Documente Academic

Documente Profesional

Documente Cultură

Future of Electronics

Încărcat de

Prad DingariDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Future of Electronics

Încărcat de

Prad DingariDrepturi de autor:

Formate disponibile

A DARPA Perspective on the Future of Electronics

John C. Zolper DARPA/MTO 3701 North Fairfax Dr., Arlington, VA 22203 jzolper@darpa.mil

PH: 703 696 7039 Keywords: DoD, electronics, DARPA, Intelligent Microsystems Abstract: This paper gives a brief review of the role of the DoD in the development of key electronics technology, offers an assessment of the current role of DoD, and particularly DARPA, in electronics technology development, and gives a view of what could occur over the next 10 years. INTRODUCTION The US Department of Defense (DoD) has always had electronic component and system requirements that far out strip current commercial needs. The requirements are driven by the need to operate in harsh environments (elevated temperature, high radiation, etc), detect small targets at long range, process high rate sensor data in real time, and operate outside of commercial spectrum bands, to name a few. This has led the DoD to often lead the development of high performance electronic components, developments that have in turn sparked large commercial applications such as the personnel computer and cellular phone. With the change in the core structure of the DoD industrial based over the past 10 years there has been a consolidation of component development and production capability. At the same time the Department has experienced a period where Commercial Off the Shelf (COTS) technology was deemed sufficient for system requirements. The COTS emphasis was driven largely by cost reduction

Copyright 2003 GaAsMANTECH, Inc.

objectives, often at the expense of system performance. However, the recent drive to transform the US military appears to require electronic component technology well in excess of that available via COTS. This has lead DARPAs Microsystems Technology Office to expand its investment in high risk, high payoff electronics research. DoD ELECTRONICS DEVELOPMENTS After the invention of the transistor in 1948 at Bell Laboratories and the Integrated Circuit in 1959 at Texas Instruments, solid state electronics has seen a steady and increasing level of performance and complexity. In the early 1980s silicon integrated circuits were being commercialized and the DoD needed to insure access to the highest performance digital circuits to maintain their technology advantage. As the level of circuit integration and complexity increased, it was further understood that advanced interconnect technology and design tools were necessary to speed circuit development and optimized performance. At that time, a program on Very High Speed Integrated Circuits (VHSICs) was initiated through the Office of the Secretary of Defense (OSD) to address these issues. The program ran from 1980 to 1990 and established the US as the premier producer of silicon ICs in the world. In a similar time period the Defense Advanced Research Projects Agency (DARPA) initiated the GaAs Pilot Line Program to establish GaAs digital integrated circuits to directly compete with silicon technology. While this effort was technically successful in developing complex, high speed GaAs digital circuits, largely based on ion implanted GaAs

2003 International Conference on Compound Semiconductor Mfg.

MESFETs, the ever increasing capability of silicon CMOS captured the dominate role in the commercial IC market as it followed Moores law with a doubling in transistor count every two years. While GaAs digital circuits did not become a dominant technology, its development, along with another DoD program, established the infrastructure that lead to the wireless revolution. In 1985 DoD initiated a program to transition the basic research progress in GaAs microwave technology funded by the Office of Naval Research, the Air Force Office of Scientific Research, and the Army Research Office to develop manufacturable GaAs high frequency amplifiers under the Microwave/Millimeter Wave Monolithic Integrated Circuits (MIMIC) program.i This effort was initially conceived to reduce the cost and increase the reliability of GaAs rf components that were needed for radar, communications, and electronic warfare. To that point, solid state rf components were largely discrete devices fabricated into hybrid circuits with each circuit requiring custom tuning. The MIMIC program, initiated in the OSD and later transfer to DARPA, lead to the first demonstration of a multi-watt monolithic microwave IC. A timeline of GaAs microwave technology development and the MIMIC program showing key technical milestones is given in Figure 1. This program established GaAs MMIC as a viable technology for DoD systems and also directly led to the subsequent explosion of wireless technology. Not only was the device and circuit manufacturing established, but also the design and testing capability was developed that enabled a broad range of circuit developments. Further still, the DoD investment directly, or indirectly, educated a generation of engineers skilled in microwave device and circuit technology. This engineering base carried the US to the forefront of rf/microwave electronics technology.

