Documente Academic

Documente Profesional

Documente Cultură

Kinetics of Coupled Reversible Reactions

Încărcat de

Roman BeránekDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Kinetics of Coupled Reversible Reactions

Încărcat de

Roman BeránekDrepturi de autor:

Formate disponibile

ENGINEERING, DESIGN, AND PROCESS DEVELOPMENT

cients for the cross flowmeter would have to be determined experimentally.

Nomenclature

= = f = g = AH =

literature Cited

orifice meter coefficient, dimensionless inside diameter, ft. Fanning friction factor, dimensionless local acceleration of gravity, ft./sec.$ meter differential, feet of fluid flowing K = velocity head coefficient, dimensionless AK = section 4 contribution to K due to pipe friction, dimensionless L = length, ft. R = meter differential, inches of carbon tetrachloride minus water Re = Reynolds number, dimensionless t = linear velocity of fluid, ft./sec.

(1) (2) (3) (4) (5)

(6)

(8) (9)

(10)

(7)

Chem. Eng., 60, No. 3, 124 (1953). Gentile, V., Jr., U. S.Patent 2,260,019 (Oct. 21, 1941). Hoopes, J. W., et al., Chem. En#. Progr., 44, 691 (1948). ENG.CHEM., 37, 588 Kroll, A. E., and Fairbanks, H. T., IND. (1945). Lansford, W. M., Ureiu.Illinois Eng. E x p t . Sta., Bull. 289 (1936). Lapple, C. E., Chem. Eng., 56, No. 5, 96 (1949). Nord, M., Ibid., 57, Ko, 7 , 113 (1950). Perry, J. H., Chemical Engineers Handbook, p. 377, New York, McGraw-Hill Book Co., 1950. Ibid., p. 415. Steams, R. F., et al., Flow Measurements with Orifice Meters, New York, D. Van Kostrand Co., 1951.

RECEIVED for review May 22, 1953.

ACCEPTED January 22, 1954. Presented before the Regional Conclave of t h e A M E R I C A N CHEMICAL SOCIETY, Kew Orleans, La., Deo. 10-12, 1953.

Kinetics of Coupled

GERARD

N. VRIENS

American Cyunumid Co., Bound Brook, N. J

kinetically like a system of coupled-i.e., consecutive, or parallel-first-order, reversible reactions. This may be so even if the reactions are truly second order, provided that either one reactant is present in considerable excess or its concentration is maintained a t a constant level throughout the reaction. In still other cases reactions of more complex order may be represented empirically with sufficient accuracy by the first-order equations. Even when a quantitative representation of the reaction kinetics is not given by the simpler first-order equations, considerable insight into the reaction mechanism may often be obtained from them. This is particularly advantageous when, as is the case with coupled reversible reactions, an exact mathematical solution of the kinetics of higher ordered reactions is generally not possible. The system of coupled, first-order, reversible reactions is one of the most complex kinetic systems to be capable of exact mathematical analysis. Solutions for the case of consecutive reactions have been given ( I , 2, 4, 6); unfortunately, in tyro cases they contain errors (2, 6). Furthermore, the solutions referred to are complex and difficult to apply. The case for parallel reactions does not appear to have been solved. The purpose of this paper is to present the solutions to this important kinetic system for both consecutive and parallel reactions in a form which is simplified for ready application by the use of dimensionless ratios and groups. These equations, in the form given, have been conveniently and successfully applied to the study of several commercial reactions in these laboratories. The special conditions under which the kinetics of parallel reactions resemble those of consecutive reactions are discussed in detail.

