Documente Academic

Documente Profesional

Documente Cultură

9171KK

Încărcat de

ermvvDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

9171KK

Încărcat de

ermvvDrepturi de autor:

Formate disponibile

Desalination 221 (2008) 576584

Seawater intake and pre-treatment/brine discharge environmental issues

Thomas Petersa*, Domnec Pintb

a

Dr.-Ing. Peters Consulting for Membrane Technology and Environmental Engineering, Broichstrasse 91, 41462 Neuss, Germany email: dr.peters.consulting@t-online.de b Catalana de Perforacions, E-Santpedor, Spain

Received 28 March 2007; accepted 10 April 2007

Abstract In some cases the only remaining option to satisfy the increasing demand for potable water in good quality for the growing population, is the desalination of seawater, being used more and more the membrane process reverse osmosis. But whereas for the design and the manufacturing of the desalination units itself meanwhile are available well known and approved technical solutions, the intake and the pre-treatment of the seawater, as well as, the discharge of the brine have to be adapted to the specific conditions at the construction site of each plant. These conditions can differ in a wide range, as beside the influences determining the raw water quality, also items like the geological situation and details related with infrastructure or logistic are usually very different and have to be considered consequently during design, construction and operation of a desalination plant. The same applies for the aspects concerning the environment, that are becoming more and more important due to changing local legislation, increasing public awareness, growing construction density at coastal areas and also due to findings regarding the impact on the marine environment based on long-term operation of desalination plants. Thereby one of the most important prerequisites for reliable long-term successful operation of reverse osmosis seawater desalination plants is a consistent high quality pre-treatment of the feed water. One possibility to fulfil this requirement is the use of directed drilled horizontal drains below the seabed as seawater intake and partial pretreatment system according to the patented Neodren technology. With these horizontal drains, that are based on an improved horizontal directional drilling (HDD) technology and high efficient patented filtering devices, the raw and fine screening, as well as, the conventional filtration of seawater and the dosage of different pre-treatment agents will not be necessary. Due to extremely low filtering velocities, this is achieved without impingement and entrainment of aquatic organism. This system, developed by Catalana de Perforacions with the first unit in operation since 1996, can be operated in sandy and karstic seabeds as ecological and economical alternative for conventional open seawater intake systems, and has even advantages in comparison with indirect seawater intake systems like beach well installations. Due to the modular design there is no limitation regarding the production of *Corresponding author. Presented at the conference on Desalination and the Environment. Sponsored by the European Desalination Society and Center for Research and Technology Hellas (CERTH), Sani Resort, Halkidiki, Greece, April 2225, 2007.

0011-9164/06/$ See front matter 2006 Elsevier B.V. All rights reserved. doi:10.1016/j.desal.0000.00.000

Th. Peters, D. Pint / Desalination 221 (2008) 576584

577

pre-filtered water. Also based on the HDD technology have been developed systems for a controlled brine discharge that consider the environmental conditions on site. Details of these different intake and discharge systems and their environmental impact will be compared. Keywords: Seawater intake; Seawater pre-treatment; Seawater desalination; Brine discharge; Reverse osmosis; Environmental impact

1. Introduction Due to the recent and very fast evolution of our world in terms of industrial, population, and urbanization development, water-related problems are recurring and even more worrisome in nearly all the regions of the globe. Water is becoming a scarce and non-renewable resource that must be managed efficiently in order to protect and save it in the long term [1]. This increasing world population and expanding industrialization are, together with the rising living standard, the main causes of the ever increasing demand for potable water and for water with high quality for industrial applications [2]. The areas affected are not only the arid regions in the world with their chronic water deficiency, but also in an increasing rate the urban agglomerations and industrial centres, specially in the coastal areas, in which the capacity limits of natural supplies have almost been reached also under consideration of the local water supply after optimisation of the water resources management and exhausting all possibilities of water reuse. In the near future it will not be possible anymore to satisfy the growing water demand by conventional methods of water procurement and processing. Therefore an increased utilization of separation techniques for the production of potable and industrial water from polluted and saline waters is called for [3]. In some cases the only remaining option to satisfy the increasing demand for potable water in good quality for a growing population, is the desalination of seawater, being used more and more the membrane process reverse osmosis.

