Documente Academic

Documente Profesional

Documente Cultură

1 s2.0 S0169409X06002717 Main

Încărcat de

Luis SorianoDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

1 s2.0 S0169409X06002717 Main

Încărcat de

Luis SorianoDrepturi de autor:

Formate disponibile

Advanced Drug Delivery Reviews 59 (2007) 3 11 www.elsevier.

com/locate/addr

Assuring quality of drugs by monitoring impurities

Satinder (Sut) Ahuja

Ahuja Consulting, 1061 Rutledge Court, Calabash, NC 28467, USA Received 14 January 2006; accepted 25 October 2006 Available online 16 November 2006

Abstract To assure the quality of drugs, impurities must be monitored carefully. It is important to understand what constitutes an impurity and to identify potential sources of such impurities. Selective analytical methods need to be developed to monitor them. It is generally desirable to profile impurities to provide a yardstick for comparative purposes. New impurities may be observed as changes are made in the synthesis, formulation, or production procedures, albeit for improving them. At times it is necessary to isolate and characterize an impurity when hyphenated methods do not yield the structure or when confirmation is necessary with an authentic material. Availability of an authentic material can also allow toxicological studies and provide a standard for routine monitoring of the drug product. 2007 Published by Elsevier B.V.

Keywords: Characterization; Chiral impurity; Degradation product; Drug product; Drug substance; Isolation; Profiling; Selective analytical methodologies; Terbutaline

Contents 1. 2. Introduction . . . . . . . . . . . . . . . . . . . . . Terminology . . . . . . . . . . . . . . . . . . . . 2.1. Commonly used terms. . . . . . . . . . . . 2.1.1. Starting material(s) . . . . . . . . . 2.1.2. Intermediates . . . . . . . . . . . . 2.1.3. Penultimate intermediate . . . . . . 2.1.4. By-products . . . . . . . . . . . . 2.1.5. Transformation products . . . . . . 2.1.6. Interaction products . . . . . . . . 2.1.7. Related products . . . . . . . . . . 2.1.8. Degradation products . . . . . . . . 2.2. Compendial terminology . . . . . . . . . . 2.2.1. Foreign substances . . . . . . . . . 2.2.2. Toxic impurities . . . . . . . . . . 2.2.3. Concomitant components. . . . . . 2.2.4. Signal impurities . . . . . . . . . . 2.2.5. Ordinary impurities. . . . . . . . . 2.2.6. Organic volatile impurities (OVIs) . 2.3. ICH terminology . . . . . . . . . . . . . . 2.3.1. Organic impurities . . . . . . . . . 2.3.2. Inorganic impurities . . . . . . . . 2.3.3. Other materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 4 4 4 4 5 5 5 5 5 5 5 5 5 5 5 5 5 6 6 6 6

This review is part of the Advanced Drug Delivery Reviews theme issue on Pharmaceutical Impurities: Analytical, Toxicological and Regulatory Perspectives". Corresponding author. Tel.: +1 910 287 7565. E-mail address: sutahuja@atmc.net.

0169-409X/$ - see front matter 2007 Published by Elsevier B.V. doi:10.1016/j.addr.2006.10.003

S. Ahuja / Advanced Drug Delivery Reviews 59 (2007) 311

2.3.4. Residual solvents . . . . . . . . . . . . . Comments on various terminologies . . . . . . . . 2.4.1. Chiral impurities . . . . . . . . . . . . . 3. Identification and qualification thresholds of impurities . . 4. Sources of impurities . . . . . . . . . . . . . . . . . . . 4.1. Synthesis-related impurities . . . . . . . . . . . . 4.2. Formulation-related impurities . . . . . . . . . . . 4.3. Degradation-related impurities . . . . . . . . . . . 4.3.1. Kinetic studies . . . . . . . . . . . . . . 5. Selective analytical methodologies . . . . . . . . . . . . 5.1. Spectroscopic methods . . . . . . . . . . . . . . . 5.1.1. Infrared spectrophotometry . . . . . . . . 5.1.2. Nuclear magnetic resonance spectroscopy 5.1.3. Mass spectrometry . . . . . . . . . . . . 5.2. Separation methods. . . . . . . . . . . . . . . . . 5.3. Hyphenated methods . . . . . . . . . . . . . . . . 6. Impurity profiling . . . . . . . . . . . . . . . . . . . . . 6.1. Samples to be profiled . . . . . . . . . . . . . . . 6.2. Components seen in a profile . . . . . . . . . . . 7. Isolating impurities . . . . . . . . . . . . . . . . . . . . 8. Characterization of impurities . . . . . . . . . . . . . . . 9. A case study. . . . . . . . . . . . . . . . . . . . . . . . 9.1. HPLC methods . . . . . . . . . . . . . . . . . . . 9.1.1. Achiral impurities . . . . . . . . . . . . . 9.1.2. Chiral impurities . . . . . . . . . . . . . 10. Conclusions . . . . . . . . . . . . . . . . . . . . . . . . References . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.4.

