Documente Academic

Documente Profesional

Documente Cultură

Gri Handbook Installation

Încărcat de

Yetkin ErdoğanDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Gri Handbook Installation

Încărcat de

Yetkin ErdoğanDrepturi de autor:

Formate disponibile

GRI/DURLON - Gasket Installation

GASKET RESOURCES INC.

DURLON GASKETING - BOLT TIGHTENING WORK SHEET

Location/Identification: Gasket Contact Surface Finish on Flange:

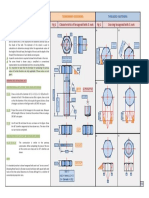

(Initial each step.)

Nominal Bolt Size: ; Lubricant Used:

1. Be sure system is at ambient temperature and depressurized. Follow local safety procedures. 2. Visually examine and clean flanges, bolts, nuts and washers. Replace components if necessary. 3. Lubricate bolts, nuts, AND flange surface AROUND BOLT HOLES, or use hardened steel washers. 4. Install new gasket. DO NOT REUSE OLD GASKET, OR USE MULTIPLE GASKETS. 5. Number bolts in cross-pattern sequence according to the appropriate sketch below. 6. IMPORTANT! HAND TIGHTEN; then PRE-TIGHTEN BOLTS to 10/20 FT-LBS torque, but DO NOT EXCEED 20% of Target Torque. 7. Check gap for uniformity. 8. Use the appropriate cross-pattern tightening sequence in the sketch below for Rounds 1, 2, and 3 and/or Round 4 (each sequence constitutes a Round).

1 8 1 8 4 4 5 4 9 4 14 6 6 2 2 7 2 11 7 10 2 15 7 11 12 1 8 5 12 5 13 3 16 4 10 18 6 14 2 11 19 7 16 1 9 8 20 12 1 13 5 17 9 3 15 20 12 4 22 14 6 18 10 2 23 15 7 8 16 24 1 9 17 5 13 21 3 11 19

10

4-bolt

8-bolt

12-bolt

16-bolt

20-bolt

24-bolt

Final Torque: ft-lbs LUBRICATE, HAND TIGHTEN, PRE-TIGHTEN bolts Round 1 - Tighten to Round 2 - Tighten to Round 3 - Tighten to

*Refer to torque chart on next page

ft-lbs - 1st torque value in torque chart* (30% of final torque) ft-lbs 2nd torque value in torque chart (60% of final torque) ft-lbs - Final torque value in torque chart (100% of final torque)

Check gap around the circumference between each of these rounds, measured at every other bolt. If the gap is not reasonably uniform around the circumference, make the appropriate adjustments by selective bolt tightening before proceeding. Final Rotational Round - 100% of Final Torque (same as Round 3 or 4 above). Use ROTATIONAL, clockwise tightening sequence, starting with Bolt No. 1, for one complete round and continue until no further nut rotation occurs at 100% of the Final Torque value for any nut. Short-term bolt preload loss can occur between four to twenty-four hours after initial tightening due to bolt relaxation. Consider retightening to help recover this loss.

TIGHTENING METHOD USED:

Hand Wrench

Impact Wrench Joint Assembler:

Manual Torque Wrench

Other

Hydraulic Torque Wrench

Date:

For torque questions, or tightening patterns for large diameter flanges, contact GRI Technical Services at: (713) 856-9445, or tech@durlon.com

** This page can be copied for use in the field **

DURLON Technical Handbook

2003-2011, Gasket Resources Inc., All Rights Reserved

August 2011

Durlon is a registered trademark of Gasket Resouces Inc.

GRI/DURLON - Gasket Installation

THE EFFECT OF BOLT LUBRICATION

Bolt lubrication greatly affects the torque values used when installing gaskets. To achieve the same gasket compression, a much higher torque value is required for a dry bolt versus using an effective lubricant such as molybdenum disulfide. In a dry bolt up, or where an inefficient lubricant is used, the effort used in tightening is overcome by the frictional forces between the bolts and nuts and to a greater extent between the nuts and nut facings. This can result in a lower gasket load and inadequate stress on the bolts, which can result in torque loss and eventual leakage in service.

