Documente Academic

Documente Profesional

Documente Cultură

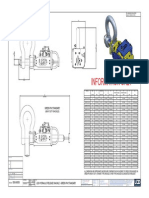

Collar EyeBolt To BS4278 Table 1

Încărcat de

Rajesh N Priya GopinathanTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Collar EyeBolt To BS4278 Table 1

Încărcat de

Rajesh N Priya GopinathanDrepturi de autor:

Formate disponibile

Collar EyeBolt To BS4278 Table 1

NOTES: All information on this page is for guidance only: For actual lifting capacities, dimensions and safe use requirements refer to the standards indicated and

be advised by the equipment suppliers. The safe working loads is for axial lifts only. For lifts not in line with axes of eyebolt the SWL has to be reduced. Please

refer to BS4278

Safe Working

Metric Thread B

Load

tonnes

dia

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

0.4

12

22

15

15

20

18

0.8

16

29

20

10

20

12

26

23

12

1.6

20

40

27

14

27

16

36

32

16

2.5

24

52

35

17

35

21

46

40

21

4.0

30

65

44

22

44

26

58

51

26

6.3

36

81

54

27

54

32

72

63

32

8.0

42

90

60

30

60

36

80

70

10

36

10.0

48

101

68

34

68

40

90

79

11

40

12.5

52

115

76

38

76

46

102

89

13

46

16.0

56

128

86

43

86

51

114

100

14

51

20.0

64

144

96

48

96

58

128

112

16

58

25.0

72

162

108

54

108

65

144

128

18

65

This Page is being developed

TYPE 1 REGULAR PATTERN EYEBOLTS

ANSI B18.15 1969

A

Nominal

Size

Shank Shank

Dia

Length

Eye

ID

Nominal

Eye

Eye OD Sect Dia

Overall

Length

Min Length

Full Thread

Thread

Size

UNC-2A

Wx

Wy

Safe

Safe Working

Working

Load, lb

Load, lb

at 45 Deg1

at 0 Deg1

Wz

Safe

Working

Load, lb

at 90 Deg1

0.25

0.25

0.28

1.00

1.06

0.69

0.81

1.19

0.19

0.25

2.06

2.38

0.75

1/4-20 or .

250-20

400

5/16* 0.31

0.31

0.34

1.12

1.19

0.81

0.94

1.44

0.25

0.31

2.44

2.75

0.81

5/16-18 or .

3125-18

800

3/8*

0.38

0.38

0.41

1.25

1.38

0.94

1.06

1.69

0.31

0.38

2.81

3.19

0.88

3/8-16 or .

375-16

1400

7/16

0.44

0.44

0.47

1.38

1.50

1.00

1.12

1.81

0.34

0.41

3.06

3.44

1.00

7/16-14 or .

4375-14

2000

400

300

1/2*

0.50

0.50

0.53

1.50

1.62

1.12

1.25

2.12

0.44

0.50

3.50

3.88

1.12

1/2-13 or .

500-13

2600

520

390

9/16

0.56

0.56

0.59

1.62

1.75

1.19

1.31

2.25

0.47

0.53

3.75

4.12

1.25

9/16-12 or .

5625-12

3000

600

450

5/8*

0.62

0.62

0.66

1.75

1.88

1.31

1.44

2.56

0.56

0.62

4.19

4.56

1.38

5/8-11 or .

625-11

4000

800

600

3/4*

0.75

0.75

0.78

2.00

2.12

1.44

1.56

2.81

0.62

0.69

4.69

5.06

1.62

3/4-10 or .

750-10

6000

1200

900

7/8*

0.88

0.88

0.91

2.25

2.38

1.56

1.69

3.19

0.75

0.81

5.31

5.69

1.81

7/8-9 or .

