Documente Academic

Documente Profesional

Documente Cultură

Zerospeed Active Stabilizer

Încărcat de

Binh PhamDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Zerospeed Active Stabilizer

Încărcat de

Binh PhamDrepturi de autor:

Formate disponibile

The Use of Roll Stabiliser Fins at Zero Speed J.

Ooms, Manager Research and Development, Quantum Controls BV, Nuth, Holland Project 2002, 18-20 November 2002, Amsterdam Abstract To reduce the roll of an anchored ship passive anti-roll tanks have for years been the only viable option. Now however, a novel development makes it possible to use stabiliser fins for this purpose. This paper explains the principle behind the ZeroSpeedTM system, compares it with the passive anti-roll tank and discusses results of model tests with the new system. Introduction For many years fin roll stabilisers have been used to reduce the roll of a ship in a seaway. Their use on motor yachts is more recent but today they have become standard issue in the mega-yacht sector. A much-cited disadvantage of fin stabilisers was that they worked poorly at low speed and not at all when adrift or anchored. The simple reason for that was the basic principle of stabiliser fins which depends on the flow of the water past the fins. When the speed is low or zero then the stabilising lift force becomes very small and at zero speed vanishes altogether. This was a major drawback of fin roll stabilisers. Recently a novel approach was developed allowing the use of fins when the ship is adrift or anchored. In this paper the new concept will be explained and its relative merits with respect to anti-roll tanks discussed. In conjunction with De Voogt Naval Architects and the MARIN ship research institute model tests were carried out to quantify the performance of the new system and compare the results with that of an anti-roll tank. The tests will be discussed and the results presented. Additional information on this subject can be found in [1}, [2] and [3]. Roll stabilisation at zero speed Roll stabilisation capability at zero speed is a welcome asset for mega-yachts. These ships often spend days on end anchored in a more or less sheltered bay. When a swell enters this bay and has a period that is near the natural roll period of the moored vessel the ship can start to roll heavily, even at small wave heights. As large motor yachts have a roll period of somewhere between 6 and 11 s and swell can have a period of anywhere between 7 and 14 s this is a regularly occurring problem. The conventional fin roll stabiliser system fails to provide stabilisation under these zero speed conditions. So, over time several concepts were developed to provide that capability. Of these only the well-known anti-roll tanks proved viable. The main advantage of such a tank is that it works over the whole speed range of the ship, hence also at zero speed. Although there are both passive and active anti-roll tanks the passive one is by far the most common. However, a serious drawback is that either its roll damping capacity is limited or otherwise it has to be made quite large (up to 5 % of the ships displacement). This increases the displacement and takes up much internal space. Therefore, in practice modern motor yachts with an anti-roll tank are also equipped with fin stabilisers to provide sufficient stabilisation capacity when underway. The tanks are then mainly intended for use when adrift or anchored. This approach has merit but means that there are two systems to design and maintain and there is still the space loss and increased displacement associated with anti-roll tanks. A compact integrated system for both underway and zero speed stabilisation is obviously preferable. Using stabiliser fins at zero speed In 1998 another zero speed stabilisation concept was introduced when the M.Y.