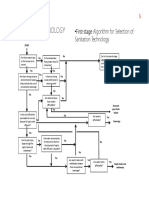

2. Desalination of seawater with reverse osmosis But whereas for the design and the manufacturing of the desalination unit itself meanwhile are available well known and approved technical solutions, the intake and the pre-treatment of the seawater, as well as, the discharge of the brine have to be adapted to the specific conditions at the construction site of each plant. These can differ in a wide range, as beside the influences determining the raw water quality, also items like the geological situation and details related with infrastructure or logistic are usually very different and have to be considered consequently during design, construction and operation of a desalination plant. This includes the systems for dosage and handling of agents for pre-treatment, needed during operation, and for the cleaning of membranes, but also the treatment and discharge of the waste water streams generated during these activities. For the specification and evaluation of correlated interdependencies has been developed the scheme that summarises the main operational areas of a desalination plant according to the overview in Fig. 1. Under consideration of aspects related with the environment, the areas seawater intake and pre-treatment, as well as, brine discharge are those with the biggest effects concerning general considerations and public discussion regarding the decision about the installation of new desalination plants. It can be deduced from the development in the last years, that they are becoming more and more important due to changing local legislation, increasing public awareness [4], growing

578

Th. Peters, D. Pint / Desalination 221 (2008) 576584

1.1

2.1

3.1

Handling pre-treatm. agents

1.0

Handling CIP, rinsing, cleaning

2.0

Handling disinfection

3.0

Seawater intake pretreatment

1.2

Reverse osmosis (RO) unit

2.2

Permeate posttreatment

4.0

Treatment rinsing effluents

5.0

Treatment cleaning effluents Infrastructure, logistic

Brine discharge

Fig. 1. Main operational area of a reverse osmosis seawater desalination plant.

construction density at coastal areas and also due to findings regarding the impact on the environment based on long term operation of desalination plants [5,6]. 3. Seawater intake The extraction of seawater to feed a reverse osmosis system is always critical with regards to limitation of suspended solids, variation of seawater temperature, contamination by pollutants and particularly oil, as well as, marine biological matter, which all individual and/or together present a great challenge for pre-treatment of the reverse osmosis (RO) process with regards to performance and operation cost. Many years of experience have shown, that the pre-treatment is the most critical area of a seawater RO desalination plant, and, that long-term successful RO plant operation is greatly influenced by the combination of pre-treatment and intake method [2,7]. 3.1. Conventional open seawater intake systems The conventional method of intake is the open intake of seawater by active or passive screens of different kind, which are of course subject to

marine biological activity and suspended matter, which needs to be removed or reduced by the pre-treatment. Particularly with active screen open intake, chlorination is widely used, which poses an additional problem to the process due to acceleration of biological fouling risk in the system, which has negative effects on operating costs and availability of plant. Use of chemicals and power consumption (particularly when multistage designs of pre-treatment are used) are the main cost factors. The pre-treatment of the seawater for classic open intake methods ranges behind the screening and sand trap from single & double stage multimedia filtration and combination with clarification or dissolved air flotation to ultrafiltration and it is obvious, that all such designs of pretreatment require a great deal of experience on running systems to opt for the most effective but economic design [7]. The construction of a classic open intake, being this long submarine pipelines installed on the ocean floor with up to few hundred or even thousand m of length from the shore into the offshore area, or intake wells with pumps in deeper water and pipelines installed on a jetty, or a open conveying channel dredged between breakwater, has a great impact on coastal and marine environment and must be carefully studied to minimise the same. This applies also for systems, were the water is extracted from cooling water at power stations. Hence a method to reduce the direct impact of seawater intake installations on the environment by indirect intake systems should be preferred. 3.2. Indirect seawater intake with beach wells The most well known indirect intake system is the beach well intake, where seawater is abstracted from the sand below the beach and below the seabed near the shore, that is acting as a filter and thus improving mechanical quality of seawater and for elimination of marine biological and

