Documente Academic

Documente Profesional

Documente Cultură

Supp Nov 2009

Încărcat de

prk74Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Supp Nov 2009

Încărcat de

prk74Drepturi de autor:

Formate disponibile

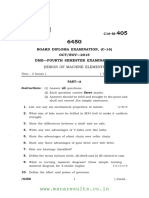

Code No: Q0303/R05

Set No. 1

III B.Tech II Semester Supplementary Examinations, Nov/Dec 2009 DESIGN OF MACHINE MEMBERS-II ( Common to Mechanical Engineering and Production Engineering) Time: 3 hours Max Marks: 80 Answer any FIVE Questions All Questions carry equal marks

1. A single row deep groove ball bearing No. 6002 is subjected to an axial thrust of 1000N and a radial load of 2200 N. Find the expected life that of 1000N and a radial load of 2200N. Find the expected life that 50% of the bearings will complete under this condition. [16] 2. Design a suitable connecting rod for Fiat 1100 car for the following data: Diameter of piston, D=68mm Weight of reciprocating parts/cylinder=2.5kg Length of connecting rod =150mm Stroke =75mm Speed=4,400rpm Compression ratio=8:1 Maximum explosion pressure = 3.5MPa Allowable bearing pressure for big end =7MPa Allowable bearing pressure for small end =14MPa Assume any other data. Rod is made of 37Mn2 alloy steel.

[16]

3. Design and sketch a cast iron piston for a single acting four stroke IC engine with a 0.14 m cylinder bore 0.19 m stroke and 0.375 m connecting rod length. The maximum gas pressure is 3.5 N/mm2 and the engine speed is 600rev/min. It develops a break mean eective pressure 0.7N/mm2 and uses 4.65 kJ/kW/Sec, check the piston for heat ow. [16] 4. The load P applied to the frame shown in gure 4 is 2.5 kN. Calculate the stresses at A and B. Also locate the position of the neutral axis. [16]

1 to of remove 3 Please purchase PDF Split-Merge on www.verypdf.com this watermark.

Code No: Q0303/R05

Set No. 1

Figure 4 5. (a) What is meant by creep of a belt and what is its eect? (b) Determine the number of manila ropes required to transmit 200kW at a speed of 12m/s. Use the following particulars of the drive. Diameter of the rope = 30mm Mass of the rope = 0.65kg/meter length Breaking load = 70kN Coecient of friction = 0.15 Pulley groove angle= 450 Angle of arc of contact = 1650 Factor of safety = 25. [4+12] 6. (a) What is the dierence between involute and cyloidal gears. (b) In a spur gear drive the diameter of pinion is 100mm and the centre distance 220mm. the power to be transmitted is 6.5kW at 900 rpm of pinion. Using 200 full depth teeth and material for pinion steel with permissible static stress of 200MPa and for gear a steel with a permissible static bending stress of 150MPa, determine the necessary module and width of the teeth using Lewis equation only. [4+12] 7. (a) Explain the procedure of checking the design of a screw for buckling. (b) A screw jack carries a load of 20kN. Assuming the coecient of friction between the screw and nut as 0.15, design the screw and nut. Neglect collar friction and column action. The permissible compressive and shear stresses in the screw should not exceed 40MPa and 25MPa respectively. The shear stress in the nut should not exceed 20MPa.The bearing pressure in the nut is 12MPa. Also determine the eort required at the handle of 250mm length, in order to raise and lower the load. What will be the eciency of the screw jack? [4+12] 8. (a) What type of material is suitable for slide ways? Give some important properties 2 to of remove 3 Please purchase PDF Split-Merge on www.verypdf.com this watermark.

Code No: Q0303/R05 (b) Write a design procedure for the slide ways.

Set No. 1

[6+10]

3 to of remove 3 Please purchase PDF Split-Merge on www.verypdf.com this watermark.

Code No: Q0303/R05

Set No. 2

III B.Tech II Semester Supplementary Examinations, Nov/Dec 2009 DESIGN OF MACHINE MEMBERS-II ( Common to Mechanical Engineering and Production Engineering) Time: 3 hours Max Marks: 80 Answer any FIVE Questions All Questions carry equal marks

1. A rolling contact bearing is subjected to the following work cycle: (a) radial load of 6000N at 150 r.p.m for 25% of the time; (b) radial load of 7500N at 600 r.p.m for 20% of the time; and (c) radial load of 2000N at 300 r.p.m for 55% of the time. The inner ring rotates and loads are steady .Select a bearing for an expected average life of 2500hours. [16] 2. Design a connecting rod of I cross section for an automobile diesel engine of the following specications. Diameter of cylinder=100mm Stroke length =125mm Maximum combustion pressure =2.8MPa Maximum engine speed=2000rpm Weight of the reciprocating parts =1.1kg Length of connecting rod between centers=31.5cm [16] Assume an allowable crushing stress =3000kg/cm2 . 3. (a) How the piston head of an IC engine is usually cooled? What are the advantages of cooling ? (b) A horizontal four stroke diesel engine has the following speciation: Break Power =5kW Speed = 1200 rpm Imep = 0.35 N/mm2 Mechanical eciency = 80% Calculate the dimensions of the cylinder and the cylinder head.