875-9

6600

1300

1000

1*

1.00

1.00

1.06

2.50

2.62

1.69

1.81

3.56

0.88

0.94

5.94

6.31

2.06

1-8 or

1.000-8

8000

1600

1200

1-1/8 1.12

1.12

1.19

2.75

2.88

1.94

2.06

4.06

1.00

1.06

6.69

7.06

2.31

1-1/8-7 or

1.125-7

10000

2000

1500

1-1/4* 1.25

1.25

1.34

3.00

3.12

2.12

2.25

4.44

1.09

1.16

7.31

7.69

2.50

1-1/4-7 or

1.250-7

15000

3000

2250

1/4*

80

160

280

60

120

210

1-1/2* 1.50

1.50

1.59

3.50

3.62

2.44

2.56

5.19

1.31

1.38

8.56

8.94

3.00

1-1/2-6 or

1.500-6

18000

3600

2700

1-3/4 1.75

1.75

1.84

3.75

3.88

2.75

3.00

6.00

1.50

1.62

9.50

10.12

3.19

1-3/4-5 or

1.750-5

22000

4400

3300

2.00

2.00

2.09

4.00

4.25

3.06

3.44

6.88

1.75

1.88

10.56

11.44

3.38

2-4-1/2- or

2.000-4.50

26000

5200

3900

2-1/2* 2.50

2.50

2.62

5.00

5.25

3.81

4.19

8.50

2.19

2.31

13.19

14.06

4.25

2-1/2-4 or

2.500-4

32000

6400

4800

2*

NOTES: *Preferred

1. These safe working loads are based on the following percentages of minimum proof loads shown in ASTM

A 489; 0 Deg - 66.6 per cent, 45 Deg - 13.3 per cent, 90 Deg - 10.0 per cent

TYPE 2 SHOULDER PATTERN EYEBOLTS

ANSI B18.15 1969

A

Nominal

Size

Shank Shank Eye

Dia Length ID

Nominal

Eye

Overall

Eye OD Sect Dia Length

Min

Length

Full

Thread

H

Thread

Size

UNC-2A

Wx

Wy

Wz

Safe

Working

Load, lb

at 0 Deg1

Safe

Working

Load, lb

at 45 Deg1

Safe

Working

Load, lb

at 90 Deg1

1/4*

0.25

0.25

0.28

1.00

1.06

0.69

0.81

1.19

0.19

0.25

2.06

2.38

0.75

1/4-20 or .

250-20

400

80

60

5/16*

0.31

0.31

0.34

1.12

1.19

0.81

0.94

1.44

0.25

0.31

2.44

2.75

0.81

5/16-18 or .

3125-18

800

160

120

3/8*

0.38

0.38

0.41

1.25

1.38

0.94

1.06

1.69

0.31

0.38

2.81

3.19

0.88

3/8-16 or .

375-16

1400

280

210

7/16

0.44

0.44

0.47

1.38

1.50

1.00

1.12

1.81

0.34

0.41

3.06

3.44

1.00

7/16-14 or .

4375-14

2000

400

300

1/2*

0.50

0.50

0.53

1.50

1.62

1.12

1.25

2.12

0.44

0.50

3.50

3.88

1.12

1/2-13 or .

500-13

2600

520

390

9/16

0.56

0.56

0.59

1.62

1.75

1.19

1.31

2.25

0.47

0.53

3.75

4.12

1.25

9/16-12 or .

5625-12

3000

600

450

5/8*

0.62

0.62

1.75

1.31

2.56

0.56

4.19

1.38

5/8-11 or .

4000

800

600

0.66

1.88

1.44

0.62

4.56

625-11

2.00

2.12

1.44

1.56

2.81

0.62

0.69

4.69

5.06

1.62

3/4-10 or .

750-10

6000

1200

900

3/4*

0.75

0.75

0.78

7/8*

0.88

0.88

0.91

2.25

2.38

1.56

1.69

3.19

0.75

0.81

5.31

5.69

1.81

7/8-9 or .

875-9

6600

1300

1000

1*

1.00

1.00

1.06

2.50

2.62

1.69

1.81

3.56

0.88

0.94

5.94

6.31

2.06

1-8 or

1.000-8

8000

1600

1200

1-1/8

1.12

1.12

1.19

2.75

2.88

1.94

2.06

4.06

1.00

1.06

6.69

7.06

2.31

1-1/8-7 or

1.125-7

10000

2000

1500

1-1/4*

1.25

1.25

1.34

3.00

3.12

2.12

2.25

4.44

1.09

1.16

7.31

7.69

2.50

1-1/4-7 or

1.250-7

15000

3000

2250

1-1/2*

1.50

1.50

1.59

3.50

3.62

2.44

2.56

5.19

1.31

1.38

8.56

8.94

3.00

1-1/2-6 or

1.500-6

18000

3600

2700

1-3/4

1.75

1.75

1.84

3.75

3.88

2.75

3.00

6.00

1.50

1.62

9.50

10.12

3.19

1-3/4-5 or

1.750-5

22000

4400

3300

2*

2.00

2.00

2.09

4.00

4.25

3.06

3.44

6.88

1.75

1.88

10.56

11.44

3.38

2-4-1/2- or

2.000-4.50

26000

5200

3900

NOTES: 1. *Preferred.

