Documente Academic

Documente Profesional

Documente Cultură

Internal Friction of Materials Anton Puskar

Încărcat de

hezihilikDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Internal Friction of Materials Anton Puskar

Încărcat de

hezihilikDrepturi de autor:

Formate disponibile

i

INTERNAL FRICTION OF MATERIALS

ii

iii

INTERNAL FRICTION OF MATERIALS

Anton Pukr

Transport and Communications Technical University

Zilina, Slovak Republic

CAMBRIDGE INTERNATIONAL SCIENCE PUBLISHING

^

iv

Published by

Cambridge International Science Publishing

7 Meadow Walk, Great Abington, Cambridge CB1 6AZ, UK

http://www.demon.co.uk/cambsci/homepage.htm

First published May 2001

Anton Pukr

Cambridge International Science Publishing

Conditions of sale

All rights reserved. No part of this publication may be reproduced or trans-

mitted in any form or by any means, electronic or mechanical, including pho-

tocopy, recording, or any information storage and retrieval system, without

permission in writing from the publisher.

British Library Cataloguing in Publication Data

A catalogue record for this book is available from the British Library

ISBN 1 898326 509

Production Irina Stupak

Printed by PWP Acrolith Printing Ltd, Hertford, England

v

PREFACE

The complete absence of books characterising the internal friction

of materials, its external and internal aspects and the application of

measurements in various scientific and technical areas, especially in

physical metallurgy and threshold states of materials, has been the

impetus for the author to write this book. Without understanding

the principle and mechanisms of anelasticity and the effect of

various factors on internal friction, together with the application of

methods of reproducible internal friction measurements, it is not

possible to solve the problems of the application of these

measurements as direct or indirect methods for the evaluation of the

structural stability of alloys, problems of cyclic microplasticity and

deeper understanding of processes associated with the response of

materials to single or repeated loading.

In addition to the original systematisation of the possibilities

of using internal friction measurements in various sciences, the

book presents the latest theories and results together with practical

approaches to the measurement and evaluation of the resultant

relationships

Anton Pukr

vi

vii

CONTENTS

1 AIMS OF INTERNAL FRICTION MEASUREMENTS....... 1

2 NATURE AND MECHANISMS OF ANELASTICITY......... 5

2.1 ELASTICITY CHARACTERISTICS........................................... 5

2.1.1 Effect on elasticity characteristics .................................................. 13

2.1.2 Elasticity characteristics of structural materials ............................. 27

2.1.3 Elasticity characteristics of composite materials ............................ 37

2.2 MANIFESTATION OF ANELASTICITY ................................. 43

2.2.1 Delay of deformation in relation to stress ....................................... 44

2.2.2 Internal friction ............................................................................... 50

2.2.3 Mechanisms of energy scattering in the material ............................ 53

2.3 DEFECT OF THE YOUNG MODULUS ................................... 62

3 FACTORS AFFECTING ANELASTICITY OF

MATERIALS ............................................................................... 79

3.1. INTERNAL FRICTION BACKGROUND................................. 80

3.1.1 The substructural and structural state of material .......................... 81

3.1.2 Vacancy mechanism........................................................................ 82

3.1.3 Diffusion-viscous mechanism......................................................... 84

3.1.4 Dislocation mechanisms ................................................................. 85

3.1.5 The relaxation mechanism.............................................................. 87

3.2. EFFECT OF TEMPERATURE ON INTERNAL FRICTION.. 87

3.2.1 Mechanisms associated with point defects ..................................... 94

3.2.2 Dislocation relaxation mechanisms ................................................ 97

3.3 EFFECT OF STRAIN AMPLITUDE ....................................... 104

3.3.1 The GranatoLcke spring model ................................................ 105

3.3.2 Thermal activation........................................................................ 107

3.3.3 Internal friction with slight dependence on strain amplitude......... 109

3.3.4 Plastic internal friction ................................................................. 114

3.4 EFFECT OF LOADING FREQUENCY .................................. 114

3.5 EFFECT OF LOADING TIME ................................................. 121

3.6 EFFECT OF MAGNETIC AND ELECTRIC FIELDS........... 128

4 MEASUREMENTS OF INTERNAL FRICTION AND THE

DEFECT OF THE YOUNG MODULUS ............................. 133

4.1 APPARATUS AND EQUIPMENT ........................................... 133

viii

4.2 EXPERIMENTAL MEASUREMENTS AND EVALUATION.....

...................................................................................................... 143

4.2.1 Infrasound methods ...................................................................... 144

4.2.2 Sonic and ultrasound methods ...................................................... 151

4.2.3 Hypersonic methods ..................................................................... 167

4.3 PROCESSING THE RESULTS OF MEASUREMENTS AND

INACCURACY........................................................................... 169

4.3.1 Inaccuracy caused by the design of equipment ............................. 169

4.3.2 Inaccuracies of the measurement method ..................................... 172

4.3.3 Errors in processing the measurement results ............................... 174

5 STRUCTURAL INSTABILITY OF ALLOYS .................... 181

5.1 DIFFUSION MOBILITY OF ATOMS ..................................... 181

5.1.1 Interstitial solid solutions .............................................................. 183

5.1.2 Substitutional and solid solutions ................................................. 195

5.2 RELAXATION OF DISLOCATIONS ...................................... 197

5.2.1 Low-temperature peaks ................................................................ 197

5.2.2 Snoek and Kster relaxation ......................................................... 198

5.2.3 Phenomena associated with martensitic transformation in steel ... 204

5.2.4 Migration of solute atoms in the region with dislocations ............ 205

5.3 RELAXATION AT GRAIN BOUNDARIES............................ 213

5.3.1 Pure metals ................................................................................... 215

5.3.2 Solid solutions .............................................................................. 216

5.3.3 Relaxation models ........................................................................ 217

5.4 ANALYTICAL PROCESSING OF THE RESULTS OF

MEASUREMENTS .................................................................... 219

5.4.1 Solubility boundaries .................................................................... 219

5.4.2 Activation energy and diffusion coefficient .................................. 221

5.4.3 Breakdown of the solid solution ................................................... 223

5.4.4 Intercrystalline adsorption ............................................................ 224

5.4.5 Transition of the material from ductile to brittle state .................. 227

5.4.6 Relaxation movement of microcracks ........................................... 230

6 CYCLIC MICROPLASTICITY ............................................ 234

6.1 CRITICAL STRAIN AMPLITUDES AND INTENSITY OF

CHANGES OF CHARACTERISTICS..................................... 237

6.1.1 Physical nature of the critical strain amplitude............................. 239

6.1.2 Methods of evaluating critical amplitudes .................................... 245

6.2 CYCLIC MICROPLASTIC RESPONSE OF MATERIALS .. 248

6.2.1 Dislocation density and the activation volume of microplasticity. 248

ix

6.2.2 Condensation temperature of the atmospheres of solute elements 257

6.2.3 Deformation history ............................................................................... 262

6.2.4 Cyclic strain curve ........................................................................ 267

6.2.5 Temperature and cyclic microplasticity ........................................ 276

6.2.6 Magnetic field and microplasticity parameters ............................. 282

6.2.7 Saturation of cyclic microplasticity .............................................. 290

6.3 FATIGUE DAMAGE CUMULATION ..................................... 297

6.3.1 Hypothesis on relationship of Q

1

and

a

N

f

dependences ... 297

6.3.2 Deformation and energy criterion of fatigue life ........................... 300

6.3.3 Effect of loading frequency on fatigue limit ................................. 311

References ................................................................................................... 315