Th. Peters, D. Pint / Desalination 221 (2008) 576584

579

other pollution, found in open seawater intakes. The seawater is collected in conventional wells and pumped to the plant. Or it is collected in horizontal wells screens that are connected to a vertical well with an integrated pump and a pump house on the beach, like the Ranney system [8]. Such design however needs to care to protect sweet water lenses at low depths and to abstract seawater only. Due to permeability of soil and draw-down of water table around the well, the distance and depth of beach wells requires a long stretch along the beach parallel to the sea, and this is often a problem or sometimes impossible. The location of wells more inland poses a greater risk of abstraction of sweet water and thus posing a great impact to ground water resources if not well designed and maintained or monitored respectively. This must be avoided [7]. The advantage of a well intake in comparison with an open seawater intake is also a more uniform seawater temperature, which allows for a more efficient process design and running cost at considerable reduced chemical consumption. Due to changing geological strata, beach wells cannot be constructed everywhere and the use of an open intake has been the only practical way in the past and in all cases for very large plant capacities. The construction of an indirect intake by beach well has no marine environmental impact during operation, but may disturb the environment during construction and afterwards with installations like pump houses or cover of collection wells on the beach or nearby. Also it has to be considered, that these installations can not be installed at places, where the access to seashore is prohibited or there are protected or recreational areas. Furthermore they may be damaged in some areas of this world that are threatened by natural catastrophes like hurricane, tsunami etc., or are affected by changes in the shoreline by erosion or wave induced transport of sand away from the beach as consequence of an increasing sea level, like it is happening actually

in coastal areas in the Mediterranean Sea [9]. As consequence some installations, formerly buried not visible in the beach, appear exposed (Fig. 2). 3.3. Indirect seawater intake with seabed filtration based on buried pipes Usually subsurface seawater intake installations consist of a submerged slow sand media filtration system located at the bottom of the ocean in the near-shore surf zone, which is connected to a series of intake wells located on the shore. Thereby the ocean floor has to be excavated to install the intake piping of the wells, being these pipes buried at the bottom of the ocean floor in excavation pits [8]. Sized and configured using the same criteria as slow sand filters, these systems are constructed using several layer like crushed stone, gravel, replaced sand and original sand (Fig. 3). The excavation of a strip with rather important size needed for the installation of such a seabed filter for the supply of seawater for bigger desalination plants will result in a very significant impact on the marine flora and fauna in this location and on the surrounding environment including the beach, as this system requires also installations for collecting the intake water prior to transferring it to the seawater desalination plant for further treatment. Depending on the location, also low dissolved oxygen concentration and high bacteriological contamination of the seawater in the area near to the shore have to be considered, as well as, the necessity to clean or change the sand layer after few years of operation [8]. 3.4. Indirect seawater intake with HDD-based Neodren technology The Neodren technology explained here in more detail because of its interesting technical approach is based on horizontal drains, consisting of patented special porous filter pipes, that are acting as wells. They are installed in bore

580

Th. Peters, D. Pint / Desalination 221 (2008) 576584

Fig. 2. Exposed part of an indirect seawater intake system (Photo: K. Peters, 2006).

holes, drilled with the horizontal directional drilling (HDD) method in the stratum below the seabed, few meter below the ocean floor and several hundred meter in length. Thereby it is used a patented special drilling aid material because of technical and environmental reasons. The seawater is extracted indirectly through the sub-seabed area, that is acting as a natural filter (Fig. 4). In this way however, only seawater will be collected without any impact on ground water resources, not only due to the distance to the sweet water lenses, but specially because the seawater in the stratum surrounding the drains is extracted with very low velocity. These extremely low filtering velocities do not influence the marine

flora and fauna, so that there is no impingement and entrainment of aquatic organism. Even during construction and installation no negative impact on the environment is to be expected, as the working area is limited to two points with reduced space, one onshore behind the beach area or further away from the coast line for the drilling rig and peripheral machinery, and one offshore at the end of the drains at the seabed [2,10]. One aspect in the Mediterranean area is for example the impact of seawater intake systems on the poseidonia prairies, that are highly protected by the environmental legislation. Drains installed in the subsoil below the seabed surface do not affect the ecosystem.