GaAs Microwave Amplifier Chronology

1st GaAs X-band MMIC 1st GaAs MESFET 1st GaAs X-band amp 400 mW X-band MMIC X-band MMIC w/ >30% PAE 4.5 W X-band FET MMIC; 5-10 W HBT MMIC

1st HEMT

1964 1970 1974 1978 1982 1986 1990 1994

MIMIC Program

Figure 1: Chronology of GaAs microwave transistor and monolithic integrated circuit development. Following the MIMIC program, DARPA initiated the Microwave Analog Front End (MAFET) program that moved on to develop InP technology to extend the frequency of operation for solid state components into the W-band. CURRENT DARPA INVESTMENTSii Currently DARPA, through the Microsystems Technology Office (MTO), is investing in the next generation of compound semiconductor materials (6.1 angstrom materials and wide bandgap semiconductors) and in the frontier of scaled silicon and SiGe technology for DoD unique circuits. The 6.1 angstrom materials (GaSb, InAs, and AlSb) are expected to enable extremely low noise mm-wave receivers and sub-one-volt mixed signal logic as a result of their extremely high mobility (up to 33,000 cm2/Vs at room temperature) and saturated electron velocity (over 4x107 cm/s) at low field. The current MTO Antimonide Based Compound Semiconductor (ABCS) program is developing InAs-based HEMTs and HBTs with high speed operation between 0.5 and 1.0 V. Wide bandgap semiconductors, namely SiC and GaN, are being developed for both power conversion and distribution, and for high frequency amplifiers. A phase I MTO program is focused at establishing the necessary substrate and epitaxial material quality and uniformity to allow large area power devices and complex microwave

Copyright 2003 GaAsMANTECH, Inc.

2003 International Conference on Compound Semiconductor Mfg.

circuits to be realized during phase II. These materials offer the potential for ten times higher power densities, with operation at high temperature and higher frequency (for a given power), than conventional solid state devices. MTO is pursuing efforts in wide bandwidth, high dynamic range mixed signal circuits to establish the components necessary for DoD systems to exploit reprogrammable, multifunction digital RF architectures. Two MTO programs are targeting complex mixed signal circuits such as direct digital synthesizers and analog-todigital converters. The first, Technology for Efficient Agile Mixed Signal Microsystems (TEAM), is exploiting the integration and processing capability of aggressively scaled SiGe HBTs to exploit this technology for mixed signal circuits with clock frequencies in the 10s of GHz enabled by HBTs with cutoff frequencies over 350 GHz.iii The program will explore circuit topologies enable by the integration of mixed bipolar and CMOS circuits for high precision circuits. A second program, Technology for Frequency Agile Digitally Synthesized Transmitters (TFAST), is developing superscaled InP DHBT to fully exploit the carrier transport and breakdown properties of this material in increasingly more complex mixed signal circuits. The phase I program is developing the core transistor technology with a bench mark demonstration targeting a 150 GHz static flip flop from DHBTs with ft and fmax both greater than 350 GHz and with a breakdown voltage 4 V. The high breakdown voltage and linearity of InP DHBTs is expected to enable higher dynamic range mixed signal circuits at lower power than competing technology. The second phase will demonstrate complex (>20,000 transistors) circuits with clock speeds over 100 GHz. INTELLIGENT MICROSYSTEMS

reconfigurable, components whereby the operating conditions (e. g. bias point, efficiency, bandwidth, center frequency, etc.) can be changed in real time in response to autonomous sensors or digital control imbedded in the component. These new Intelligent Microsystems that can include aspects of sensing, computation, actuation, and power control, are seeking to exploit the technology overlaps of traditional digital, analog and mixed signal electronic technology with MicroElectroMechanical Systems (MEMS) and other dynamic circuit control techniques. To realize Intelligent Microsystems the functionality of different materials systems and device types must be seamlessly combined at the device, circuit, and sub-module level. This will require heterogeneous integration and design tools that can model complex interfaces and multiple device models. Increasingly, the core circuit and resulting microsystems will exploit three dimensional topologies to minimize signal and clock paths and optimize the overall performance. One example in this area is the Intelligent RF Front Ends (IRRFE) program that is seeking to embed digital control in analog RF components for real time control and optimization of RF front ends. This effort requires real time sensing of the analog waveform and dynamic reconfiguration of the input and output matching networks to alter the output for changing environmental conditions or mission requirements. With the combination of multiple materials and devices in closely spaced Microsystems, heat management and removal will become an ever more critical component. Removal of the excess heat will require the inclusion of advanced thermoelectrical cooling layers, embedded micro-channel cooling, or other advanced cooling schemes. CONCLUSION

Beyond the development of new materials and device structures, MTO is pursuing a new class of intelligent,