Dimensionless Groups and Ratios Are Employed To Develop Solutions for First-Order Rate Equations

ANY chemical proccsses of industrial importance behave

2

where

5

k,x - ksy - kay + k4z

r + y + z = l

= mole fraction of mixture present as A a t time t = mole fraction present as B at time 1

y

z

= mole fraction present kl = specific rate constant kz = specific rate constant k3 = specific rate constant ka = specific rate constant

as C a t time t for conversion for conversion for conversion for conversion

of of of of

A to B B to A B to C C to B

Equations 1 to 4 can be solved simultaneously to give the following second-order differential equations:

(5)

d2z

+ (kl + kz + ka + ka) 2 + (kik + kzka + kika) z

dz

kika

(6)

Consider the following system of equations:

A &BaC kz k4

Then

ki

k3

@

dt

= kzy -

klx

Solutions to Equations 5 and 6 will be given under the boundary conditions imposed by the t a o most important cases, that of consecutive reactions in which case the starting material consists entirely of A and that of parallel reactions in which case the starting material consists entirely of B. Case I. Consecutive Reversible Reactions. Consecutive reversible reactions are commonly encountered in practice as, for example, in the case of alkylations in which 2 moles of alkylating agent react successively with the substrate. If the alkylating agent is present in excess or is maintained a t a constant concentration, or pressure, the first-order equations may be expected to apply. Of course, in such a case the pseudo equilibrium constants for the first-order reactions will be a function of the particular concentration of alkylating agent used. The equations for consecutive, firsborder, reversible reactions were first solved and discussed in detail by Lowry and John (4). Solutions have also been presented, in slightly different forms, by Frost and Pearson ( I ) , Sherwood and Reed (6), and Hougen and Watson ( 2 ) . I n the case of the latter two references, errors in

April 1954

INDUSTRIAL AND ENGINEERING CHEMISTRY

669

ENGINEERING, DESIGN, AND PROCESS DEVELOPMENT

sign occur in several of the formulas for the constants of integration. These discrepancies ma>- bc observed by comparing the formulas given in this paper with those in the references cited. I n all of these prior solut,ions, from two to four reaction rate constants appear in the final equations, thue making them estrrmely awkward to apply t o actual reaction rate studies. I n the follo.il-ing solutions these constants have been completely eliminated. Before solving Equations 5 and 6 it is desirable to simplify the constants. Although the four reaction rate constant. will vary wit,h the process variables, it is usually true that ratios of these constants are relatively independent of th(3 temperature, catalyst, etc. For esample, k l / k 2 and k3/k4 represent equilibrium constants which are completely independent oi' the catalyst, and, in most cases, nearly independent' of the temperature over the narrow temperature ranges normally of commercial interest. Similarly, the ratio of t,he forward rat? constants for the two reactions, 1;3/kl: may be expected to h t comparatively constant over varying reaction conditions, provided the consecutive reactions are of the same general t>.pp. Equations 5 and 6 may be rewritten as follows:

In order to use these equations it if necessary to determine the values of the three constants, K I ,K z ,and a. The two equilibrium constants may easily be evaluated by making a single run under conditions such that a close approach to equilibrium is attained and then measuring the resulting ratios of the three c*omponents. The value of a may be estimated by experimentally determining the variation of composition as the rea~tion proceeds. If y has a maximum, which will be true whenever cu <K?, then the problem is simplified to finding that value of a xhich, when substituted in Equations 11 and 12, will give thi. same maximum for 1-2-8. As a first approximation the relatioriship, ymaS. = N which holds for consecutive irreversiblc reactions. map frequently be convenient to use. After the constants have been evaluated, a plot may bc constructed of 5, y, and z versus e from Equations 4, 11, and 12. This graph will be characte ic of t,he reaction system unt1i.r. consideration and essentially independent of the process conditions. From the composition of a given reaction product, the corresponding value of 6' may either be read from the plot or calculated from Equations 11 or 12. Rl- dividing 6' by the time of reaction t,he value of t,he rate constant, kl, may be determind and used to characterize the rate of reaction under the particular conditione used. Thus, the effect of the process variables on the reaction rate may be studied directly in spite of the fact that four different rate constants appear in the general solution to the kinetic equations. Case 1 1 . Parallel Reversible Reactions. Parallel reversi1)k reactions occur most frequently in the case of substitution rc:l'-tions in which two isomers may be formed-for esample, in certain sulfonations. First-order kinetics may apply i f the sulfonating agent is present in large excess: if it is continually fortifie:l, or if the water of reaction is removed continuously. Although the pseudo equilibrium constants for the first-order reactioria will be a function of the strength of the sulfonating agent, the equilibrium between the tn-o isomers is independent of this variable. By making substitutions of the same general type as were made in Case I, Equations 5 and G may be converted to the following form, in which all of the rate const,antshave been eliminated:

u-here

I<:

= =

k 1 / k 2 = equilibriuni constant for the formation of B

Icy

cI

from A k J k 4 = equilibrium conptant for the formation of C from B = k3,'k, = ratio of forward rate constants for t h e consecutive reactions

All but one of the reaction rate constants have been eliminatctl If the final substitution of % = h ~ is t made in Equations 7 and 8 the resulting equations take the f o ~ m

d2X

de? -

+(]+K+"+&i

.Ir

There 6 = a measure of the extent of approach t o equilibrium. A11 of the terms of Equations 9 and 10 consist of dimensionless ratios or groups and every constant is essentially independent of the r e a d o n conditions, including the reaction rate. The boundary conditions for this case are, when e = 0: x = 1; 0 dx - = -1 , @ d B = 0 . Using standard methods for solving 2

d6

linear differential equations with constant coefficients, t,he following solution may be obtained:

where

IC3

e

670

from R = k , / h z = ratio oi. forward rate constants for the parallel reactions

=

Ic2t

ki/'kl = equilibrium constarit for the formation of

i l

INDUSTRIAL A N D ENGINEERING CHEMISTRY

Vol. 46, No. 4

ENGINEERING, DESIGN, AND PROCESS DEVELOPMENT

The boundary conditions for this case are when 6 = 0, x = 0,

2

1oi

08

= 0,

dx

~

dB = 1,

CiZ

2 6

p.

On applying these conditions to the

i:

- Consecutive

- - Parallel

6

where

c.

a

P I+m3 __0 3 - Da

0 0 w 0 1

------2

I

io

Figure 1.

Comparison of Kinetics of Hypothetical Systems of Consecutive and Parallel Reactions

As was true in Case I, only three constants, K,, Ks. and @-all relatively independent of reaction conditions-must be known in order to use Equations 15 and 16 and to construct a graph of 2, y, and z versus e. The equilibrium constants may again be determined by an equilibrium run, and the value of p is best calculated by extrapolating the ratio of the reaction products obtained a t low conversions back to zero conversion. The value of 6 corresponding to a given reaction product may be divided by the time of reaction to give a value of the rate constant, kz, which may then be used as a measure of the reaction rate.

Kinetics of Parallel Reactions Resemble Those of Consecutive Reactions under Special Conditions

Under certain conditions the kinetics of reversible parallel reactions are similar to those of consecutive reactions. This is true when the product-e.g., isomer-which is formed more rapidly is the less stable thermodynamically. Under these circumstances this product will initially increase to a maximum and then gradually be replaced by the other product. The effect is as though it were the intermediate in a series of consecutive reactions, whereas actually the transformation of one product into the other involveb first a reversal of the reaction bv which the former was formed. This situation is illustrated by Figure 1, in which the kinetics of two hypothetical systems of consecutive and parallel reactions are compared. The solid lines represent consecutive reactions; the data were obtained by solving Equations 4, 11, and 12 for a = 0.30, K1 = 9.45, and Kz = 1.246. The broken lines represent parallel reactions and were obtained by solving Equations 4, 15. and 16 where p = 0.40, K Z = 100, and K B = 4.65. I n view of the general similarity of the two sets of curves, it is not surprising that controversy has frequently appeared in the literature over which mechanism applies in a given case. A good method of distinguishing between the two cases in such a situation is to study the reaction a t a very low