Index ...................................................................................................... 325

x

xi

A - coefficient of anisotropy

A

p

- approximate coefficient of anisotropy

a - lattice spacing

B - proportionality coefficient

BHR - Blair, Hutchins and Rogers model

b - Burgers vector

b - fatigue life coefficient

c - fatigue life exponent

c

ikmn

- elasticity constant

c

m

- average concentration

c

0

- initial concentration

c

p

- heat capacity at constant pressure

D - diffusion coefficient

D

, D

||

- diffusion coefficient normal and parallel to the dis-

location

d

z

- grain size

E - modulus of elasticity (Young modulus) in tension or

compression

E

D

- dynamic modulus of elasticity (Young modulus)

E

N

- non-relaxed modulus of elasticity

E

R

- relaxed modulus of elasticity

E

S

- modulus of elasticity

E

ef

- effective modulus of elasticity

E/E - defect of modulus of elasticity (Young modulus)

e - temperature coefficient of the change of the modulus

of elasticity

F - coefficient of the shape of the hysteresis loop

F

, F

||

- force acting normal and parallel in relation to the

dislocation

FR - Finkelstein-Rozin relaxation

G - shear modulus of elasticity

G - difference of moduli of elasticity

H - activation enthalpy

h - Plancks constant

I - magnetization current

i - interstitial atom

K - bulk modulus of elasticity

K

S

- mean capaci t y of absorpt i on of energy i n t he

microvolume

k - Boltzmanns constant

k

I

- coefficient of magnetomechanical bond

L

ef

- effective length of the dislocation segment

L

n

- length of the pinned dislocation segment

SYMBOLS

xii

L

p

- spacing of pinning points

M - ratio of the extent of internal friction and the defect

of the modulus of elasticity

N

f

- number of cycles to fracture

n - coefficient of cyclic strain hardening

n

o

- density of geometrical inflections

P - pressure

Q

c

- activation energy for creep

Q

1

- internal friction

Q

1

S

- height of Snoeks peak

Q

1

SK

- height of Snoek and Kster peak

Q

1

m

- internal friction slightly depending on

Q

1

o

- internal friction independent of , the so-called

background

Q

1

p

- internal friction strongly dependent on , so-called

plastic friction

Q

1

t

- internal friction strongly dependent on loading time

R - degree of dynamic relaxation

R

e

- yield stress

R

m

- ultimate tensile strength

SK - Snoek and Kster relaxation

S - entropy difference

s - substitutional atom

s

mnik

- elasticity constant

ss - designation of a pair of substitutional atoms

T - oscillation period

TF - thermal fluctuation relaxation

T

h

- homologous temperature

T

p

- ductile to brittle transition temperature

T

t

- melting point

t - time

V - volume

V

+

- activation volume

v - vacancy

v

d

- dislocation velocity

v

l

- velocity of the longitudinal wave

v

t

- velocity of the transverse wave

W - total energy supplied to the system

W

t

- energy consumed by material up to fracture

W

k

- half energy of the formation of a double kink

W - energy scattered in the material during a cycle

Z

1

, Z

2

- total power of the exciter and power required to

overcome resistance in the exciter

- coefficient of intensity of damping

- widening of the peak of internal friction

- thermal conductivity coefficient

xiii

kr1

- first critical strain amplitude

kr2

- second critical strain amplitude

- logarithmic decrement of damping

ac

- total strain amplitude

ap

- plastic strain amplitude

c

- total strain

d

- additional strain

e

- elastic strain

i

- fatigue ductility coefficient

mn

- strain tensor

kr1

- first critical strain amplitude

kr2

- second critical strain amplitude

kr3

- third critical strain amplitude

p

- plastic strain

t

- strain at crack formation

d

- rate of change of additional strain

D

- Debye temperature

E

- Einstein temperature

- coefficient of proportionality

1

,

2

- parameters of the ellipsoid of deformation

- Poisson number

- Debye frequency

- specific density

a

- density of active dislocation sources

d

- dislocation density

n

- density of stationary dislocations

p

- density of mobile dislocations

- normal stress

a

- stress amplitude

C

- fatigue limit

f

- fatigue strength coefficient

ik

- stress tensor

K

- physical yield limit

- shear stress

r

- relaxation time

- relaxation time at constant strain

- phase shift

o

- angle of deflection of the pendulum

- relative amount of scattered energy

- circular frequency

- half width of the resonance peak at half its

height

xiv

1

Nature and Mechanisms of Anelasticity

1

AIMS OF INTERNAL FRICTION

MEASUREMENTS

The elasticity characteristics belong in the group of the important

parameters of solids because they are often used in the analytical

solution of the problems of deformation and failure. The elasticity

values are used in all engineering calculations and the design of

components, sections and whole structures. In the development and

application of specific materials and high-strength components pro-

duced from them, it is necessary to consider the required rigidity

and also the probability that a certain amount of energy will build

up in the system during service. Actual solids are characterised by

the scattering of mechanical energy in them, i.e. internal friction.

This representation of the anelasticity of materials and their tran-

sition from elastic to anelastic, microplastic or even plastic response

to external loading are the consequences of the effects of external

loading and the activity of various mechanisms and sources of scat-

tering of mechanical energy in the material which may be charac-

t eri sed by rel axat i on, di sl ocat i onal , mechani cal and magnet o-

mechanical hysteresis. These mechanisms result in changes of the

structure-sensitive properties of materials and also the structure-

sensitive component of the Young modulus which is still regarded

erroneously in a number of publications as a material constant. The

external factors, such as mechanical loading, temperature, the effect

of the magnetic field, different frequency of the changes of loading,

etc., lead to changes of the nature and mechanisms of the processes

of scattering of mechanical energy in materials. The relationships

between the changes of internal friction and the defect of the Young

modulus with changes taking place in the material on the atomic

level, on the level of a group of grains, in the volume of the loaded

solid or in a group of solids, have already been confirmed and veri-

fied.

2

Internal Friction of Materials

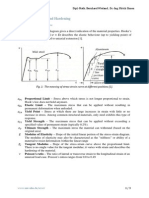

The author of the book has developed an original system, Fig.

1.1, which, using the currently available data, shows the possibili-

ties of the application of internal friction measurements in differ-

ent sciences, from the atomic size up to entire structural complexes.

The effect of the external factors on the occurrence of threshold

F FF FFig ig ig ig ig.1.1 .1.1 .1.1 .1.1 .1.1

Internal

friction

Solid state

physics

Damage

Threshold

state

of materials

Vibroacoustics

of system

solid solutions

diffusion

thermal activ. param.

phase transformations

point defects

dislocation structure

grain boundaries

strain

thermal

cyclic loading

radiation

hydrogen

damping capacity

Young's modulus

micromechanical

characteristics

relaxation

additional loading

creep

cracking resistance

quality of system

noise in system

amplitude-frequency

spectrum of system

structural damping

aerodynamic damping

flaw inspection

vibrothermography

vibrotechnologies

3

Nature and Mechanisms of Anelasticity

states of materials and components [1] is associated with continu-

ous changes of the response of the material to their effect. This is

reflected in changes of internal friction [2]. After compiling and

verifying a physical model explaining the nature of changes of in-

ternal friction with the changes of the external factor it is possible

to conclude that the internal friction measurements can be used as

an indirect method of the monitoring of processes taking place in

solids. The evaluation and quantification of the dynamics of changes

in solid solutions, during diffusion and phase transformations, are

often associated with the determination of the parameters of ther-

mal activation, with the data on the point, line and area defects of

the crystal lattice taken into account.

The changes of temperature, static and cyclic deformation, and

also radiation or the presence of hydrogen in the material are re-

flected in the degradation of the characteristics of the material as

a result of damage cumulation. Accurate measurements of internal

friction enable indirect quantification of this phenomenon.

When evaluating the threshold state of materials and structures,

it is also essential to quantify the damping capacity, the defect of

the Young modulus, microplastic characteristics, relaxation and

additional elasticity phenomena, etc. these processes are also accom-

panied by changes of internal friction so that the internal friction

measurements can be used for examining the process and critical

characteristics of specific materials.