Copyright 2003 GaAsMANTECH, Inc.

military

The transformation of the US will require extending the

2003 International Conference on Compound Semiconductor Mfg.

underlying technology well beyond that available from commercial components. In particular, in the area of electronics, or more broadly, Intelligent Microsystems, the DoD will require dynamic, reconfigurable, components that can out performance the adversary in adverse conditions and be adapted to changing mission needs. The Microsystems Technology Office at DARPA is pursuing technology investments to deliver Intelligent Microsystems to the future warfighter and, as occurred with earlier generations of electronics, enable new commercial opportunities for DoD sponsored research. Acknowledgement: Dr. Robert Leheny, Director of MTO, is gratefully acknowledged for his contribution to this manuscript and establishing the vision for Intelligent Microsystems within MTO.

Acronyms: MMIC: Monolithic Microwave Integrated Circuit MESFET: Metal Semiconductor Field Effect Transistor HEMT: High Electron Mobility Transistor HBT: Heterojunction Bipolar Transistor MEMS: MicroElectroMechanical Systems VHSIC: Very High Speed Integrated Circuits

REFERENCES: i Eliot D. Cohen, MIMIC from the Department of Defense Perspective, IEEE Trans. Microwave Theory and Technique, vol. 38, no. 9, 1171 (1990). ii For details on DARPA/MTO programs see: https://www.darpa.mil/mto/radprograms.html iii J. -S. Rieh, et.al., SiGe HBTs with Cut-off Frequency of 350GHz, IEDM-02, paper 31.4 (2002).

S-ar putea să vă placă și

- 5HP500-590 4139 - 751 - 627dDocument273 pagini5HP500-590 4139 - 751 - 627ddejanflojd100% (24)

- Booklet - Frantic Assembly Beautiful BurnoutDocument10 paginiBooklet - Frantic Assembly Beautiful BurnoutMinnie'xoÎncă nu există evaluări

- Jake Atlas Extract 2Document25 paginiJake Atlas Extract 2Walker BooksÎncă nu există evaluări

- How Is Extra-Musical Meaning Possible - Music As A Place and Space For Work - T. DeNora (1986)Document12 paginiHow Is Extra-Musical Meaning Possible - Music As A Place and Space For Work - T. DeNora (1986)vladvaidean100% (1)

- 2001 Fiber Optic Technologies P-IIDocument34 pagini2001 Fiber Optic Technologies P-IIAnkur SagtaniÎncă nu există evaluări

- Integrating Scada Load SheddingDocument9 paginiIntegrating Scada Load Sheddinganeesh100% (1)

- Linearization and Efficiency Enhancement Techniques for Silicon Power Amplifiers: From RF to mmWDe la EverandLinearization and Efficiency Enhancement Techniques for Silicon Power Amplifiers: From RF to mmWÎncă nu există evaluări

- Favis vs. Mun. of SabanganDocument5 paginiFavis vs. Mun. of SabanganAyra CadigalÎncă nu există evaluări

- Jun2013 HFE0613 OEDocument68 paginiJun2013 HFE0613 OEMilorad RadenovicÎncă nu există evaluări

- Progress of Quantum Electronics and The Future of Wireless TechnologiesDocument5 paginiProgress of Quantum Electronics and The Future of Wireless TechnologiesMAZEN S MALÎncă nu există evaluări

- Dotfive: Towards 0.5 TeraHertz Silicon/Germanium Heterojunction Bipolar Technology (SiGe HBT)Document4 paginiDotfive: Towards 0.5 TeraHertz Silicon/Germanium Heterojunction Bipolar Technology (SiGe HBT)Audrey POGETÎncă nu există evaluări

- A Comparison, Opportunities and Challenges of Wireless Communication Technologies For Smart Grid ApplicationsDocument7 paginiA Comparison, Opportunities and Challenges of Wireless Communication Technologies For Smart Grid Applicationssaiful7271Încă nu există evaluări

- Design and Development of RF Energy Harvesting System: November 2020Document8 paginiDesign and Development of RF Energy Harvesting System: November 2020Alice LiewÎncă nu există evaluări

- Ijece 2023Document10 paginiIjece 2023Beulah JacksonÎncă nu există evaluări

- Massive MIMO Systems: Signal Processing Challenges and Future TrendsDocument9 paginiMassive MIMO Systems: Signal Processing Challenges and Future TrendsabdelÎncă nu există evaluări