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

6 6 6 6 6 6 7 7 7 7 8 8 8 8 8 8 9 9 9 9 9 10 10 10 10 10 10

1. Introduction Webster's dictionary defines impurity as something that is impure or makes something else impure. An impure substance may be defined as follows: a substance of interest mixed or impregnated with an extraneous or usually inferior substance. These definitions can help generate a more concise definition of an impurity: any material that affects the purity of the material of interest, viz., an active pharmaceutical ingredient (API) or drug substance [14]. The purity of a drug product is in turn determined on the basis of the percentage of the labeled amount of API found in it by a suitable analytical method. Later discussion will also reveal that a drug product can have impurities that need to be monitored even though they do not affect the labeled content. The presence of some impurities may not deleteriously impact on drug quality if they have therapeutic efficacy that is similar to or greater than the drug substance itself. Nevertheless, a drug substance can be considered as compromised with respect to purity even if it contains an impurity with superior pharmacological or toxicological properties. Consequently, in order to ensure that an accurate amount of the drug substance is being administered to the patient, drug substance purity must be assessed independently from these undesirable extraneous materials (e.g., inert, toxic, or pharmacologically superior impurities). 2. Terminology A large number of terms have been used to describe the materials that can affect purity of the API. For the purpose of

this discussion, they are all considered impurities. To better acquaint the reader with advantages and limitations of the use of various terms, a brief description of these terms is given below, followed by some comments. 2.1. Commonly used terms A number of terms have been commonly used in the pharmaceutical industry to describe organic impurities: Starting material(s) Intermediates Penultimate intermediate (Final intermediate) By-products Transformation products Interaction products Related products Degradation products

Some of these terms denote potential sources of impurities, e.g., intermediates; others tend to de-emphasize the negativity, e.g., related products. Let us review them individually. 2.1.1. Starting material(s) These are the materials that are used to begin the synthesis of an API. 2.1.2. Intermediates The compounds produced during synthesis of the desired material are called intermediates, especially when they have

S. Ahuja / Advanced Drug Delivery Reviews 59 (2007) 311

been isolated and characterized. The most important criterion is characterization, i.e., they cannot be just theorized potential reaction products (see by-products below). The theorized compounds are best designated as potential intermediates. 2.1.3. Penultimate intermediate As the name suggests, this is the last compound in the synthesis chain prior to the production of the final desired compound. It is more appropriate to call it Final Intermediate. Sometimes confusion arises when the desired material is a salt of a free base or a free acid. In the opinion of this author, it is inappropriate to label the free acid or base as the penultimate intermediate if the drug substance is a salt. 2.1.4. By-products The unplanned compounds produced in the reaction are generally called by-products. It may or may not be possible to theorize all of them. Hence, they present a challenging problem to the analytical chemist in that a methodology cannot be optimally planned if it is not known what needs to be excluded from evaluations. 2.1.5. Transformation products This is a relatively nondescript term that relates to theorized and non-theorized products that may be produced in the reaction, which can include synthetic derivatives of by-products. Transformation products are very similar to by-products, except this term tends to connote that more is known about the reaction products. 2.1.6. Interaction products Interaction products is a slightly more comprehensive term than the two described above (by-products and transformation products); however, it is more difficult to evaluate in that it considers interactions that could occur between various involved chemicals intentionally or unintentionally. Two types of interaction products that can be commonly encountered are drug substanceexcipient interactions and drug substance container/closure interactions. 2.1.7. Related products As mentioned before, the term related products tends to suggest that the impurity is similar to the drug substance and thus tends to play down the negativity frequently attached to the term impurity. Clearly these products generally have similar chemical structures as the API and may exhibit potentially similar biological activity; however, as discussed later, this by itself does not provide any guarantee to that effect. 2.1.8. Degradation products These are the compounds produced because of decomposition of the material of interest or active ingredient. This term can also include those products produced from degradation of other compounds that may be present as impurities in the drug substance.