Vibroacoustic examination of a structure or machine under dif-

ferent service conditions, by evaluation of the acoustic quality, noise

and amplitudefrequency spectrum makes it possible to propose

measures for ensuring high reliability and safety of operation of the

system, especially under resonance conditions. Design or aerody-

namic damping of components, sections of the entire structure may

be utilised here.

The efficient selection of materials with the required damping ca-

pacity improves the functional behaviour and reliability of opera-

tion of the machine and decreases the ecological damage from vi-

brations and noise of machines. In technical practice, flaw inspec-

tion methods are used on a wide scale, but the possibilities of these

methods have not as yet been exhausted. Vibrothermography is not

yet used widely as a method for identification of the areas of pref-

erential absorption and scattering of energy in a real solid. However,

it represents a significant tool in the solution of problems of stress-

strain heterogenities and concentrators in the solids, with one of the

internal friction mechanisms playing the dominant role. Vibro-tech-

Aims of Internal Friction Measurements

4

Internal Friction of Materials

nologies are gradually introduced into various production and trans-

port applications where the level of internal friction in certain com-

ponents may be very low whereas in others it may be high, depend-

ing on the system utilising vibrotechnology.

Taking the actual scale of this subject, in this book, special at-

tention is given only to some selected problems, associated mainly

with physical metallurgy and threshold states.

5

Nature and Mechanisms of Anelasticity

2

NATURE AND MECHANISMS OF

ANELASTICITY

The solution of a set of problems associated with the nature, meas-

urements, evaluation and application of information on the internal

friction and the defect of the Young modulus of materials is based

on a brief and functional characterisation of the elasticity param-

eters of structural monoliths and composite materials, and also on

the evaluation of the effect of different internal and external factors

on their magnitude. A special position is occupied by the effect of

factors causing nonlinearity between stress and strain, i.e. anelastic

behaviour of the materials. This includes the explanation of the phe-

nomenon of deformation lagging behind stress, irreversible scattering

of energy in materials and mechanisms by which the energy of vi-

brations is irreversibly scattered in the materials. These processes

are also reflected in the level of the Young modulus and the occur-

rence of defects of the Young modulus, and this may influence the

accuracy of calculations of permitted stresses in components or

whole structures.

2.1 ELASTICITY CHARACTERISTICS

Under the effect of a generally oriented force the solid can change

its dimensions and shape. If the relative strain in a specific direc-

tion is denoted by the strain sensor mn and the force per unit cross-

section, causing this strain, is denoted as the stress sensor ik, then

s e

ik ikmn mn

c = , (2.1)

e s

mn mnik ik

s = , (2.2)

where c

ikmn

and s

nmik

are the elasticity constants. Strain tensor

mn

6

Internal Friction of Materials

and stress tensor

ik

are the tensors of the second order. They can

be described by nine pairs of strain components or nine pairs of

stress components, and the unit volume is selected sufficiently small

to ensure that the strain of stress unit is the same everywhere.

Three pairs of components act in the direction of the x axis, i.e.

xx

in the direction normal to the wall of the cube; these pairs are

oriented normal to the x axis. They include the normal stress which

is positive for tension and negative for compression. The second

pair of the components in the direction of the x axis acts on the

walls oriented normal to the y axis. This pair is denoted

xy

and

yx

.

The third pair of the components in the direction of the x axis acts

on the walls normal to the z axis. This pair is denoted

xz

and

zx

.

The second and third pair act in the given planes and tend to shift

them mutually. They are denoted as tangential or shear stress. Since

the elementary volume of the material does not rotate, the compo-

nents must be in equilibrium, i.e.

xz

=

zx

, and they are denoted

xz

,

and also

xy

=

yz

, denoted

xy

. Consequently, this gives a symmet-

ric tensor of the second order with six components

s

s t t

t s t

t t s

ik

xx xy xz

xy yy yz

xz yz zz

= .

(2.3)

Every symmetric tensor of the second order has three main axes.

Since the axes of the coordinates are regarded as synonymous with

the axes of the tensor, only the main stress

1

is obtained.

For an anisotropic medium, equation (2.1) can be expanded into

a system of linear equations, i.e. for stresses

xx

,

yy

,

zz

,

yz

,

xy

,

strains

xx

,

yy

,

zz

,

yx

,

zx

and

xy

, using the elasticity constants c

ikmn

,

as given for the first of six rows in the form

s e e e g g g

xx xx yy zz yz zx xy

c c c c c c = + + + + +

11 12 13 14 15 16

, (2.4)

where is shear.

Similarly, equation (2.2) can be expanded utilising the elasticity

constants s

mnik

, as given for the first of the six rows

e s s s t t t

xx xx yy zz yz zx xy

c s s s s s = + + + + +

11 12 13 14 15 16

. (2.5)

7

Nature and Mechanisms of Anelasticity

Generally, the elasticity constant c

ikmn

(and also s

mnik

) has the

form of a tensor with 39 components, where the first of the 6 rows

is c

11

, c

12

, c

13

, c

14

, c

15

, c

16

(or s

11

, s

12

, s

13

, s

14

, s

15

, s

16

).

Proportionality is found between the elasticity constants c

12

= c

21

or s

11

= s

21

and, generally, c

= c

, or s

= s

. As a result of this

symmetry, the crystallographic system with the lowest symmetry

(triclinic) has only 21 independent components, and the number of

independent components in the orthorhombic system decreases to 9,

in the tetragonal and diagonal systems it decreases to 6, and in the

hexagonal system to 5.

For cubic crystals there are three elasticity constants, c

11

, c

12

and

c

44

. The elasticity constants c

ikmn

and s

nmik

are linked by the defined

relationships [3].

The physically determined elasticity constants for technical ap-

plications are complicated. For crystallographic systems with the

symmetry higher than orthorhombic, the normal tensile stress in the

direction of the x axis (

xx

) results in relative elongation

xx

and two

reduction in areas

yy

and

zz

:

e

s

e m e e m e

xx

xx

yy xx zz xx

E

= =- = -

1

12 13

, , .

(2.6)

If we consider the normal stress in the direction of the y and z axes,

we obtain three moduli in tension (Young modulus) and six Poisson

numbers, of which only three are mutually independent, because

E E E E E E

1

12

2

12

2

23

3

32

3

31

1

13

m m m m m m

= = = , , .

(2.7)

Shear stress

yz

in the yz plane causes shearing

yz

. Consequently,

yz

= G

1

yz

. Similarly, in the xz plane, where

xz

= G

2

xz

and in the

xy plane, where

xy

= G

3

xy

.

The orthorhombic crystal in the system of the technical elastic-

ity moduli has only nine independent elasticity characteristics, i.e.

three tensile (Young) moduli E, three shear (Coulomb) moduli g, and

three Poisson numbers . For the cubic crystal, these are three char-

acteristics (E, G, ), and for an isotropic solid it is E, G, because

G

E

=

+ 2 1 m a f

.

(2.8)

8

Internal Friction of Materials

Equation (2.8) is also important because polycrystalline metals and

alloys without a sharp texture behave as isotropic materials.

The bulk Young modulus K is defined as isotropic pressure P

divided by the relative volume change caused by this pressure

K

P

V

V

E

=

-

=

-

D

3 1 2m a f

.

(2.9)

The values of the elasticity moduli (E, G), the bulk Young modu-

l us (K) and Poi sson number () for a number of met al s are

presented in Table 2. 1. For rock and glass = 0. 25, G = 0. 4E,

K = 2/3E, for metals = 0.33, G = 3/8E, K = E, and for elastomers

= 0.5, G = 1/3E, and the K/E ratio is high.