- Wireless Communication Technology: A Case-Study Submitted For The Requirement ofDocument19 paginiWireless Communication Technology: A Case-Study Submitted For The Requirement ofJagdish PadhyÎncă nu există evaluări

- Comparative Analysis of Wireless Sensor Network Motes: Sachin Gajjar Nilav Choksi Mohanchur Sarkar Kankar DasguptaDocument6 paginiComparative Analysis of Wireless Sensor Network Motes: Sachin Gajjar Nilav Choksi Mohanchur Sarkar Kankar DasguptadhvbkhnÎncă nu există evaluări

- Seminar Report Submitted in Partial Fulfilment of The Requirements For The Award of The Degree ofDocument37 paginiSeminar Report Submitted in Partial Fulfilment of The Requirements For The Award of The Degree ofderviii100% (1)

- Thesis On Microwave DevicesDocument5 paginiThesis On Microwave Devicesleanneuhlsterlingheights100% (1)

- Souma Badombena Wanta, Cognitive Radios - Technical Report - Research PaperDocument17 paginiSouma Badombena Wanta, Cognitive Radios - Technical Report - Research Paperslinc_a82Încă nu există evaluări

- 1V DSP in Wireless Communication SystemsDocument4 pagini1V DSP in Wireless Communication SystemsInternational Jpurnal Of Technical Research And ApplicationsÎncă nu există evaluări

- 3G BTS Systems and NEC Electronics (1/2) : Mobile Phone System StructureDocument7 pagini3G BTS Systems and NEC Electronics (1/2) : Mobile Phone System StructureAnkit BajpaiÎncă nu există evaluări

- Circular Monopole Microstrip Antenna For UWB ApplicationsDocument10 paginiCircular Monopole Microstrip Antenna For UWB Applicationscommando1180Încă nu există evaluări

- 01 Overview of Broadband CommunicationsDocument51 pagini01 Overview of Broadband CommunicationsAimÎncă nu există evaluări

- Belleville 2013Document8 paginiBelleville 2013Gauswami HirvaÎncă nu există evaluări

- Communication Technology Resource ManagementDocument19 paginiCommunication Technology Resource ManagementClique for Applied Research in Electronic TechnologyÎncă nu există evaluări

- Technologies 11 00034 v2Document15 paginiTechnologies 11 00034 v2Moo NY RAÎncă nu există evaluări

- Energies: A Comprehensive Review On Iot Protocols' Features in Smart Grid CommunicationDocument24 paginiEnergies: A Comprehensive Review On Iot Protocols' Features in Smart Grid CommunicationCORAL ALONSO JIMÉNEZÎncă nu există evaluări

- WSN Based Smart Grid ApplicationDocument24 paginiWSN Based Smart Grid Applicationsarath1998shajiÎncă nu există evaluări

- The Application of A Wireless Sensor Network Design Based On Zigbee in Petrochemical Industry FieldDocument4 paginiThe Application of A Wireless Sensor Network Design Based On Zigbee in Petrochemical Industry FieldThi AgoÎncă nu există evaluări

- Research Article: Ming-An Chung and Chih-Wei YangDocument12 paginiResearch Article: Ming-An Chung and Chih-Wei YangSubba Rao ChalasaniÎncă nu există evaluări

- Technologies For Move Towards 5GDocument9 paginiTechnologies For Move Towards 5GAnonymous izrFWiQÎncă nu există evaluări

- Using IoT Applications For Detection and MonitorinDocument8 paginiUsing IoT Applications For Detection and Monitorinmadu1998Încă nu există evaluări

- 1 PBDocument9 pagini1 PBPhan PhúcÎncă nu există evaluări

- CNTFET - Technology - For - RF - Applications - Review - and - Future - Perspective - AplicaçõesDocument13 paginiCNTFET - Technology - For - RF - Applications - Review - and - Future - Perspective - AplicaçõesCarlosÎncă nu există evaluări

- Challenges in The Migration To 4GDocument36 paginiChallenges in The Migration To 4GSatti PanduÎncă nu există evaluări

- IoT Based Digital Twin For Energy CyberDocument19 paginiIoT Based Digital Twin For Energy CyberLindo PatoÎncă nu există evaluări

- Investigation of Future 5G-Iot Millimeter-Wave Network Performance at 38 GHZ For Urban Microcell Outdoor EnvironmentDocument26 paginiInvestigation of Future 5G-Iot Millimeter-Wave Network Performance at 38 GHZ For Urban Microcell Outdoor EnvironmentNhat Tran XuanÎncă nu există evaluări

