Documente Academic

Documente Profesional

Documente Cultură

GHD Plans

Încărcat de

Ryan BezzDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

GHD Plans

Încărcat de

Ryan BezzDrepturi de autor:

Formate disponibile

Home Gym GHD CrossFit loves the GHD and most affiliates count this bit of kit as essential.

However, for those of us with home gyms the cost, and more critically the physical size of commercial GHDs make them hard to justify. A few hours of making saw-dust in the sun and then you too can have a GHD.

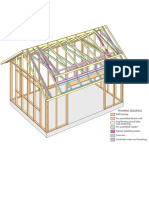

1.5 * 1.5 battens You will need: 2 12 * 14 sheets of plywood 2 8 * 16 sheets of plywood 5 16 long 1 * 1 softwood battens 32 wood-screws drill and drill bits jigsaw wood glue steel rule 10 12 feet of 2 * 4 timber saw frame fixings 3 5 6 bolts and tee nuts 3 feet 25mm metal steel pipe hacksaw 3 feet foam pipe cladding

6 radius

8 * 16 plywood walls

14

5.25

12

Find the centre of your end piece and scribe a 6 radius arc about that point Also, scribe a 5.25 arc to help later in locating pilot holes to screw in the battens.

14

Scribe lines from the bottom corners of your end piece running tangent to the larger arc you drew earlier. Cut along the lines you have drawn to get your shaped end pieces.

Next, test fit the other pieces to help in locating pilot holes in preparation for screwing and gluing. Shift the walls up until the bottom corner is flush with the bottom edge of the end piece. Alternatively you could angle cut it so the whole thing sits flush but this is not really necessary. Position one batten at the top the space the remainder out evenly between it and the two side walls. Two screws for each batten spaced along the smaller arc work well. Three screws in each side wall are sufficient.

You may also want to drill a couple of holes big enough for your jig-saw blade and cut out a handle in each end piece. Once this is all done, it is time to put it all together. Best to screw the end pieces and walls together and then the battens. Try to get them as close to flush with the rounded edge as possible.

The end result should look something like this:

To complete this part of the project, I recommend applying a strip of rubber flooring over the battens and screwing it to the top of front and back walls. This is pretty firm but will ensure you do not feel the sharp corners of the battens. Over this a couple of layers of foam camping mat will provide the necessary cushioning for sensitive bits. Next we need to fashion some foot holds. For this bit I will assume that you have a sturdy wall which you can drill holes into. Make sure you avoid electrical cables and gas and water pipes. First cut your length of pipe in half (i.e. 2 * 50cm lengths) Cut your foam pipe cladding into 4 25cm lengths and glue or tape along the seams. Slide one of the foam pieces onto each end of your two pipe lengths, these are your foot rests. Rest your GHD box on top of the largest plyo box you expect to use as a base (nb. Anything larger than 24 is overkill in my opinion) and measure the height of the combined unit. Cut three lengths of 2*4 just longer than this combined height. Say 40 if your unit is 36 tall. Starting level with the top of your unit, drill a series 3 4 pilot holes into the 2 face of one of your 2 by 4s. Space them about 2 apart. If you want the flexibility to use more than one height box as a base, drill an additional series for each height. I would also drill a set based on the GHD box sitting directly on the floor. Once all the pilots are drilled drill the big diameter holes. After the first one is done, make sure that it is big enough to easily accommodate the pipe from your foot rest. If not, you can try wiggling the drill around or using a rasp to loosen it but I would recommend buying the right size bit. Assuming it fits nicely, slide it through and then slip the foam pad onto the exposed pipe end until it snugs up against the 2*4. The series of pics below shows how this works:

After all the big holes are drilled, we prepare to fix the rig to the wall. Butt the three 2*4s together so you have a single block 4*6. We want to drill 3 holes through the whole block big enough to accommodate your bolts. Make sure that they do not run through any of your foot rest holes! You

may also want to use your 26mm bit to drill recesses for the bolt head and tee nut. Fix the tee nut on the wall-side of the block (a little wood glue wont hurt here), push your bolt through from the front and tighten the whole lot together to make sure the tee-nuts are secure and also that the ends of the bolts wont stick into the wall.