Th. Peters, D. Pint / Desalination 221 (2008) 576584

581

Fig. 3. Cross-section of seabed intake system based on a filter bed (source: [8]).

With these horizontal drains, that are based on an improved HDD technology and the high efficient filtering devices, the conventional pretreatment with different treatment steps like raw and fine screening, as well as, sand filtration

of the seawater, and the dosage of different pre-treatment agents will not be necessary. The technological advantage compared to the classic intake method is the reduction of suspended matter and pollutants by 90% and more, and a

Fig. 4. Schematic of the drains of the Neodren system (source: Catalana de Perforacions).

582

Th. Peters, D. Pint / Desalination 221 (2008) 576584

more uniform temperature curve throughout the seasons, which allows for a more effective and cost efficient pre-treatment compared to open intake methods. So it is possible to simplify the pre-treatment to conventional fine filtration like dead-end ultrafiltration without advanced and cost intensive methods, and to reduce also the chemical consumption significantly. Under certain circumstances, and operating with adapted process and module technology, desalination is possible avoiding the use of pre-treatment agents. Therefore the direct cost for the Neodren system, if compared to classic open intake, has to be evaluated always for individual locations and considering the indirect cost as well. The Neodren technology, developed by Catalana de Perforacions with the first unit in operation since 1996, can be operated in sandy and karstic seabeds as ecological and economical alternative for conventional open seawater intake systems and has even advantages in comparison with all other indirect seawater intake systems, like for example beach well installations. Actually are in operation 10 Neodren installations with a total capacity of nearly 300,000 m3/d (status March 2007). Based on projects under development it is expected an increase of few hundred thousand m3/d in the next years. The Neodren technology also allows for larger plant capacities due to grouping of drains and allows for construction of intake systems at places, where access to the beach for construction measures is prohibited and where seawater quality could be very bad; e.g. at port basins, dredging areas and other permanent or seasonal problematic seawater conditions [7]. Due to its positioning below the seabed the system is not affected by dynamic action in the sea, as consequence for example during and after natural catastrophes like hurricane, tsunami etc., nor affected by changes in the shoreline by erosion. This system is also a valuable option for seawater intakes at critical locations and where the

seabed is very shallow and requires long distance piping into the sea for open intakes and the related great impact on environment. It is a convincing solution for the seawater intake for desalination plants that can help to save costs and does meet the most stringent environmental regulations. 4. Seawater outfall system The outfall system discharges the rejects produced in the desalination plant into the sea. Depending from the local conditions, the reject water is discharged in the coastal area [11], discharged together with cooling water [12] or transported with submarine pipelines installed on the ocean floor few hundred meter offshore, where the salt concentration is reduced with diffuser [13], if it is not diluted already before. These diffusers should promote rapid mixing with surrounding seawater in order to not disturb the local ecosystem. In any case it is necessary the realisation of an intensive investigation regarding the environmental impact and the positioning of the intake and outfall systems to avoid brine recirculation into the seawater intake, based between other on mathematical recirculation assessment and detailed bathymetric survey. An alternative for seawater outfall systems is the use of directed horizontal drilling for the first section, installing a pipeline below the ocean floor that is coming to the seabed surface at few hundred meter offshore. The second section comprises the installation of a usual diffuser at the end of this pipeline, or a pipeline with a number of diffusers, connected to the first pipeline section and placed on the ocean floor, as usual with ballast units. Depending on the conditions on site, also the inversed operation of the Neodren technology could be used for the brine discharge, as it has been successfully realized for backwash water [14].