range of conversions. I n Case I1 (parallel reactions) the ratio of the two products will be nearly constant over this range, while in Case I this ratio r i l l change rapidly. A classical example is the monosulfonation of naphthalene in 13 hich a-naphthalenesulfonic acid, the predominating product duiing the early stages of the reaction, is gradually replaced by the beta isomer as the reaction proceeds. In a brilliant paper, Lantz (3)demonstrated qualitatively that the conversion of the alpha to the beta sulfonic acid takes place by a desulfonationresulfonation mechanism rather than by a direct isomerization. The solutions presented in the present paper for parallel reversible reactions show quantitatively how this type of transformation may take place and give mathematical support to the intuitive concepts of Lantz. Another example is the dialkylation of benzene, in which the ortho and para derivatives that form the predominant product a t low temperatures or with mild catalysts are converted to the more stable b u t less rapidly formed meta isomer under more *were reaction conditions. I t is generally agreed that this transformation involves dealkylation-realkylation and, therefore, it may be expected that if the ortho and para isomers are treated AS a single compound the equations for parallel reversible reactions may also be applied to this case. Undoubtedly, many other reaction systems exhibit this type of behavior and it is hoped that the equations presented will be of some value in studying the kinetics of such systems. The equations derived in this paper are valid only for batch ieactions or for continuous reactions in long tubular reactors and do not hold for continuous stirred tank reactors.

Acknowledgment

The review and suggestions of R. H. Wilhelm of Princeton University are gratefully acknowledged.

literature Cited

(1) Frost, A. A ,

p.

(2)

(3)

(4)

(5)

and Pearson, R. G., Kinetics and Mechanism, 162, New York, John Wiley & Sons, 1953. Hougen, 0. A., and Watson, K. >I., Chemical Process Principles, p. 831, New York, John Wiley & Sons, 1947. Lantz, R., Bull. SOC. chim., 2, 2092 (1935). Lowry, T. M., and John, W. T., J . Chem. SOC., 97, 2634 (1910). Sherwood, T. K., and Reed, C. E., Applied Mathematics in Chemical Engineering, p. 110, New York, McGram-Hill Book Co., 1939.

RECEIVED for review October 16, 1953. ACCEPTED February 1, 1954. Presented before the Industrial and Engineering Group at the Meeting-inf the North Jersey Section of the AMERICAN CHEMICAL SOCIETY, Miniature o Jan. 2 5 , 1954.

~~

~~

April 1954

INDUSTRIAL AND ENGINEERING CHEMISTRY

671

S-ar putea să vă placă și

- LS050T1SX01 PDFDocument23 paginiLS050T1SX01 PDFRoman BeránekÎncă nu există evaluări

- Er63419 Rev101 140628Document329 paginiEr63419 Rev101 140628Roman BeránekÎncă nu există evaluări

- Acre MSC Part 3 20 Feb 2014Document16 paginiAcre MSC Part 3 20 Feb 2014Salman HaroonÎncă nu există evaluări

- Linear Free Energy Relationships (LFER) As A One Hour Class-Room Lecture For Post-Graduate Students: Correlation of The Nature of The Transition StatesDocument8 paginiLinear Free Energy Relationships (LFER) As A One Hour Class-Room Lecture For Post-Graduate Students: Correlation of The Nature of The Transition StatesLe BlubÎncă nu există evaluări

- Analysis of Ester Hydrolysis Reactions in A Chromatographic Reactor Using Equilibrium Theory and A Rate ModelDocument10 paginiAnalysis of Ester Hydrolysis Reactions in A Chromatographic Reactor Using Equilibrium Theory and A Rate ModelCarlos Andrés Martínez CristanchoÎncă nu există evaluări

- The Behaviour of Porous Catalyst Particles in View of Internal Mass and Heat Diffusion EffectsDocument8 paginiThe Behaviour of Porous Catalyst Particles in View of Internal Mass and Heat Diffusion EffectsJosé Manuel CarreónÎncă nu există evaluări

- Loba To 2006Document4 paginiLoba To 2006usercmdmcÎncă nu există evaluări

- Flash Calculation Stability PDFDocument12 paginiFlash Calculation Stability PDFAndre BecÎncă nu există evaluări

- Days 1 and 2: Introduction and Overview: Definitions Of, and Notation For, Reaction RatesDocument13 paginiDays 1 and 2: Introduction and Overview: Definitions Of, and Notation For, Reaction RatesClarence AG YueÎncă nu există evaluări