Applies if shoulder is properly seated, otherwise safe working load of Type 1 applies. These safe working loads are based on the following

percentages of minimum proof loads shown in ASTM A 489; 0 Deg - 66.6 per cent, 45 Deg - 16.7 per cent, 90 Deg - 13.3 per cent.

THE CROSBY GROUP

REGULAR NUT EYE BOLTS

G-291

Recommended for straight line pull.

All Bolts Hot Dip galvanized after threading (UNC).

Furnished with standard Hot Dip galvanized hex nuts.

Forged Steel Quenched and Tempered.

Fatigue rated at 1-1/2 times the Working Load Limit at 20,000 cycles.

Shank

Dia. & Length

(in.)

G-291

Stock No.

Galv.

Working

Load Limit *

(lbs.)

Weight

Per 100

(lbs.)

1/4 x 2

1043230

1/4 x 4

1043258

5/16x 2-1/4

Dimensions. (in.)

A

650

8.20

.25

.50

1.00

.25

1.50

2.00

3.06

.56

650

11.70

.25

.50

1.00

.25

2.50

4.00

5.06

.56

1043276

1200

13.30

.31

.62

1.25

.31

1.50

2.25

3.56

.69

5/16x 4-1/4

1043294

1200

25.00

.31

.62

1.25

.31

2.50

4.25

5.56

.69

3/8 x 2-1/2

1043310

1550

23.30

.38

.75

1.50

.38

1.50

2.50

4.12

.88

3/8 x 4-1/2

1043338

1550

29.50

.38

.75

1.50

.38

2.50

4.50

6.12

.88

3/8 x 6

1043356

155

35.20

.38

.75

1.50

.38

2.50

6.00

7.62

.88

1/2 x 3-1/4

1043374

2600

50.30

.50

1.00

2.00

.50

1.50

3.25

5.38

1.12

1/2 x 6

1043392

2600

66.10

.50

1.00

2.00

.50

3.00

6.00

8.12

1.12

1/2 x 8

1043418

2600

82.00

.50

1.00

2.00

.50

3.00

8.00

10.12

1.12

1/2 x 10

1043436

2600

88.00

.50

1.00

2.00

.50

3.00

10.00

12.12

1.12

1/2 x 12

1043454

2600

114.20

.50

1.00

2.00

.50

3.00

12.00

14.12

1.12

5/8 x 4

1043472

5200

103.10

.62

1.25

2.50

.62

2.00

4.00

6.69

1.44

5/8 x 6

1043490

5200

118.20

.62

1.25

2.50

.62

3.00

6.00

8.69

1.44

5/8 x 8

1043515

5200

135.10

.62

1.25

2.50

.62

3.00

8.00

10.69

1.44

5/8 x 10

1043533

5200

153.60

.62

1.25

2.50

.62

3.00

10.00

12.69

1.44

5/8 x 12

1043551

5200

167.10

.62

1.25

2.50

.62

4.00

12.00

14.69

1.44

3/4 x 4-1/2

1043579

7200

168.60

.75

1.50

3.00

.75

2.00

4.50

7.69

1.69

3/4 x 6

1043597

7200

184.50

.75

1.50

3.00

.75

3.00

6.00

9.19

1.69

3/4 x 8

1043613

7200

207.90

.75

1.50

3.00

.75

3.00

8.00

11.19

1.69

3/4 x 10

1043631

7200

235.00

.75

1.50

3.00

.75

3.00

10.00

13.19

1.69

3/4 x 12

1043659

7200

257.50

.75

1.50

3.00

.75

4.00

12.00

15.19

1.69

3/4 x 15

1043677

7200

298.00

.75

1.50

3.00

.75

5.00

15.00

18.19

1.69

*Ultimate Load is 5 times the Working Load Limit.

Working Load Limit shown is for in-line pull.

shoulder

THE CROSBY GROUP

SHOULDER NUT EYE BOLTS

G-277

Forged Steel.

All Bolts Hot Dip galvanized after threading (UNC).

Furnished with standard Hot Dip galvanized, heavy hex nuts.

Fatigue rated at 1-1/2 times the Working Load Limit at 20,000 cycles

Shank

Diameter

& Length

(in.)

G-277

Stock No.