Undo everything and decide where on your wall you want to place your foot support. Square it up, mark the wall and then locate positions for three additional holes through the 2*4 to accommodate the frame fixings. Drill these out using your wood bit then change to a same-sized masonry bit. With the timber in place on the wall, put the masonry bit through the timber and drill your wall holes. Make sure they are deep enough for the fixings. Push the plastic sleeves through the wood and into the wall all the way then drive the screws all the way in. Powered screw-drivers are a good idea here! After that, all that is left to do is line the other two timbers up and run your bolts through, snugging everything up nice and tight. Now that all that is done, instructions for use are pretty simple. But your plyo-box a couple of feet from the foot-rig and place the GHD on top. Pick the height for your foot pad and you are just about ready to go. You can tweak the spacing from the wall until your hips, pelvis are positioned correctly on the pad. Safety Points If you have rubber topping on your plyo-box then the GHD box should stay in place pretty reliably. If not, simply use a tie-down strap anchored on the bottom edges of the box and running fore and aft over the GHD. It is possible to tip the whole tower over if you throw yourself about. It is not a major issue (at least on a 24 square sided box). The simple fix is to loop the end of your tie-down strap through one of the bottom holes in your foot rig and tie it off. You can see this in the bottom right corner of the pic below. Maybe someone else can suggest a more elegant fix.

Cheers, kempie

S-ar putea să vă placă și

- Building A Garden Shed Step By Step Instructions and PlansDe la EverandBuilding A Garden Shed Step By Step Instructions and PlansEvaluare: 2 din 5 stele2/5 (1)

- Build A Retaining WallDocument13 paginiBuild A Retaining WallAnonymous 1TTYYaÎncă nu există evaluări

- How to Build A Laminate Square Edge CountertopDe la EverandHow to Build A Laminate Square Edge CountertopEvaluare: 2 din 5 stele2/5 (1)

- David de Lossy/Photodisc/Getty ImagesDocument15 paginiDavid de Lossy/Photodisc/Getty ImagesasiasiÎncă nu există evaluări

- Building A Playhouse: Step By Step InstructionsDe la EverandBuilding A Playhouse: Step By Step InstructionsEvaluare: 5 din 5 stele5/5 (1)

- Yurt Construction DocumentDocument26 paginiYurt Construction DocumentsepaulsenÎncă nu există evaluări

- How to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideDe la EverandHow to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideÎncă nu există evaluări

- Barn Door Baby GateDocument17 paginiBarn Door Baby GateNovitates1Încă nu există evaluări

- Guide To Building Your First ShedDocument10 paginiGuide To Building Your First Shedpatience peters100% (1)

- Installing a Garage Door and Opener- Special Bundle: Cake Decorating for BeginnersDe la EverandInstalling a Garage Door and Opener- Special Bundle: Cake Decorating for BeginnersÎncă nu există evaluări

- Arbor - Lath Arch Rose ArborDocument6 paginiArbor - Lath Arch Rose ArborDaniel LourençoÎncă nu există evaluări

- 00 Folding Picnic Table DIY Out of 2x4 LumberDocument48 pagini00 Folding Picnic Table DIY Out of 2x4 Lumberbf100% (2)

- 50 Contractor Garage Plans ConstructionDocument90 pagini50 Contractor Garage Plans Constructionapsaraso100% (5)

- How To Build Modern Barstools Like A ProDocument17 paginiHow To Build Modern Barstools Like A Progerman100% (1)

- The Infinite Oval: Tools For WoodworkingDocument2 paginiThe Infinite Oval: Tools For Woodworkingoqab18Încă nu există evaluări

- Lean To Shed Plan: Free Streamlined VersionDocument9 paginiLean To Shed Plan: Free Streamlined VersionjesusdoliÎncă nu există evaluări