[6+10]

4. A ring is made of a 50 mm diameter round bar as shown in the gure 4. Calculate the stresses at point A and B. [16]

1 to of remove 3 Please purchase PDF Split-Merge on www.verypdf.com this watermark.

Code No: Q0303/R05

Set No. 2

Figure 4 5. (a) What are the factors that eect power transmission by a belt drive? (b) Design the elliptical cross-section of a belt pulley arm near the hub for the following specications: the mean pulley diameter is 300mm and the numbers of pulley arms are 4. The elliptical section has major axis twice the minor axis length the tight and slack sides tension in the belt are 600N and 200N respectively. Assume half number of arms transmit torque at any time and the load factor of 1.75 to account for dynamic eects on the pulley while transmitting torque. The permissible tensile stress for cast iron pulley material is 15MPa. The pulley hub diameter is 60mm. [4+12] 6. (a) Dene the terms of Module and Circular pitch. (b) Design a spur gear drive required to transmit 45kW at a speed of 800rpm. The velocity ratio is 3.5:1. The teeth are 20degree full depth involute with 18 teeth on the pinion. Both the pinion and gear are made of steel with a maximum safe static stress of 180MPa for the material of the shaft and key. [2+14] 7. (a) What is the main advantage of a power screw? (b) A screw jack is used to raise a load of 50kN. The mean diameter of the single start square threaded screw is 70mm and the pitch is 20mm. Determine the force to be applied at the end of 0.9m long handle, when the load is lifted and the load rotate with the spindle. Take coecient of thread friction as 0.2. Also, determine the eciency of the screw jack. [4+12] 8. (a) Why a combination of at and V type of slide ways is preferred for machine Tools. (b) Explain the design criteria and calculations for slide ways. [4+12]

2 to of remove 3 Please purchase PDF Split-Merge on www.verypdf.com this watermark.

Code No: Q0303/R05

Set No. 2

3 to of remove 3 Please purchase PDF Split-Merge on www.verypdf.com this watermark.

Code No: Q0303/R05

Set No. 3

III B.Tech II Semester Supplementary Examinations, Nov/Dec 2009 DESIGN OF MACHINE MEMBERS-II ( Common to Mechanical Engineering and Production Engineering) Time: 3 hours Max Marks: 80 Answer any FIVE Questions All Questions carry equal marks

1. (a) Dene the following terms: i. journal ii. Eccentricity ratio. (b) A bearing, supporting a power transmitting shaft, is subjected to 3000N radial load and 45000N axial thrust. The shaft rotates at 400r.p.m and the expected life of the bearing is 10,000hours. Select a suitable bearing, if the diameter of the shaft is 40mm. [2+14] 2. An engine with following particulars is available: Piston diameter =75mm, Stroke of piston =100mm, Length of connecting rod =200mm, Max explosion Pressure=2.45MPa, maximum speed =2,500rpm, weigth of reciprocating parts =1.125 kg, width of cap =35mm,distance between cap bolts=70mm, density of rod material =0.008kg/cm3 . Find (a) The diameter and length of crank pin bearing if the permissible pressure is 7MPa and l/d ratio is 0.8. (b) Size of the bolts if the stress in the cross section is not to exceed 42MPa. The bolts may be designed to with stand maximum inertia force of the reciprocating parts at the end of the exhaust stroke. (c) Thickness of the cap along the longitudinal axis of the connecting rod, if the safe bending stress is 84MPa. (d) Cross section of the connecting rod of mild steel forging I section. (e) Necessary dimensions for small end allowing a bearing pressure of 14MPa. [16] 3. Design a Cast iron piston for a single acting four stroke engine for the following specications. Cylinder bore = 100mm, Stroke = 120mm, Maximum gas pressure = 5N/mm2 , Break mean eective pressure = 0.65N/mm2 , Fuel consumption = 0.227kg/kW/hr, Speed =2200 rev/min, Assume suitable data. [16] 4. A curved bar of rectangular section, initially unstressed, is subjected to bending moment of 1400 N-m which tends to straighten the bar. The section is 4 cm wide by 5 cm deep in the plane of bending, and the mean radius of curvature is 10 cm. Find the position of the neutral axis and magnitudes of the greatest bending stress and draw a diagram to show approximately how the stress varies across the section. [16]

1 to of remove 2 Please purchase PDF Split-Merge on www.verypdf.com this watermark.