Galv.

Working

Load Limit *

(lbs.)

Weight

Per 100 (lbs.)

Dimensions. (in.)

A

1/4 x 2

1045014

650

6.60

.25

.50

.88

.19

1.50

2.00

2.94

.50

.47

1/4 x 4

1045032

650

9.10

.25

.50

.88

.19

2.50

4.00

4.94

.50

.47

5/16x 2-1/4

1045050

1200

12.50

.31

.62

1.12

.25

1.50

2.25

3.50

.69

.56

5/16x 4-1/4

1045078

1200

18.80

.31

.62

1.12

.25

2.50

4.25

5.50

.69

.56

3/8 x 2-1/2

1045096

1550

21.40

.38

.75

1.38

.31

1.50

2.50

3.97

.78

.66

3/8 x 4-1/2

1045112

1550

25.30

.38

.75

1.38

.31

2.50

4.50

5.97

.78

.66

1/2 x 3-1/2

1045130

2600

42.60

.50

1.00

1.75

.38

1.50

3.25

5.12

1.00

.91

1/2 x 6

1045158

2600

56.80

.50

1.00

1.75

.38

3.00

6.00

7.88

1.00

.91

5/8 x 4

1045176

5200

68.60

.62

1.25

2.25

.50

2.00

4.00

6.44

1.31

1.12

5/8 x 6

1045194

5200

102.40

.62

1.25

2.25

.50

3.00

6.00

8.44

1.31

1.12

3/4 x 4-1/2

1045210

7200

144.50

.75

1.50

2.75

.62

2.00

4.50

7.44

1.56

1.38

3/4 x 6

1045238

7200

167.50

.75

1.50

2.75

.62

3.00

6.00

8.94

1.56

1.38

7/8 x 5

1045256

10600

225.00

.88

1.75

3.25

.75

2.50

5.00

8.46

1.84

1.56

1x6

1045292

13300

366.30

1.00

2.00

3.75

.88

3.00

6.00

9.97

2.09

1.81

1x9

1045318

13300

422.50

1.00

2.00

3.75

.88

4.00

9.00

12.97

2.09

1.81

1-1/4 x 8

1045336

21000

650.00

1.25

2.50

4.50

1.00

4.00

8.00

12.72

2.47

2.28

1-1/4 x 12

1045354

21000

795.00

1.25

2.50

4.50

1.00

4.00

12.00

16.72

2.47

2.28

1-1/2 x 15

1045372

24000

1425.00

1.50

3.00

5.50

1.25

6.00

15.00

20.75

3.00

2.75

*Ultimate Load is 5 times the Working Load Limit.

Working Load Limit shown is for in-line pull

machinery

THE CROSBY GROUP

SHOULDER TYPE MACHINERY EYE BOLTS

S-279

Fatigue rated at 1-1/2 times the Working Load Limit at 20,000 cycles.

Working Load Limits shown are for In-line pull.

Forged Steel Quenched & Tempered.

Recommended for straight linie pull.

All Bolts threaded UNC

Size

Stock No.

Working

Load Limit *

(lbs.)

Weight

per 100

(lbs.)

Dimensions. (in.)

A

1/4 x 1

9900182

650

5.10

.25

1.00

.88

.50

1.94

.19

.47

.50

5/16x1-1/8

9900191

1200

6.20

.31

1.13

1.12

.62

2.38

.25

.56

.69

3/8 x 1-1/4

9900208

1550

12.50

.38

1.25

1.38

.75

2.72

.31

.66

.78

1/2 x 1-1/2

9900217

2600

25.00

.50

1.50

1.75

1.00

3.38

.38

.91

1.00

5/8 x 1-3/4

9900226

5200

50.00

.63

1.75

2.25

1.25

4.19

.50

1.12

1.31

3/4 x 2

9900235

7200

87.50

.75

2.00

2.75

1.50

4.94

.62

1.38

1.56

7/8 x 2-1/4

9900244

10600

157.20

.88

2.25

3.25

1.75

5.72

.75

1.56

1.84

1 x 2-1/2

9900253

13300

218.00

1.00

2.50

3.75

2.00

6.47

.88

1.81

2.09

1-1/4 x 3

9900262

21000

380.00

1.25

3.00

4.50

2.50

7.72

1.00

2.28

2.47

1-1/2x 3-1/2

9900271

24000

700.00

1.50

3.50

5.50

3.00

9.25

1.25

2.75

3.00

* Ultimate Load is 5 times the Working Load Limit

Shoulder Nut Eye Bolt --Installation for Angular Loading

S-ar putea să vă placă și

- Problems Solutions On Fracture MechanicsDocument50 paginiProblems Solutions On Fracture MechanicsRajesh N Priya Gopinathan100% (5)

