Documente Academic

Documente Profesional

Documente Cultură

9A03403 Manufacturing Technology

Încărcat de

sivabharathamurthyDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

9A03403 Manufacturing Technology

Încărcat de

sivabharathamurthyDrepturi de autor:

Formate disponibile

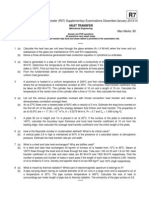

Code: 9A03403

1

(Mechanical Engineering)

B.Tech II Year II Semester (R09) Regular & Supplementary Examinations, April/May 2013 MANUFACTURING TECHNOLOGY Time: 3 hours Answer any FIVE questions All questions carry equal marks ***** 1 (a) (b) 2 (a) (b) 3 (a) (b) 4 (a) (b) 5 (a) (b) 6 (a) (b) 7 (a) (b) 8 (a) (b) (c) Explain any five types of patterns with sketch giving their applications. Explain the parting line gate with sketch. Write the advantages? Explain the following centrifugal casting methods with sketch: True centrifugal casting. Semi centrifugal casting. Explain the Volt-ampere (V-I) characteristics of welding power source. What are the applications and advantages of explosive welding? Explain the friction welding process with sketch. What are the advantages of friction welding process? Sketch and describe the different types of rolls used in rolling. What is the power required in rolling? Describe the following cold working process: Coining. Roll bending. Why can open die forging be made larger than closed die forging? Why can metals such as aluminium and tin extruded cold? Why is EDM widely used? Give the reasons. What is the difference between the chemical milling and electro chemical milling? What is principal cause of tool wear in ECM? Max Marks: 70

*****

Code: 9A03403

2

(Mechanical Engineering)

B.Tech II Year II Semester (R09) Regular & Supplementary Examinations, April/May 2013 MANUFACTURING TECHNOLOGY Time: 3 hours Answer any FIVE questions All questions carry equal marks ***** 1 2 (a) (b) 3 (a) (b) 4 (a) (b) 5 (a) (b) Explain the steps involved in preparing the sand mould. Explain the working of a cupola furnace with a neat sketch. Write the advantages of a cupola furnace. Explain the thermit welding process with sketch. What are the applications of thermit welding? What are the various methods of non destructive testing of welds? List them. What are the advantages and limitations non destructive testing? Mention the materials used for rolls What are the different types of rolling mills? Explain the tandem and planetary rolling mills with neat diagrams, Define blanking, punching and piercing operations. What are different types of drawing? Explain any one. What is cold forging? What for cold heading is used? Explain the process of rotary forging with help of neat sketch. What is principle of working of electrochemical machining (ECM)? Describe in brief an ECM machine. What is the function of electrolyte in ECM? List common electrolytes used in ECM. Max Marks: 70

6 (a) (b) 7 (a) (b) 8 (a) (b) (c)

*****

Code: 9A03403

3

(Mechanical Engineering)

B.Tech II Year II Semester (R09) Regular & Supplementary Examinations, April/May 2013 MANUFACTURING TECHNOLOGY Time: 3 hours Answer any FIVE questions All questions carry equal marks ***** 1 (a) (b) Define the following terms related to casting: (i) Casting. (ii) Sprue. (iii) Runner. (iv) Chaplets. Explain the following types of gates with sketch: (i) Pencil gate. (ii) Branch gate. (iii) Ring gate. What is directional solidification? Explain it with the help of a diagram. Explain the solidification of a pure metal with sketch. Explain the carbon arc welding process with sketch. What are the advantages and limitations of arc welding? What are the various types of destructive tests conducted on welds? List them. Explain the procedure of tensile testing of a weld with sketch. Differentiate between two high reversing mill and three high mill. Sketch them. Discuss the various stages of shape rolling of a component with sketches? What are its applications? Draw a sketch of a punch and a die set used for punching operation. Indicate its various parts. Explain the following terms: (i) Coining. (ii) Embossing. (iii) Trimming. A board hammer receives its name because of what feature. Compare the forging press to a drop hammer press and discuss the energy transmitted to the work. Explain why the EBM process is performed in vacuum chamber. List product applications of EBM. What is the difference between the EBM and LBM processes? Max Marks: 70

2 (a) (b) 3 (a) (b) 4 (a) (b) 5 (a) (b)

6 (a) (b) 7 (a) (b)

8 (a) (b) (c)

*****

Code: 9A03403

4

(Mechanical Engineering)

B.Tech II Year II Semester (R09) Regular & Supplementary Examinations, April/May 2013 MANUFACTURING TECHNOLOGY Time: 3 hours Answer any FIVE questions All questions carry equal marks ***** 1 (a) (b) 2 (a) (b) Explain the parting line gate and bottom gate with sketches and their advantages and disadvantages. Explain the functions of runner extension in a gating system. What are the two basic categories of casting processes? Explain. What are the advantages and disadvantages of sand casting over investment casting? What is welding? How the welding processes are classified? Explain. Explain the various types of welded joints with sketch. Explain the two types of impact testing of welds with sketch. What is the difference between Izod and Charpy impact testing of welds? Explain the significance of recrystallization temperature in metal working. Why is hot working sometimes preferred to cold working in spite of some disadvantages? What is drawing? Sketch and explain hot drawing process. Describe the process of cold spinning stating its advantages and specific uses. Explain with simple sketches, the process of forward and backward extrusion. Explain how the various variables affect the extrusion pressure. What is over cutting in EDM process and how it is affected by amperage and frequency? Describe in brief an EDM machine. What are the special requirements of the EDM? Max Marks: 70

