Documente Academic

Documente Profesional

Documente Cultură

A-Scan Principle

Încărcat de

Jeevanandam ShanmugasundaramDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

A-Scan Principle

Încărcat de

Jeevanandam ShanmugasundaramDrepturi de autor:

Formate disponibile

Pulse echo A- scan test method :

Pulse echo test method uses reflected ultrasound as a means of collecting test information. A single crystal probe is normally used for ultrasound generation as well as reception. The transmitter circuit of the flaw detector supplies short excitation pulses of few hundred volts at regular interval to the probe crystal. The excitation pulse oscillates the crystal to generate short burst of ultrasound such that the arrival of each returning echo may be identifiable as a discrete event. During the interval between two successive pulses, the crystal is at rest and detects any return echo such as from the back wall. A large percentage of the sound is reflected from the front surface of the test part and the remainder is reflected by the back surface or discontinuities. The flaw detectors CRT screen displays the whole operation by producing separated signals of transmission and the time of arrival of defect echo and the back wall echo. The transmission pulse and subsequent echoes appear as peaks rising out of the CRTs base line. The distance between the peaks is a measure of the defects location or the parts thickness. Transmission of high frequency ultrasound cannot takes place in air. It is carried out through an intermediate liquid, in bulk or as a thin layer. Oily substances or water are generally used. They are called couplants. The initial or transmitter pulse appears first in time and represents the electrical zero. This is the exact start time of crystal excitation. The exact point in time when ultrasound enters the test material is called acoustical zero. Acoustical zero is superimposed within the initial pulse and is not distinguishable. The next pulse represents the total elapsed time for sound to travel from the entry surface to the reflector and back to the entry surface again. At the instant the electrical pulse is removed the oscillations of the crystal do not cease immediately but decreases in an exponential manner until they reach zero. A dead zone is produced, starting immediately after entry into the test surface, in which echoes can not be detected. One single test cycle is so fast that it is not physically visible in the detectors screen. Hence the flaw detector repeats the test cycle several times per second by supplying successive excitation pulses to the crystal and make the event appear as constant due to persistence of vision. The number of times, the crystal is electrically pulsed per second is called the pulse repetition rate.

A sufficient amount of time between successive pulses is necessary to allow ultrasound to travel through the material under examination. Higher pulse repetition rate produces brighter screen display. Very high pulse repetition rate produces spurious signals [ ghost echoes ] on the CRT screen. The ultrasonic pulses used by the flaw detector are radio frequency type and have a serrated look. The pulses are filtered and rectified to smooth looking shapes by the flaw detector before display. Pulse echo A-scan method displays distance along the horizontal scale called the baseline and amplitude of the reflection along the vertical scale. Because of similar return path, the screen is calibrated to display one way travel only. A scan test method can accurately locate a discontinuity. The amplitude of the return signal is a relative measure of the amount of reflected energy and depends on the area and orientation of the reflecting surface. Amplitude of the signal can be used for accept / reject decision.

K. Chatterjee, 75643

Center for NDT

P 00 Rv 02

Self study material.

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- NAKED Singularities - PenroseDocument10 paginiNAKED Singularities - PenroseLeon FosiltÎncă nu există evaluări

- Values in Work LifeDocument3 paginiValues in Work LifeJeevanandam ShanmugasundaramÎncă nu există evaluări

- Part Cat-Soil Compactor BW 212Document218 paginiPart Cat-Soil Compactor BW 212Dhru Ti100% (7)

- DESIGN AND FABRICATION OF Mini Bench Saw MachineDocument1 paginăDESIGN AND FABRICATION OF Mini Bench Saw MachineJeevanandam ShanmugasundaramÎncă nu există evaluări

- Manonmaniam Sundaranar University: B.B.A. - Iii YearDocument72 paginiManonmaniam Sundaranar University: B.B.A. - Iii YearJeevanandam ShanmugasundaramÎncă nu există evaluări

- Eg Ii Cat 2 QPDocument1 paginăEg Ii Cat 2 QPJeevanandam ShanmugasundaramÎncă nu există evaluări

- CO PSO I YearDocument9 paginiCO PSO I YearJeevanandam ShanmugasundaramÎncă nu există evaluări

- CO PO I YearDocument8 paginiCO PO I YearJeevanandam ShanmugasundaramÎncă nu există evaluări

- Essaki Title PagesDocument16 paginiEssaki Title PagesJeevanandam ShanmugasundaramÎncă nu există evaluări

- PPCE U 1 NotesDocument10 paginiPPCE U 1 NotesJeevanandam ShanmugasundaramÎncă nu există evaluări