- Facilities On Offshore Installations: Guide For Building and ClassingDocument209 paginiFacilities On Offshore Installations: Guide For Building and ClassingKarthick VenkatswamyÎncă nu există evaluări

- Ionic Bonding Worksheet - Type 1 PracticeDocument2 paginiIonic Bonding Worksheet - Type 1 Practicerichwenekylejc o Evaristo100% (6)

- Welcome To The Institute For Timber Construction-South Africa Itc-SaDocument75 paginiWelcome To The Institute For Timber Construction-South Africa Itc-SaMclyb GumbieÎncă nu există evaluări

- Ladder Is Designed As Per Bs 5395-3 For 1 KN Loading: Front View Side ViewDocument1 paginăLadder Is Designed As Per Bs 5395-3 For 1 KN Loading: Front View Side ViewKashyapÎncă nu există evaluări

- Fender Accessories (Panels, Chains, Brackets) Catalogue en V1.3Document10 paginiFender Accessories (Panels, Chains, Brackets) Catalogue en V1.3loicdertyÎncă nu există evaluări

- Use of BS 5950Document3 paginiUse of BS 5950Smr Only100% (1)

- As Standard ListDocument6 paginiAs Standard ListNguyen Duc DungÎncă nu există evaluări

- Green Pin Standard Hydraulic ShackleDocument1 paginăGreen Pin Standard Hydraulic ShackleAthox QhurienÎncă nu există evaluări

- Rosewood Case AnalysisDocument5 paginiRosewood Case AnalysisJayant KushwahaÎncă nu există evaluări

- Fluid Power FormulasDocument2 paginiFluid Power FormulasRajesh N Priya GopinathanÎncă nu există evaluări

- Timco TDS Drywall ScrewDocument2 paginiTimco TDS Drywall ScrewNajeeb AhmedÎncă nu există evaluări

- Calculation of Block Wall Load On First & Second FloorDocument1 paginăCalculation of Block Wall Load On First & Second FloorIrfan AliÎncă nu există evaluări

- Conformity of Structural Steel Products and StructuresDocument5 paginiConformity of Structural Steel Products and StructuresStephen HicksÎncă nu există evaluări

- Steel NTC DF Manual enDocument67 paginiSteel NTC DF Manual enADPÎncă nu există evaluări

- Technical Data Sheet For HIT-HY-200 Injectable Mortar For Anchor and Rebar Technical Information ASSET DOC 2331175Document85 paginiTechnical Data Sheet For HIT-HY-200 Injectable Mortar For Anchor and Rebar Technical Information ASSET DOC 2331175ing urbanÎncă nu există evaluări

- K 541Document2 paginiK 541igbnsÎncă nu există evaluări

- Lesson Plan Letter SDocument4 paginiLesson Plan Letter Sapi-317303624100% (1)

- Anchor Rods: ManufacturingDocument22 paginiAnchor Rods: Manufacturingjacopap100% (1)

- Medical Colleges in IndiaDocument11 paginiMedical Colleges in IndiaKaraikal S.M. Arif Maricar100% (1)

- Thermosorb Paint ThicknessDocument5 paginiThermosorb Paint ThicknessKawser HossainÎncă nu există evaluări

- L9 Fastening System PDFDocument6 paginiL9 Fastening System PDFMarcel BaqueÎncă nu există evaluări

- Induction Melting Furnace Quotation 010720Document4 paginiInduction Melting Furnace Quotation 010720ranamzeeshanÎncă nu există evaluări

- Gracella Irwana - G - Pert 04 - Sia - 1Document35 paginiGracella Irwana - G - Pert 04 - Sia - 1Gracella IrwanaÎncă nu există evaluări

- Installation of Submarine PE PipesDocument84 paginiInstallation of Submarine PE Pipeswaseemiqbal133100% (2)

- Training Design SprintDocument11 paginiTraining Design Sprintardi wiantoÎncă nu există evaluări

- Design Capacity Check For New Proposed MaterialDocument2 paginiDesign Capacity Check For New Proposed MaterialKawser HossainÎncă nu există evaluări