2.2. Compendial terminology The United States Pharmacopoeia (USP) deals with impurities in several sections: Impurities in official articles Ordinary impurities Organic volatile impurities The USP acknowledges that concepts about purity are susceptible to change with time, and purity is intimately related to the developments in analytical chemistry. What we consider pure today may be considered impure at some future date if methods are found that can resolve other components contained in a particular compound. Inorganic, organic, or polymeric components can all be considered impurities. The following terms have been used by the USP to describe impurities: Foreign substances Toxic impurities Concomitant components Signal impurities Ordinary impurities Organic volatile impurities (OVIs)

2.2.1. Foreign substances The materials that are introduced by contamination or adulteration, not as a consequence of synthesis or preparation, are labeled foreign substances, e.g., pesticides in oral analgesics. 2.2.2. Toxic impurities These impurities have significant undesirable biological activity, even as minor components; and they require individual identification and quantification by specific tests. 2.2.3. Concomitant components Bulk pharmaceutical chemicals may contain concomitant components, e.g., antibiotics that are mixtures and are geometric and optical isomers (see Section 2.4.1). 2.2.4. Signal impurities These are distinguished from ordinary impurities discussed below in that they require individual identification and quantification by specific tests. These impurities include some process-related impurities or degradation products that provide key information about the process. 2.2.5. Ordinary impurities The species of impurities in bulk pharmaceutical chemicals that are innocuous by virtue of having no significant undesirable biological activity in the amounts present are called ordinary impurities. 2.2.6. Organic volatile impurities (OVIs) This term relates to residual solvents that may be found in the drug substance. OVIs are generally solvents used in the

S. Ahuja / Advanced Drug Delivery Reviews 59 (2007) 311

synthesis or during formulation of the drug product. The solvents have been classified as follows by ICH. Class I (to be avoided): benzene, carbon tetrachloride, 1,2-dichloromethane, 1,1-dichloroethane, and 1,1,1-trichloroethane. Class II (should be limited): acetonitrile, chloroform, methylene chloride, 1,1,2-trichloroethane, 1,4-dioxane, and pyridine. Class III: low toxic potential and permitted daily exposure (PDE) of 50 mg or more. Class IV: solvents for which adequate toxic data are not available. 2.3. ICH terminology 2.3.1. Organic impurities Starting materials Process-related impurities Intermediates Degradation products. 2.3.2. Inorganic impurities Salts Catalysts Ligands Heavy metals or other residual metals. 2.3.3. Other materials Filter aids Charcoal. 2.3.4. Residual solvents Organic and inorganic liquids used during production and/or crystallization. 2.4. Comments on various terminologies The impurities that may be present in the starting material(s) can potentially be carried into the active ingredient of interest. And the impurities that relate to the solvents used during synthesis and the inert ingredients (excipients) used for formulation must also be considered potential impurities that may be found in API or drug product. Inorganic impurities may also be found in compendial articles. These impurities may be as simple as common salt or other compounds that are controlled, such as heavy metals, arsenic, etc., which can be introduced during various synthetic steps. Potential reaction by-products, degradation products, and drug substanceexcipient interactions must also be evaluated. All of these impurities have the potential of being present in the final drug product. Of the various terminologies described above, the International Conference on Harmonisation (ICH) provides a simple classification to adequately address various impurities that may be present in pharmaceutical products. However, all of these terminologies fail to adequately highlight that enantiomeric (chiral) impurities might warrant additional considerations.

2.4.1. Chiral impurities Chiral impurities have the identical molecular formula and the same connectivity between various atoms, and they differ only in the arrangement of their atoms in three-dimensional space. The differences in pharmacological/toxicological profiles have been observed with chiral impurities in vivo [4,5]. This suggests that chiral impurities should be monitored carefully. 3. Identification and qualification thresholds of impurities The International Conference on Harmonisation addresses questions relating to impurities as follows [6]: Q1A (R) stability testing of new drug substances and products Q3A (R) impurities in drug substances Q3B (R) impurities in drug products Q3C impurities: residual solvents Q6A specifications: test procedures and acceptance criteria for new drug substances and new drug products; chemical substances ICH guidelines for the identification and qualification threshold of impurities and degradation products are provided in Table 1. As can be seen from the data in Table 2, ICH treats the degradation products slightly differently than impurities even though for all intents and purposes the degradation products are impurities. 4. Sources of impurities Discussed below are three important sources of impurities. 4.1. Synthesis-related impurities Impurities in a drug substance or a new chemical entity (NCE) originate mainly during the synthetic process from raw materials, solvents, intermediates, and by-products. The raw materials are generally manufactured to much lower purity requirements than a drug substance. Hence, it is easy to understand why they can contain a number of components that can in turn affect the purity of the drug substance. Similarly, solvents used in the synthesis are likely to contain a number of impurities that may range from trace levels to significant amounts that can react with various chemicals used