Figure 1 Standard (right) and zero speed (left) fin shapes. Boadicea was equipped with a roll stabilisation system using the stabiliser fins to stabilise when adrift or anchored. This system used the fins in a different way when operating in zero speed mode. However, as the system can also be used in the conventional underway mode it meets the desirable requirement of a single integrated system for both underway and zero speed stabilisation. The results with this system were very promising and after a few years it was commercialised jointly by Quantum Controls of the Netherlands and Quantum Marine Engineering in Florida, USA. Going under the brand names OnAnchorTM and ZeroSpeedTM at present 18 ships have already been fitted or retrofitted with zero speed stabilisation. Users report very good performance and are extremely satisfied with it. So how does this wonder system work? Operating principle The operating principle is based on the paddle principle which can be illustrated as follows. Suppose somebody standing in a small rowing boat in calm water and having an oar over the side with the blade flat, immersed in the water and pivoting in the thole. If that person starts moving the blade up and down a force is exerted on the boats gunwale that will cause the boat to roll. A number of observations can now be made. The faster the oar moves through the water the larger the drag force needed to move it. This increases quadratic with speed. So if the oar is moved slowly the force is small. When starting the motion or changing the oars speed a certain mass of water is accelerated or decelerated which gives an additional mass force. If the person in the boat moves the oar in a regular way and starts slowly and then gradually faster then: o the boat will roll just a little when the oar is moved slowly because a relatively large force is needed to heel the boat but the force generated by the oar is small; o the boat will gradually start rolling more and more when the oar is moved faster and faster because the force generated by the oar is increasing; o at a certain point the boat will roll a lot with only a moderate amount of effort. The time for a full roll from one side to the other and back is at this point equal to the natural roll period of the boat; o if the oar is moved even faster and faster the boat will again start to roll less because the inertia force of the boat increases also very rapidly thereby cancelling the effect of the increasing oar force. What the observations illustrate is that the boat rolls quite easily at its natural roll period and that the force on the oar has drag and inertia contributions. If waves exert a force on the boat it is clear that the boat will also roll easily when the wave period is equal to the boats natural roll period. If the person on board is now observing this roll motion and starts moving the oar in such a way that the force he/she generates opposes the waveinduced roll action he can reduce the roll

dramatically with only moderate effort. If instead of sticking out in a transverse direction the oar was made to pivot on an outrigger on the boat and then turned 90 degrees so that it is parallel with the boat and the oars blade is moved up and down again then the system works equally well. If as a next step this 90 degree rotated oar is replaced by a fin-sized contraption with a sufficiently large chord and a low balance then the principle is still valid. The ZeroSpeedTM system employs this principle to reduce the roll motion. Here the oar is replaced by the fin. This fin does not have the normal plan form and balance. Instead the fin has less balance than a normal fin and also the chord is increased to have maximum sweep area (see figure 1). Having this plan form gives high speeds (and hence drag forces) near the trailing fin edge and a large catchment area where water is trapped and accelerated or

decelerated. Moreover, there is minimal cancelling effect which happens with a more balanced fin where large amounts of water are moved in opposite directions meaning that the forces needed for that partially cancel each other. All the observations about the boat-oar system also apply to the ZeroSpeedTM system. In practice the fin motion is controlled by a controller. A roll sensor continuously measures the roll of the ship and sends this information to the controller which controls the fin rotation. Initially the fin is waiting at a certain start angle of around 30 degrees with respect to the centre position. At the right moment the fin starts rotating, accelerating until a certain rotational speed is achieved. When approaching an angle of 30 degrees in the opposite direction the fin decelerates to stop at this position. There it waits again until in the next half-roll it moves in the same

ZeroSpeedTM

Anti-roll tank (passive)

+ - Works underw ay and at anchor + - No extra internal space required beyond that used by ordinary stabilisers + - Can be easily retro-fitted + - Equal or better performance than anti-roll tank in typical conditions + - Only one system to install and maintain + - No extra displacement + - Better behaviour in quartering follow ing seas w hen underw ay + - Suitable for later improvements in control algorithms

+ - Works underw ay and at anchor -- - Takes up valuable space (1.5 to 4 % of displacement filled w ith w ater plus extra air space, ducts etcetera) -- - Very difficult to retro-fit -- - Insufficient capacity for good underw ay performance, most of the time augmented by fin stabilisers. -- - Tw o systems to care for w hen additional fin stabilisers are fitted. -- - Displacement increases -- - Can show undesirable behaviour in stern quartering and follow ing seas -- - Reduces static stability of ship -- - Hard to modify or update + - Proven solution

-- - Some extra drag -- - Requires ship pow er -- - More w ear and tear on fin hull units -- - Potential for noise problems

+ - No drag due to fins (if no extra fins are fitted) + - No electrical/hydraulic pow er required (for passive anti-roll tank) -- - There are reports about noise caused by anti-roll tanks -- - Must be re-tuned w hen ship conditions change.