- Restrained Beams HandoutDocument2 paginiRestrained Beams Handoutikanyu79Încă nu există evaluări

- Bo QDocument9 paginiBo QAdnan Ali ChaudhryÎncă nu există evaluări

- KD Panels - Tds (En)Document4 paginiKD Panels - Tds (En)Dilon FernandoÎncă nu există evaluări

- Eurocode 5 PDFDocument2 paginiEurocode 5 PDFTerriÎncă nu există evaluări

- Wall Load Chase Down ExampleDocument2 paginiWall Load Chase Down ExampleBunkun15Încă nu există evaluări

- BORAL Silkwood Installation Guide & WarrantyDocument12 paginiBORAL Silkwood Installation Guide & Warrantyjonzak1234Încă nu există evaluări

- Topic 1 - ExamplesDocument15 paginiTopic 1 - ExamplesnurulselangorÎncă nu există evaluări

- LTS 6 TableOfContents PDFDocument29 paginiLTS 6 TableOfContents PDFTAHAÎncă nu există evaluări

- Wind Loads For Permiable Facades With High PorosityDocument12 paginiWind Loads For Permiable Facades With High PorosityNikola IvanovicÎncă nu există evaluări

- 141667-FAF-SPE-EOH-000007 OEE Galvanised Structural Steel Specifications PDFDocument12 pagini141667-FAF-SPE-EOH-000007 OEE Galvanised Structural Steel Specifications PDFmarigusatuÎncă nu există evaluări

- Structural ShapesDocument48 paginiStructural ShapesTimbo6808Încă nu există evaluări

- KDS 41 12 00 건축물 설계하중 PDFDocument126 paginiKDS 41 12 00 건축물 설계하중 PDFPark SHÎncă nu există evaluări

- Indiga Indiga: Tech TechDocument32 paginiIndiga Indiga: Tech Techsunny100% (1)

- Client Name: Prepared By: Date: A Project Name: Location: DescriptionDocument1 paginăClient Name: Prepared By: Date: A Project Name: Location: Descriptionvj8584Încă nu există evaluări

- Steel Structure Design CalculationDocument12 paginiSteel Structure Design CalculationSenthooran MahendranÎncă nu există evaluări

- Wind Load On Porous MediaDocument11 paginiWind Load On Porous Mediamomo honeyÎncă nu există evaluări

- 2014 Davis and AvciDocument11 pagini2014 Davis and Avcigene_sparcÎncă nu există evaluări

- Sch40 80 ASTM A53 - Brochure - 042512 PDFDocument2 paginiSch40 80 ASTM A53 - Brochure - 042512 PDFMohamed AmmarÎncă nu există evaluări

- Standard Pipe A53 PDFDocument6 paginiStandard Pipe A53 PDFArvindÎncă nu există evaluări

- Gate Level ComputationDocument1 paginăGate Level ComputationAsan IbrahimÎncă nu există evaluări

- Chapter 9-Design of Services Final Edition - 24!11!2011Document44 paginiChapter 9-Design of Services Final Edition - 24!11!2011Umesh ChamaraÎncă nu există evaluări

- EN ISO 11542-2 PropertiesDocument17 paginiEN ISO 11542-2 Propertieschaminda nayanajithÎncă nu există evaluări

- Taha Associates CatalogueDocument34 paginiTaha Associates CatalogueZAHIDÎncă nu există evaluări

- Index: 3-A Sanitary Standards, 3-A Accepted Practices, E-3-A Sanitary Standards, & P3-A Sanitary StandardsDocument4 paginiIndex: 3-A Sanitary Standards, 3-A Accepted Practices, E-3-A Sanitary Standards, & P3-A Sanitary StandardsCHRISTIAN ZAVALAÎncă nu există evaluări

- Din en Iso 2338Document1 paginăDin en Iso 2338Janak MistryÎncă nu există evaluări

- Manhole Cover and Grate RemoverDocument16 paginiManhole Cover and Grate RemoverComstar SupplyÎncă nu există evaluări

- Iso 7380Document1 paginăIso 7380MarioÎncă nu există evaluări

- Tightening Torque StableDocument5 paginiTightening Torque Stablemasmarkun4444Încă nu există evaluări

- Din 471 Ext CirclipsDocument5 paginiDin 471 Ext Circlipschaitanya_kumar_13Încă nu există evaluări

- Certificate of Compliance: Certificate Number Report Reference Issue DateDocument3 paginiCertificate of Compliance: Certificate Number Report Reference Issue DatefelipeÎncă nu există evaluări