- AbstractDocument3 paginiAbstracttariq qureshiÎncă nu există evaluări

- Some Recent Developments in RF and Microwave Circuit IntegrationDocument2 paginiSome Recent Developments in RF and Microwave Circuit Integrationarunkr1Încă nu există evaluări

- Meeting Challenges in IotDocument11 paginiMeeting Challenges in IotToni PerkovićÎncă nu există evaluări

- Green Communications Using Ambient Backscattered The Review PaperDocument6 paginiGreen Communications Using Ambient Backscattered The Review PaperIJRASETPublicationsÎncă nu există evaluări

- Energy Efficient Routing in Ad Hoc Disaster Recovery NetworksDocument10 paginiEnergy Efficient Routing in Ad Hoc Disaster Recovery NetworksLaura Jaramillo UparelaÎncă nu există evaluări

- Research Paper On WcdmaDocument8 paginiResearch Paper On Wcdmab0pitekezab2100% (1)

- Cybersecurity in Smart Grids, Challenges and SolutionsDocument14 paginiCybersecurity in Smart Grids, Challenges and Solutionsaramaky2001Încă nu există evaluări

- Space-Time Block Coding (STBC) For Wireless NetworksDocument13 paginiSpace-Time Block Coding (STBC) For Wireless NetworksijdpsÎncă nu există evaluări

- Enabling Process Bus Communication For Digital Substations Using 5G Wireless SystemDocument8 paginiEnabling Process Bus Communication For Digital Substations Using 5G Wireless SystemMarques SilvaÎncă nu există evaluări

- Radio Over Fiber Thesis GSKDocument50 paginiRadio Over Fiber Thesis GSKGoosaja100% (1)

- ADL High Throughput Satellites-Main ReportDocument20 paginiADL High Throughput Satellites-Main ReportSiapaajaÎncă nu există evaluări

- Development in Integrated CircuitsDocument6 paginiDevelopment in Integrated CircuitsRahul PanwarÎncă nu există evaluări

- VLSI SymposiaDocument20 paginiVLSI SymposiaaetherdexÎncă nu există evaluări

- Iec 61850 - Communication Networks and Systems in SubstationsDocument16 paginiIec 61850 - Communication Networks and Systems in SubstationsCamiloÎncă nu există evaluări

- Rfic DesignDocument8 paginiRfic DesignPravin SalunkheÎncă nu există evaluări

- 7 RemoteMonitoring PDFDocument7 pagini7 RemoteMonitoring PDFIjaems JournalÎncă nu există evaluări

- ECE Pre PHD SyllabusDocument22 paginiECE Pre PHD SyllabusAremarati RamakanthÎncă nu există evaluări

- Unit 3 - Internet of Things - WWW - Rgpvnotes.inDocument7 paginiUnit 3 - Internet of Things - WWW - Rgpvnotes.inShivam Pratap Singh RajawatÎncă nu există evaluări

- A Survey of Communication Protocols For Automatic Meter Reading ApplicationsDocument15 paginiA Survey of Communication Protocols For Automatic Meter Reading ApplicationsnixbaÎncă nu există evaluări

- Wireless Energy Transfer Powered Wireless Sensor Node For Green Iot: Design, Implementation & EvaluationDocument27 paginiWireless Energy Transfer Powered Wireless Sensor Node For Green Iot: Design, Implementation & EvaluationManjunath RajashekaraÎncă nu există evaluări

- 10.1109 LCOMM.2013.020413.122896 Solutions To The Computer Networking Challenges of The Distribution Smart GridDocument4 pagini10.1109 LCOMM.2013.020413.122896 Solutions To The Computer Networking Challenges of The Distribution Smart GridjÎncă nu există evaluări

- Ext 40392Document10 paginiExt 40392Laxman JakatiÎncă nu există evaluări

- The Evolution To 4G SystemsDocument5 paginiThe Evolution To 4G Systemsjuanjho1Încă nu există evaluări

- Wireless Oscilloscope Using ZigbeeDocument4 paginiWireless Oscilloscope Using ZigbeemichaelÎncă nu există evaluări

- Performance Evaluation of 2G and 3G Networks in The City of BaghdadDocument16 paginiPerformance Evaluation of 2G and 3G Networks in The City of BaghdadHà NguyễnÎncă nu există evaluări

- 4G Wireless TerminalsDocument8 pagini4G Wireless TerminalsbachirtalebalifaceÎncă nu există evaluări