Code No: Q0303/R05

Set No. 3

5. (a) Derive an expression for the length of cross belt drive for at belts. (b) Determine the percentage increase in power capacity made possible in changing over from a at belt to a V- belt drive. The diameter of at pulley is the same as the pitch diameter of the grooved pulley. The pulley rotates at the same speed as the grooved pulley. The coecient of friction for the at belt and V- belt is the same and is equal to 0.35. The V- belt pulley groove angle is 600 . The belts are of the same material, and have the same cross-sectional area. In each case, the angle of lap is 1600 . [8+8] 6. A helical cast steel gear with 400 helix angle has to transmit 80kW at 1800 rpm. If the gear has 24 teeth, determine the necessary module, pitch diameter and face width for 200 full depth. The static stress for cast steel may be taken as 56MPa. The width of face may be taken as 3 times the normal pitch. What would be the end thrust on the gear? The tooth factor for 20degree full depth involute gear may be taken as 0.154-0.912/ no. of teeth. [16] 7. (a) Name the devices in which a power screw forms a part; mentioning the applications of each. (b) A double-threaded power screw, used for lifting the load, has a nominal diameter of 32mm and pitch of 6mm. The coecient of friction at the screw threads is 0.12. Neglecting collar friction, calculate i. eciency of the screw with square threads, and ii. eciency with ACME threads. 8. (a) what are the protecting devices for slide ways? (b) A 4m long, 2m high and 0.3m wide lathe bed consists of two vertical walls strengthened by perpendicular or diagonal stiness. The thickness of the walls is 70mm. While that of the stiness is 45mm. Calculate the reduced bending rigidity of the beds having perpendicular and diagonal stieners. [6+10] [6+10]

2 to of remove 2 Please purchase PDF Split-Merge on www.verypdf.com this watermark.

Code No: Q0303/R05

Set No. 4

III B.Tech II Semester Supplementary Examinations, Nov/Dec 2009 DESIGN OF MACHINE MEMBERS-II ( Common to Mechanical Engineering and Production Engineering) Time: 3 hours Max Marks: 80 Answer any FIVE Questions All Questions carry equal marks

1. (a) Explain the following terms: i. Rated life ii. Basic load rating iii. Dynamic load. (b) Select the suitable dimensions for a journal bearing which is subjected to 3.5kN radial load. The diameter and length of the bearing are 75mm each. The journal rotates at 400r.p.m. [6+10] 2. The maximum combustion pressure in an automotive diesel engine is 6MPa. Cylinder bore is 1350mm. Determine the desirable I-section for the middle of the connecting rod 32.0cm long. If the engine stroke is 12.5cm and the maximum speed is 2000rpm, determine the whipping stress in the connecting rod. [16] 3. Design and draw a trunk type piston for the following data: bhp = 10, Speed =1,000rpm. Allowable bearing pressure on gudgeon pin of carbon =105 to 140kg/mm2 . Permissible stress on the gudgeon pin of carbon steel =560kg/mm2 . Weight of reciprocating parts per sq-cm of piston =0.14 kg. Ratio of connecting rod to crank =4. Assume suitable values of other missing data. [16] 4. A curved bar of circular cross-section 100 mm in diameter has a radius of curvature of 25 mm at the inner bers. The bending moment acting on the bar causes a tensile stress of 20 N/mm2 in the inner bers. What will be the stress in the outer bers? [16] 5. (a) What is meant by creep of a belt and what is its eect? (b) A belt,10010mm is transmitting power at 15m/s. The angle of contact on the driver (smaller ) pulley is 1560 . If the permissible stress for the belt material is 2N/mm2 ; determine the power that can be transmitted at this speed. Take the density of leather as 1000kg/m3 , and coecient of friction as 0.25. Calculate the maximum power that can be transmitted by this belt, and the speed at which this can be transmitted. [4+12] 6. (a) Explain the methods for prevention of interference (b) A bronze spur pinion rotating at 560rpm drives a cast steel gear transmission ratio is 4. The pinion has 18 teeth with 200 full depth involute prole; The module being 5mm. The face width of the gearing is 25mm. Determine the power that can be transmitted from the stand point of strength. Static strength for bronze is 80MPa, and for cast steel it is 100MPa. [4+12] 1 to of remove 2 Please purchase PDF Split-Merge on www.verypdf.com this watermark.

Code No: Q0303/R05 7. (a) Sketch the dierent thread proles.