Table 1. Advantages and disadvantages of ZeroSpeedT M and passive anti-roll tanks.

way back to the initial position. During the three stages of the motion, accelerating - high speed decelerating different forces are generated. If the start moment is precisely timed with the roll motion then these forces can be made to oppose the roll motion and thereby reduce it. The start moment with respect to the ships roll, the initial fin start angle, acceleration, maximum speed and deceleration are important parameters that must be carefully tuned to deliver maximum performance. Pros and Cons The only practical alternative to the ZeroSpeedTM system is the use of antirolling tanks. To assess their relative merits table 1 lists their relative strengths and weaknesses. However, although the main advantages are clear there are three

secondary points which are often brought up in discussions with prospective customers. These points are: power consumption wear and tear potential noise problems. Power consumption. Unlike an anti-roll tank the ZeroSpeedTM system needs power to operate. Using good load management techniques in the hydraulic power pack this has proven to be no insurmountable problem so far. However, it is possible that in a retrofit situation on board of an older ship generator capacity must be increased. Wear and tear. The ZeroSpeedTM system is clearly racking up more operating hours than a stabiliser system solely used underway. Hence yes, wear and tear increases. However, loads on the hull units at zero speed are not larger than underway and a well-designed hull unit is designed for continuous use. So, this point has not been

Decay tests Test# 1 2 3 Fins Centred Operating Centred Anti-roll tank Not operating Not operating Operating Test conditions - calm water - ship initially heeled and then released.

Seakeeping tests Test# Wave height (m ) 4 5 6 7 8 9 10 11 12 0.5 1 2 0.5 1 2 0.5 1 2 Not operating Not operating Not operating Operating Operating Operating Not operating Not operating Not operating Not operating Not operating Not operating Not operating Not operating Not operating Operating Operating Operating Test conditions - irregular seas, wave direction 120 (stern quartering) - wave spectrum used, JONSWAP, long-crested - model restrained in horizontal plane by weak springs. - runs 3, 10, 11 and 12 not reported here - fin timing at optimum setting Fins Anti-roll tank

Table 2. Test programme w ith model of 55 m motor yacht. All tests carried out at zero speed.

Figure 2 Results of a roll decay test without and with fins active. an issue so far. Noise problems. When the main engines are switched off, other noise sources become more dominant. Possible sources of noise in the ZeroSpeedTM system are: the hydraulic power-pack; hydraulic lines and/or servo valves; and water noise. The preferred power-packs (Quantum Marine Engineerings QIS series) where designed with low noise in mind. Moreover, being placed inside the engine room adds another layer of isolation. Because fin units and hydraulic control valves are often placed inside the engine room what little noise they make is also well suppressed. In those cases where hull units were placed in or near staterooms local isolation eliminated possible problems. The water moved by the fins was reported by some customers who slept near the fins to be just audible but of an (quote!) insomnia-curing quality. So far, no noise-related problems have been reported. Model tests Many people wonder about the performance of the ZeroSpeedTM system. After all, it was foisted upon a system that was never intended for such an application. So, can the performance be on a par with established systems tailor-made for the purpose? A telling sign that it can is that throughout the history of the ZeroSpeedTM system feedback from customers about the performance of the system has been very positive. These are qualitative assessments which are extremely important because they also include the perception of the customers. However, there is also a need for quantitative data, preferably obtained under controlled conditions which can only be achieved with model tests. Therefore a series of tests was planned and executed in May 2002 at MARIN. These were carried out using the model of a 55 m motor yacht with a natural roll period of 8.6 s and equipped with both an anti-roll tank and two fins of 3.8 m2 each. The model was tested in an irregular long-crested stern quartering sea and zero ship speed. JONSWAP type wave height spectra were used with a (narrow) spectral peak at 8.6 s and significant wave heights of 0.5, 1.0 and 2 m. These conditions represented a worst-case roll