- Effectiveness Factor For Porous Catalysts: Langmuir-Hiizshelwood Kinetic ExpressionsDocument6 paginiEffectiveness Factor For Porous Catalysts: Langmuir-Hiizshelwood Kinetic ExpressionsnoviÎncă nu există evaluări

- GPU-based Reaction Ensemble Monte Carlo Method For Non-Ideal Plasma ThermodynamicsDocument28 paginiGPU-based Reaction Ensemble Monte Carlo Method For Non-Ideal Plasma ThermodynamicsAndreina Dell'olioÎncă nu există evaluări

- Mathematical BiologyDocument15 paginiMathematical BiologyAsna AzkiaÎncă nu există evaluări

- Estabilizacion de Reactores CSTRDocument28 paginiEstabilizacion de Reactores CSTRlamtrauÎncă nu există evaluări

- " - Si, - P-Z: Convergence Criteria For Iterative ProcessesDocument2 pagini" - Si, - P-Z: Convergence Criteria For Iterative ProcessesKtk ZadÎncă nu există evaluări

- Philip 1981Document9 paginiPhilip 1981swatiÎncă nu există evaluări

- Nico 2005Document7 paginiNico 2005ERICK JESUS MUÑOZ HERNANDEZÎncă nu există evaluări

- Articulo Equilibrioquimico 19661Document4 paginiArticulo Equilibrioquimico 19661dexgigiÎncă nu există evaluări

- Approximation Techniques in Complex Reaction Kinetics: DannyDocument18 paginiApproximation Techniques in Complex Reaction Kinetics: DannyDeep GhoseÎncă nu există evaluări

- Nonequilibrium Contributions To The Rate of Reaction. I. Perturbation of The Velocity Distribution FunctionDocument18 paginiNonequilibrium Contributions To The Rate of Reaction. I. Perturbation of The Velocity Distribution FunctionCarolina RibeiroÎncă nu există evaluări

- SenkinDocument26 paginiSenkinSudip AdhikariÎncă nu există evaluări

- Chemical Reactor Stability and SensitivityDocument9 paginiChemical Reactor Stability and Sensitivityturki aljowderÎncă nu există evaluări

- Experiment 6Document11 paginiExperiment 6CarlosLorenzoSaninÎncă nu există evaluări

- Applications of The Group Contribution Lattice Fluid 2002 Fluid Phase EquiDocument21 paginiApplications of The Group Contribution Lattice Fluid 2002 Fluid Phase EquiAnonymous ypVNIIÎncă nu există evaluări

- 01 Ethacet 367 101Document4 pagini01 Ethacet 367 101Saeed KazemiÎncă nu există evaluări

- Instability of Successive SubstitutionDocument9 paginiInstability of Successive SubstitutionYTÎncă nu există evaluări

- Three-Parameter Cubic Equation of State For Normal SubstancesDocument4 paginiThree-Parameter Cubic Equation of State For Normal SubstancesFiorela VillalobosÎncă nu există evaluări

- Vapor-Liquid Equilibria of Nonideal Solutions: Harrison C. Carlson, and Allan P. ColburnDocument10 paginiVapor-Liquid Equilibria of Nonideal Solutions: Harrison C. Carlson, and Allan P. ColburnAlfonso Dominguez GonzalezÎncă nu există evaluări

- Introduction & Overview To Chemical Reaction Engineering IIDocument12 paginiIntroduction & Overview To Chemical Reaction Engineering IIshubhamÎncă nu există evaluări

- Diffusion and Reaction in Ideal Multicomponent Systems - II. Behavior Away From Equilibrium (1971)Document5 paginiDiffusion and Reaction in Ideal Multicomponent Systems - II. Behavior Away From Equilibrium (1971)sutrimaÎncă nu există evaluări

- Reactors1 16Document3 paginiReactors1 16Mourad kharbachÎncă nu există evaluări

- L3 Competencies: This One Is Too EasyDocument12 paginiL3 Competencies: This One Is Too Easykrymxen100% (1)