Bolt Preload vs. Torque

60000 Molybdenum disulfide 50000

40000

Load, lbs

30000 As Received 20000

10000

Dry

0 0 100 200 300 400

Torque, ft-lbs

TORQUE VALUES ASME B16.5 RAISED FACE FLANGES

ANSI B16.21 - RING GASKETS 1/16 & 1/8 DURLON Gasket Material - Torque: ft-lbs

Flange Size 1/2" 3/4" 1" 1-1/4" 1-1/2" 2" 2-1/2" 3" 3-1/2" 4" 5" 6" 8" 10" 12" 14" 16" 18" 20" 24" ANSI B16.5 Class 150 RF Torque / Round (ft-lbs) Bolt Tighten Seq* 1st 2nd Final Dwg*/No. Size 5 11 16 4-bolt 1/2" 8 15 23 4-bolt 1/2" 10 20 30 4-bolt 1/2" 15 30 45 4-bolt 1/2" 18 37 56 4-bolt 1/2" 37 75 113 4-bolt 5/8" 37 75 113 4-bolt 5/8" 43 86 130 4-bolt 5/8" 37 75 113 8-bolt 5/8" 37 75 113 8-bolt 5/8" 67 133 202 8-bolt 3/4" 67 133 202 8-bolt 3/4" 78 156 236 8-bolt 3/4" 108 216 327 12-bolt 7/8" 108 216 327 12-bolt 7/8" 162 325 492 12-bolt 1" 162 325 492 16-bolt 1" 241 482 731 16-bolt 1-1/8" 241 482 731 20-bolt 1-1/8" 342 684 1036 20-bolt 1-1/4" ANSI B16.5 Class 300 RF Torque / Round (ft-lbs) Bolt Tighten Seq* 1st 2nd Final Dwg*/No. Size 5 11 16 4-bolt 1/2" 13 25 38 4-bolt 5/8" 13 25 38 4-bolt 5/8" 18 36 55 4-bolt 5/8" 30 60 90 4-bolt 3/4" 20 40 60 8-bolt 5/8" 30 60 90 8-bolt 3/4" 42 83 125 8-bolt 3/4" 47 93 141 8-bolt 3/4" 59 118 179 8-bolt 3/4" 67 133 200 8-bolt 3/4" 62 123 187 12-bolt 3/4" 98 196 297 12-bolt 7/8" 102 205 310 16-bolt 1" 153 306 460 16-bolt 1-1/8" 134 267 400 20-bolt 1-1/8" 188 376 570 20-bolt 1-1/4" 213 425 645 24-bolt 1-1/4" 234 469 710 24-bolt 1-1/4" 363 726 1100 24-bolt 1-1/2"

Note: It is assumed that new A193 Gr. 7 studs with 2H heavy hex nuts are used. And studs, nuts and the flange facings on the nuts are lubricated with a never-seize type paste using the installation and bolt tightening practices outlined above. Lubricant should not be applied to the gasket or flange faces as a release agent. Hardened steel washers are also recommended to reduce friction. * Refer to the appropriate bolt tightening sequence drawing under gasket installation on the previous page for the number of bolts listed. ** A minimum gasket stress of 4800 psi or a torque value > 40% of bolt yield, whichever is higher, is recommended to reduce torque loss.

DURLON Technical Handbook

2003-2011, Gasket Resources Inc., All Rights Reserved

August 2011

Durlon is a registered trademark of Gasket Resouces Inc.

S-ar putea să vă placă și

- Weldinghuide Eng BohlerDocument515 paginiWeldinghuide Eng BohlerJorge VasquezÎncă nu există evaluări

- Lincoln Electric Welding Stick Maual c210Document48 paginiLincoln Electric Welding Stick Maual c210Kaan çelikoğlu100% (1)

- Seaplus Fire Fighting SystemsDocument24 paginiSeaplus Fire Fighting SystemsYetkin Erdoğan100% (1)

- Defect Sizing in Pipeline Welds - What Can We Really AchieveDocument10 paginiDefect Sizing in Pipeline Welds - What Can We Really AchieveYetkin ErdoğanÎncă nu există evaluări

- What Every Engineer Should Know About WeldingDocument10 paginiWhat Every Engineer Should Know About WeldingYetkin ErdoğanÎncă nu există evaluări

- Weld Flange To PipeDocument1 paginăWeld Flange To PipeGraham MooreÎncă nu există evaluări

- En 1090Document47 paginiEn 1090Darren Thoon100% (5)