Figure 3 Roll spectrum with passive and active fins. Results of active fins shown for different timing settings. scenario. The tests were carried out with fins centred, fins operating and with fins centred and anti-roll tank operating. Prior to these main tests some roll decay tests were carried out in calm water to establish the roll damping with centred and operating stabiliser fins and with centred fins and

operating anti-roll tank. Table 2 gives an overview of the test programme. Unfortunately space does not permit a full discussion of the results. Figure 2 shows the roll decay of the ship with centred fins and with fins operating. In the latter case the damping has increased considerably which in practical conditions means less rolling. This was also proven in an irregular sea with a significant wave height of 1 m. Figure 3 shows the roll spectrum with the fins centred and operating with different settings of the fin timing. This figure shows two things, namely the: large influence of the fins importance of optimal fin timing. Finally, figure 4 shows the significant roll angle as a function of the significant wave height and with the fins centred and operating. The reduction is very large, varying from 80 % at 0.5 m wave height to 40 % at 2 m wave height. The reduction of the performance at high wave heights is due to the systems limited capacity which at some point can no longer completely compensate the wave forces. However, at the much more typical 0.5 to 1m swell the performance of the system is very good indeed. Final remarks This paper attempted to: explain the principle of the ZeroSpeedTM system; the practical issues of implementing it on board of a ship; and its performance. It showed that the results are excellent. The technology used has proven itself repeatedly on board ships. This does not mean that there will be no further developments. Being a relatively new technology means that there is still room for improvement. At present Quantum Controls BV is working on: better fin performance prediction at zero speed conditions an even more optimised fin shape improved control algorithms. Doing so will broaden the range of ships where this system is feasible and further increase its performance.

Figure 4 Roll angle with passive and active fins as a function of wave height.

References [1] Dallinga, R.P.: Roll Stabilisation at Anchor: Hydrodynamic Aspects of the Comparison of Anti-Roll Tanks and Fins, Project 2002, Amsterdam, Nov 2002 Wieringen, H.M. van: Design Considerations on At Anchor Stabilising Systems, Project 2002,

[2]

Amsterdam, Nov 2002

[3] Dallinga, R.P.: Roll Stabilisation of Motor Yachts: Use of Fin Stabilizers in anchored Conditions, Project 99, Amsterdam, Nov. 1999

S-ar putea să vă placă și

- UKOOA FPSO Design Guidance NotesDocument176 paginiUKOOA FPSO Design Guidance Notesnazwan14100% (5)

- Jack-Up Rigs Operational Aspects (Offshore Drilling)Document22 paginiJack-Up Rigs Operational Aspects (Offshore Drilling)myusuf_engineer100% (8)

- Technical Reference 2007 CompleteDocument782 paginiTechnical Reference 2007 CompleteIvan GradÎncă nu există evaluări

- Jack Up Rigs Operational Aspects Offshore DrillingDocument22 paginiJack Up Rigs Operational Aspects Offshore Drillinganang WahjudiÎncă nu există evaluări

- Rolling of ShipsDocument37 paginiRolling of ShipsMark Antolino75% (8)

- Effects of Tide and Wind in Ship HandlingDocument19 paginiEffects of Tide and Wind in Ship Handlingpolaris25100% (8)

- Anchoring N Ship Handel IngDocument19 paginiAnchoring N Ship Handel IngRishav Raj0% (1)

- Illustrated Sail & Rig Tuning: Genoa & mainsail trim, spinnaker & gennaker, rig tuningDe la EverandIllustrated Sail & Rig Tuning: Genoa & mainsail trim, spinnaker & gennaker, rig tuningEvaluare: 3.5 din 5 stele3.5/5 (2)

- Pivot PointDocument26 paginiPivot PointJet RocetÎncă nu există evaluări

- Turning Circles and Stopping DistancesDocument7 paginiTurning Circles and Stopping DistancesBisrat100% (1)

- 11 SwathDocument16 pagini11 SwathGSÎncă nu există evaluări

- Mcnichols Master CatalogDocument56 paginiMcnichols Master CatalogULISES MONTANOÎncă nu există evaluări