The Young modulus is closely linked with the velocity of propa-

gation of sound in a metallic material. In the case of a longitudi-

nal elastic wave, the velocity of propagation is

n

r

l

E

=

(2.10)

and in propagation of a transverse elastic wave, the velocity of

propagation is

n

r

t

G

= ,

(2.11)

where is the specific density of the metallic material [4].

This phenomenon is utilised in accurate measurements of E and

G, because measurements are taken without exchange of heat with

the environment which enables also the determination of adiabatic

elasticity moduli which differ from the elasticity moduli obtained

under isothermal conditions (for example, in the tensile test). Table

2.1 gives values of v

1

and v

t

for several metals.

The values of the elasticity constant make it possible to deter-

mine accurately the anisotropic factor of the elastic properties of

metallic materials from the equation

9

Nature and Mechanisms of Anelasticity

T TT TTa aa aab bb bble 2.1 le 2.1 le 2.1 le 2.1 le 2.1 Elasticity moduli and other characteristics of several metals at 20C

f o e p y T

l a t e m

E

) a P G (

G

) a P G (

K

) a P G (

V

l

s m (

1

)

V

t

s m (

1

)

*

l A

a C

i N

u C

d P

g A

r I

t P

u A

b P

8 . 0 7

6 . 9 1

2 . 1 3 2

3 . 5 4 1

7 . 2 4 1

1 . 1 8

0 . 8 2 5

9 . 9 6 1

1 . 8 8

3 . 7 3

3 . 6 2

4 . 7

1 . 9 8

8 . 4 5

8 . 1 5

6 . 9 2

0 . 4 1 2

0 . 1 6

1 . 1 3

6 . 3 1

4 3 . 0

1 3 . 0

1 3 . 0

5 3 . 0

9 3 . 0

8 3 . 0

6 2 . 0

4 4 . 0

2 4 . 0

4 4 . 0

5 . 7 7

2 . 7 1

0 . 0 9 1

6 . 9 3 1

1 . 2 9 1

6 . 3 0 1

0 . 0 7 3

7 . 2 7 2

4 . 5 7 1

8 . 8 4

5 5 3 6

4 9 8 5

6 2 7 4

4 9 5 4

6 8 6 3

1 6 3 3

8 5 1 2

6 2 1 3

9 1 2 3

8 9 2 2

7 8 9 1

7 7 6 1

9 3 2 1

0 6 8

* *

i L

a N

K

V

r C

e F

b R

b N

o M

a T

5 . 0 1

2 . 7

6 . 4

2 . 1 3 1

7 . 9 7 2

2 . 3 2 2

3 . 1

0 . 7 0 1

0 . 0 3 3

0 . 0 9 1

7 . 3 9 3

0 . 4

7 . 2

7 . 1

3 . 8 4

0 . 2 0 1

9 . 6 8

7 4 . 0

2 . 9 3

7 . 9 1 1

1 . 1 7

0 . 3 5 1

6 3 . 0

2 3 . 0

5 3 . 0

6 3 . 0

8 2 . 0

9 3 . 0

0 3 . 0

5 3 . 0

9 2 . 0

8 . 1 1

3 . 8

0 . 4

3 . 4 5 1

5 . 6 9 1

1 . 3 7 1

0 . 9 5 1

5 . 2 8 2

3 . 4 9 1

1 . 8 0 3

9 0 7 5

8 7 0 3

0 0 0 6

4 6 0 6

4 0 1 5

9 4 6 6

7 4 4 4

9 1 3 5

1 2 8 2

4 3 4 1

0 8 7 2

5 2 3 3

9 8 0 2

2 1 5 3

9 3 0 2

3 4 8 2

* * *

g M

i T

o C

d C

8 . 4 4

4 . 4 1 1

9 . 0 2 2

5 . 5 6

6 . 7 1

3 . 3 4

5 . 4 8

6 . 4 2

8 2 . 0

6 3 . 0

2 3 . 0

0 3 . 0

5 . 4 3

2 . 7 0 1

3 . 0 9 1

2 . 2 6

5 9 8 5

3 6 2 6

7 2 8 5

0 3 1 3

6 7 2 3

2 2 9 2

9 4 0 3

3 6 6 1

* * * *

n I

n S

9 . 3 1

1 . 0 6

8 . 4

6 . 3 2

6 4 . 0

3 3 . 0

6 . 1 4

6 . 0 6

9 5 4 2

0 0 3 3

9 0 7

9 4 6 1

Comment: * - cubic face centred; ** - cubic body centred; *** - hexagonal closed-

packed; **** tetragonal

A

c

c c

=

-

2

44

11 12

,

(2.12)

where for an isotropic case A = 1. For some metals, the dependence

of the mechanical properties on the loading direction is shown in

Fig. 2.1.

10

Internal Friction of Materials

The approximate coefficient of anisotropy of the elastic proper-

ties can be determined as the ratio of the maximum and minimum

values of the elasticity moduli. Table 2.2 gives the accurate (A) and

also approximate (A

p

) anisotropy coefficients of the elastic proper-

ties of some metals.

If E

max

(= E

111

) and E

min

(= E

100

) are available, it is possible to

determine E in the direction characterised by the angles , , to

the axes of the cube using the Weerts equation in the form

1

3

1 1

100 111

2 2 2 2 2 2

E E E

= -

F

H

G

I

K

J

+ + cos cos cos cos cos cos . a b b g g a

c h

(2.13)

The equation can also be used for polycrystalline materials with a

texture, if the latter is expressed by two or more ideal orientations.

F FF FFig ig ig ig ig.2.1. .2.1. .2.1. .2.1. .2.1. Directions of true stress at fracture of aluminium single crystal (a), elongation

of aluminium single crystal (b), Young modulus of aluminium single crystal (c),

Young modulus of iron single crystal (d), shear modulus of elasticity of iron single

crystal (e) and Young modulus of magnesium single crystal in tension (f).

T TT TTa aa aab bb bble 2.2 le 2.2 le 2.2 le 2.2 le 2.2 Approximate (A

p

) and accurate (A) anisotropy coefficients of elastic properties

f o e p y T

l a t e m

E

x a m

n i

n o i t c e r i d

> 1 1 1 <

) a P G (

E

n i m

n i

n o i t c e r i d

> 0 0 1 <

) a P G (

A

p

G

x a m

n i

n o i t c e r i d

> 0 0 1 <

) a P G (

G

n i m

n i

n o i t c e r i d

> 1 1 1 <

) a P G (

A

p

A

p

l A

u C

e F

W

7 . 7

4 . 9 1

0 . 9 2

0 . 0 4

4 . 6

8 . 6

5 . 3 1

0 . 0 4

5 7 1 . 1

0 7 8 . 2

0 5 1 . 2

0 0 0 . 1

9 . 2

7 . 7

8 . 1 1

5 . 5 1

5 . 2

1 . 3

1 . 6

5 . 5 1

3 1 . 1

0 5 . 2

3 9 . 1

0 0 . 1

2 . 1

3 . 3

4 . 2

0 . 1

11

Nature and Mechanisms of Anelasticity

The elasticity moduli are associated with the characteristics de-

termined by the force influence of interaction of the atoms in the

crystal lattice linked with the thermal expansion coefficient, Debye

temperature, sublimation temperature, melting point, etc. These con-

siderations show that the elasticity moduli can be determined ap-

proximately, with an acceptable correlation factor, using the meas-

ured values of these characteristics.

The relationship between the Young modulus E (or G) and the

melting point of metal T

m

has the form

T k A E

t

=

1

,

(2.14)

where k

1

= 5K in determination of E, and k

1

= 8.5K in determina-

tion of G, where K is the bulk Young modulus, and A is the pro-

portionality coefficient.