- 2012 Shed TechartDocument15 pagini2012 Shed TechartMujÎncă nu există evaluări

- 8x12 Shed PlansDocument15 pagini8x12 Shed PlansRocio Cajo0% (1)

- Wood Joint Work Part 4Document2 paginiWood Joint Work Part 4Lo M'hÎncă nu există evaluări

- Adjustable Table PlansDocument7 paginiAdjustable Table PlansMauroÎncă nu există evaluări

- Chicken Run Plans 4x8Document21 paginiChicken Run Plans 4x8Ivan RochfordÎncă nu există evaluări

- Software Deck GuideDocument19 paginiSoftware Deck GuideEdward EncarnacionÎncă nu există evaluări

- ForeverRedwood Brochure EverythingPergolaDocument66 paginiForeverRedwood Brochure EverythingPergolaMircea Tomus100% (1)

- Camp TrailerDocument6 paginiCamp TrailerGreg Phillpotts100% (3)

- Diyhuntress Igbc Desk PlansDocument23 paginiDiyhuntress Igbc Desk PlansEdwin Espinoza obandoÎncă nu există evaluări

- Hide Your Bins in A Handy Trash CentreDocument4 paginiHide Your Bins in A Handy Trash Centret_w_3_0_7Încă nu există evaluări

- Rust Repair Patches Made EasyDocument8 paginiRust Repair Patches Made EasyeduardowilkÎncă nu există evaluări

- Typical Garage / Storage Shed / Shop DetailsDocument28 paginiTypical Garage / Storage Shed / Shop DetailskennypetersÎncă nu există evaluări

- Woodsmith Magazine - Plans Now - Router Table ReviewDocument6 paginiWoodsmith Magazine - Plans Now - Router Table ReviewPaweł JamrożekÎncă nu există evaluări

- Diy - Woodwork - Plans - Shed Framing PDFDocument0 paginiDiy - Woodwork - Plans - Shed Framing PDFSignora LofaroÎncă nu există evaluări

- WOOD Store: Thank You!Document12 paginiWOOD Store: Thank You!lacroitoruÎncă nu există evaluări

- Folding Workbench PlansDocument11 paginiFolding Workbench Plansbwatkins6Încă nu există evaluări

- Auto Restoration Rotisserie PlansDocument26 paginiAuto Restoration Rotisserie PlansbeegoodÎncă nu există evaluări

- Sun ScopeDocument3 paginiSun ScopeJimÎncă nu există evaluări

- Build Your Own French Doors - Popular Woodworking MagazineDocument34 paginiBuild Your Own French Doors - Popular Woodworking Magazinekostas1977Încă nu există evaluări

- Firewood GarbageShedDocument13 paginiFirewood GarbageShedJeremy SmathersÎncă nu există evaluări

- Chiefsshop Pirateschest PDFDocument12 paginiChiefsshop Pirateschest PDFdonguie100% (1)

- Entry Bench PlanDocument8 paginiEntry Bench PlancajemarÎncă nu există evaluări

- Boral Installation MasonryGuideDocument25 paginiBoral Installation MasonryGuidem0172Încă nu există evaluări

- Design A Deck Planning PDFDocument18 paginiDesign A Deck Planning PDFdvsÎncă nu există evaluări

- Makerspace Workbench PDFDocument9 paginiMakerspace Workbench PDFBeatriz FreitasÎncă nu există evaluări

- Build Your Acrylic AquariumDocument10 paginiBuild Your Acrylic AquariumgnllindsayÎncă nu există evaluări

- Classic Entry BenchDocument5 paginiClassic Entry BenchO'Neil JonesÎncă nu există evaluări

- Swing Garden SwingDocument7 paginiSwing Garden SwingAlicia MariaÎncă nu există evaluări

- ShopsmithDocument12 paginiShopsmithJhon Torr LueÎncă nu există evaluări

- Shed PlansDocument16 paginiShed PlansFrancis Wolfgang Urban100% (7)