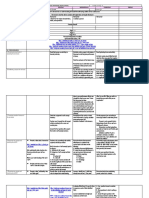

Table 1 Thresholds for reporting impurities Maximum daily dose Less or equal to 2 g/day >2 g/day Reporting threshold 0.05% 0.03% Identification threshold 0.10% or 1.0 mg/day (whichever is lower) 0.05% Qualification threshold 0.15% or 1.0 mg/day (whichever is lower) 0.05%

S. Ahuja / Advanced Drug Delivery Reviews 59 (2007) 311 Table 2 Threshold for reporting degradation products in a new drug product Maximum daily dose 1g >1 g Threshold 0.1% 0.05%

4.3. Degradation-related impurities A number of impurities can be produced because of API degradation or other interactions on storage. Therefore, it is very important to conduct stability studies to predict, evaluate, and ensure drug product safety [7]. Stability studies include evaluation of stability of API, preformulation studies to evaluate compatibility of API with the excipients to determine its stability in the formulation matrix, accelerated stability evaluations of the test or final drug product, stability evaluation via kinetic studies and projection of expiration date, routine stability studies of drug products in marketed, sample or dispensed package under various conditions of temperature light, and humidity. The stability studies under various exaggerated conditions of temperature, humidity, and light can help us determine what potential impurities can be produced by degradation reactions (for details see Chapter 8 of reference [1]). It is important to establish a viable stability program to evaluate impurities. A good stability program integrates well the scientific considerations with regulatory requirements. The importance of kinetic studies in monitoring and evaluating impurities is discussed below. 4.3.1. Kinetic studies Most of the degradation reactions of pharmaceuticals occur at finite rates and are chemical in nature. These reactions are affected by conditions such as solvent, concentration of reactants, temperature, pH of the medium, radiation energy, and the presence of catalysts. The order of the reaction is described by the manner in which the reaction rate depends on the concentration of reactant. The degradation of most pharmaceuticals can be classified as zero order, first order, or pseudo-first order, even though they may degrade by complicated mechanisms, and the true expression may be of higher order or be complex and noninteger. An understanding of the limitations of experimentally obtained heat of activation values is critical in stability predictions. For example, the apparent heat of activation of a pH value where two or more mechanisms of degradation are involved is not necessarily constant with temperature. Also, the ion product of water, pKw, is temperature-dependent, and Ha is approximately 12 kcal, a frequently overlooked factor that must be considered when calculating hydroxide concentration. Therefore, it is necessary to obtain the heat of activation for all bimolecular rate constants involved in a ratepH profile to predict degradation rates at all pH values for various temperatures. It is incumbent upon the chemist to perform some kinetic studies to predict stability of a drug substance and to evaluate degradation products. However, it is also important to recognize the limitations of such predictions. The importance of kinetic studies and the effect of various additives on the reaction rates are discussed at some length in Chapter 7 of reference [1]. 5. Selective analytical methodologies Development of a new drug mandates that meaningful and reliable analytical data be generated at various steps of the new

in the synthesis to produce other impurities. Intermediates are also not generally held to the purity level of the drug substancehence the remarks made for the raw materials apply. It is not reasonably possible to theorize all by-products; as a result, any such products that may be produced in the synthesis would be hard to monitor. The pot reactions, i.e., when the intermediates are not isolated, are convenient, economical, and timesaving; however, they raise havoc in terms of the generation of impurities because a number of reactions can occur simultaneously. Incidentally, this problem of numerous reactions occurring simultaneously can be also encountered in single reactions where intermediate is isolated. The final intermediate is generally controlled in the pharmaceutical synthesis by conducting regulatory impurity testing. This typically entails residual solvents (that are not used in further downstream processing) or process impurities (in cases where they conclusively demonstrate that these moieties are not also degradation products). It is important to remember that this step is the last major source of potential impurities, therefore, it is very desirable that the methods used for analysis at this stage be rigorous. It should be remembered that base-tosalt or acid-to-salt conversions could also generate new impurities. Furthermore, thermally labile compounds can undergo decomposition if any further processing involves heating. 4.2. Formulation-related impurities A number of impurities in a drug product can arise out of interactions with excipients used to formulate a drug product. Furthermore, in the process of formulation, a drug substance is subjected to a variety of conditions that can lead to its degradation or other deleterious reactions. For example, if heat is used for drying or for other reasons, it can facilitate degradation of thermally labile drug substances. Solutions and suspensions are potentially prone to degradation that is due to hydrolysis or solvolysis (see kinetic studies discussed below). These reactions can also occur in the dosage form in a solid state, such as in the case of capsules and tablets, when water or another solvent has been used for granulation. Not only can the water used in the formulation contribute its own impurities, it can also provide a ripe situation for hydrolysis and metal catalysis. Similar reactions are possible in other solvents that may be used. Oxidation is possible for easily oxidized materials if no precautions are taken. Similarly, light-sensitive materials can undergo photochemical reactions. Details are provided in Chapter 6 of reference [1] regarding how various excipients can contribute to degradation and the resulting impurities.