- Joljrnal of Computational PhysicsDocument17 paginiJoljrnal of Computational PhysicsKaustubhÎncă nu există evaluări

- Dynamics of Reactions in Polar Solvents. Semiclassical Trajectory Studies of Electron-Transfer and Proton-Transfer ReactionsDocument7 paginiDynamics of Reactions in Polar Solvents. Semiclassical Trajectory Studies of Electron-Transfer and Proton-Transfer ReactionsMoh SyaifudinÎncă nu există evaluări

- Molecular OrbitalsDocument123 paginiMolecular Orbitalsel ioiosxdxdxdxzdÎncă nu există evaluări

- A Complex Plane Representation of Dielectric and Mechanical Relaxation Processes in Some PolymersDocument50 paginiA Complex Plane Representation of Dielectric and Mechanical Relaxation Processes in Some Polymerslezki100% (1)

- A Theoretical Justification For The Application of The Arrhenius Equation To Kinetics of Solid State Reactions (Mainly Ionic Crystals)Document12 paginiA Theoretical Justification For The Application of The Arrhenius Equation To Kinetics of Solid State Reactions (Mainly Ionic Crystals)Mwengei MutetiÎncă nu există evaluări

- Referenced Paper PDFDocument8 paginiReferenced Paper PDFMichael Taylor WarrenÎncă nu există evaluări

- Draft 75 Applications of Inverse Gas Chromatography in The Study of Liquid Crystalline Stationary PhasesDocument36 paginiDraft 75 Applications of Inverse Gas Chromatography in The Study of Liquid Crystalline Stationary PhasesberkahÎncă nu există evaluări

- Propiedades de LindemanDocument31 paginiPropiedades de LindemanMari MHÎncă nu există evaluări

- Determination of Binary Gas Diffusion Coefficients in SPH - 1988 - MathematicalDocument5 paginiDetermination of Binary Gas Diffusion Coefficients in SPH - 1988 - MathematicaldarshanÎncă nu există evaluări

- Complex Reactions: Dr. Rer. Nat. Deni RahmatDocument38 paginiComplex Reactions: Dr. Rer. Nat. Deni Rahmathelenismaya100% (1)

- Sridhar 1989Document11 paginiSridhar 1989zhexuanliuoutlook.comÎncă nu există evaluări

- Numerical Aspect of Equation of State in Flash CalculationsDocument11 paginiNumerical Aspect of Equation of State in Flash CalculationsHalima OunisÎncă nu există evaluări

- Kinetics: A Common Case of Increased Complexity Is When Consecutive or Parallel Reactions Occur in The Food MatrixDocument12 paginiKinetics: A Common Case of Increased Complexity Is When Consecutive or Parallel Reactions Occur in The Food MatrixKurnia Perdana PangestikaÎncă nu există evaluări

- Computation of Hydration Free Energies A Parameterized Continuum Model: Equilibrium Geometries and Reactive Processes Water SolutionDocument8 paginiComputation of Hydration Free Energies A Parameterized Continuum Model: Equilibrium Geometries and Reactive Processes Water SolutionLata DeshmukhÎncă nu există evaluări

- MIT5 07SCF13 Lec7 8Document19 paginiMIT5 07SCF13 Lec7 8Ruben RodriguezÎncă nu există evaluări

- PhysRevE 77 066210 2008Document9 paginiPhysRevE 77 066210 2008Vagaf1825Încă nu există evaluări

- Evaluation of Kinetic Parameter Calculation Methods For Non-Isothermal Experiments in Case of Varying Activation Energy in Solid-State Transformations PDFDocument19 paginiEvaluation of Kinetic Parameter Calculation Methods For Non-Isothermal Experiments in Case of Varying Activation Energy in Solid-State Transformations PDFnonameÎncă nu există evaluări

- 1 s2.0 000925097780225X MainDocument8 pagini1 s2.0 000925097780225X MainLiew Sing JieÎncă nu există evaluări