3 (a) (b) 4 (a) (b) 5 (a) (b)

6 (a) (b) 7 (a) (b) 8 (a) (b) (c)

*****

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- HVAC Master Validation PlanDocument51 paginiHVAC Master Validation Plannavas197293% (30)

- Employee Confidentiality and Non-Disclosure AgreementDocument5 paginiEmployee Confidentiality and Non-Disclosure AgreementshamoojeeÎncă nu există evaluări

- History of Microfinance in NigeriaDocument9 paginiHistory of Microfinance in Nigeriahardmanperson100% (1)

- Control Systems (CS) Notes As Per JntuaDocument203 paginiControl Systems (CS) Notes As Per Jntuasivabharathamurthy100% (3)

- SSC Telugu (FL) (AP)Document232 paginiSSC Telugu (FL) (AP)sivabharathamurthyÎncă nu există evaluări

- 9A13701 Robotics and AutomationDocument4 pagini9A13701 Robotics and AutomationsivabharathamurthyÎncă nu există evaluări

- R7311506 Operating SystemsDocument1 paginăR7311506 Operating SystemssivabharathamurthyÎncă nu există evaluări

- R7410506 Mobile ComputingDocument1 paginăR7410506 Mobile ComputingsivabharathamurthyÎncă nu există evaluări

- R7311205 Distributed DatabasesDocument1 paginăR7311205 Distributed DatabasessivabharathamurthyÎncă nu există evaluări

- R7410407 Operating SystemsDocument1 paginăR7410407 Operating SystemssivabharathamurthyÎncă nu există evaluări

- SSC Social Textbook (AP)Document100 paginiSSC Social Textbook (AP)sivabharathamurthyÎncă nu există evaluări

- 07A4EC01 Environmental StudiesDocument1 pagină07A4EC01 Environmental StudiessivabharathamurthyÎncă nu există evaluări

- R5410201 Neural Networks & Fuzzy LogicDocument1 paginăR5410201 Neural Networks & Fuzzy LogicsivabharathamurthyÎncă nu există evaluări

- R7312301 Transport Phenomena in BioprocessesDocument1 paginăR7312301 Transport Phenomena in BioprocessessivabharathamurthyÎncă nu există evaluări

- 9A05707 Software Project ManagementDocument4 pagini9A05707 Software Project ManagementsivabharathamurthyÎncă nu există evaluări

- R7311006 Process Control InstrumentationDocument1 paginăR7311006 Process Control InstrumentationsivabharathamurthyÎncă nu există evaluări

- Code: R7311306: (Electronics & Control Engineering)Document1 paginăCode: R7311306: (Electronics & Control Engineering)sivabharathamurthyÎncă nu există evaluări

- R7310306 Heat TransferDocument1 paginăR7310306 Heat Transfersivabharathamurthy100% (1)

- R7310406 Digital CommunicationsDocument1 paginăR7310406 Digital CommunicationssivabharathamurthyÎncă nu există evaluări

- R7310206 Linear Systems AnalysisDocument1 paginăR7310206 Linear Systems AnalysissivabharathamurthyÎncă nu există evaluări

- R7310506 Design & Analysis of AlgorithmsDocument1 paginăR7310506 Design & Analysis of AlgorithmssivabharathamurthyÎncă nu există evaluări

- R7310106 Engineering GeologyDocument1 paginăR7310106 Engineering GeologysivabharathamurthyÎncă nu există evaluări

- R5310406 Digital CommunicationsDocument1 paginăR5310406 Digital CommunicationssivabharathamurthyÎncă nu există evaluări

- 9A15502 Digital System DesignDocument4 pagini9A15502 Digital System Designsivabharathamurthy100% (1)

- R5310204 Power ElectronicsDocument1 paginăR5310204 Power ElectronicssivabharathamurthyÎncă nu există evaluări

- 9A05505 Operating SystemsDocument4 pagini9A05505 Operating SystemssivabharathamurthyÎncă nu există evaluări

- 9A23501 Heat Transfer in BioprocessesDocument4 pagini9A23501 Heat Transfer in BioprocessessivabharathamurthyÎncă nu există evaluări

- 9A14503 Principles of Machine DesignDocument8 pagini9A14503 Principles of Machine DesignsivabharathamurthyÎncă nu există evaluări

- 9A02505 Electrical Machines-IIIDocument4 pagini9A02505 Electrical Machines-IIIsivabharathamurthyÎncă nu există evaluări

