-TRBKL (10-14)Document10 paginiTricare IVSA-TRBKL (10-14)Jeff Scott Brazeau100% (1)

- 2017 Nissan SentraDocument485 pagini2017 Nissan SentraAmelia AzizÎncă nu există evaluări

- IC Engine Lab ReportDocument7 paginiIC Engine Lab ReportnewUserÎncă nu există evaluări

- QRH Bell 505 RFM Rev 06 Nov 2017Document74 paginiQRH Bell 505 RFM Rev 06 Nov 2017maydhi50% (2)

- Dumper: Workshop ManualDocument40 paginiDumper: Workshop ManualSebastian SzymkiewiczÎncă nu există evaluări

- Audi A8 Transmission Fluid Level CheckDocument6 paginiAudi A8 Transmission Fluid Level CheckIstvánTóthÎncă nu există evaluări

- Freda Rebecca Volvo Tad1340ve Engine Tax InvoiceDocument2 paginiFreda Rebecca Volvo Tad1340ve Engine Tax InvoiceHugh O'Brien GwazeÎncă nu există evaluări

- United States Patent (10) Patent N0.: US 7,695,075 B1Document8 paginiUnited States Patent (10) Patent N0.: US 7,695,075 B1Marc GlebÎncă nu există evaluări

- Parts Manual: 324D & 324D L ExcavatorsDocument676 paginiParts Manual: 324D & 324D L ExcavatorsRicky Vil100% (3)

- Belt Hyunday 2.4lDocument8 paginiBelt Hyunday 2.4lluca100% (1)

- SYM QUADLANDER 300 Service Manual PDFDocument248 paginiSYM QUADLANDER 300 Service Manual PDFUmar Shamsudin100% (1)

- Manual X100 EU4 Siemense X100RM1C61Document49 paginiManual X100 EU4 Siemense X100RM1C61جواد جاويدانÎncă nu există evaluări

- J10281 - Cab layout overview for Volvo 9700 Prestige Plus coachDocument2 paginiJ10281 - Cab layout overview for Volvo 9700 Prestige Plus coachMiloš StijeljaÎncă nu există evaluări

- Gujarat Technological University Aeronautical EngineeringDocument2 paginiGujarat Technological University Aeronautical EngineeringHarnil VaghasiyaÎncă nu există evaluări

- Diagrama Chevrolet Sail NewDocument16 paginiDiagrama Chevrolet Sail NewHildemar Javier Liscano100% (1)

- Brake SystemDocument24 paginiBrake SystemIonut StoleruÎncă nu există evaluări

- 4Y Operation Manual MDN-18SDocument53 pagini4Y Operation Manual MDN-18SJefferson Diaz100% (1)

- Haltech Platinum Sprint 500 ECU ReviewDocument1 paginăHaltech Platinum Sprint 500 ECU ReviewErnesto RomeroÎncă nu există evaluări

- Farm Power and Machinery Quiz Question PaperDocument5 paginiFarm Power and Machinery Quiz Question PaperPooja BhusalÎncă nu există evaluări

- Aprilia Atlantic 500 FromDEBENITODocument162 paginiAprilia Atlantic 500 FromDEBENITODavid BenitoÎncă nu există evaluări

- Cylinder Head - Install 3516Document6 paginiCylinder Head - Install 3516CH MUBASHER MAQSOOD ALAM50% (2)

- Wa320 3 PDFDocument12 paginiWa320 3 PDFMuhaiminÎncă nu există evaluări

- John Deere Generator Drive Applications Brochure 2017 02Document28 paginiJohn Deere Generator Drive Applications Brochure 2017 02Fernando Martinez BravoÎncă nu există evaluări

- Acert EnginesDocument12 paginiAcert EnginesAnonymous alQXB11EgQ100% (1)

- Tech Data MTDocument61 paginiTech Data MTSaggu RamuÎncă nu există evaluări

- Anti-Corrosion Coating For Engine CompartmentDocument3 paginiAnti-Corrosion Coating For Engine Compartmentsasdq100% (1)

- IS 11852 (Part 8) : 2001Document21 paginiIS 11852 (Part 8) : 2001Jagan SandeepÎncă nu există evaluări

- 2011 Mitsubishi Outlander Sport 36865Document602 pagini2011 Mitsubishi Outlander Sport 36865Jose MoralesÎncă nu există evaluări

- Optimize engine performance with intake and exhaust systemsDocument11 paginiOptimize engine performance with intake and exhaust systemsCarlos Eduardo Zelidon100% (2)

- CalibracionDocument4 paginiCalibraciontallerÎncă nu există evaluări