Documente Academic

Documente Profesional

Documente Cultură

PT Pindo Deli - Water Conservation in Paper Mills To Reduce

Încărcat de

Andy PratamaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

PT Pindo Deli - Water Conservation in Paper Mills To Reduce

Încărcat de

Andy PratamaDrepturi de autor:

Formate disponibile

P.T.

PINDO DELI: Water Conservation in Paper Mills

P. T. PINDO DELI PULP & PAPER MILLS

Water Conservation in Paper Mills to Reduce Paper Sludge

SUMMARY OF THE OPTION

PT. Pindo Deli Pulp & Paper produces photocopy paper, specialty paper and tissue paper with a production capacity of 1,465,000 tons per year. The GERIAP proje ct focused on machine number 8 (PM# 8) that produces mainly photocopy paper with a production capacity of 240,000 tons per year. At Pindo Deli s Waste Water Plant, 1000 to 1500 tons of paper sludge are collected at the Belt Press. Until the year 2003, 40% (~300 400 tones per month) of the sludge produced on site was given away, at no cost, to the local mushroom and cassava growers for use as compost. At this time Pindo Deli II produced fiber in waste to a level of about 3.7 %. In the year 2005 Pindo Deli has a target to reduce water consumption in the whole of the Pindo Deli II plant from about 10 m3 to 5 m3 per ton product. Reducing water consumption automatically reduces the fibers that run off into the effluent. The target of water consumption efficiency on PM8 and PM9 is reducing average water usage from 11.2 m3 / tons in the year 2004 to 7.5 m3 / tons in March 2005. To achieve this target, some activities are done are as follows:

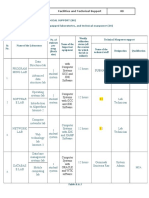

No. 1. 2 Project Item Chemical Dilution Sealing Water Action Plan Replace fresh water with white water for chemical dilution Install sealing water recovery to recover water from dryer drainage (make sump pit of concrete) Reduce sealing water for pulper agitator, stock pumps, chest agitators, refiners, etc. Install rotameter for sealing system Study possibility for use white water for nash pump deculator sealing system Use cooling tower water for Turbo blower cooling system, dry end oil, heating/cooling roll kuster thermal oil and chilling water for pan. Study possibility for using white water for Uhle Box shower & felt Roll Doctor Shower. Reduce make up water for white water system (make SOP and implement) Improve efficiency of water circulation system (make SOP and implement) Reduce fresh water usage when machine cleaning and boil out (make SOP and implement) Fix leaking in water piping line, tank, toilets, etc.

3. 4. 5. 6.

Cooling Water Shower for Press Make Up Water Others

These activities will save water consumption in PM 8 and PM 9 by about 888,000 m3 per year. The cost of producing water is Rp. 900/ m3 (US $ 0.1/ m3 ), therefore this project will give an annual cost saving of about US$ 88,800 (Rp. 799,200,000*) as the cost of producing water is Rp. 900/ m3 (US $ 0.1/ m3 * ). Environmental benefits are reducing electricity consumption for (1) producin g process water, (2) transport reduced process water, (3) transport waste water to the waste water treatment plant and also the potential to reduce greenhouse gas emissions.

Energy Efficiency Guide for Industry in Asia www.energyefficiencyasia.org

In this project, waste water is screened before reuse, and then the fibre which is retained on the screen, can be put back to the process. Therefore, reducing water consumption will also automatically reduce fiber run-off into the effluent. But the amount of fiber reduced cannot be predicted at this time .

KEYWORDS

Indonesia, Pulp & Paper, Paper Sludge, Water, Cooling Water

FOR MORE INFORMATION

GERIAP National Focal Point for Indonesia Dr. Ir. Tusy A. Adibroto or Ms. Widiatmini Sih Winanti BPPT - Jl. MH Thamrin 8 BPPT II building 20th floor Jakarta, Indonesia Tel: + 62 21 316 9758/68 Fax:+ 62 21 316 9760 E-mail: tusyaa@ceo.bppt.go.id / widiatmini@yahoo.com GERIAP Company in Indonesia Mr. Suwandi Mulyono or Mr. Himawan Anwar PT. Pindo deli Pulp & Paper Ds. Kuta Mekar, Ciampel-Karawang, West Java-Indonesia E-mail: suwandi_mulyono@app.co.id; himawan_anwar@app.co.id

Disclaimer:

This case study was prepared as part of the project Greenhouse Gas Emission Reduction from Industry in Asia and the Pacific (GERIAP). While reasonable efforts have been made to ensure that the contents of this publication are factually correct, UNEP does not accept responsibility for the accuracy or completeness of the contents, and shall not be liable for any loss or damage that may be occasioned directly or indirectly through the use of, or reliance on, the contents of this publication. UNEP, 2006.