- Etd Chapt 6Document69 paginiEtd Chapt 6Miruna PetriaÎncă nu există evaluări

- Modelling of Low-Mach Number Gas Flame PropagationDocument10 paginiModelling of Low-Mach Number Gas Flame Propagationfrancesco_sm64Încă nu există evaluări

- Approach To: Renormalization-Group InteractingDocument64 paginiApproach To: Renormalization-Group InteractingChern ChuangÎncă nu există evaluări

- Houk 1997Document11 paginiHouk 1997Nicolas Rodriguez CaviedesÎncă nu există evaluări

- Compositional SimulationDocument61 paginiCompositional SimulationCorey McKeonÎncă nu există evaluări

- Unit-I 10Document17 paginiUnit-I 10Dude BoysÎncă nu există evaluări

- 22-2002-Residue Map ReadingDocument16 pagini22-2002-Residue Map Readingehsan zeraatkarÎncă nu există evaluări

- Lo Cholette 1983Document6 paginiLo Cholette 1983Angel MarianoÎncă nu există evaluări

- Frequency Dependence of Catalyzed Reactions in A Weak Oscillating FieldDocument6 paginiFrequency Dependence of Catalyzed Reactions in A Weak Oscillating Fielddeanast1Încă nu există evaluări

- TMP 7421Document14 paginiTMP 7421FrontiersÎncă nu există evaluări

- 2tgnkokpct (5rgekhkecvkqp: %Wuvqogt0Cogj6% 2Tqfwev0Cogȟ&Kcoqpf93 &#/1.'& /Qfgn0Cog#/5-& Dncem &guetkrvkqpȟ93 & /%QNQTDocument56 pagini2tgnkokpct (5rgekhkecvkqp: %Wuvqogt0Cogj6% 2Tqfwev0Cogȟ&Kcoqpf93 &#/1.'& /Qfgn0Cog#/5-& Dncem &guetkrvkqpȟ93 & /%QNQTRoman BeránekÎncă nu există evaluări

- LS055R1SX04 PDFDocument33 paginiLS055R1SX04 PDFRoman Beránek100% (1)

- Spec KWH050ST26 F01 PDFDocument25 paginiSpec KWH050ST26 F01 PDFRoman BeránekÎncă nu există evaluări

- Specification OF LCD Module Module No. : TL040WVV27CT3-H1098ADocument23 paginiSpecification OF LCD Module Module No. : TL040WVV27CT3-H1098ARoman BeránekÎncă nu există evaluări

- Er63311 Rev101 121112Document331 paginiEr63311 Rev101 121112Roman BeránekÎncă nu există evaluări

- MIPI DCS Specification v1.02.00Document128 paginiMIPI DCS Specification v1.02.00Roman BeránekÎncă nu există evaluări

- Ili9806e An V093 20140328 PDFDocument116 paginiIli9806e An V093 20140328 PDFRoman BeránekÎncă nu există evaluări

- Pioneer CDJ 800 Service ManualDocument78 paginiPioneer CDJ 800 Service ManualRoman BeránekÎncă nu există evaluări

- Unit 3. Mixtures and Pure SubstancesDocument36 paginiUnit 3. Mixtures and Pure SubstancesArman VillagraciaÎncă nu există evaluări

- Passive Layer (EDTA Cleaning)Document7 paginiPassive Layer (EDTA Cleaning)coincoin1Încă nu există evaluări

- Carbon Dioxide Utilization in Ready-Mixed Concrete ProductionDocument24 paginiCarbon Dioxide Utilization in Ready-Mixed Concrete Productionjack21ab100% (1)

- PHMD 311 NMR 20121Document91 paginiPHMD 311 NMR 20121kafful1321Încă nu există evaluări

- Curriculum Vitae (CV)Document4 paginiCurriculum Vitae (CV)Muhammad Fitrah SaidussuhurÎncă nu există evaluări

- Electrostatic Precipitator Modeling and SimulationDocument37 paginiElectrostatic Precipitator Modeling and Simulationshruti001shah100% (1)

- Moles Concept WorksheetDocument2 paginiMoles Concept Worksheetbernadeth m. barajas100% (1)