Set No. 4

(b) A sluice weighing 600kN is raised and lowered by means of two square threaded screws. The coecient of friction between the thrust collar and screw is 0.003 and that between the screw and that between the screw and nut is 0.05. Design the screw and the nut. Assume the data if necessary. [6+10] 8. A lathe has two at, CI slide ways of equal width and height half the width. While turning a 100 mm diameter work piece, the tangential, radial and axial components of the cutting force were found to be Px =1200N, Py =1300N and Pz =3000N respectively. The lathe slide ways width assuming suitable values. Cast iron slide ways can with stand a maximum pressure of 2500 kN/m2 . [16]

2 to of remove 2 Please purchase PDF Split-Merge on www.verypdf.com this watermark.

S-ar putea să vă placă și

- rr320305 Design of Machine Members IIDocument8 paginirr320305 Design of Machine Members IISrinivasa Rao GÎncă nu există evaluări

- 07a6ec05 Designofmachinemembers IIDocument11 pagini07a6ec05 Designofmachinemembers IIzahid_polyÎncă nu există evaluări

- Dmm2 Mar2006Document8 paginiDmm2 Mar2006Abdul Saleem MohammedÎncă nu există evaluări

- DMM Ii (2015)Document35 paginiDMM Ii (2015)gorijalaÎncă nu există evaluări

- r05320305 Design of Machine Members IIDocument11 paginir05320305 Design of Machine Members IISrinivasa Rao G100% (4)

- Makalah GTWDocument8 paginiMakalah GTWfaisalÎncă nu există evaluări

- 4363 111 Machine Design IDocument6 pagini4363 111 Machine Design Iyogesh_b_k100% (2)

- 05-04 Machine Design & Cad-II (Me)Document2 pagini05-04 Machine Design & Cad-II (Me)Abdul AhadÎncă nu există evaluări

- MD II Machine Design AssignmentsDocument5 paginiMD II Machine Design Assignmentsrishabhk28995Încă nu există evaluări

- 12ME5DCDM2Document3 pagini12ME5DCDM2Abhyudaya SinghÎncă nu există evaluări

- Design of Machine Elements-II Exam QuestionsDocument9 paginiDesign of Machine Elements-II Exam QuestionsPrasinÎncă nu există evaluări

- Design of Transmission SystemsDocument3 paginiDesign of Transmission SystemsSaravanan KumarÎncă nu există evaluări

- Design of Machine Members-II Feb 2022Document3 paginiDesign of Machine Members-II Feb 2022Anand KedhariÎncă nu există evaluări

- Machine Design-II Question BankDocument32 paginiMachine Design-II Question BankAbhishek SakatÎncă nu există evaluări

- r05320305 Design of Machine Members IIDocument9 paginir05320305 Design of Machine Members IISRINIVASA RAO GANTAÎncă nu există evaluări

- rr321401 Principles of Machine DesignDocument8 paginirr321401 Principles of Machine DesignSRINIVASA RAO GANTA100% (1)

- ME 331 - DESIGN OF MACHINE ELEMENTS EXAMDocument5 paginiME 331 - DESIGN OF MACHINE ELEMENTS EXAMarumugam_rÎncă nu există evaluări

- rr321401 Principles of Machine DesignDocument8 paginirr321401 Principles of Machine DesignSRINIVASA RAO GANTAÎncă nu există evaluări

- Design of Machine Elements Exam with Questions on Shafts, Couplings, Keys, Springs, Bearings, FlywheelsDocument3 paginiDesign of Machine Elements Exam with Questions on Shafts, Couplings, Keys, Springs, Bearings, FlywheelsHariharanAutoÎncă nu există evaluări

- r05321403 Principles of Machine DesignDocument8 paginir05321403 Principles of Machine DesignSRINIVASA RAO GANTAÎncă nu există evaluări

- 1 ST Assignment Section-A&B 3-1 Semester Dmm-2: Sir CR Reddy College of EngineeringDocument3 pagini1 ST Assignment Section-A&B 3-1 Semester Dmm-2: Sir CR Reddy College of EngineeringChadaram JagadishÎncă nu există evaluări

- 2019 May ME402-A - Ktu QbankDocument3 pagini2019 May ME402-A - Ktu Qbankbilalfocus0% (1)

- Machine Design-I Exam Guide for University of Pune StudentsDocument56 paginiMachine Design-I Exam Guide for University of Pune Studentsavinash119870% (1)

- Design of Machine Members II R5320305 Set 3Document2 paginiDesign of Machine Members II R5320305 Set 3Ravi Kumar KamarthiÎncă nu există evaluări

- Question Paper - Design of Machine Elements 2 Oct-19-October - 2019Document2 paginiQuestion Paper - Design of Machine Elements 2 Oct-19-October - 2019ChanduÎncă nu există evaluări

- 2020-11-10SupplementaryME402ME402-E - Ktu QbankDocument2 pagini2020-11-10SupplementaryME402ME402-E - Ktu QbankbilalfocusÎncă nu există evaluări