The relationship between the Young modulus, the volume coeffi-

cient of thermal expansion and the relative molar heat capacity

at constant pressure c

p

is determined by the equation

K

c

V

p

a

=

g

b

0

,

(2.15)

where

0

is a constant and V

a

is the molar volume. At room tempera-

ture and elevated temperatures T, the approximate validity of the

following equation has been confirmed

E

c

V

T

T

p

a

t

ln ,

(2.16)

The Poisson number and constant

0

are linked by the equation

m

g h

g h

=

-

+

2

3

0

0

,

(2.17)

where = 1.5 for fcc metals, and = 0.945 for bcc metals.

Debye temperature

D

is linked with the Young modulus by the

equation

12

Internal Friction of Materials

Q

D

E

A

F

H

G

I

K

J

168

2

1

2

1 6

r

/

,

(2.18)

where is specific density, and A

1

is atomic density.

The elasticity moduli can also be determined from accurately re-

corded results of tensile or torsion tests. However, the most accu-

rate data are obtained by measuring the velocity of propagation of

elastic waves v

1

or v

t

(equations 2.10 and 2.11).

The resonance methods are effective and accurate (error 0.5-

0.8%) in the determination of the elasticity moduli. However, it

should be noted that the natural frequency of the longitudinal vibra-

tions is an order of magnitude higher than the natural frequency of

the bending vibrations. Increase of the loading frequency increases

the intensity of relaxation processes. This is reflected in an increase

of temperature and the associated decrease of the Young modulus.

This results in a systematic error in the measurement of the elas-

ticity moduli by the resonance method. This shortcoming can be

eliminated using the pulsed methods of Young modulus measure-

ments. These methods are based on the measurement of the veloc-

ity of propagation of a pulsed elastic wave in metal, and the wave-

length is small in comparison with the dimensions of the solid.

The Poisson number can be determined from X-ray diffraction

measurements of the lattice parameters of the metallic material.

The accuracy of the pulsed methods of measurement of the Young

modulus is high (error is approximately 0. 1%). However, these

methods also have certain shortcomings. The most important prob-

lem is the fact that when measuring the velocity of propagation of

a pulsed wave it is necessary to measure the Poisson number at a

specific moment of time. Procedural problems do not enable meas-

urements of the Young modulus to be taken at higher temperatures.

The tabulated data on the elasticity moduli of metals and alloys

are limited because they represent the characteristics at room tem-

perature and do not describe the initial state of the material or its

thermal-deformation history. This shortcoming is partially eliminated

by a set of data [5] which contains the elasticity moduli for a large

number of metals and alloys at elevated temperatures.

The elasticity constants and also technical elasticity moduli are

influenced by a large number of external and internal factors.

13

Nature and Mechanisms of Anelasticity

2.1.1 Effect on elasticity characteristics

The effect of temperature on the elasticity characteristics is asso-

ciated with the thermal expansion of the material, i.e. with the tem-

perature dependence of the atomic spacing. Analysis of this prob-

lem has shown that the change of the elasticity moduli is not asso-

ciated with absolute temperature, but is linked with homologous

temperature T

h

= T/T

m

, where T is the temperature at which the

Young modulus is determined.

For the same homologous temperatures, the relative change of the

elasticity characteristics for many metals is the same (Fig. 2.2).

This relationship is linked with the identical homologous tempera-

ture dependence of the change of atomic spacings.

Increase of temperature results in a decrease of E, G and K. The

value of the Poisson number initially slowly decreases and then in-

creases with a further increase of temperature; because of the dif-

ferent thermal strain history of the material, the dependence is more

complicated.

Decrease of temperature, like increase of pressure, results in the

same change of the atomic spacing in the crystal lattice. This shows

that the change of the Young modulus will be similar. The change

of bulk Young modulus K at absolute temperature from 0 to T is de-

scribed by the equation

DK

K

g T

0

3

=

b

,

(2.19)

T

h

E

/

E

0

F FF FFig ig ig ig ig.2.2. .2.2. .2.2. .2.2. .2.2. Dependence of relative values of the Young modulus of various metals on

homologous temperature, where E

0

is the Young modulus at 0 K.

14

Internal Friction of Materials

where

g

K

K

=

1

0

d

de

(2.20)

is the change of the Young modulus during deformation of the lat-

tice by the value , K

0

is the bulk Young modulus at 0 K. Modu-

lus K is proportional to the curvature of the relief of the potential

energy of the crystal lattice in the area with the atom.

Depending on the distance of the atom from the equilibrium po-

sition, the curvature of the potential relief decreases as a result of

increase of . This shows that g < 0, and the value of the modu-

lus decreases with increasing temperature. Consequently

0

0 0

.

3

p

a

gc T

K

K V K

(2.21)

Equation (2.21) shows that the resultant value is strongly influ-

enced by the value of c

p

. As in the case of equation (2.21), it is

possible to write similar equations for the change of E or G. Like

the temperature dependence of the heat capacity at constant pres-

sure, the temperature dependence of the elasticity moduli can be

divided into three ranges: low-temperature range, where T <<

D

,

transition range, where

D

T 0.5T

t

, and high-temperature range,

where T > 0.5T

t

.

In the low-temperature range, the coefficient of the effect of tem-

perature on the change of the modulus e is proportional to t

0

g c

p

,

and also proportional to (T/

D

)

3

. In the entire temperature range the

dependence of the Young modulus on temperature has the shape K/

K

0

~ T

4

.

Two cases can occur in the transition temperature range. If the

Debye temperature for a specific metal or alloy is significantly

lower than 0.5T

t

, then c

p

3R, where R is the gas constant, and

e = const. This shows that the modulus of elasticity increases pro-

portionately with increasing temperature. When

D

is close to 0 or

higher than 0.5T

t

, the value of c

p

increases with increasing tempera-

ture and the dependence is domed in the upward direction. The in-

crease of temperature by one degree results in a decrease of the

Young modulus by 0.020.04%, with the approximation sufficient

for a wide range of the materials.

15

Nature and Mechanisms of Anelasticity

The selection of experimental dependences is very important; it

is necessary to ensure that they describe with sufficient accuracy the

changes of the elasticity moduli of the materials. For example, in

Ref. 6, the temperature dependences of the Young modulus for VSt3

steel in the form E = (21.68 6710

4

T)10

4

MPa, where T is in

C, were verified for the temperature range from 70 to +70C.

For metals with high melting points, for temperatures of up to

2000C, the authors of Ref. 7 published the empirical dependences:

for vanadi um i n t he form E = (12. 8 9. 6110

4

T)10

4

or G =

(4. 88 8. 48 10

4

T)10

4

, for niobium E = (10 + 9. 1810

4

T -

4.1110

7

T

2

)10

4

or G = (3.12 + 9.910

5

T )10

4

, and for tantalum

E = (16. 98. 2210

4

T1. 6610

7

T

2

)10

4

or G = (7. 741. 73

10

4

T)10

4

, always in MPa.

For tungsten, we can use the equations in the form E = E

0

[(T

t

-

T)1/T

t

]

0.4

, or G = G

0

[(T

t

T)1/T

t

]

0.263

, E = E

0

[(T

t

T)1/T

t

]

0.463

, G =

G

0

[(T

t

T)1/T

t

]

0.465

, where E

0

and G

0

are the moduli at 0 K.

On the basis of analysis of the elastic characteristics of 40 al-

loys based on Fe, Ni, Cu and Al in the temperature range below

500 K, it was shown [8] that, with the exception of Invar alloys,

the temperature dependence of the Young modulus is described quite

accurately by the following equation

0

,

1

E

T

E E

e

(2.22)

here

E

is the Einstein temperature, /

E

is the limiting value of

the tangent dE/dT to the E(T) dependence.