- Drillship Hull Structure Design and AnalysisDocument214 paginiDrillship Hull Structure Design and AnalysisBinh PhamÎncă nu există evaluări

- CP 1 - PPT 2 - Manoeuvring CharacteristicsDocument28 paginiCP 1 - PPT 2 - Manoeuvring CharacteristicsAjay KumarÎncă nu există evaluări

- Ctec CatalogDocument51 paginiCtec CatalogFAISHAH ISAHAKÎncă nu există evaluări

- QFD PresentationDocument75 paginiQFD PresentationBhushan Verma100% (3)

- Turning Circle NotesDocument6 paginiTurning Circle Notesss_tayadeÎncă nu există evaluări

- The Ultimate Actionable Guide of Anchoring A Ship: Written by On February 13, 2016Document19 paginiThe Ultimate Actionable Guide of Anchoring A Ship: Written by On February 13, 2016Panagiotis MouzenidisÎncă nu există evaluări

- Understanding Different Types of Manoeuvres of A VesselDocument9 paginiUnderstanding Different Types of Manoeuvres of A VesselGiorgi Kandelaki100% (1)

- Dynamic Positioning SimulatorDocument79 paginiDynamic Positioning Simulatortm5u2r100% (3)

- Staad Pro TutorialsDocument17 paginiStaad Pro Tutorialsrandhir981Încă nu există evaluări

- 1.1 Ship Manoeuvring - Approach Pilot - Q&ADocument14 pagini1.1 Ship Manoeuvring - Approach Pilot - Q&Avishnu k100% (5)

- 04) ZEEPod & Other Project ExperienceDocument72 pagini04) ZEEPod & Other Project Experiencebapaobao100% (1)

- MooringDocument38 paginiMooringBinh Pham100% (1)

- Sten A Voyager ReportDocument45 paginiSten A Voyager ReportBinh PhamÎncă nu există evaluări

- Performance Boat TermsDocument6 paginiPerformance Boat TermsParamaet TamÎncă nu există evaluări

- API Deepwater Standards PosterDocument1 paginăAPI Deepwater Standards PosterBoonme ChinnaboonÎncă nu există evaluări

- Collission RickmersDubaiDocument88 paginiCollission RickmersDubaiBinh Pham100% (1)

- Otc19607 About API RP 2skDocument12 paginiOtc19607 About API RP 2skBinh PhamÎncă nu există evaluări

- The Ultimate Actionable Guide of Anchoring A Ship: Written by On February 13, 2016Document19 paginiThe Ultimate Actionable Guide of Anchoring A Ship: Written by On February 13, 2016Panagiotis Mouzenidis100% (1)

- Rudders: Semi Balanced Rudder Semi Balanced Rudder With Rudder HornDocument10 paginiRudders: Semi Balanced Rudder Semi Balanced Rudder With Rudder Hornsunil1237Încă nu există evaluări

- ASD TugsDocument3 paginiASD TugsVaruna Shantha100% (1)

- Azimuthal PropellersDocument7 paginiAzimuthal PropellersElena Turcu0% (1)

- Skandi HerculesDocument9 paginiSkandi Herculesiw2fualÎncă nu există evaluări

- BS IEC 61882 - 2001 - Hazard and Operability StudiesDocument60 paginiBS IEC 61882 - 2001 - Hazard and Operability Studiesd-fbuser-230265495100% (2)

- Standardized Tractor Tug Commands For Ship-Assist WorkDocument5 paginiStandardized Tractor Tug Commands For Ship-Assist WorkPoyraz Rüzgar100% (1)

- Hoegh Osaka MAIB ReportDocument86 paginiHoegh Osaka MAIB ReportIWCPOnlineÎncă nu există evaluări

- Maruti Bba Project For MarketingDocument92 paginiMaruti Bba Project For Marketingkaushal244256% (9)