- WWW - Manaresults.co - In: (Mechanical Engineering)Document2 paginiWWW - Manaresults.co - In: (Mechanical Engineering)Mohammed SohailÎncă nu există evaluări

- 9A14503 Principles of Machine DesignDocument8 pagini9A14503 Principles of Machine DesignsivabharathamurthyÎncă nu există evaluări

- 3-1 DMM1 (Nov 2009 Regular)Document9 pagini3-1 DMM1 (Nov 2009 Regular)micmechÎncă nu există evaluări

- DMM-2 3 1 Q&aDocument6 paginiDMM-2 3 1 Q&aAnand vinayÎncă nu există evaluări

- Machine Design Exam Questions on Gears, Bearings and Other Mechanical ComponentsDocument3 paginiMachine Design Exam Questions on Gears, Bearings and Other Mechanical ComponentsNILESH SUTHARÎncă nu există evaluări

- Me1302 Dme 2Document4 paginiMe1302 Dme 2sumikannu100% (1)

- rr320305 Design of Machine Members IIDocument8 paginirr320305 Design of Machine Members IISRINIVASA RAO GANTAÎncă nu există evaluări

- Design of Machine Element-IIDocument53 paginiDesign of Machine Element-IIPramod R Bidve100% (1)

- r05312401 Design of Machine ElementsDocument8 paginir05312401 Design of Machine ElementsSrinivasa Rao GÎncă nu există evaluări

- Dme Model QPDocument3 paginiDme Model QPCody LeeÎncă nu există evaluări

- Design Machine Elements ExamDocument2 paginiDesign Machine Elements ExamPraba KaranÎncă nu există evaluări

- Dme Model Key 2019Document25 paginiDme Model Key 2019Siva RamanÎncă nu există evaluări

- B.Tech Degree S8 (S, FE) / S6 (PT) (S, FE) Examination June 2023 (2015 Scheme)Document3 paginiB.Tech Degree S8 (S, FE) / S6 (PT) (S, FE) Examination June 2023 (2015 Scheme)Venkitaraj K PÎncă nu există evaluări

- 12 Me 5dcdm2Document3 pagini12 Me 5dcdm2Abhyudaya SinghÎncă nu există evaluări

- WWW Manaresults Co inDocument4 paginiWWW Manaresults Co inGod deva123Încă nu există evaluări

- DME Model QuesDocument3 paginiDME Model QuesSiva RamanÎncă nu există evaluări

- Design of Machine Members - II April 2017Document8 paginiDesign of Machine Members - II April 2017Abhishek Goud AkkapalliÎncă nu există evaluări

- Dme Quest Ut-2Document9 paginiDme Quest Ut-2aadhithyarajasekaranÎncă nu există evaluări

- Snist Dom Previous PaperDocument9 paginiSnist Dom Previous PaperKapil Siddhant DevulapalliÎncă nu există evaluări

- dmm1 PDFDocument9 paginidmm1 PDFmohan_rapaka6095Încă nu există evaluări

- WWW - Manaresults.Co - In: (Common To Ame, Me)Document3 paginiWWW - Manaresults.Co - In: (Common To Ame, Me)Vikranth DeepakÎncă nu există evaluări

- No of Pages: 4 Course Code: 12M502: Fig.1 Fig 2Document4 paginiNo of Pages: 4 Course Code: 12M502: Fig.1 Fig 2CRAZY PIANO PLAYERÎncă nu există evaluări

- Mechatronics exam with questions on control systems and PLC applicationsDocument62 paginiMechatronics exam with questions on control systems and PLC applicationshaptooorÎncă nu există evaluări

- ME2352 Design of Transmission Question BankDocument4 paginiME2352 Design of Transmission Question BankKarthik SubramaniÎncă nu există evaluări

- Me 2303 - Design of Machine Elements December 2010Document3 paginiMe 2303 - Design of Machine Elements December 2010Ilaya Perumal K0% (1)

- 08 r05310305 Design of Machine Members IDocument9 pagini08 r05310305 Design of Machine Members IKrupanandareddyYarragudiÎncă nu există evaluări

- B.Tech Exam Design of Machine Members QuestionsDocument8 paginiB.Tech Exam Design of Machine Members Questionsprk74Încă nu există evaluări

- 0326 Me 2303 Design of Machine ElementsDocument3 pagini0326 Me 2303 Design of Machine ElementsSaravanan MathiÎncă nu există evaluări

- DME Chapter Three: or (Summer 15)Document7 paginiDME Chapter Three: or (Summer 15)honeyfunnyÎncă nu există evaluări

- PMD ModelDocument8 paginiPMD ModelDamodara SatyaDeva MadhukarÎncă nu există evaluări