- Fundamentals of Electromigration-Aware Integrated Circuit DesignDe la EverandFundamentals of Electromigration-Aware Integrated Circuit DesignÎncă nu există evaluări

- Traps - 2008 12 30Document15 paginiTraps - 2008 12 30smoothkat5Încă nu există evaluări

- Bab 3 - Soal-Soal No. 4 SD 10Document4 paginiBab 3 - Soal-Soal No. 4 SD 10Vanni LimÎncă nu există evaluări

- DissertationDocument59 paginiDissertationFatma AlkindiÎncă nu există evaluări

- Average Waves in Unprotected Waters by Anne Tyler - Summary PDFDocument1 paginăAverage Waves in Unprotected Waters by Anne Tyler - Summary PDFRK PADHI0% (1)

- Working Capital Management-FinalDocument70 paginiWorking Capital Management-FinalharmitkÎncă nu există evaluări

- Nespresso Case StudyDocument7 paginiNespresso Case StudyDat NguyenÎncă nu există evaluări

- D5 PROF. ED in Mastery Learning The DefinitionDocument12 paginiD5 PROF. ED in Mastery Learning The DefinitionMarrah TenorioÎncă nu există evaluări

- Ib Physics SL - Unit 4 ReviewDocument46 paginiIb Physics SL - Unit 4 ReviewMax HudgenesÎncă nu există evaluări

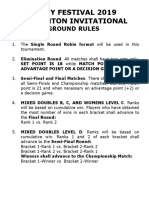

- Ground Rules 2019Document3 paginiGround Rules 2019Jeremiah Miko LepasanaÎncă nu există evaluări

- CSEC Eng A Summary ExerciseDocument1 paginăCSEC Eng A Summary ExerciseArisha NicholsÎncă nu există evaluări

- Personal Philosophy of Education-Exemplar 1Document2 paginiPersonal Philosophy of Education-Exemplar 1api-247024656Încă nu există evaluări

- Delaware Met CSAC Initial Meeting ReportDocument20 paginiDelaware Met CSAC Initial Meeting ReportKevinOhlandtÎncă nu există evaluări

- Marcelo H Del PilarDocument8 paginiMarcelo H Del PilarLee Antonino AtienzaÎncă nu există evaluări

- Cognitive ApprenticeshipDocument5 paginiCognitive ApprenticeshipRandall RobertsÎncă nu există evaluări

- Genpact - Job Description - One Data and AI - B Tech Circuit and MCA (3) 2Document4 paginiGenpact - Job Description - One Data and AI - B Tech Circuit and MCA (3) 2SHIVANSH SRIVASTAVA (RA2011053010013)Încă nu există evaluări

- Pathfinder CharacterSheet.1.8InterActiveDocument3 paginiPathfinder CharacterSheet.1.8InterActiveJessica AlvisÎncă nu există evaluări

- How To Create Partner Function in SAP ABAPDocument5 paginiHow To Create Partner Function in SAP ABAPRommel SorengÎncă nu există evaluări

- The Cognitive Enterprise For HCM in Retail Powered by Ibm and Oracle - 46027146USENDocument29 paginiThe Cognitive Enterprise For HCM in Retail Powered by Ibm and Oracle - 46027146USENByte MeÎncă nu există evaluări

- Anti-Epileptic Drugs: - Classification of SeizuresDocument31 paginiAnti-Epileptic Drugs: - Classification of SeizuresgopscharanÎncă nu există evaluări

- 201606300437271127888362list of Prescribed Textbooks ISC 2017 PDFDocument10 pagini201606300437271127888362list of Prescribed Textbooks ISC 2017 PDFShrimanta SatpatiÎncă nu există evaluări

- Em - 1110 1 1005Document498 paginiEm - 1110 1 1005Sajid arÎncă nu există evaluări

- Literature Review On Catfish ProductionDocument5 paginiLiterature Review On Catfish Productionafmzyodduapftb100% (1)

- Introduction To PTC Windchill PDM Essentials 11.1 For Light UsersDocument6 paginiIntroduction To PTC Windchill PDM Essentials 11.1 For Light UsersJYÎncă nu există evaluări

- Accomplishment Report: For Service Credits (Availment/claim) Election May 2019Document1 paginăAccomplishment Report: For Service Credits (Availment/claim) Election May 2019Glazy Kim Seco - JorquiaÎncă nu există evaluări

- Hero Cash Cash Lyrics - Google SearchDocument1 paginăHero Cash Cash Lyrics - Google Searchalya mazeneeÎncă nu există evaluări