- Pivot Point & Stopping Distance and Turning CircleDocument30 paginiPivot Point & Stopping Distance and Turning Circleمرتضى جبار السودانيÎncă nu există evaluări

- Towing Solutions IncDocument6 paginiTowing Solutions Incboca1966100% (1)

- 01a-3.3.2 - TugsDocument21 pagini01a-3.3.2 - TugsRajiv VigÎncă nu există evaluări

- Principles of Ship HandlingDocument10 paginiPrinciples of Ship HandlingGlen MacÎncă nu există evaluări

- Rudders: Semi Balanced RudderDocument10 paginiRudders: Semi Balanced RudderAurvin SinghÎncă nu există evaluări

- Quantum XT Stabilising SystemDocument18 paginiQuantum XT Stabilising Systemmariusamd100% (1)

- Marius Jonutis Quantum XT Stabilising SystemDocument18 paginiMarius Jonutis Quantum XT Stabilising SystemmariusamdÎncă nu există evaluări

- Type Stabilizer PDFDocument7 paginiType Stabilizer PDFHUNG NIKKOÎncă nu există evaluări

- Understanding Turning Circle of A ShipDocument3 paginiUnderstanding Turning Circle of A Shipandrew1970gÎncă nu există evaluări

- SeakeepingDocument5 paginiSeakeepingPallavi YempadaÎncă nu există evaluări

- StabilizerDocument46 paginiStabilizerlana ska100% (1)

- Stabilising SystemsDocument4 paginiStabilising Systemsshafwan1980Încă nu există evaluări

- Stabilising Systems: Bilge KeelsDocument5 paginiStabilising Systems: Bilge KeelsS SanchitÎncă nu există evaluări

- Anti-Heeling With Simulaneous Roll-Reduction - RRMDocument2 paginiAnti-Heeling With Simulaneous Roll-Reduction - RRMYao WeiÎncă nu există evaluări

- Anti-Rolling DevicesDocument26 paginiAnti-Rolling DevicesSaurav SainiÎncă nu există evaluări

- Mech CEP - Abstract, Intro & MechanismsDocument4 paginiMech CEP - Abstract, Intro & MechanismsTolphasÎncă nu există evaluări

- Bow Thruster, Ship Stabilizer MGPSDocument13 paginiBow Thruster, Ship Stabilizer MGPSSayem kaifÎncă nu există evaluări

- Whitepaper-1402-How Gyrostabilizers Work PDFDocument32 paginiWhitepaper-1402-How Gyrostabilizers Work PDFdanieldorelleÎncă nu există evaluări

- Ship Stability at The Management LevelDocument4 paginiShip Stability at The Management LevelShree Kanha100% (1)

- T Foil RuddersDocument4 paginiT Foil RuddersSlavi72Încă nu există evaluări

- DW Offshore Deck Mating Onto A Pre-Installed Semi-Submersible by Means of A Self-Propelled Heavy Transport VesselDocument42 paginiDW Offshore Deck Mating Onto A Pre-Installed Semi-Submersible by Means of A Self-Propelled Heavy Transport VesselSHARATHÎncă nu există evaluări

- Basic Ship HandlingDocument1 paginăBasic Ship HandlingCostisÎncă nu există evaluări

- (Swath) : Small Waterplane Area Twin HullDocument64 pagini(Swath) : Small Waterplane Area Twin HullDin ThorpeÎncă nu există evaluări

- Escorting Ships With Tractor TugsDocument5 paginiEscorting Ships With Tractor TugsDiego Ramón Gonzalez-LlanosÎncă nu există evaluări

- High Speed MArine VehiclesDocument11 paginiHigh Speed MArine VehiclesAnonymous e3ceN15Încă nu există evaluări

- Ccfi Bulbs Anti Roll Devices PDFDocument2 paginiCcfi Bulbs Anti Roll Devices PDFtoshugoÎncă nu există evaluări

- 6 - Motion StabilizationDocument19 pagini6 - Motion StabilizationJofin LukoseÎncă nu există evaluări