At elevated temperatures, above 0.5T

m

, the rate of decrease of the

Young modulus rapidly increases, and the temperature at which the

rapid decrease of the modulus starts is close to or identical with the

temperature of the start of increase of the high-temperature back-

ground of internal friction.

There are several hypotheses explaining the rapid decrease of the

Young modulus in the high-temperature range. This may be caused

by the nonlinear dependence of atomic forces on additional thermal

strain. Some hypotheses are based on the assumption according to

which this behaviour is the consequence of deformation due to dis-

location movement. The hypotheses are supported by the assumption

according to which the mobility of dislocations increases with in-

creasing temperature. This is reflected in an increase of the contri-

16

Internal Friction of Materials

bution of dislocational anelasticity.

The elasticity moduli also decrease with increasing internal fric-

tion. Measurements of the temperature dependence of the elasticity

moduli in the temperature range (0.50.7) T

m

show that the activa-

tion energy of the change of the elasticity moduli is close to the ac-

tivation energy for self-diffusion [9] which is close to the activa-

tion energy of the relaxation process at the grain boundaries in poly-

crystalline materials. In the temperature range close to the melting

point (0.950.97) T

m

the Young modulus changes as a result of the

temperature maximum on the temperature dependence of internal

friction. Measurements of the Young modulus of Sn, Bi, Cd and Pb

up to the melting point showed that in the vicinity of the melting

point the Young modulus rapidly decreases, and a slight increase of

the Young modulus is recorded only in the case of Sn at tempera-

tures higher than 0.98T

m

[10]. This phenomenon was also reflected

in the arrest of the decrease of the Young modulus of specimens of

sintered iron with a tin filler in the vicinity of the melting point of

Sn.

Acceleration of decrease of the Young modulus with increasing

temperature is also caused by relaxation processes taking place in

the process of gradual increase of external stress.

In the forties, Frenkel showed that a metal starts to melt when

the Young modulus is 0. Theoretical calculation showed that the

Young modulus at the melting point is 0.70.75 of the modulus at

0 K. The experimental dependences and also Fig. 2.2 show that with

increase of temperature up to the melting point the Young modulus

decreases by 4060%. The difference between the theoretical calcu-

lations and the results of measurements confirms the effect of high-

temperature relaxation.

The form of the temperature dependence of the Young modulus

at high temperatures may have a significant effect on the activation

energy of creep [11]. In steady-state creep, the creep rate is deter-

mined by the equation

2

e

Q

n

RT

A e

&

(2.23)

where A

2

is the proportionality constant, is the acting stress, n is

the strain hardening coefficient, Q

c

is the activation energy for

creep, and R is the gas constant. If we take into account the tem-

perature dependence of the Young modulus, the equation has the

17

Nature and Mechanisms of Anelasticity

following form

( )

*

3

,

e

n

Q

RT

A e

E T

, ]

, ]

, ]

]

&

(2.24)

where A

3

is the proportionality constant and Q

c

is the modified ac-

tivation energy of creep which can be determined from the equation

( )

*

ln

ln

1 1

c

d E T

Q R nR

d

T T

j \ j \

, ( , (

( , ( ,

&

(2.25)

Consequently

2

*

.

c c c

nRT dE

Q Q Q

E dT

The change of the activation energy of creep may be quite consid-

erable. For example, in the case of Inconel alloy at a temperature

of 704C, Q

*

c

= 551.7 kJ mol , Q = 80.9 kJ mol, and at 1037C,

Q = 251. 4 kJmol

1

and Q

c

= 59.5 kJmol

1

. This example shows

that in calculations it is important to take into account the infor-

mation on the change of the Young modulus with increasing tem-

perature.

External pressure and internal stress also influence the level of

the Young modulus.

The increase of external pressure P results in increase of the

Young modulus. Up to a pressure of 5 GPa, we can use the follow-

ing dependence

( )

0

1

1 , E E P + (2.26)

where E

0

is the Young modulus at the atmospheric pressure, and the

value

1

varies from 10

1

to 10

2

GPa

1

. Specific values of

1

for

various materials are presented in Ref. 5.

The increase of the Young modulus with increasing hydrostatic

pressure is caused by a decrease of the atomic spacing in the crystal

18

Internal Friction of Materials

lattice. This hypothesis has been verified theoretically and also by

measurements [12].

The dependence of the Young modulus on stress is general not

only for the hydrostatic pressure conditions. The dependence of the

Young modulus on the state of the structure of the hardened mate-

rial, observed in a large number of experiments, is usually inter-

preted from the viewpoint of the magnitude, nature and distribution

of internal stresses in the material [13]. Theoretical calculations of

the dependence of the Young modulus on the microstrain of the crys-

tal lattice a/a were carried out by Levin [14]. The calculated and

experimental results are presented in Fig. 2.3.

Increasing microstrain decreases the Young modulus but the scat-

ter of the measured Young modulus values increases. This is the

result of the scatter of distribution of the internal stresses in the ma-

terial. The results show that the Young moduli of the materials

which contain internal stresses are in fact random quantities for

which it is possible to obtain the corresponding dependence of dis-

persion S

2

on microstrain a/a. In the case of the experimentally

determined change of dispersion moduli S

2

it is necessary to take

into account the dispersion caused by the measuring procedure and

this value characterises the inaccuracy of determination of the elas-

ticity moduli of the metals and alloys.

F FF FFig ig ig ig ig.2.3. .2.3. .2.3. .2.3. .2.3. Dependence of Young modulus on microstrain a/a for heat treated St3

steel.

19

Nature and Mechanisms of Anelasticity

The change of the Young modulus with increasing pressure and

temperature has the same basis, i.e. the change of the atomic spac-

ing, thus yielding the equation

3 ,

C V T

E E E

K

T T P

j \ j \ j \

, ( , ( , (

( , ( , ( ,

(2.27)

where C, V and T indicate that the values are determined at constant

concentration, volume, and temperature, and is the coefficient of

linear thermal expansion [15].

The quantity (E/T)

V

is included in the equation due to the de-

pendence of the elasticity moduli of ferromagnetic materials on the

degree of arrangement of magnetic domains. At temperatures lower

than T

c

(Curie temperature) and for non-ferromagnetic materials,

(E/T)

V

= 0. Consequently

( )

0

0

3 .

T

T T

T

T

E

E E K T dT

P

j \

, (

( ,

(2.28)

For pure iron and binary alloys of iron with cobalt, nickel, chro-

mium and molybdenum at T << T

c

equation (2.28) describes satis-

factorily the experimentally measured values.

The dependence of the Young modulus on the type and severity

of the stress state and, in particular, strain state is of principal im-

portance not only for predicting the changes of the elastic materi-

als in service but also for the development of suitable theoretical

models of the strength and plasticity behaviour of metals and alloys.

The level of the Young modulus is also influenced significantly

by the strain.

The addition of alloying elements to the main metal changes its

elastic characteristics as a result of changes of the interatomic

bonds in the alloys. This takes place in relation to the chemical

interactions between foreign atoms as a result of the change of the

concentration of free electrons (electron factor) or as a result of

the effect of lattice defects and, consequently, lattice parameters,

which is the result of different atomic radii of the added and main

metal (dimensional factor). In reality, these factors can affect the

Young modulus in the same or opposite direction. Experiments show

that the dependence of the change of the Young modulus on the con-

20

Internal Friction of Materials

centration of the alloying element (c) is the result of these factors

acting in the same direction. This result can be expressed by the

equation in the form

ln

3 .

l

T T

E a

E E K c

P c

j \ j \

, ( , (

( , ( ,

(2.29)

where E

e

is the component of the change of the Young modulus as

a result of the change of the number of electrons, a is the lattice

spacing.