- 9A21506 Mechanisms & Mechanical DesignDocument8 pagini9A21506 Mechanisms & Mechanical DesignsivabharathamurthyÎncă nu există evaluări

- 9A10505 Principles of CommunicationsDocument4 pagini9A10505 Principles of CommunicationssivabharathamurthyÎncă nu există evaluări

- 9A04504 Digital IC ApplicationsDocument4 pagini9A04504 Digital IC ApplicationssivabharathamurthyÎncă nu există evaluări

- 9A03505 Heat TransferDocument4 pagini9A03505 Heat TransfersivabharathamurthyÎncă nu există evaluări

- Pemaknaan School Well-Being Pada Siswa SMP: Indigenous ResearchDocument16 paginiPemaknaan School Well-Being Pada Siswa SMP: Indigenous ResearchAri HendriawanÎncă nu există evaluări

- ITP Exam SuggetionDocument252 paginiITP Exam SuggetionNurul AminÎncă nu există evaluări

- Form 709 United States Gift Tax ReturnDocument5 paginiForm 709 United States Gift Tax ReturnBogdan PraščevićÎncă nu există evaluări

- Three Comparison of Homoeopathic MedicinesDocument22 paginiThree Comparison of Homoeopathic MedicinesSayeed AhmadÎncă nu există evaluări

- Dolni VestoniceDocument34 paginiDolni VestoniceOlha PodufalovaÎncă nu există evaluări

- Worksheet 5 Communications and Privacy: Unit 6 CommunicationDocument3 paginiWorksheet 5 Communications and Privacy: Unit 6 Communicationwh45w45hw54Încă nu există evaluări

- Breaking NewsDocument149 paginiBreaking NewstigerlightÎncă nu există evaluări

- AA ActivitiesDocument4 paginiAA ActivitiesSalim Amazir100% (1)

- Indian Journal of Natural Products and Resources Vol 1 No 4 Phytochemical pharmacological profile Cassia tora overviewDocument8 paginiIndian Journal of Natural Products and Resources Vol 1 No 4 Phytochemical pharmacological profile Cassia tora overviewPRINCIPAL BHILWARAÎncă nu există evaluări

- Analyze and Design Sewer and Stormwater Systems with SewerGEMSDocument18 paginiAnalyze and Design Sewer and Stormwater Systems with SewerGEMSBoni ClydeÎncă nu există evaluări

- Mil STD 2154Document44 paginiMil STD 2154Muh SubhanÎncă nu există evaluări

- Training Customer CareDocument6 paginiTraining Customer Careyahya sabilÎncă nu există evaluări

- Techniques in Selecting and Organizing InformationDocument3 paginiTechniques in Selecting and Organizing InformationMylen Noel Elgincolin ManlapazÎncă nu există evaluări

- Mobile ApplicationDocument2 paginiMobile Applicationdarebusi1Încă nu există evaluări

- NABARD road inspection report formatDocument24 paginiNABARD road inspection report formatSrinivas PÎncă nu există evaluări

- Nokia CaseDocument28 paginiNokia CaseErykah Faith PerezÎncă nu există evaluări

- LSMW With Rfbibl00Document14 paginiLSMW With Rfbibl00abbasx0% (1)

- CTR Ball JointDocument19 paginiCTR Ball JointTan JaiÎncă nu există evaluări

- Correlation Degree Serpentinization of Source Rock To Laterite Nickel Value The Saprolite Zone in PB 5, Konawe Regency, Southeast SulawesiDocument8 paginiCorrelation Degree Serpentinization of Source Rock To Laterite Nickel Value The Saprolite Zone in PB 5, Konawe Regency, Southeast SulawesimuqfiÎncă nu există evaluări

- Certification Presently EnrolledDocument15 paginiCertification Presently EnrolledMaymay AuauÎncă nu există evaluări

- Trillium Seismometer: User GuideDocument34 paginiTrillium Seismometer: User GuideDjibril Idé AlphaÎncă nu există evaluări

- Key Fact Sheet (HBL FreedomAccount) - July 2019 PDFDocument1 paginăKey Fact Sheet (HBL FreedomAccount) - July 2019 PDFBaD cHaUhDrYÎncă nu există evaluări

- IQ CommandDocument6 paginiIQ CommandkuoliusÎncă nu există evaluări

- Galaxy Owners Manual Dx98vhpDocument10 paginiGalaxy Owners Manual Dx98vhpbellscbÎncă nu există evaluări

- HP HP3-X11 Exam: A Composite Solution With Just One ClickDocument17 paginiHP HP3-X11 Exam: A Composite Solution With Just One ClicksunnyÎncă nu există evaluări

- Allan S. Cu v. Small Business Guarantee and FinanceDocument2 paginiAllan S. Cu v. Small Business Guarantee and FinanceFrancis Coronel Jr.Încă nu există evaluări

- Strategies For StartupDocument16 paginiStrategies For StartupRoshankumar BalasubramanianÎncă nu există evaluări