S. Ahuja / Advanced Drug Delivery Reviews 59 (2007) 311

drug development [7]. Ensuring the safety of a new pharmaceutical compound or drug requires that it meet the established purity standards as a chemical entity or when admixed with animal feeds for toxicity studies or pharmaceutical excipients for human use. Furthermore, it should exhibit excellent stability throughout its shelf life. These requirements demand that the analytical methodology that is used be sensitive enough to measure low levels of impurities. This has led to analytical methods that are suitable for determination of trace/ultratrace levels, i.e., sub-microgram quantities of various chemical entities [812]. A variety of methods are available for monitoring impurities. The primary criterion is the ability to differentiate between the compounds of interest. This requirement reduces the availability of methods primarily to spectroscopic and separation methods or a combination thereof. 5.1. Spectroscopic methods The following spectroscopic methods can be used: Ultraviolet (UV) Infrared (IR) Nuclear magnetic resonance (NMR) Mass spectrometry (MS)

5.2. Separation methods The following separation methods can be used: Thin-layer chromatography (TLC) Gas chromatography (GC) High-pressure liquid chromatography (HPLC) Capillary electrophoresis (CE) Supercritical fluid chromatography (SFC)

UV at a single wavelength provides minimal selectivity of analysis; however, with the availability of diode array detectors (DAD), it is now possible to get sufficient simultaneous information at various wavelengths to ensure greater selectivity. 5.1.1. Infrared spectrophotometry Infrared spectrophotometry provides specific information on some functional groups that may allow quantification and selectivity. However, low-level detectability is frequently a problem that may require more involved approaches to circumvent the problem. 5.1.2. Nuclear magnetic resonance spectroscopy Nuclear magnetic resonance spectroscopy provides fairly detailed structural information on a molecule and is a very useful method for characterization of impurities; however, it has limited use as a quantitative method because of cost and time considerations. 5.1.3. Mass spectrometry Mass spectrometry provides excellent structural information, and, based on the resolution of the instrument, it may provide an effective tool for differentiating molecules with small differences in molecular weight. However, it has limited use as a quantitative technique because of cost and time considerations. In summary, IR, NMR, and MS are excellent techniques for characterization of impurities that have been isolated by any of the techniques discussed above. UV has been found to be especially useful for analyzing most samples with high-pressure liquid chromatography. This combination is commonly used in pharmaceutical analysis.

A brief account of the above-listed methods is given here to provide a quick review of their potential use [10]. Except for CE, all these techniques are chromatographic methods. CE is an electrophoretic method that is frequently lumped with the chromatographic methods because it shares many of the common requirements of chromatography. However, it is not strictly a two-phase separation system a primary requirement in chromatography. Hyphenated methods such as GCMS, LCMS, GCLCMS, LCMSMS, etc. are all discussed later in this chapter. A broad range of compounds can be resolved using TLC by utilizing a variety of different plates and mobile phases. The primary difficulties related to this method are limited resolution, detection, and ease of quantification. The greatest advantages are the ease of use and low cost. Gas chromatography is a very useful technique for quantification. It can provide the desired resolution, selectivity, and ease of quantification. However, the primary limitation is that the sample must be volatile or has to be made volatile by derivatization. This technique is very useful for organic volatile impurities. High-pressure liquid chromatography is frequently casually referred to as high-performance liquid chromatography today. Both of these terms can be abbreviated as HPLC, and they are used interchangeably by chromatographers. This is a useful technique with applications that have been significantly extended for the pharmaceutical chemist by the use of a variety of detectors such as fluorescence, electrometric, MS, etc. Capillary electrophoresis is a useful technique when very low quantities of samples are available and high resolution is required. The primary difficulty is assuring reproducibility of the injected samples. Supercritical fluid chromatography offers some of the advantages of GC in terms of detection and HPLC in terms of separations, in that volatility of the sample is not of paramount importance. This technique is still evolving, and its greatest application has been found in the extraction of samples. 5.3. Hyphenated methods The following hyphenated methods can be used effectively to monitor impurities [3]: GCMS LCMS LCDADMS LCNMR