- Civil 2019 v22 Release NoteDocument25 paginiCivil 2019 v22 Release NoteNilay GandhiÎncă nu există evaluări

- Aisc Member Dimensions and Properties ViewerDocument4 paginiAisc Member Dimensions and Properties ViewercoolkaisyÎncă nu există evaluări

- Technical Data Sheet Jindal Stainless Steel Grade JSL AUS (J1)Document5 paginiTechnical Data Sheet Jindal Stainless Steel Grade JSL AUS (J1)Dudung SÎncă nu există evaluări

- RRC 271 DDocument64 paginiRRC 271 Drfuentes73Încă nu există evaluări

- DIN580 Eye BoltDocument7 paginiDIN580 Eye BoltReda El-AwadyÎncă nu există evaluări

- Saisc Structural Steel Section PropertiesDocument12 paginiSaisc Structural Steel Section Propertiesabduldon052000Încă nu există evaluări

- Standard C - Channel PDFDocument1 paginăStandard C - Channel PDFavaneeshpandeyÎncă nu există evaluări

- Pulleys TechDocument8 paginiPulleys TechashkansoheylÎncă nu există evaluări

- C Lift+Lash PointsDocument10 paginiC Lift+Lash PointssabanimÎncă nu există evaluări

- LV Technical BrochureDocument44 paginiLV Technical BrochurenssainiÎncă nu există evaluări

- Stainless Steel Grade 410Document5 paginiStainless Steel Grade 410Rajesh N Priya Gopinathan100% (1)

- VelocityDocument5 paginiVelocityRajesh N Priya GopinathanÎncă nu există evaluări

- Shear Stress BasicDocument5 paginiShear Stress BasicRajesh N Priya GopinathanÎncă nu există evaluări

- Moment of Inertia Basics UnderstandingDocument20 paginiMoment of Inertia Basics UnderstandingRajesh N Priya GopinathanÎncă nu există evaluări

- Grey IronDocument3 paginiGrey IronRajesh N Priya Gopinathan100% (1)

- Power (Physics) : James WattDocument5 paginiPower (Physics) : James WattRajesh N Priya GopinathanÎncă nu există evaluări

- Unit ConverterDocument23 paginiUnit ConverterRajesh N Priya GopinathanÎncă nu există evaluări

- Cast Steel Gate Valve Class 150Document1 paginăCast Steel Gate Valve Class 150Rajesh N Priya GopinathanÎncă nu există evaluări

- Ductile Iron, Also Known As Ductile Cast Iron, Nodular Cast Iron, Spheroidal Graphite Iron, Spherulitic Graphite Cast IronDocument3 paginiDuctile Iron, Also Known As Ductile Cast Iron, Nodular Cast Iron, Spheroidal Graphite Iron, Spherulitic Graphite Cast IronRajesh N Priya GopinathanÎncă nu există evaluări

- Great Britain BS Metals Standard NumbersDocument10 paginiGreat Britain BS Metals Standard NumbersRajesh N Priya GopinathanÎncă nu există evaluări

- CI Properties TTT CompiledDocument8 paginiCI Properties TTT CompiledRajesh N Priya GopinathanÎncă nu există evaluări

- 1237Document1 pagină1237Rajesh N Priya GopinathanÎncă nu există evaluări

- Unit Conversion SimplicityDocument12 paginiUnit Conversion SimplicityRajesh N Priya GopinathanÎncă nu există evaluări

- The Bernoulli EquationDocument7 paginiThe Bernoulli EquationRajesh N Priya GopinathanÎncă nu există evaluări

- Evaluation of Liquid MetalDocument12 paginiEvaluation of Liquid MetalRajesh N Priya GopinathanÎncă nu există evaluări

- Welding Symbols PresentationDocument23 paginiWelding Symbols PresentationRajesh N Priya GopinathanÎncă nu există evaluări

- Anchor Bolt Design GuideDocument55 paginiAnchor Bolt Design GuideRajesh N Priya GopinathanÎncă nu există evaluări

- 3D RenderingDocument16 pagini3D RenderingRajesh N Priya GopinathanÎncă nu există evaluări

- 12378Document1 pagină12378Rajesh N Priya GopinathanÎncă nu există evaluări

- Emhart Teknologies HeliCoil Thread Insert System CatalogueDocument36 paginiEmhart Teknologies HeliCoil Thread Insert System CatalogueThor InternationalÎncă nu există evaluări