- Plan 1Document24 paginiPlan 1ParZiValÎncă nu există evaluări

- Figure B Framing: Pre-Assembled Dormer Wall Roof Framing (Install After Wall Sheathing) Wall FramingDocument13 paginiFigure B Framing: Pre-Assembled Dormer Wall Roof Framing (Install After Wall Sheathing) Wall FramingMúsica viajera MX0% (1)

- 8 Foot Picnic Table PlansDocument5 pagini8 Foot Picnic Table Planstom2susanÎncă nu există evaluări

- Arcadia Glasshouse Planning Guide PDFDocument12 paginiArcadia Glasshouse Planning Guide PDFArya ParamelÎncă nu există evaluări

- Simple Elegance: A Table With Few Parts and Uncomplicated Joinery Proves That Less Is MoreDocument5 paginiSimple Elegance: A Table With Few Parts and Uncomplicated Joinery Proves That Less Is Moreanca mariaÎncă nu există evaluări

- WRCLA Installing SidingDocument16 paginiWRCLA Installing SidingITLHAPNÎncă nu există evaluări

- Wood Shingles and ShakesDocument6 paginiWood Shingles and Shakesjack.simpson.changÎncă nu există evaluări

- Roll Around Kitchen Cart: MLCS Items UsedDocument15 paginiRoll Around Kitchen Cart: MLCS Items UsedTETSUO111Încă nu există evaluări

- How To Build An Adirondack Chair: Introduction and Cutting ListDocument6 paginiHow To Build An Adirondack Chair: Introduction and Cutting ListSamir Joguncic100% (1)

- How To Build A Wild Bird Feeder PDFDocument17 paginiHow To Build A Wild Bird Feeder PDFmihaly61Încă nu există evaluări

- Shed Storage2Document9 paginiShed Storage2Bob Pouliot88% (8)

- Workshop Assignment: By: Sneha Motghare Div: B Roll No:26 Batch:2 Taught By: Vilas SirDocument15 paginiWorkshop Assignment: By: Sneha Motghare Div: B Roll No:26 Batch:2 Taught By: Vilas SirVinay MotghareÎncă nu există evaluări

- 2010 Travel Predictions - SunsetDocument8 pagini2010 Travel Predictions - Sunsetapi-26020661100% (2)

- Shravana CharacterDocument5 paginiShravana CharacterSuresh SharmaÎncă nu există evaluări

- 2 2 1 A Productanalysis 2Document5 pagini2 2 1 A Productanalysis 2api-308131962Încă nu există evaluări

- English: Third Quarter - Module 3Document12 paginiEnglish: Third Quarter - Module 3Anna Agravante-SulitÎncă nu există evaluări

- Iec 62031 PDFDocument16 paginiIec 62031 PDFAlbertoÎncă nu există evaluări

- Electric Circuits 1 MSDocument4 paginiElectric Circuits 1 MSEvaÎncă nu există evaluări

- Blender To Google EarthDocument41 paginiBlender To Google Earthrichx7Încă nu există evaluări

- Rangtong Shentong ViewDocument19 paginiRangtong Shentong Viewlongjim31100% (1)

- Osawa Catalogue 2021Document708 paginiOsawa Catalogue 2021lorenzo.lima1706Încă nu există evaluări

- A Review of The Opportunities For Desalination in Agriculture PDFDocument15 paginiA Review of The Opportunities For Desalination in Agriculture PDFMilind KshirsagarÎncă nu există evaluări

- Renault Gearbox and Final Drive OilsDocument10 paginiRenault Gearbox and Final Drive OilsPhat0% (1)

- I-R Nirvana IRN250-300H-2S Parts ManualDocument28 paginiI-R Nirvana IRN250-300H-2S Parts ManualMistysParts100% (4)

- Proposed Revisions To Usp Sterile Product - Package Integrity EvaluationDocument56 paginiProposed Revisions To Usp Sterile Product - Package Integrity EvaluationDarla Bala KishorÎncă nu există evaluări

- Allegheny Power Planning CriteriaDocument19 paginiAllegheny Power Planning Criteriaksdp1Încă nu există evaluări

- Aspire 7535 ManualDocument220 paginiAspire 7535 ManualinklabsÎncă nu există evaluări