S. Ahuja / Advanced Drug Delivery Reviews 59 (2007) 311

LCDADNMRMS LCMSMS Of course, these methods are not always available or applicable a detailed discussion is included in Chapters 4 and 9 of reference [1] as to why it is not always possible to use these methods. In case it is necessary to procure authentic material for purposes of structure confirmation, synthesis or isolation methods should be utilized. 6. Impurity profiling Ideally an impurity profile should show all impurities in a single format to allow monitoring of any variation in the profile because of planned or unplanned changes in synthesis, formulation, or stability, etc. The driving forces for studying an impurity profile are Quality considerations Regulatory (FDA) requirements It is the belief of this author that quality considerations should be the driving force for profiling. 6.1. Samples to be profiled Impurity profiling should be done for the following samples: Active ingredient Process check (synthesis or formulation) Final product. 6.2. Components seen in a profile Ideally, an impurity profile should show the following: Synthesis-related impurities Formulation-related impurities Degradation products Interaction products.

Accelerated solvent extraction Supercritical fluid extraction Column chromatography Flash chromatography Thin-layer chromatography Gas chromatography High-pressure liquid chromatography Capillary electrophoresis Supercritical fluid chromatography.

Isolation should be initiated based on simple extraction or partition methods. It may be possible to extract impurities selectively on the basis of acidity, basicity, or neutrality. The extraction process usually involves liquidliquid extraction, where one phase is an aqueous solution and the other is an organic phase that is nonpolar. By appropriate adjustment of the pH of the aqueous solution, one can extract acidic, basic, or neutral impurities. Further separations can be made by chromatographic methods. Frequently, the isolation methods tend to be the same methods that are used for analysis. 8. Characterization of impurities The characterization of impurities is generally achieved by the following means: Matching retention data UV IR NMR MS

Once an impurity has been detected, it becomes necessary to estimate its content. Detectability frequently means that a given component provides a signal at least twice that of background noise or the baseline. For quantification of impurity, the mul-

7. Isolating impurities It is often necessary to isolate impurities because the instrumental methods mentioned above are not available or further confirmation is needed. For example, when hyphenated methods such as LCMS are not suitable or do not provide unambiguous characterization, it may be necessary to isolate impurities for further confirmation of structure or for conducting toxicity studies. Of course, after the structure has been established, these impurities can be synthesized by a suitable route. The following methods have been used for isolation of impurities: Solid-phase extraction Liquidliquid extraction

Fig. 1. Resolution of potential degradation products. 1 = 3,5-dihydroxyacetophenone, 2 = 3,5-dihydroxybenzaldehyde, 3 = 2-t-butyl-4,6,8-trihodroxy-tetrahydroisoquinoline, 4 = terbutaline, 5 = 3,5-dihydroxy-- t-butylaminoacetophenone, 6 = 3,5-dihydroxybenzoic acid, ethyl ester. Copyright ( 1998) from Impurities Evaluation of Pharmaceuticals by Satinder Ahuja. Reproduced by permission of Routledge/Taylor and Francis Group, LLC.