- Dry Gas SealDocument23 paginiDry Gas Sealdrg100% (1)

- Worksheet 5 (Acids-Bases III) With AnswersDocument2 paginiWorksheet 5 (Acids-Bases III) With AnswersDelilah StephenieÎncă nu există evaluări

- 124 06 Iodine Clock Kinetics JAN 2014Document10 pagini124 06 Iodine Clock Kinetics JAN 2014M Faqri Fahrozi HÎncă nu există evaluări

- Cambridge O Level: Chemistry 5070/21 October/November 2022Document12 paginiCambridge O Level: Chemistry 5070/21 October/November 2022Ayman Obaidur RahmanÎncă nu există evaluări

- Thermodynamic Properties of Nitrogen Tetroxide: Donald F. Stai, Frank Bizjak, F and S. E. Stephanou!Document4 paginiThermodynamic Properties of Nitrogen Tetroxide: Donald F. Stai, Frank Bizjak, F and S. E. Stephanou!Tu LEÎncă nu există evaluări

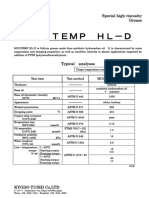

- Multemp HL-DDocument1 paginăMultemp HL-DVishal AmleÎncă nu există evaluări

- CHEM 430 NMR Spectroscopy Chapter 6Document77 paginiCHEM 430 NMR Spectroscopy Chapter 6Triana FebriantiÎncă nu există evaluări

- Lectures 2.1 - One Dimensional Heat Conduction PDFDocument14 paginiLectures 2.1 - One Dimensional Heat Conduction PDFHussain AliÎncă nu există evaluări

- Thermal Resistance of Air CavityDocument1 paginăThermal Resistance of Air CavityAhmed MostafaÎncă nu există evaluări

- Thermo ChemistryDocument13 paginiThermo ChemistryGalib FidaÎncă nu există evaluări

- Andrea Callegari Et Al - Dipole Moments of Highly Vibrationally Excited WaterDocument3 paginiAndrea Callegari Et Al - Dipole Moments of Highly Vibrationally Excited WaterKmaxx2Încă nu există evaluări

- Physics Investigatory ProjectDocument12 paginiPhysics Investigatory ProjectAyushi ShakyaÎncă nu există evaluări

- Siloxane Removal With Gas Permeation MembranesDocument2 paginiSiloxane Removal With Gas Permeation MembranesaydinjalaliÎncă nu există evaluări

- Correlated Metals As TCO SIDocument34 paginiCorrelated Metals As TCO SISaeed MishalÎncă nu există evaluări

- Wetted Wall Column Experiment and Set UPDocument4 paginiWetted Wall Column Experiment and Set UPvarun kumarÎncă nu există evaluări

- Principles of Operation and Theory: 2-1. Types of Adsorption MediaDocument20 paginiPrinciples of Operation and Theory: 2-1. Types of Adsorption MediaYoyoo SuharyoÎncă nu există evaluări

- A Comparison of Evaporative and Conventional Freezing Prior To Freeze-Drying of Fruits and VegetablesDocument6 paginiA Comparison of Evaporative and Conventional Freezing Prior To Freeze-Drying of Fruits and VegetablesMelih SahinÎncă nu există evaluări

- 9what Is A Boiler?Document59 pagini9what Is A Boiler?Ali MuradÎncă nu există evaluări

- Specific Heat CapacityDocument25 paginiSpecific Heat CapacityZae ZayÎncă nu există evaluări

- Ion-Exchange Membranes: Preparative Methods For Electrodialysis and Fuel Cell ApplicationsDocument23 paginiIon-Exchange Membranes: Preparative Methods For Electrodialysis and Fuel Cell ApplicationsJose Antonio Siñani VilteÎncă nu există evaluări

- Preliminary Examination: Physical State Color Odor (Waft)Document5 paginiPreliminary Examination: Physical State Color Odor (Waft)tincuyuganÎncă nu există evaluări

- Cro Tut8Document13 paginiCro Tut8Ernst SmitÎncă nu există evaluări