The characteristic E

e

has complicated form and depends on

many influences, such as the change of the energy of positive ions

in the electron gas, the change of the degree of overlapping of

electron paths of the adjacent atoms, the zonal structure of the

metal, etc.

The dependence of the Young modulus on the concentration of the

alloying elements is determined by the characteristics of the atoms

of the alloying element and the main metal. Examples for binary

systems with complete solubility of the metals in the solid state are

presented in Fig. 2.4.

For alloys of the metals which do not form intermetallic com-

pounds together, the elasticity moduli are an additive property to a

first approximation. For the majority of non-transitional and some

transitional elements in the range of the mass concentration from 10

to 20% and for CuPt, MoW, CuNi and other alloys, the results

obtained by Kster show that the concentration dependence of the

Young modulus in the entire concentration range is almost linear.

The contribution of the electron factor to the value of the Young

modulus increases with increasing difference of the valency of the

components of the alloying and the main metal (Fig. 2.4a).

In most cases, the elasticity moduli of intermediate phases are

higher than those of pure components. The experimental results ob-

tained for the CuSn and CuZn systems show, Fig. 2.5, that higher

elasticity moduli of the intermetallic phases influence the changes

of the elasticity moduli in a wide concentration range.

Compounds of metals and an intermetallic phase are character-

ised by high elasticity moduli. In the case of carbides, it should not

be assumed that the Young modulus of carbon is E = 0.09 10

5

MPa. It is more accurate to consider the value for diamond, i.e.

E = 1 10

5

MPa. For example, for titanium E = 1.1 10

5

MPa,

and for TiC E = 0. 46 10

5

MPa. For tungsten E = 3. 96 10

5

21

Nature and Mechanisms of Anelasticity

F FF FFig ig ig ig ig.2.4. .2.4. .2.4. .2.4. .2.4. Effect of composition of alloys on their Young modulus.

F FF FFig ig ig ig ig.2.5. .2.5. .2.5. .2.5. .2.5. Change of the Young modulus of CuZn and CuSn in relation to composition

indicating the formation of intermetallic phases.

MPa, and for WC E = 6.7 10

5

MPa. These approaches are of in-

formation nature.

In the systems with superlattices, the magnitude of the Young

modulus depends on the state of the structure, for example, the val-

wt.%

22

Internal Friction of Materials

ues for the disordered state of an alloy are presented in Fig. 2.6.

After the formation of a superlattice, there are significant changes

in relation to the initial condition.

The dependence of the elasticity moduli on the composition of the

al l oyi ng for some t ransi t i onal el ement s i s compl i cat ed becaus

d-electrons take part in the formation of bonds in these metals. Cs,

Ti, Mg and Fe are characterised by unstable electron configurations,

refl ect ed i n al l ot ropi c t ransformat i ons. Ext rema on t he E(c)

dependences may also form when the transitional metal is the main

component (FeAl, TiAl) or it is also an addition (CuTi), or both

(TiMo).

The complicated nature of the changes of binding forces in alloy-

ing of transition metals has so far prevented the construction of a

unified mechanism of the effect of foreign atoms on the elastic

characteristics of the transition metals.

In ferrous alloys, it is possible to evaluate the effect of the elec-

tron factor on the change of the Young modulus in alloying with dif-

ferent elements [14]. The electron factor of the transition metals of

the same period as iron (chromium, vanadium, cobalt, nickel, man-

ganese) is almost 0 and, consequently, all changes of the elasticity

moduli in alloying are associated with the dimensional factor. The

atoms of the transitional elements from higher periods are charac-

F FF FFig ig ig ig ig.2.6. .2.6. .2.6. .2.6. .2.6. Change of the elasticity moduli in relation to the concentration of the solid

solution.

23

Nature and Mechanisms of Anelasticity

terised by non-zero electron factor values. The values of the elec-

tron factor of the elements from the same period (for example, Ru

and Rh or Re, Ir, Pt) are the same and increase with increase of the

number of the period.

The dependence of the Young modulus on composition for iron-

based alloys is complicated (Fig. 2.7 and 2.8). The most significant

changes of the E(c) dependence are recorded at small amounts of the

additions. This phenomenon is associated with the fact that the for-

mation of the solid solutions of the transitional metals is accompa-

nied by an increase of the number of electrons when interaction

takes place between s and d electrons. This increases the Young

modulus. The increase of the concentration of the alloying element

is accompanied by an increase of the strength of the effect of the

dimensional factor which increases the distance between the atoms.

The determination of the changes of the Young modulus and the

accompanying change of the parameters of the crystal lattice with

the change of the composition of the alloy has made it possible to

conclude that, after dissolving in iron, the alloying elements form

additional bonds and the effect becomes stronger with the distance

of the added element from iron in the periodic system of elements.

The temperature dependence of the Young modulus for binary

F FF FFig ig ig ig ig.2.7. .2.7. .2.7. .2.7. .2.7. Dependence of the Young modulus of iron-based alloys on the content of

different additions (molar %).

24

Internal Friction of Materials

F FF FFig ig ig ig ig.2.8. .2.8. .2.8. .2.8. .2.8. Effect of temperature on the dependence of the Young modulus on the temperature

of an FeCr alloy.

alloys is characterised by the temperature coefficient which depends

only slightly on the concentration of the added element. Conse-

quently, the E(T) dependences with increasing content of the alloying

element are almost parallel.

The increase of the carbon content of iron decreases the elasticity

characteristics. In annealed steels, the largest increase of the Young

modulus is recorded at low carbon concentrations (to 0.2 wt.%). In

quenched steels, the E(c) dependence decreases, even though the

increase of the carbon content accelerates the increase of the Young

modulus in comparison with the annealed condition.

The dependence of the elasticity characteristics on composition

in the case of the FeNi system is also influenced by prior tensile

deformation and annealing (Fig. 2.9).

In the steels, carbon is present in most cases in cementite Fe

3

C

and, consequently, the evaluated dependences E(c) are examined

mainly from the viewpoint of the effect of different factors on ce-

mentite. Cementite is a ferromagnetic phase with T

C

210C. Since

Armco iron has a conventional, almost linear dependence E(T), the

dependence for carbon steels at T 200C is characterised by a

small delay which changes to a local maximum with the increase of

the carbon content of the alloy, for example in white cast iron. The

25

Nature and Mechanisms of Anelasticity

form of the previously plotted curves also enables extrapolation of

the changes of the E(T) dependence for cementite.

Examination of the titanium alloys with different iron and alu-

minium content [16] showed higher elasticity moduli and the in-

crease of the Debye temperature with increasing content of the al-

loying elements. If the different electron structures of the Al and Fe

atoms are considered, it may be concluded that aluminium has a

significant effect on the nature of atomic interactions in titanium

alloys. Increase of the aluminium content increases the force char-

acteristics of the atomic bonds; this may be one of the reasons for

the increase of the ultimate tensile strength when alloying titanium

with aluminium from 480 MPa (for example, titanium alloy VT1-

0) up to 1000 MPa (for example, titanium alloy VT5).

Investigations of the elasticity characteristics of alloys of tita-

nium with molybdenum, vanadium and niobium shows that the for-

mation of extrema on the E(c) curves may be attributed to the start

and finish of transformation of the -phase to -phase, and in the

case of the titanium alloys with these elements, the dependences are

quantitatively similar indicating the same nature of the mutual ef-

fect of titanium alloys with these elements. The additions decrease

the elasticity moduli of the alloys with the -phase and also with

F FF FFig ig ig ig ig.2.9 .2.9 .2.9 .2.9 .2.9. Dependence of the Young modulus and Poisson number on the composition

of ferrous and nickel alloys after cold tensile deformation (symbol 1) and after annealing

(symbol 2).

wt.%

26

Internal Friction of Materials

F FF FFig ig ig ig ig.2.10. .2.10. .2.10. .2.10. .2.10. Dependence of the Young modulus of alloys of Ti with Mo (a) and with

V (b) after rapid cooling (1) and tempering (2).