10

S. Ahuja / Advanced Drug Delivery Reviews 59 (2007) 311

legends in Figs. 1 and 2) that must be resolved. HPLC was clearly indicated as the preferred methodology of choice, based on physicochemical properties of terbutaline (for more details, see reference [1]). 9.1.1. Achiral impurities All of the potential impurities were classified into four groups to assist the method development: Dihydroxyphenyl compounds with t-butylamino side chain Cyclized dihydroxyphenyl compounds with basic N in the ring Dibenzyloxyphenyl compounds with no t-butylamino side chain Dihydroxyphenyl compounds with no t-butylamino side chain Two HPLC methods were developed to resolve all achiral impurities with the same C-8 column with 3-m particle size [1]. System 1 (suitable for degradation products and less likely synthetic impurities): 0.005 mol 1-octanesulfonic acid in water:tetrahydrofuran:methanol (75:11:14). System 2 (suitable for dibenzyloxyphenyl compounds; starting material and intermediates): water:tetrahydrofuran: acetonitrile:acetic acid:triethylamine (500:465:35:5:2). In summary, System 2 was designed primarily for quality control of API. Since no impurities were found in the API with System 2, the quality of drug product for QC and stability studies can be monitored using System 1 only. 9.1.2. Chiral impurities The L-isomer of terbutaline is 3000 times more potent as a relaxant of tracheal smooth muscle than the D-isomer [4]. 1. The isomers can be resolved on AGP column with 0.003 M tetrapropylammonium bromide solution adjusted to pH 7.0. 2. Capillary electrophoresis can be used to resolve enantiomers with a background electrolyte that contains -cyclodextrin or heptakis (2,6-di-O-methyl)--cyclodextrin. 9.1. HPLC methods The first step in this process was to review all potential sources of impurities in terbutaline. Synthesis: starting materials, solvents used, intermediates, theorize potential by-products. Formulation: solvents used, potential interaction products, any potential degradation products. Stability: potential degradation products or reaction products that may be produced because of thermal, hydrolytic, oxidation, or photochemical reactions. A careful assessment revealed that there could be 13 potential impurities in terbutaline (for chemical names, see 10. Conclusions To assure quality of drug substances and drug products, it is important to give a careful consideration as to what constitutes impurities for a given case and proceed carefully to design a program to achieve the desired results. It is believed that the discussion included herein would be helpful in developing such a program. References

[1] S. Ahuja, Impurities Evaluations of Pharmaceuticals, Dekker, New York, 1998.

Fig. 2. Resolution of potential dibenzyloxyphenyl impurities. 1 = terbutaline, 2 = solvent, 3 = solvent, 4 = -[(t-butylamino)methyl]-3,5-dibenzyloxybenzyl alcohol, 5 = -methyl-3,5-dibenzyloxybenzyl alcohol, 6 = 3,5-dibenzyloxyacetophenone, 7 = -[(benzyl-t-butylamino)methyl]-3,5-dibenzyloxybenzyl alcohol, 8 = 3,5-dibenzyloxy-2,6-dibromoacetophenone, 9 = 3,5-dibenzyloxy-1bromoacetophenone, 10 = 3,5-dibenzyloxy-2,6,-tribromacetophenone, 11 = 1-benzyl-t-butylamino-3,5-dibenzyloxyacetophenone. Copyright ( 1998) from Impurities Evaluation of Pharmaceuticals by Satinder Ahuja. Reproduced by permission of Routledge/Taylor and Francis Group, LLC.

tiple is set much higher. Initial estimations are generally done against the parent compound because in most cases the authentic sample of impurity is not available. When the authentic sample is available, it is important that it be used for estimations. If the estimations indicate that a given impurity content is greater than 0.1%, it must be characterized as per the FDA and ICH requirements. 9. A case study A case study is presented below relating to monitoring impurities in terbutaline sulfate (it is sold as a racemate).

S. Ahuja / Advanced Drug Delivery Reviews 59 (2007) 311 [2] S. Gorog, Identification and Determination of Impurities in Drugs, Elsevier, Amsterdam, 2000. [3] S. Ahuja, K. Alsante, Handbook of Isolation and Characterization of Impurities in Pharmaceuticals, Academic, San Diego, CA, 2003. [4] S. Ahuja, Chiral Separations by Chromatography, Oxford, New York, 2000. [5] S. Ahuja, Chiral Separations by Liquid Chromatography, ACS, Washington, DC, 1991. [6] ICH Web site (http://www.ich.org). [7] J.A. Mollica, S. Ahuja, J. Cohen, J. Pharm. Sci. 67 (1978) 443. [8] S. Ahuja, Chromatography of Pharmaceuticals. Natural, Synthetic and

11

[9] [10] [11] [12]

Recombinant Products, ACS Symposium Series #512, ACS, Washington, DC, 1992. S. Ahuja, Trace and Ultratrace Analysis by HPLC, Wiley, New York, 1992. S. Ahuja, Chromatography and Separation Science, Academic, San Diego, CA, 2003. S. Ahuja, S. Scypinsky, Handbook of Modern Pharmaceutical Analysis, Academic, New York, NY, 2001. S. Ahuja, M. Dong, Handbook of Pharmaceutical Analysis by HPLC, Academic, San Diego, CA, 2005.