- Invention Disclosure Form-26.2.2020Document3 paginiInvention Disclosure Form-26.2.2020Jeevanandam ShanmugasundaramÎncă nu există evaluări

- Unit - I Properties of Fluids and Pressure MeasurementsDocument2 paginiUnit - I Properties of Fluids and Pressure MeasurementsJeevanandam ShanmugasundaramÎncă nu există evaluări

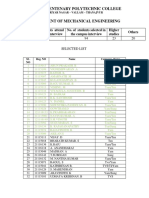

- Periyar Centenary Polytechnic College: Department of Mechanical EngineeringDocument6 paginiPeriyar Centenary Polytechnic College: Department of Mechanical EngineeringJeevanandam ShanmugasundaramÎncă nu există evaluări

- Unit-Ii Flow of Fluids and Flow Through Pipes 2.1. Flow of FluidsDocument14 paginiUnit-Ii Flow of Fluids and Flow Through Pipes 2.1. Flow of FluidsJeevanandam ShanmugasundaramÎncă nu există evaluări

- 3.1 Establish The Correlation Between The Courses and The Pos & Psos (20) Programme OutcomesDocument7 pagini3.1 Establish The Correlation Between The Courses and The Pos & Psos (20) Programme OutcomesJeevanandam ShanmugasundaramÎncă nu există evaluări

- Unit-Iv Pneumatic Systems: 4.2. Types of Motion Performed by Pneumatic ComponentsDocument17 paginiUnit-Iv Pneumatic Systems: 4.2. Types of Motion Performed by Pneumatic ComponentsJeevanandam ShanmugasundaramÎncă nu există evaluări

- Periyar Centenary Polytechnic College, Vallam Department of Mechanical EngineeringDocument2 paginiPeriyar Centenary Polytechnic College, Vallam Department of Mechanical EngineeringJeevanandam ShanmugasundaramÎncă nu există evaluări

- Monthly Examination: Answer All The QuestionsDocument5 paginiMonthly Examination: Answer All The QuestionsJeevanandam ShanmugasundaramÎncă nu există evaluări

- Answer All The Questions.: Periyar Nagar - Vallam - 613 403 - ThanjavurDocument5 paginiAnswer All The Questions.: Periyar Nagar - Vallam - 613 403 - ThanjavurJeevanandam ShanmugasundaramÎncă nu există evaluări

- First Monthly Examination: PO4 PO1 PO1 PO4Document4 paginiFirst Monthly Examination: PO4 PO1 PO1 PO4Jeevanandam ShanmugasundaramÎncă nu există evaluări

- Periyar Centenary Polytechnic CollegeDocument2 paginiPeriyar Centenary Polytechnic CollegeJeevanandam ShanmugasundaramÎncă nu există evaluări

- Department of Mechanical Engineering: Periyar Nagar - Vallam - 613 403 - ThanjavurDocument4 paginiDepartment of Mechanical Engineering: Periyar Nagar - Vallam - 613 403 - ThanjavurJeevanandam ShanmugasundaramÎncă nu există evaluări

- Material Handling Is The MovementDocument1 paginăMaterial Handling Is The MovementJeevanandam ShanmugasundaramÎncă nu există evaluări

- Periyar Centenary Polytechnic College: Department of Mechanical EngineeringDocument7 paginiPeriyar Centenary Polytechnic College: Department of Mechanical EngineeringJeevanandam ShanmugasundaramÎncă nu există evaluări

- Mech Placement Format (20.03.2018)Document4 paginiMech Placement Format (20.03.2018)Jeevanandam ShanmugasundaramÎncă nu există evaluări

- Fire Fighting Robot VehicleDocument3 paginiFire Fighting Robot VehicleJeevanandam ShanmugasundaramÎncă nu există evaluări

- Electrical Power Generation by Gym Unit 1Document1 paginăElectrical Power Generation by Gym Unit 1Jeevanandam ShanmugasundaramÎncă nu există evaluări

- Floor Clening Machine AbstractDocument2 paginiFloor Clening Machine AbstractJeevanandam ShanmugasundaramÎncă nu există evaluări

- Refrigerant Charging Procedure For Air Conditioner or Heat Pump Repair or Refrigeration Equipment RepairDocument10 paginiRefrigerant Charging Procedure For Air Conditioner or Heat Pump Repair or Refrigeration Equipment RepairJeevanandam ShanmugasundaramÎncă nu există evaluări

- Parallelogram LawDocument7 paginiParallelogram LawJeevanandam ShanmugasundaramÎncă nu există evaluări

- Course Outcome (Co) Vs Program Specific Outcomes (Psos)Document9 paginiCourse Outcome (Co) Vs Program Specific Outcomes (Psos)Jeevanandam ShanmugasundaramÎncă nu există evaluări