- Advent of SkyscrapersDocument27 paginiAdvent of SkyscrapersJoshua AlboÎncă nu există evaluări

- Maximizing Bass Reflex System Performance Through Optimization ofDocument32 paginiMaximizing Bass Reflex System Performance Through Optimization ofGilberto MontaniÎncă nu există evaluări

- Patel, Anita - Super Indian Snack and Street Food Recipes PDFDocument117 paginiPatel, Anita - Super Indian Snack and Street Food Recipes PDFBella ImèneÎncă nu există evaluări

- Gas AbsorptionDocument93 paginiGas AbsorptionArgie Adduru73% (11)

- Ecological Fire MGMT Guidelines V5Document40 paginiEcological Fire MGMT Guidelines V5MeÎncă nu există evaluări

- 24 - Al Nahda The Sheffeild Privat To International City, Greece K12 Dubai Bus Service TimetableDocument10 pagini24 - Al Nahda The Sheffeild Privat To International City, Greece K12 Dubai Bus Service TimetableDubai Q&AÎncă nu există evaluări

- Seismic Isolation For Buildings Catalog 2013 by Bridgestone Corp - Multi Rubber BearingDocument44 paginiSeismic Isolation For Buildings Catalog 2013 by Bridgestone Corp - Multi Rubber BearingitetejacÎncă nu există evaluări

- Surface Chemistry: by General CharacteristicsDocument8 paginiSurface Chemistry: by General CharacteristicssriÎncă nu există evaluări

- HP 300s+ Scientific Calculator: Sophisticated Design Ideal For Math and Science StudentsDocument3 paginiHP 300s+ Scientific Calculator: Sophisticated Design Ideal For Math and Science StudentsgemaÎncă nu există evaluări

- ERIC Section4 Hadrian - C. AlbinusDocument83 paginiERIC Section4 Hadrian - C. AlbinusDarko SekulicÎncă nu există evaluări

- Technology VocabularyDocument3 paginiTechnology VocabularyChixo GalaxyÎncă nu există evaluări

- Assignment Oumh2103 English For Science Technical PurposesDocument12 paginiAssignment Oumh2103 English For Science Technical PurposesKhairul AnuarÎncă nu există evaluări

- What Makes A Cup of NESCAFÉ So Special? The Best Coffee Beans andDocument4 paginiWhat Makes A Cup of NESCAFÉ So Special? The Best Coffee Beans andYenny YanyanÎncă nu există evaluări

- 21 Day Fasting & Prayer 2022Document29 pagini21 Day Fasting & Prayer 2022StephenÎncă nu există evaluări

- Drugs and Tinnitus - Neil Bauman PHD - April '09Document2 paginiDrugs and Tinnitus - Neil Bauman PHD - April '09DownTheTheRabbitHole108Încă nu există evaluări

- Colegio de San Gabriel Arcangel of Caloocan, IncDocument7 paginiColegio de San Gabriel Arcangel of Caloocan, IncKIRITO SALINASÎncă nu există evaluări

- Survive!: Essential Skills and Tactics to Get You Out of Anywhere—AliveDe la EverandSurvive!: Essential Skills and Tactics to Get You Out of Anywhere—AliveÎncă nu există evaluări

- Merle's Door: Lessons from a Freethinking DogDe la EverandMerle's Door: Lessons from a Freethinking DogEvaluare: 4 din 5 stele4/5 (326)

- Crazy for the Storm: A Memoir of SurvivalDe la EverandCrazy for the Storm: A Memoir of SurvivalEvaluare: 3.5 din 5 stele3.5/5 (217)

- The Last Dive: A Father and Son's Fatal Descent into the Ocean's DepthsDe la EverandThe Last Dive: A Father and Son's Fatal Descent into the Ocean's DepthsÎncă nu există evaluări

- Welcome to the Goddamn Ice Cube: Chasing Fear and Finding Home in the Great White NorthDe la EverandWelcome to the Goddamn Ice Cube: Chasing Fear and Finding Home in the Great White NorthEvaluare: 4 din 5 stele4/5 (59)