+ phases. Transition to the single-phase region () is associ-

ated with the minimum on the E(c) dependence. Alloying of the

single-phase () solid solutions results in a monotonic increase of

the elasticity moduli up to the values typical of the pure compo-

nents.

Figure 2.10 shows that -Ti is characterised by higher values of

the Young modulus in comparison with -Ti. Differences are also

evident in alloying. Whilst in the case of -Ti the Young modulus

decreases, in the case of -Ti the Young modulus increases with in-

creasing concentration of the additions.

Rapid cooling of the alloy greatly changes the dependence of the

Young modulus on concentration, Fig. 2.10. The rapid decrease of

the Young modulus in the range of low concentration is associated

with the formation of supersaturated - and -solid solutions. In

the case of the TiMo alloy this takes place up to 6 wt.% Mo. The

subsequent increase of the E(c) dependence is caused by the forma-

tion of the martensitic phase which formed as a result of the

transformation of to . The maximum of the E(c) dependence

corresponds to the highest volume content of the -phase. The sec-

ond minimum of the E(c) dependence can be explained by the in-

crease of the content of the -phase. This results in an increase of

wt.% Mo wt.% V

27

Nature and Mechanisms of Anelasticity

the volume fraction of the metastable cubic volume-centred struc-

ture with less dense packing and, consequently, in a decrease of the

Young modulus. In the region where there is only the -phase, the

increase of the Young modulus takes place as a result of the in-

crease of the strength of the effect of alloying elements on the

change of the interatomic forces. In the region of the single-phase

-alloys there are no significant differences in the values of the

elasticity moduli for the annealed and quenched condition.

The differences in the elasticity moduli are characterised by dif-

ferent sensitivity to the composition of the alloy. In the TiZn al-

loy, the E(c) dependence is represented by a smooth curve with the

mi ni mum at c = 50 wt . %. In t hi s range, K and change non-

monotonically in relation to composition.

In alloys where the components form a mechanical mixture, spe-

cifically AlBe, AlSi, BiSn, FeFe

3

C, etc., the dependence of the

Young modulus on composition is linear. The Young modulus also

depends on the distribution of the inclusions which is reflected in

the upper and lower boundary of the elasticity moduli of the me-

chani cal mi xt ures. Cal cul at i ons show t hat at concent rat i ons

c < 40 wt.%, the elasticity moduli are the additive characteristics

of the phases present. At a large amount of the second phase in the

alloy, the calculated and measured values of the elasticity moduli

differ.

Ordering in the alloys also influences the elasticity moduli be-

cause the effect of the electron factor is very strong. Ordering in-

creases the interatomic forces, the electron factor has the positive

orientation and increases the level of the Young modulus. The de-

pendence of t he Young modul us on t emperat ure i n ordered

alloys at temperatures below Kurnakov temperature T

k

is character-

ised by a constant value of the temperature factor of the change of

the Young modulus e. With the increase of temperature to the range

T T

k

, the dependence E(T) shows an anomaly in the form of a

jump or a sudden decrease of the Young modulus to the value cor-

responding to the difference of the elasticity moduli of the ordered

and disordered state of the alloy (Fig. 2.11).

2.1.2 Elasticity characteristics of structural materials

In most cases, multiphase and multicomponent alloys with different

chemical composition are used in technical practice. The compli-

cat ed phase composi t i on and t he di fferences i n t he degree of

metastability of structural components result in large differences in

extent of the utilisation of the processes of structural and phase

28

Internal Friction of Materials

changes, ageing, recovery, etc. in the application of various mate-

rials. Analysis of the effect of these factors on the elasticity char-

acteristics is complicated owing to the fact that factors, determin-

ing the actual value of the Young modulus, are also important.

These processes determine the effective value of the interatomic

forces by the change of the concentration of the alloying elements

in the solid solutions, the change of internal stresses at coherent

phase boundaries, actual changes of the elasticity moduli of the in-

dependent phases, the increase of the number of structural defects,

etc. (the first group of factors).

The second group of fact ors i ncl udes t he processes of

anelasticity; this is reflected in the structural sensitivity of the elas-

ticity moduli. The change of the structure and phases of the alloys

in quenching, tempering, ageing, etc. results in a change of the level

of the elasticity moduli; this change is large in comparison with the

values given in the tables. Consequently, it is necessary to have not

only the values from various tables or material specifications, but

also data on the specific structural state and the relationships of

their changes in the expected working conditions of the material.

The sensitivity of the elasticity moduli of the material to the

change of the structure and phases is the reason for the qualitatively

new thermal hysteresis of the moduli. In this case, the curves E(T)

in heating and cooling differ. Hysteresis is found only in a specific

F FF FFig ig ig ig ig.2.11. .2.11. .2.11. .2.11. .2.11. Effect of temperature on the Young modulus of ordered CuZn and Cu

3

Au

alloys.

29

Nature and Mechanisms of Anelasticity

temperature range (Fig. 2. 12, curves 2). Figure 2. 12 shows the

changes of the Young modulus in relation to temperature for a steel

with 0.4 wt.% C (curves 1) and for white cast iron with 2.8 wt.%

C and 1.4 wt.% Si (curves 2). Both materials were normalised in

the initial condition. In the temperature region below the eutectoid

t ransformat i on t emperat ure (curves 1) t he dependence E(T) i s

slightly nonlinear. In the eutectoid transformation temperature range

there is a large decrease of the elasticity moduli associated with the

start of dissolution of cementite particles. Completion of the

transformation results in a drop in the rate of decrease of the E(T)

dependence. The large increase of E at temperatures of 10001050

C is interpreted by the equalisation of the composition of the

phases as a result of the dissolution of the solutes built up at the

grain boundaries in the disappearance of the old grain boundaries

during the growth of austenite grains. With the reversed change of

temperature the extent of relaxation at the grain boundaries de-

creases and the dependence E(T) is shifted higher in comparison

with gradual heating. The curves E(T) in heating and cooling be-

come identical below the eutectoid transformation temperature.

F FF FFig ig ig ig ig.2.12. .2.12. .2.12. .2.12. .2.12. Effect of temperature on the Young modulus of steel 40 (1) and white

cast iron (2).

30

Internal Friction of Materials

The special feature of the E(T) dependence of cast iron is the

presence of a wide temperature range in which thermal hysteresis

forms. The form of the E(T) dependence depends on the process of

breakdown of cementite and ferrite formation. The most significant

changes are recorded in the temperature range 680850C. In heat-

ing, the E(T) curve shows two distinctive steps associated with the

start (710720C) and finish (810840C) of eutectoid transforma-

tion in white cast iron. The first stage corresponds to the transfor-

mation of pearlite to austenite which is part of ledeburite, and also

to the compressive stress in the transformation of ferrite to austenite

as a result of the differences in the coefficient of thermal expansion

of eutectic cementite and pearlite. The second stage corresponds to

the completion of the breakdown of pearlite at the original austenite

grain boundaries where extensive relaxation of a large part of the

residual stresses could have taken place during the tests. The meas-

urements of internal friction with the change of temperature showed

that every step on the E(T) curve corresponds to the internal fric-

tion maximum. The relaxation mechanism is associated with the

change of the susceptibility of the grain boundaries to stress relaxa-

tion with the formation and growth of new phase particles on them.

The elasticity characteristics of the materials change in relation

to the method and conditions of heat treatment. The final results are

the consequence of the mutual effect of the factors which increase

or decrease the Young modulus. In quenching of carbon steels, the

volume fraction of cementite in the structure of steel decreases. The

Young modulus of cementite is lower. Therefore, this process in-