- The Measurement of Weight Distribution of Olympic Class Dinghies and KeelboatsDocument32 paginiThe Measurement of Weight Distribution of Olympic Class Dinghies and KeelboatsPeter HinrichsenÎncă nu există evaluări

- Ship StabilityDocument5 paginiShip StabilityRachmat Hidayat SapwariÎncă nu există evaluări

- Dynamic Positioning c11Document60 paginiDynamic Positioning c11S DÎncă nu există evaluări

- Nama: Hasan Rohmani NRT: 20.11.21.033 Kelas: Nautika B English MaritimeDocument4 paginiNama: Hasan Rohmani NRT: 20.11.21.033 Kelas: Nautika B English Maritimehasanrohmani77Încă nu există evaluări

- HSC Machinery RequirementsDocument174 paginiHSC Machinery RequirementssasikumarmarineÎncă nu există evaluări

- TurningDocument8 paginiTurningFaizaan BadarÎncă nu există evaluări

- Different Ways To Reduce Ship Propeller Vibrations and Increase Its EfficiencyDocument14 paginiDifferent Ways To Reduce Ship Propeller Vibrations and Increase Its Efficiencynauval.archÎncă nu există evaluări

- Model Solar Boat HelpDocument38 paginiModel Solar Boat HelpAimanul HakimÎncă nu există evaluări

- Seam 5 Topic 1 Principles of Ship HandlingDocument16 paginiSeam 5 Topic 1 Principles of Ship Handlingbryan.negriteÎncă nu există evaluări

- Natural Stability and the Parachute Principle in AeroplanesDe la EverandNatural Stability and the Parachute Principle in AeroplanesÎncă nu există evaluări

- Understanding Mooring IncideDocument8 paginiUnderstanding Mooring IncideIan MaldonadoÎncă nu există evaluări

- Failure CPP - Key BoraDocument12 paginiFailure CPP - Key BoraBinh PhamÎncă nu există evaluări

- STRIKING of OSV Maersk DetectorDocument45 paginiSTRIKING of OSV Maersk DetectorBinh PhamÎncă nu există evaluări

- UnderstandingMooringIncidents PDFDocument8 paginiUnderstandingMooringIncidents PDFBinh PhamÎncă nu există evaluări

- Technical Investigation Accident Twin Crane LiftDocument6 paginiTechnical Investigation Accident Twin Crane LiftBinh PhamÎncă nu există evaluări

- Add MassDocument9 paginiAdd MassjamesÎncă nu există evaluări

- MAIB - Collision Due To Anchor DragDocument16 paginiMAIB - Collision Due To Anchor DragBinh Pham100% (1)

- Chief Ton TugDocument69 paginiChief Ton TugBinh PhamÎncă nu există evaluări

- MAIB Report On MSC Napoli CasualtyDocument56 paginiMAIB Report On MSC Napoli CasualtyBinh PhamÎncă nu există evaluări

- Annabella ReportDocument40 paginiAnnabella ReportBinh PhamÎncă nu există evaluări

- Annabella ReportDocument40 paginiAnnabella ReportBinh PhamÎncă nu există evaluări

- Failure CPP - Key BoraDocument12 paginiFailure CPP - Key BoraBinh PhamÎncă nu există evaluări

- Dutch NavigatorDocument66 paginiDutch NavigatorBinh Pham100% (1)

- Tie-In Spool - A Verification Study (MSC)Document213 paginiTie-In Spool - A Verification Study (MSC)Binh PhamÎncă nu există evaluări

- DP Class Notation: BV ABS GL LR NK Rina RS IRS CCS NMD KR DNVDocument1 paginăDP Class Notation: BV ABS GL LR NK Rina RS IRS CCS NMD KR DNVswapneel_kulkarniÎncă nu există evaluări

- Wave Drift Forces and Responses in Deep Water and Extreme Environmental ConditionsDocument4 paginiWave Drift Forces and Responses in Deep Water and Extreme Environmental Conditionssaeed-21Încă nu există evaluări