- Contact No:: E-Mail (Alternative)Document4 paginiContact No:: E-Mail (Alternative)Jeevanandam ShanmugasundaramÎncă nu există evaluări

- Act 4070Document10 paginiAct 4070Diego PachecoÎncă nu există evaluări

- Maintenance Issues of Photovoltaic System: Presented byDocument10 paginiMaintenance Issues of Photovoltaic System: Presented byjunaid bashirÎncă nu există evaluări

- Hns 36W 4P Se: Product DatasheetDocument4 paginiHns 36W 4P Se: Product Datasheetaban Ibis MedicalÎncă nu există evaluări

- BS en 00054-1-2021Document26 paginiBS en 00054-1-2021Mike DluÎncă nu există evaluări

- Module 1 Capital and Cost EstimationDocument39 paginiModule 1 Capital and Cost EstimationYozora夜空Încă nu există evaluări

- TGEL BatteryDocument4 paginiTGEL BatteryharishwarreddyÎncă nu există evaluări

- E05-E01 - 2 Plant BLDG Elect DesignDocument13 paginiE05-E01 - 2 Plant BLDG Elect DesignMuhammad IrfanÎncă nu există evaluări

- MC 10206242 0001Document8 paginiMC 10206242 0001Yang MaÎncă nu există evaluări

- SPCSP CatalogDocument24 paginiSPCSP Catalogleojay24Încă nu există evaluări

- Cross-Curricular Focus: Life Science: NameDocument2 paginiCross-Curricular Focus: Life Science: NameAndreea Dragomir67% (3)

- Slope Efficiency: Threshold Above Current Input in Increase Power Output Optical in IncreaseDocument34 paginiSlope Efficiency: Threshold Above Current Input in Increase Power Output Optical in IncreaseRIzwanaÎncă nu există evaluări

- New Microsoft Word DocumentDocument5 paginiNew Microsoft Word DocumentmonotoshÎncă nu există evaluări

- Southwark Schools For The FutureDocument59 paginiSouthwark Schools For The FuturewilliamsaminÎncă nu există evaluări

- kx0804 PDFDocument519 paginikx0804 PDFstefan corjuc100% (7)

- Sungrow Hybrid SH5K-30 5kW Inverter ManualDocument154 paginiSungrow Hybrid SH5K-30 5kW Inverter Manualraymknd gerard macarineÎncă nu există evaluări

- Radiation Dose Limits: Appendix BDocument6 paginiRadiation Dose Limits: Appendix BVaradha RajanÎncă nu există evaluări

- BMW - Us X1 - 2015Document66 paginiBMW - Us X1 - 2015Alex PaunaÎncă nu există evaluări

- Presentation Mahmud Totonji DarwishDocument13 paginiPresentation Mahmud Totonji DarwishMahmoud ToutounjyÎncă nu există evaluări

- Class 9 Science Study Material Chapter 12Document16 paginiClass 9 Science Study Material Chapter 12rajman1990Încă nu există evaluări

- Dryers: DRYERS - Are Equipment Used For Producing A Dry Solid Product From A Wet Feed General Types of DryersDocument5 paginiDryers: DRYERS - Are Equipment Used For Producing A Dry Solid Product From A Wet Feed General Types of DryersTristan Paul Guerra OrodioÎncă nu există evaluări

- d20 ThundarrDocument27 paginid20 ThundarrAlebrije1100% (1)

- KJLC Ed09 Sec09 Web200910Document54 paginiKJLC Ed09 Sec09 Web200910NickMoloÎncă nu există evaluări

- Aula Balancim DifusaoDocument29 paginiAula Balancim DifusaoGabrielAntoniazziÎncă nu există evaluări

- CATERPILAR3516 1550-2200 BHPDocument6 paginiCATERPILAR3516 1550-2200 BHPNadia AnandaÎncă nu există evaluări

- Sugar Sector PDF - 1608046711Document29 paginiSugar Sector PDF - 1608046711Mustafa Farooq100% (1)

- Deshidratador PhillipsDocument4 paginiDeshidratador Phillipssandra fiorelaÎncă nu există evaluări

- Air Circuit Breakers For The 21st Century: Catalogue No.'00-P55EDocument4 paginiAir Circuit Breakers For The 21st Century: Catalogue No.'00-P55EAsif ShahÎncă nu există evaluări

- 250 WATT Power Inverter: Power Small Appliances From Your Car or Any Other 12-Volt Source With Our 250-Watt InverterDocument3 pagini250 WATT Power Inverter: Power Small Appliances From Your Car or Any Other 12-Volt Source With Our 250-Watt Invertertaner56Încă nu există evaluări