Th. Peters, D. Pint / Desalination 221 (2008) 576584

583

5. Evaluation criteria As it is obvious that the intake and pretreatment of seawater, as well as, the discharge of the reject water produced in a desalination plant have to be adapted to the specific conditions at the construction site of each plant, the elaboration of evaluation criteria that help to select the best available technology and the optimal solution for the intake and outfall system at a plant under discussion is mandatory. Thereby the most important items with equal value as commercial details are aspects related with the environment, to be considered in the construction phase and during the long-term operation. Important items regarding the environmental impact requirements that should be considered for different options are between other: Wastewater discharge standards Air pollution control requirements Noise control standards Land use Public services and utilities Aesthetics, light and glare In the frame of a risk assessment should be checked and compared: Design and development risk Construction risk Operating risk Hazardous materials risk Revenue risk Financial risk Force majeure risk Insurance risk Environmental risk, as mentioned above.

are not only the arid regions in the world, but, in an increasing rate, also the urban agglomerations and industrial centres, specially in the coastal areas, in which the capacity limits of natural supplies have been reached in many cases. One possibility to resolve this problem with fast growing importance and in some cases the only remaining option to satisfy the increasing demand for potable water in good quality for a growing population is the desalination of seawater. Thereby is used more and more the membrane process reverse osmosis. But even if in the last two decades numerous important technological improvements helped to create a reliable and cost effective process, the seawater intake and pre-treatment, as well as, the brine discharge are still areas with technological developing potential, as they have to be adapted case by case. Thereby environmental related considerations are becoming more and more important. In consequence, more detailed investigation and intensive risk assessment are necessary in order to identify the suitable solution for each case. In this regard, the innovative Neodren technology based on HDD is one interesting option with increasing importance. References

[1] [2] www.naseba.com, 2006. Th. Peters, D. Pint and E. Pint, Improved seawater intake and pre-treatment system based on Neodren technology, Desalination, 203 (2007) 134140. Th. Peters, Improving seawater desalination with reverse osmosis, in: Proceedings, International Conference FILTECH 2007, Wiesbaden, 27.002/ 01.03. 2007. V. Hennessey, Proposal threatens desalination plants, Monterey Herald, 15.02.2006. S. Lattemann and Th. Hpner, Seawater desalination impacts of brine and chemical discharge on the marine environment, Balaban Desalination Publ., LAquila, 2003. F.M.A. Al-Awadhi, The year of the ocean and its crucial importance to the Gulf, in: Fourth

[3]

[4]

6. Conclusion The increasing world population, the rising living standard and the expanding industrialization are the causes of the ever growing demand for potable water and for water with high quality for industrial applications. The areas affected

[5]

[6]

584

Th. Peters, D. Pint / Desalination 221 (2008) 576584

Gulf Water Conference, Bahrain, February, 1999. R. Edlinger, Aqua Engineering, Technical evaluation, 2007. Poseidon Resources Corporation, Seawater Desalination Project at Huntington Beach, April 5, 2005, in: www.ci.huntington-beach.ca.us/files/ users/planning/sec07.pdf. South Costa Brava, Archives of Catalana de Perforacions, 2006. Th. Peters and D. Pint, Sub-seabed drains provide intake plus pre-treatment, Desalination Water Reuse, 16 (2) (2006) 2327. [11] M. Farias, La desaladora de Javea dos aos vertiendo la salmuera de rechazo, Preprints, DESALACIN04, Madrid, 2004. [12] N. Voutchkov, Innovative method to evaluate tolerance of marine organism, Desalination Water Reuse, 16 (2) (2006) 2934. [13] B. Marn, Aplicacin de eductores para dilucin de salmuera con agua de mar en instalaciones desaladoras, VI Congreso Nacional AEDyR, Palma de Mallorca, 2006. [14] System for discharge of backwash water, Comunidad de Regantes, guilas, Catalana de Perforacions, personal information, 2006.