- Tightness Control SystemDocument4 paginiTightness Control SystemYetkin Erdoğan100% (1)

- Tightness Control SystemDocument4 paginiTightness Control SystemYetkin Erdoğan100% (1)

- Design & Calculation Cathodic Protection Impressed Cureent SystemDocument107 paginiDesign & Calculation Cathodic Protection Impressed Cureent Systemmtuanlatoi9704Încă nu există evaluări

- Thickness of Small Diameter TubingDocument3 paginiThickness of Small Diameter TubingYetkin ErdoğanÎncă nu există evaluări

- NORSOK Standard for Cathodic Protection M-CR-503Document16 paginiNORSOK Standard for Cathodic Protection M-CR-503Yetkin ErdoğanÎncă nu există evaluări

- Incoterms GuideDocument1 paginăIncoterms GuideYetkin ErdoğanÎncă nu există evaluări

- Detection of Hydrogen-Induced Cracking (HIC)Document2 paginiDetection of Hydrogen-Induced Cracking (HIC)Yetkin ErdoğanÎncă nu există evaluări

- Weld Gauges - GAL and Western Instruments - Weld Gauges - Pit Depth - M-TestDocument6 paginiWeld Gauges - GAL and Western Instruments - Weld Gauges - Pit Depth - M-TestYetkin ErdoğanÎncă nu există evaluări

- InfoDocument40 paginiInfoYetkin Erdoğan100% (1)

- GasesforLife 7 enDocument20 paginiGasesforLife 7 enYetkin ErdoğanÎncă nu există evaluări

- Original Gasket Technology GuideDocument40 paginiOriginal Gasket Technology GuideAtty AttyÎncă nu există evaluări

- TECHCENTER ColdFormingDocument54 paginiTECHCENTER ColdFormingsonurahul_yadav100% (1)

- Durlon Is A Good Fit, For Shopping Efficiency ... : ... and For Newly Constructed Tank CarsDocument2 paginiDurlon Is A Good Fit, For Shopping Efficiency ... : ... and For Newly Constructed Tank CarsYetkin ErdoğanÎncă nu există evaluări

- How Boilers WorkDocument18 paginiHow Boilers Workhozipek5599100% (1)

- GasesforLife 7 enDocument20 paginiGasesforLife 7 enYetkin ErdoğanÎncă nu există evaluări

- Gases For Life 01Document20 paginiGases For Life 01Yetkin ErdoğanÎncă nu există evaluări

- Weld Overlay Cladding1Document3 paginiWeld Overlay Cladding1Yetkin ErdoğanÎncă nu există evaluări

- GasesforLife 8 enDocument20 paginiGasesforLife 8 enYetkin ErdoğanÎncă nu există evaluări

- Gases For Life 02Document20 paginiGases For Life 02Yetkin ErdoğanÎncă nu există evaluări

- Man Instruc Boiler ViessmannDocument53 paginiMan Instruc Boiler ViessmannYetkin ErdoğanÎncă nu există evaluări

- Original Gasket Technology GuideDocument40 paginiOriginal Gasket Technology GuideAtty AttyÎncă nu există evaluări

- Catalog enDocument36 paginiCatalog enYetkin ErdoğanÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- United States Patent (19) : (22 Filed: June 4, 1976 Assistant Examiner-James C. YeungDocument8 paginiUnited States Patent (19) : (22 Filed: June 4, 1976 Assistant Examiner-James C. YeungHarshal TalsaniaÎncă nu există evaluări

- Analysis and Design of Flexible Pavement Using Empirical-Mechanistic Based Software (KENPAVE)Document7 paginiAnalysis and Design of Flexible Pavement Using Empirical-Mechanistic Based Software (KENPAVE)salvo2miceliÎncă nu există evaluări

- Alver AaltoDocument5 paginiAlver AaltoJayant RajÎncă nu există evaluări

- 1148 01 Mattawan HS-MS Bid Specs PDFDocument192 pagini1148 01 Mattawan HS-MS Bid Specs PDFdexterÎncă nu există evaluări

- Transfer PumpDocument3 paginiTransfer Pumpemad aminÎncă nu există evaluări

- The Early Chicago Tall Office Building: Artistically and Functionally ConsideredDocument9 paginiThe Early Chicago Tall Office Building: Artistically and Functionally ConsideredDorian VujnovićÎncă nu există evaluări