- DTS ND06-QPDocument3 paginiDTS ND06-QPsrajapratyÎncă nu există evaluări

- MDDocument2 paginiMDAbhijeet PramanikÎncă nu există evaluări

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDe la EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsEvaluare: 4.5 din 5 stele4.5/5 (10)

- Machine Design Elements and AssembliesDe la EverandMachine Design Elements and AssembliesEvaluare: 3.5 din 5 stele3.5/5 (2)

- A: For Nominee: Name of Team: 2014-15 Batch Names of Team MembersDocument1 paginăA: For Nominee: Name of Team: 2014-15 Batch Names of Team Membersprk74Încă nu există evaluări

- Kanok-Nukulchai W, Barry W, Saran-Yasoontorn K, Bouillard PH. On Elimination of Shear Locking in The ElementDocument1 paginăKanok-Nukulchai W, Barry W, Saran-Yasoontorn K, Bouillard PH. On Elimination of Shear Locking in The Elementprk74Încă nu există evaluări

- Extensive Literature Is Devoted To The Methods Developed in Studies On The Vibrations of Strings With Timevariable LengthsDocument1 paginăExtensive Literature Is Devoted To The Methods Developed in Studies On The Vibrations of Strings With Timevariable Lengthsprk74Încă nu există evaluări

- Ahna, A.C. and Grodzinskyc, A.J., Relevance of Collagen Piezoelectricity To Wolff's Law'Document1 paginăAhna, A.C. and Grodzinskyc, A.J., Relevance of Collagen Piezoelectricity To Wolff's Law'prk74Încă nu există evaluări

- Qian LF, Batra RC, Chen LM. Static and Dynamic Deformations of Thick Functionally GradedDocument1 paginăQian LF, Batra RC, Chen LM. Static and Dynamic Deformations of Thick Functionally Gradedprk74Încă nu există evaluări

- Rabczuk T, Eibl J. Numerical Analysis of Prestressed Concrete Beams Using A Coupled Element Free GalerkinDocument1 paginăRabczuk T, Eibl J. Numerical Analysis of Prestressed Concrete Beams Using A Coupled Element Free Galerkinprk74Încă nu există evaluări

- Ventura G, Xu JX, Belytschko T. A Vector Level Set Method and New Discontinuity Approximations For Crack Growth by EFGDocument1 paginăVentura G, Xu JX, Belytschko T. A Vector Level Set Method and New Discontinuity Approximations For Crack Growth by EFGprk74Încă nu există evaluări

- Liew KM, Peng LX, Kitipornchai S. Vibration Analysis of Corrugated Reissner - Mindlin Plates Using A Mesh-Free Galerkin MethodDocument1 paginăLiew KM, Peng LX, Kitipornchai S. Vibration Analysis of Corrugated Reissner - Mindlin Plates Using A Mesh-Free Galerkin Methodprk74Încă nu există evaluări

- Duan, L., Kang, Q., Hu, R.W., Li, G.P. and Wang, D.C., The Mass Transfer Process and The Growth Rate of Protein CrystalsDocument1 paginăDuan, L., Kang, Q., Hu, R.W., Li, G.P. and Wang, D.C., The Mass Transfer Process and The Growth Rate of Protein Crystalsprk74Încă nu există evaluări

- Zhang Z, Liew KM. Improved Element-Free Method (IEFG) For Solving Threedimensional Elasticity Problems. InteractDocument1 paginăZhang Z, Liew KM. Improved Element-Free Method (IEFG) For Solving Threedimensional Elasticity Problems. Interactprk74Încă nu există evaluări

- Yao, X.F., Xu, W. and Yeh, H.Y., Fracture Visualization Using Hybrid Optical Technique Combining Coherent Gradient Sensing (CGS) With CausticsDocument1 paginăYao, X.F., Xu, W. and Yeh, H.Y., Fracture Visualization Using Hybrid Optical Technique Combining Coherent Gradient Sensing (CGS) With Causticsprk74Încă nu există evaluări

- Kim NH, Choi KK, Chen JS, Botkin ME. Meshfree Analysis and Design Sensitivity Analysis ForDocument1 paginăKim NH, Choi KK, Chen JS, Botkin ME. Meshfree Analysis and Design Sensitivity Analysis Forprk74Încă nu există evaluări

- Areias Rabczukt, Pma Belyyschkot. A Meshfree Thin Shell Method For Nonlinear Dynamic FractureDocument1 paginăAreias Rabczukt, Pma Belyyschkot. A Meshfree Thin Shell Method For Nonlinear Dynamic Fractureprk74Încă nu există evaluări

- Bobaru F, Mukherjee S. Meshless Approach To Shape Optimization of Linear ThermoelasticDocument1 paginăBobaru F, Mukherjee S. Meshless Approach To Shape Optimization of Linear Thermoelasticprk74Încă nu există evaluări