- 406 Lesson 9bDocument41 pagini406 Lesson 9bBinh PhamÎncă nu există evaluări

- 17.01 General HSE Induction EmployeesDocument4 pagini17.01 General HSE Induction EmployeesRetselisitsoeÎncă nu există evaluări

- MHPQ Pharm 35 Ayurvedic DrugsDocument104 paginiMHPQ Pharm 35 Ayurvedic DrugsDurban Chamber of Commerce and IndustryÎncă nu există evaluări

- Line History SheetDocument4 paginiLine History SheetBethel NdifonÎncă nu există evaluări

- Irshad Ansari: Al Raha Village Mafraq Abu Dhabi UAEDocument2 paginiIrshad Ansari: Al Raha Village Mafraq Abu Dhabi UAEirshadÎncă nu există evaluări

- Ecc 5.0-Sap-Sd For CRMDocument2 paginiEcc 5.0-Sap-Sd For CRMsnd31Încă nu există evaluări

- CV Sekretaris PC Tidar Batam PDFDocument4 paginiCV Sekretaris PC Tidar Batam PDFGlobal Inovasi BersamaÎncă nu există evaluări

- 09574099710805556Document50 pagini09574099710805556heartback100% (2)

- User Guide TemplateDocument12 paginiUser Guide TemplateClass InstructorÎncă nu există evaluări

- Signals Spectra Processing PowerPoint PresentationDocument8 paginiSignals Spectra Processing PowerPoint PresentationJohn Francis DizonÎncă nu există evaluări

- RVT Column Internals EN WEB 20220809Document11 paginiRVT Column Internals EN WEB 20220809Göksel VATANÎncă nu există evaluări

- Builders Hardware Manufacturers Association (BHMA) : Code Finish Description Base Material Category Nearest US EquivDocument5 paginiBuilders Hardware Manufacturers Association (BHMA) : Code Finish Description Base Material Category Nearest US EquivRey Eduard Q. UmelÎncă nu există evaluări

- Quick Fields 8Document11 paginiQuick Fields 8Khaled ElayyanÎncă nu există evaluări

- Draft Curriculum Telecommunication EngineeringDocument85 paginiDraft Curriculum Telecommunication EngineeringalareeqiÎncă nu există evaluări

- R & S Gratings CatalogueDocument48 paginiR & S Gratings CatalogueBarrasons Engineers TeamÎncă nu există evaluări

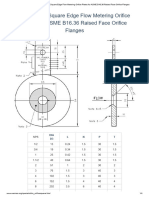

- Wermac - Dimensions of Square Edge Flow Metering Orifice Plates For ASME B16.36 Raised Face Orifice FlangesDocument4 paginiWermac - Dimensions of Square Edge Flow Metering Orifice Plates For ASME B16.36 Raised Face Orifice Flangestechnicalei sulfindoÎncă nu există evaluări

- Mj19 Sample Apm QuestionsDocument9 paginiMj19 Sample Apm QuestionsAakash AadeezÎncă nu există evaluări

- Vishnu Dutt PMDocument2 paginiVishnu Dutt PMvishnu choudharyÎncă nu există evaluări

- Conference Delegate Wish ListDocument55 paginiConference Delegate Wish ListThinkLink, Foreign Affairs www.thinklk.comÎncă nu există evaluări

- Export PDF Form Data To Microsoft AccessDocument2 paginiExport PDF Form Data To Microsoft AccessTamaraÎncă nu există evaluări

- Gables EngineeringDocument2 paginiGables EngineeringShamsuddin HasnaniÎncă nu există evaluări

- Project Chapter 2Document22 paginiProject Chapter 2N EÎncă nu există evaluări

- Emax DCDocument97 paginiEmax DCAhmad HamoudaÎncă nu există evaluări

- Tda1085c DDocument12 paginiTda1085c DpamururamuÎncă nu există evaluări

- CNC Roo:M: I Qumjtr AssuranceDocument2 paginiCNC Roo:M: I Qumjtr AssuranceSalvador TiñoÎncă nu există evaluări