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Zombie in The Brain and The Woman Who Died LaughingDocument40 paginiThe Zombie in The Brain and The Woman Who Died Laughingcory_ruda100% (1)

- 17-QA-QC ManualDocument34 pagini17-QA-QC ManualAbdul Gaffar100% (3)

- (R#1) XQ-450 - 600-800VDocument121 pagini(R#1) XQ-450 - 600-800VFrancisco PestañoÎncă nu există evaluări

- Evaluation of Bond Strenght of Dentin Adhesive at Dry and Moist Dentin-Resin Interface PDFDocument4 paginiEvaluation of Bond Strenght of Dentin Adhesive at Dry and Moist Dentin-Resin Interface PDFOpris PaulÎncă nu există evaluări

- Souvenir Mushrooms 1986Document106 paginiSouvenir Mushrooms 1986Ankit MishraÎncă nu există evaluări

- Wel-Come: Heat Treatment Process (TTT, CCT & CCR)Document14 paginiWel-Come: Heat Treatment Process (TTT, CCT & CCR)atulkumargaur26Încă nu există evaluări

- War RoomDocument88 paginiWar RoomDada Sasa100% (1)

- Cruz v. CA - G.R. No. 122445 - November 18, 1997 - DIGESTDocument2 paginiCruz v. CA - G.R. No. 122445 - November 18, 1997 - DIGESTAaron Ariston80% (5)

- Pinoy Ree - EeDocument138 paginiPinoy Ree - EeChilvin ChipmunkÎncă nu există evaluări

- FACSDocument8 paginiFACSKarthick ThiyagarajanÎncă nu există evaluări

- Arc Welding Rod Chart byDocument1 paginăArc Welding Rod Chart bytayyab aliÎncă nu există evaluări

- Di SilvioDocument47 paginiDi SilviomaryroseengÎncă nu există evaluări

- Multiscale Modeling of Bone Tissue MechanobiologyDocument12 paginiMultiscale Modeling of Bone Tissue MechanobiologyLina AvilaÎncă nu există evaluări

- Plumbing Design Calculation - North - Molino - PH1 - 5jun2017Document5 paginiPlumbing Design Calculation - North - Molino - PH1 - 5jun2017Jazent Anthony RamosÎncă nu există evaluări

- Saving AccountDocument9 paginiSaving AccountpalkhinÎncă nu există evaluări

- Antibacterial Effects of Essential OilsDocument5 paginiAntibacterial Effects of Essential Oilsnightshade.lorna100% (1)

- Daily Lesson Log Personal Dev TDocument34 paginiDaily Lesson Log Personal Dev TRicky Canico ArotÎncă nu există evaluări

- Research Paper CalamansiDocument7 paginiResearch Paper Calamansih040pass100% (1)

- PsychodramaDocument5 paginiPsychodramaAkhila R KrishnaÎncă nu există evaluări

- Department of Education: Republic of The PhilippinesDocument1 paginăDepartment of Education: Republic of The PhilippinesAre Em GeeÎncă nu există evaluări

- Magtech 2013 - 04 - 05 - MPV - Eng PDFDocument2 paginiMagtech 2013 - 04 - 05 - MPV - Eng PDFPabloÎncă nu există evaluări

- Anthracite: 2 PropertiesDocument8 paginiAnthracite: 2 PropertiesHasim BenziniÎncă nu există evaluări

- Deviance, Crime, and Social ControlDocument17 paginiDeviance, Crime, and Social ControlSaad MaqboolÎncă nu există evaluări

- Leadership Roles and Management Functions in Nursing Theory and ApplicationDocument2 paginiLeadership Roles and Management Functions in Nursing Theory and Applicationivan0% (3)

- Paramagnetic Article PDFDocument5 paginiParamagnetic Article PDFJonathan SinclairÎncă nu există evaluări

- Yumiko@Document2 paginiYumiko@api-25886263Încă nu există evaluări

- 04 TitrimetryDocument7 pagini04 TitrimetryDarwin Fetalbero ReyesÎncă nu există evaluări

- Nomenclature Practice ProblemsDocument4 paginiNomenclature Practice ProblemsMax DavidsonÎncă nu există evaluări

- Contoh Permintaan Obat CitoDocument2 paginiContoh Permintaan Obat CitoAriandy yanuarÎncă nu există evaluări

- Nutritional Classification of BacteriaDocument7 paginiNutritional Classification of BacteriaRalphpinno SanchezÎncă nu există evaluări