- Sun YZ, Liew KM. Application of The Higher-Order Cauchy-Born Rule in Meshfree Continuum and Multiscale Simulation of Carbon NanotubesDocument1 paginăSun YZ, Liew KM. Application of The Higher-Order Cauchy-Born Rule in Meshfree Continuum and Multiscale Simulation of Carbon Nanotubesprk74Încă nu există evaluări

- Chen XL, Liu GR, Lim SP. An Element Free Galerkin Method For The Free Vibration Analysis of Composite Laminates of Complicated ShapeDocument1 paginăChen XL, Liu GR, Lim SP. An Element Free Galerkin Method For The Free Vibration Analysis of Composite Laminates of Complicated Shapeprk74Încă nu există evaluări

- Dai KY, Liu GR, Han X, Lim KM. Thermomechanical Analysis of Functionally Graded MaterialDocument1 paginăDai KY, Liu GR, Han X, Lim KM. Thermomechanical Analysis of Functionally Graded Materialprk74Încă nu există evaluări

- Amirani MC, Khalili SMR, Nemati N. Free Vibration Analysis of Sandwich Beam With FG Core Using The Element Free Galerkin MethodDocument1 paginăAmirani MC, Khalili SMR, Nemati N. Free Vibration Analysis of Sandwich Beam With FG Core Using The Element Free Galerkin Methodprk74Încă nu există evaluări

- Karim MR, Nogami T, Wang JG. Analysis of Transient Response of Saturated Porus Elstic Soil Under Cyclic Loading Using Element-Free Galerkin MethodDocument1 paginăKarim MR, Nogami T, Wang JG. Analysis of Transient Response of Saturated Porus Elstic Soil Under Cyclic Loading Using Element-Free Galerkin Methodprk74Încă nu există evaluări

- Free Vibration Analysis of Conical Shell Panels Using kp-Ritz MethodDocument1 paginăFree Vibration Analysis of Conical Shell Panels Using kp-Ritz Methodprk74Încă nu există evaluări

- Peng LX, Kitipornchai S, Liew KM. Free Vibration Analysis of Folded Plate Structures by The FSDT Mesh-Free MethodDocument1 paginăPeng LX, Kitipornchai S, Liew KM. Free Vibration Analysis of Folded Plate Structures by The FSDT Mesh-Free Methodprk74Încă nu există evaluări

- Rahman S, Rao BN. An Element-Free Galerkin Method For Probalistic Mechanics and ReliabilityDocument1 paginăRahman S, Rao BN. An Element-Free Galerkin Method For Probalistic Mechanics and Reliabilityprk74Încă nu există evaluări

- Parameter calculations for system modelingDocument2 paginiParameter calculations for system modelingprk74Încă nu există evaluări

- Mass of TheDocument1 paginăMass of Theprk74Încă nu există evaluări

- Time ofDocument1 paginăTime ofprk74Încă nu există evaluări

- Answer All Questions, Each Carries 5 Marks: RegdDocument1 paginăAnswer All Questions, Each Carries 5 Marks: Regdprk74Încă nu există evaluări

- X. Wang and G. Lu - Local Buckling of Composite Laminar Plates With Various Delaminated ShapesDocument1 paginăX. Wang and G. Lu - Local Buckling of Composite Laminar Plates With Various Delaminated Shapesprk74Încă nu există evaluări

- Internal Exam in Respect of Substitute SubjectsDocument1 paginăInternal Exam in Respect of Substitute Subjectsprk74Încă nu există evaluări

- Journal of Reinforced Plastics and CompositesDocument1 paginăJournal of Reinforced Plastics and Compositesprk74Încă nu există evaluări

- Exhaust Gas Heat Is Being Used To Generate Steam For Fuel Heating PurposeDocument1 paginăExhaust Gas Heat Is Being Used To Generate Steam For Fuel Heating Purposeprk74Încă nu există evaluări

- Ball Valve Floating From Kitz Model F14AZ - SCTDZM-FSDocument10 paginiBall Valve Floating From Kitz Model F14AZ - SCTDZM-FSMeanRatÎncă nu există evaluări

- Kingsley InstructionsDocument12 paginiKingsley InstructionsCristian PascariÎncă nu există evaluări

- Sonatrach: First Calgary Petroleums MLEG-00-FP-P-00OO64Document17 paginiSonatrach: First Calgary Petroleums MLEG-00-FP-P-00OO64AHMED AMIRAÎncă nu există evaluări

- Rolta Piping GuideDocument224 paginiRolta Piping GuideSudhesh Rajamoorthy100% (3)

- Hydril - GK BopDocument66 paginiHydril - GK Bopnkk1790% (10)