- 1237Document1 pagină1237Rajesh N Priya GopinathanÎncă nu există evaluări

- 4340 High Tensile SteelDocument3 pagini4340 High Tensile SteelsumoomusÎncă nu există evaluări

- 4140 Q&TDocument36 pagini4140 Q&TAnderson MarimÎncă nu există evaluări

- 12375Document1 pagină12375Rajesh N Priya GopinathanÎncă nu există evaluări

- The AhhkashkhkaDocument1 paginăThe AhhkashkhkaRajesh N Priya GopinathanÎncă nu există evaluări

- Richardson ResumeDocument3 paginiRichardson Resumeapi-549248694Încă nu există evaluări

- 全新全真题库一 PDFDocument36 pagini全新全真题库一 PDFTzarlene100% (1)

- Teaching PowerPoint Slides - Chapter 5Document19 paginiTeaching PowerPoint Slides - Chapter 5Azril ShazwanÎncă nu există evaluări

- Antenatal Care (ANC)Document77 paginiAntenatal Care (ANC)tareÎncă nu există evaluări

- Monster Hunter: World - Canteen IngredientsDocument5 paginiMonster Hunter: World - Canteen IngredientsSong HoeÎncă nu există evaluări

- Chapter 3 Extension - Game Theory-StDocument25 paginiChapter 3 Extension - Game Theory-StQuynh Chau TranÎncă nu există evaluări

- Hand Winches 122 Load Sheaves 126 Gear-And Worm Gear Winches 127 Electric Worm Gear Winches 131 Snatch Blocks 133Document14 paginiHand Winches 122 Load Sheaves 126 Gear-And Worm Gear Winches 127 Electric Worm Gear Winches 131 Snatch Blocks 133Rajaram JayaramanÎncă nu există evaluări

- Matutum View Academy: (The School of Faith)Document14 paginiMatutum View Academy: (The School of Faith)Neil Trezley Sunico BalajadiaÎncă nu există evaluări

- Earth Science NAME - DATEDocument3 paginiEarth Science NAME - DATEArlene CalataÎncă nu există evaluări

- QSasDocument50 paginiQSasArvin Delos ReyesÎncă nu există evaluări

- Using Your Digital Assets On Q-GlobalDocument3 paginiUsing Your Digital Assets On Q-GlobalRemik BuczekÎncă nu există evaluări

- Operation and Maintenance Manual Compressor Models: P105WJD, P130DWJD, P160DWJD, P175DWJDDocument70 paginiOperation and Maintenance Manual Compressor Models: P105WJD, P130DWJD, P160DWJD, P175DWJDManuel ParreñoÎncă nu există evaluări

- Simple Enzymes Kinetics and Kinetics ModelDocument14 paginiSimple Enzymes Kinetics and Kinetics ModelSidra-tul MuntahaÎncă nu există evaluări

- Support Vector Machine Master ThesisDocument7 paginiSupport Vector Machine Master Thesistammymajorsclarksville100% (2)

- Off Grid Solar Hybrid Inverter Operate Without Battery: HY VMII SeriesDocument1 paginăOff Grid Solar Hybrid Inverter Operate Without Battery: HY VMII SeriesFadi Ramadan100% (1)

- Final Lesson PlanDocument3 paginiFinal Lesson Planapi-510713019Încă nu există evaluări

- Structure of NABARD Grade ADocument7 paginiStructure of NABARD Grade ARojalin PaniÎncă nu există evaluări

- Bhavesh ProjectDocument14 paginiBhavesh ProjectRahul LimbaniÎncă nu există evaluări

- Maskote WB Zinc Stop-OffDocument7 paginiMaskote WB Zinc Stop-OffbondsivamaniÎncă nu există evaluări

- M2252D PS PDFDocument36 paginiM2252D PS PDFCarmen da SilvaÎncă nu există evaluări

- Royal British College Dancesport TeamDocument10 paginiRoyal British College Dancesport TeamAnna rose CabatinganÎncă nu există evaluări

- Effects of Corneal Scars and Their Treatment With Rigid Contact Lenses On Quality of VisionDocument5 paginiEffects of Corneal Scars and Their Treatment With Rigid Contact Lenses On Quality of VisionJasmine EffendiÎncă nu există evaluări

- Module 5Document14 paginiModule 5shin roseÎncă nu există evaluări