[7] [8]

[9] [10]

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Water Level - Bundi 2010Document2 paginiWater Level - Bundi 2010Ankush JainÎncă nu există evaluări

- Assignment-I (Syllabus Up To Mid-I)Document5 paginiAssignment-I (Syllabus Up To Mid-I)Nitish KumarÎncă nu există evaluări

- Chapter 1 IntroDocument13 paginiChapter 1 IntroshambelÎncă nu există evaluări

- SlidesDocument7 paginiSlidesturnt toastÎncă nu există evaluări

- Wetland Conservation in West BengalDocument28 paginiWetland Conservation in West Bengalvaswati_planÎncă nu există evaluări

- Mid-Term Test SolutionDocument7 paginiMid-Term Test Solutionsui sui mangÎncă nu există evaluări

- RAINWATER HAREVESTING Mini Project (1702700024)Document13 paginiRAINWATER HAREVESTING Mini Project (1702700024)Alok100% (1)

- Mathura 20130314Document6 paginiMathura 20130314Rohit TangriÎncă nu există evaluări

- Hydrosphere NotesDocument10 paginiHydrosphere Notesmatthewsc2013Încă nu există evaluări

- Volume 3b - Hydrologic ReportDocument198 paginiVolume 3b - Hydrologic ReportAjith Shyam Prasad100% (1)

- LD-P2M2 (MAIN) - EIA As Source of Power To Control ESC in Malaysia - 20170919 - TRG PDFDocument162 paginiLD-P2M2 (MAIN) - EIA As Source of Power To Control ESC in Malaysia - 20170919 - TRG PDFJohn ConnorsÎncă nu există evaluări

- Tideflex General BrochureDocument24 paginiTideflex General BrochureSujitH Sekar GnanasekaranÎncă nu există evaluări

- Tanya Corazon Torres Robert Torrest Jr. Proposed Two-Storey ResidenceDocument1 paginăTanya Corazon Torres Robert Torrest Jr. Proposed Two-Storey ResidenceMiguel EllaÎncă nu există evaluări

- Storm Water Calculation (20.01.21)Document3 paginiStorm Water Calculation (20.01.21)psn_kylmÎncă nu există evaluări

- Alabama Rain Garden BrochureDocument2 paginiAlabama Rain Garden BrochureFree Rain Garden ManualsÎncă nu există evaluări

- Design Response: Basiru Niang MATT NO: 220110014Document6 paginiDesign Response: Basiru Niang MATT NO: 220110014Basiru NiangÎncă nu există evaluări

- Water PollutionDocument11 paginiWater PollutionlordniklausÎncă nu există evaluări

- 2023 Capstone Project Report Template - Engineering Services ReportDocument14 pagini2023 Capstone Project Report Template - Engineering Services ReportNokwanda PoliteÎncă nu există evaluări

- ETP PresentationDocument22 paginiETP Presentationzeeshan afzal0% (1)

- Water PollutionDocument26 paginiWater PollutionSNNÎncă nu există evaluări

- National Technical Regulation On Industrial WastewaterDocument5 paginiNational Technical Regulation On Industrial WastewaterpaultonkesÎncă nu există evaluări

- Review Paper On "Irrigation Water Pollution and Its Minimization Measures"Document10 paginiReview Paper On "Irrigation Water Pollution and Its Minimization Measures"Abayneh WubetuÎncă nu există evaluări

- FlowChart SeleksiTeknologiSANITASI PDFDocument3 paginiFlowChart SeleksiTeknologiSANITASI PDFClarita BangunÎncă nu există evaluări

- Waste Water EngineeringDocument14 paginiWaste Water EngineeringMuhammad MubasharÎncă nu există evaluări

- Biological Wastewater Treatment in Context of Circular EconomyDocument8 paginiBiological Wastewater Treatment in Context of Circular EconomyMario Enrique Martinez ArismendiÎncă nu există evaluări

- Project - Electric Dam in KalagarhDocument9 paginiProject - Electric Dam in KalagarhRajul GargÎncă nu există evaluări

- ClassEA MidHalton ESR FinalDocument150 paginiClassEA MidHalton ESR FinalDikshant SharmaÎncă nu există evaluări

- Hydrogeology of SylhetDocument9 paginiHydrogeology of SylhetMy Photo boothÎncă nu există evaluări

- Project 1Document2 paginiProject 1Devanshu Agrawal 10D 3012Încă nu există evaluări

- CHECKLIST FOR LAYING OF Under Ground Drainage & Storm Water PipelineDocument2 paginiCHECKLIST FOR LAYING OF Under Ground Drainage & Storm Water Pipelinevidyanathvinayv100% (2)