- The Last of His Kind: The Life and Adventures of Bradford Washburn, America's Boldest MountaineerDe la EverandThe Last of His Kind: The Life and Adventures of Bradford Washburn, America's Boldest MountaineerEvaluare: 4 din 5 stele4/5 (23)

- The Art of Resilience: Strategies for an Unbreakable Mind and BodyDe la EverandThe Art of Resilience: Strategies for an Unbreakable Mind and BodyEvaluare: 4.5 din 5 stele4.5/5 (117)

- Grandma Gatewood's Walk: The Inspiring Story of the Woman Who Saved the Appalachian TrailDe la EverandGrandma Gatewood's Walk: The Inspiring Story of the Woman Who Saved the Appalachian TrailEvaluare: 4.5 din 5 stele4.5/5 (308)

- 438 Days: An Extraordinary True Story of Survival at SeaDe la Everand438 Days: An Extraordinary True Story of Survival at SeaEvaluare: 4.5 din 5 stele4.5/5 (188)

- Mind Gym: An Athlete's Guide to Inner ExcellenceDe la EverandMind Gym: An Athlete's Guide to Inner ExcellenceEvaluare: 3.5 din 5 stele3.5/5 (18)

- Strong Is the New Beautiful: Embrace Your Natural Beauty, Eat Clean, and Harness Your PowerDe la EverandStrong Is the New Beautiful: Embrace Your Natural Beauty, Eat Clean, and Harness Your PowerEvaluare: 4 din 5 stele4/5 (5)

- How to Survive Anything: From Animal Attacks to the End of the World (and Everything in Between)De la EverandHow to Survive Anything: From Animal Attacks to the End of the World (and Everything in Between)Evaluare: 4.5 din 5 stele4.5/5 (3)

- Last Child in the Woods: Saving Our Children From Nature-Deficit DisorderDe la EverandLast Child in the Woods: Saving Our Children From Nature-Deficit DisorderEvaluare: 4 din 5 stele4/5 (283)

- Divided: A Walk on the Continental Divide TrailDe la EverandDivided: A Walk on the Continental Divide TrailEvaluare: 4 din 5 stele4/5 (17)

- Freediving Manual: Learn How to Freedive 100 Feet on a Single BreathDe la EverandFreediving Manual: Learn How to Freedive 100 Feet on a Single BreathEvaluare: 5 din 5 stele5/5 (4)

- The Optimist: A Case for the Fly Fishing LifeDe la EverandThe Optimist: A Case for the Fly Fishing LifeEvaluare: 4.5 din 5 stele4.5/5 (18)

- Upside Down in the Yukon River: Adventure, Survival, and the World's Longest Kayak RaceDe la EverandUpside Down in the Yukon River: Adventure, Survival, and the World's Longest Kayak RaceEvaluare: 4.5 din 5 stele4.5/5 (2)

- The Lost Explorer: Finding Mallory on Mount EverestDe la EverandThe Lost Explorer: Finding Mallory on Mount EverestEvaluare: 4.5 din 5 stele4.5/5 (31)

- Free Outside: A Trek Against Time and DistanceDe la EverandFree Outside: A Trek Against Time and DistanceEvaluare: 4 din 5 stele4/5 (26)

- Hiking Through: One Man's Journey to Peace and Freedom on the Appalachian TrailDe la EverandHiking Through: One Man's Journey to Peace and Freedom on the Appalachian TrailEvaluare: 4 din 5 stele4/5 (99)

- Above the Clouds: How I Carved My Own Path to the Top of the WorldDe la EverandAbove the Clouds: How I Carved My Own Path to the Top of the WorldEvaluare: 4.5 din 5 stele4.5/5 (25)

- How To Think Like A Spy: Spy Secrets and Survival Techniques That Can Save You and Your FamilyDe la EverandHow To Think Like A Spy: Spy Secrets and Survival Techniques That Can Save You and Your FamilyEvaluare: 4 din 5 stele4/5 (4)