- 2te15-18 Repair Manual Ce660Document495 pagini2te15-18 Repair Manual Ce660Eriflona75% (4)

- Suspended Acoustical Ceiling SystemsDocument8 paginiSuspended Acoustical Ceiling Systemsjack.simpson.changÎncă nu există evaluări

- PIP PN03SD0B02 Piping Material Specification 3SD0B02 Class 300, 316/316L Stainless Steel, Butt Weld, 0.000 C.A., Process (PTFE Packing/Gaskets)Document5 paginiPIP PN03SD0B02 Piping Material Specification 3SD0B02 Class 300, 316/316L Stainless Steel, Butt Weld, 0.000 C.A., Process (PTFE Packing/Gaskets)César SantanaÎncă nu există evaluări

- PARTLIST-Benelli-RFS-150i-RFS 150i-Key112-D2021-08-14-09-57-25amDocument81 paginiPARTLIST-Benelli-RFS-150i-RFS 150i-Key112-D2021-08-14-09-57-25amMohamed ali AmeurÎncă nu există evaluări

- PUK-PL2015 de - Price List Cable Trays New EnglishDocument134 paginiPUK-PL2015 de - Price List Cable Trays New EnglishDaniel Uculmana LemaÎncă nu există evaluări

- ProblemSet - Shear JointsDocument2 paginiProblemSet - Shear JointsOjay ScottÎncă nu există evaluări

- Method Statement For Installation of Clean Agent Fire Suppression SystemDocument6 paginiMethod Statement For Installation of Clean Agent Fire Suppression Systemamg007100% (1)

- Atlas Specialty Metals: Stainless Steel Wire & BarDocument29 paginiAtlas Specialty Metals: Stainless Steel Wire & Barsattar12345Încă nu există evaluări

- Jazzman Steering Rack RebuildDocument69 paginiJazzman Steering Rack Rebuildbsmith21-2000Încă nu există evaluări

- HF SN Manual ServoMotor Mitsubishi PDFDocument96 paginiHF SN Manual ServoMotor Mitsubishi PDFDiana PitreÎncă nu există evaluări

- Euclid Catalog Front End 760cDocument274 paginiEuclid Catalog Front End 760cjoshÎncă nu există evaluări

- Kohler SV Service ManualDocument84 paginiKohler SV Service ManualfishuenntÎncă nu există evaluări

- FL - Cable Trays For Electrical Systems - CabitrayDocument9 paginiFL - Cable Trays For Electrical Systems - CabitrayRashel HasanÎncă nu există evaluări

- MC-SUZUKI@LS 650 (F) (P) @G J K L M R@601-750cc@175Document103 paginiMC-SUZUKI@LS 650 (F) (P) @G J K L M R@601-750cc@175Lanz Silva100% (1)

- Can-Am 2019 Maverick x3 Turbo Service Manual Electronic VersionDocument778 paginiCan-Am 2019 Maverick x3 Turbo Service Manual Electronic VersionWashington Luíz100% (10)

- 15 HDB SorDocument236 pagini15 HDB SorKamal SelvarajuÎncă nu există evaluări

- NL Trigen Meta Nail Retrograde SurgicaltechniqueDocument68 paginiNL Trigen Meta Nail Retrograde SurgicaltechniqueSara MorenoÎncă nu există evaluări

- BOMBARDIER 650DS 2001 Manual de Servicio.Document181 paginiBOMBARDIER 650DS 2001 Manual de Servicio.Thure Mollerhoj50% (2)

- KERN ABS Service ManualDocument51 paginiKERN ABS Service Manualrestor3d100% (1)

- Test Report: H.D.G. Bolts, Nuts & Plain WasherDocument1 paginăTest Report: H.D.G. Bolts, Nuts & Plain WasherSumanta AdhikariÎncă nu există evaluări

- Piparsewa DPR (Part 1 and Part 2) PDFDocument175 paginiPiparsewa DPR (Part 1 and Part 2) PDFFaisal KhanÎncă nu există evaluări

- Radio Shack Alarm PanelDocument32 paginiRadio Shack Alarm Panel123v456s789cÎncă nu există evaluări

- Installation Guide For Securedge 3000 XT: #9 X 1-1/2" Ss Screw W/ WasherDocument2 paginiInstallation Guide For Securedge 3000 XT: #9 X 1-1/2" Ss Screw W/ WasherConstantin GubavuÎncă nu există evaluări

- John Deere 4055-4255-4455-4555-4755-4955 Shopmanual Sec WatDocument203 paginiJohn Deere 4055-4255-4455-4555-4755-4955 Shopmanual Sec WatLucyan Ionescu40% (5)

- 100C Air Compressor Kit Safety and Installation GuideDocument8 pagini100C Air Compressor Kit Safety and Installation GuideRubenÎncă nu există evaluări