- Boiler Structure Erection MethodDocument76 paginiBoiler Structure Erection MethodSuman GhoshÎncă nu există evaluări

- Critical Review of Use of Glass Fiber Reinforced G PDFDocument4 paginiCritical Review of Use of Glass Fiber Reinforced G PDFDharmendra PawarÎncă nu există evaluări

- Avk Double Eccentric Butterfly Valve, Pn25 756/118-002Document3 paginiAvk Double Eccentric Butterfly Valve, Pn25 756/118-002thehuy015Încă nu există evaluări

- Highway Materials Manual: Kingdom of Saudi Arabia Ministry of CommunicationsDocument75 paginiHighway Materials Manual: Kingdom of Saudi Arabia Ministry of CommunicationsAyman KandeelÎncă nu există evaluări

- Hk42fz017 Carrier 58cta 58ctx FurnaceDocument56 paginiHk42fz017 Carrier 58cta 58ctx FurnaceJerry Han100% (1)

- ELECT-TIC-7.2-Installation of Grounding System, Grounding and Bonding AccessoriesDocument2 paginiELECT-TIC-7.2-Installation of Grounding System, Grounding and Bonding AccessoriesMuhammad IrfanÎncă nu există evaluări

- DeliviroDocument4 paginiDeliviroDanielÎncă nu există evaluări

- Max-3 Plus (420-2700) Technical Information & Assembly Instructions Manual PDFDocument60 paginiMax-3 Plus (420-2700) Technical Information & Assembly Instructions Manual PDFFlorentina SanduÎncă nu există evaluări

- Bhatia Gummidipoondi WHRSG O&m Manual FinalDocument224 paginiBhatia Gummidipoondi WHRSG O&m Manual Finalt_syamprasadÎncă nu există evaluări

- Hardware Auto & MachineryDocument86 paginiHardware Auto & MachineryHenry ChanÎncă nu există evaluări

- Csyc12mkf Service ManualDocument71 paginiCsyc12mkf Service ManualcoronaqcÎncă nu există evaluări

- ITP - Fire Extinguisher InstallationDocument7 paginiITP - Fire Extinguisher InstallationGultom Juliana LiliesÎncă nu există evaluări

- Machine Drawing: Hexagonal Bolts & NutsDocument1 paginăMachine Drawing: Hexagonal Bolts & Nutsyesbee100% (1)

- COMPATIBILITY OF KNOCKOUTS AND FITTINGSDocument4 paginiCOMPATIBILITY OF KNOCKOUTS AND FITTINGSTinkyTonk86Încă nu există evaluări

- Pre-Drill Planning Saves Money: IntegrityDocument3 paginiPre-Drill Planning Saves Money: Integritythauwui86Încă nu există evaluări

- Steel PVC CPVC Pipes Dimensions Weight ChartDocument5 paginiSteel PVC CPVC Pipes Dimensions Weight Chartdh24992499Încă nu există evaluări

- Directory Database India Professionals Builders Real Estate AgentsDocument11 paginiDirectory Database India Professionals Builders Real Estate AgentsDoctor SamÎncă nu există evaluări

- Student Industrial Work Experience ReportDocument13 paginiStudent Industrial Work Experience ReportAWHEN FITZGERALD100% (1)

- Compressor Inspection ReportDocument2 paginiCompressor Inspection ReportHussain MasoodÎncă nu există evaluări

- PDF - Existing Bridge FB06 PDFDocument28 paginiPDF - Existing Bridge FB06 PDF6082838708Încă nu există evaluări

- Finite Element Analysis of Fiber Reinforced Polymer (FRP) Bridge Deck StructuresDocument9 paginiFinite Element Analysis of Fiber Reinforced Polymer (FRP) Bridge Deck StructuresVietnhut PhanÎncă nu există evaluări

- Terex Rh200 Maintenance Training: Hydraulic Cooling SystemDocument14 paginiTerex Rh200 Maintenance Training: Hydraulic Cooling Systemchurypizarro2367Încă nu există evaluări

- Rust Build CalcDocument2 paginiRust Build CalcMihai AlexandruÎncă nu există evaluări

- Construction of District Court Complex Electrical WorksDocument76 paginiConstruction of District Court Complex Electrical WorkssunilrauloÎncă nu există evaluări