Energy Efficiency Guide for Industry in Asia www.energyefficiencyasia.org

S-ar putea să vă placă și

- Waste Paper Recycling MachineDocument5 paginiWaste Paper Recycling MachineLeo BoyÎncă nu există evaluări

- Stone Paper, An Eco-Friendly and Free-Tree Papers: Articles You May Be Interested inDocument13 paginiStone Paper, An Eco-Friendly and Free-Tree Papers: Articles You May Be Interested inRamya Reddy VajralaÎncă nu există evaluări

- Materi Kajian Teknis4 - Nov 2021Document10 paginiMateri Kajian Teknis4 - Nov 2021Guruh SaputraÎncă nu există evaluări

- Keywords:-Water Resources Energy Efficiency and Green: ManufacturingDocument8 paginiKeywords:-Water Resources Energy Efficiency and Green: ManufacturingInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Entrepreneurship Project: Tanuja Water'S ReportDocument16 paginiEntrepreneurship Project: Tanuja Water'S ReportPrabir Kumar PatiÎncă nu există evaluări

- NR Latex Tech Concerns and The Remedies Part II ADocument28 paginiNR Latex Tech Concerns and The Remedies Part II ASHRIKANT PRABHAKAR ATHAVALEÎncă nu există evaluări

- National Award For Excellence in W Ater Management-2008 16 & 17 December 2008 CII - Sohrabji Godrej Green Business Centre, HyderabadDocument11 paginiNational Award For Excellence in W Ater Management-2008 16 & 17 December 2008 CII - Sohrabji Godrej Green Business Centre, HyderabadMahesh KumarÎncă nu există evaluări

- 01.packaged Drinking WaterDocument15 pagini01.packaged Drinking WaterAmjad PervazÎncă nu există evaluări

- Water Treatment in The Pulp and Paper Industry - Water TechnologyDocument12 paginiWater Treatment in The Pulp and Paper Industry - Water TechnologyMahmudul HasanÎncă nu există evaluări

- Smart Water Management in MCITDocument42 paginiSmart Water Management in MCITJONNA FRANCISCOÎncă nu există evaluări

- Project Plan2Document8 paginiProject Plan2Student NurseÎncă nu există evaluări

- Proposal ReportDocument26 paginiProposal ReportKALEMA BEMME2025Încă nu există evaluări

- Ms-09-Development of A Paper Recycling ProcessDocument7 paginiMs-09-Development of A Paper Recycling ProcesshidaiÎncă nu există evaluări

- Multilevel Reuse System With Source SeparatDocument30 paginiMultilevel Reuse System With Source SeparatSchaelCooperÎncă nu există evaluări

- S5P3 Mostafa ShehataDocument42 paginiS5P3 Mostafa Shehatas.b.v.seshagiri1407Încă nu există evaluări

- Reduction in Power Plant Specific Water Consumption: February 2016Document9 paginiReduction in Power Plant Specific Water Consumption: February 2016aedi0611Încă nu există evaluări

- Paper Recycling Research ch1.3Document6 paginiPaper Recycling Research ch1.3Dela Torre, Emilio Joseph N.Încă nu există evaluări

- PRP Final File According To The Irslan AkramDocument20 paginiPRP Final File According To The Irslan AkramarslanakramrajputÎncă nu există evaluări

- Design and Fabrication of Waste Paper Recycling Machine For Laboratory and Medium Scale OperationDocument7 paginiDesign and Fabrication of Waste Paper Recycling Machine For Laboratory and Medium Scale OperationKenn MendozaÎncă nu există evaluări

- Sewegw Treatment PlantDocument6 paginiSewegw Treatment PlantRajavelu.kÎncă nu există evaluări

- 11-87802 Factsheet NPC Ebook PDFDocument2 pagini11-87802 Factsheet NPC Ebook PDFMarina MúsicaÎncă nu există evaluări

- Automated Plastic Bottle Recycling Machine: Test Engineering and Management March 2021Document8 paginiAutomated Plastic Bottle Recycling Machine: Test Engineering and Management March 2021Khryss Joseph SolimanÎncă nu există evaluări

- LSM PROJECT DeraDocument17 paginiLSM PROJECT DeraDEDEFOÎncă nu există evaluări

- Paper N PulpDocument43 paginiPaper N PulpAshwin KumarÎncă nu există evaluări

- Sugar Cane Wastewater Treatment PlantDocument7 paginiSugar Cane Wastewater Treatment PlanteztwarinzÎncă nu există evaluări

- Project On Cost Analysis of Setting Up A Waste Paper Recycling UnitDocument15 paginiProject On Cost Analysis of Setting Up A Waste Paper Recycling UnitPrakhar KulshreshthaÎncă nu există evaluări

- Bplan Paper RecyclingDocument18 paginiBplan Paper RecyclingSwathi Bollineni100% (1)

- Aarohi Paper ProductsDocument5 paginiAarohi Paper ProductsRaviArryanÎncă nu există evaluări

- At A Care Cent DevelopmentsDocument21 paginiAt A Care Cent DevelopmentsJose Heli Vallejos CoronadoÎncă nu există evaluări

- UK Greywater Recycling: An Information GuideDocument27 paginiUK Greywater Recycling: An Information GuideFree Rain Garden ManualsÎncă nu există evaluări

- Volume Reduction PDFDocument29 paginiVolume Reduction PDFJne ByerÎncă nu există evaluări

- Water Usage and Recycling in QatarDocument5 paginiWater Usage and Recycling in QatarMaheerah Gamieldien-MohamedÎncă nu există evaluări

- SectionB - Group2 - Communication ChallengeDocument12 paginiSectionB - Group2 - Communication ChallengeManu BÎncă nu există evaluări

- Paper Mill READYDocument85 paginiPaper Mill READYagility dreamsÎncă nu există evaluări

- Evaloc FinalDocument17 paginiEvaloc FinalRahul PillaiÎncă nu există evaluări

- Maulana Azad National Institute of Technology (A Institute of National Importance) BHOPAL-462007Document24 paginiMaulana Azad National Institute of Technology (A Institute of National Importance) BHOPAL-462007Prakhar KulshreshthaÎncă nu există evaluări

- Detailed Project Report On Thermocol & Paper Disposable Plates and Cups Manufacturing PlantDocument12 paginiDetailed Project Report On Thermocol & Paper Disposable Plates and Cups Manufacturing PlantTana RobinÎncă nu există evaluări

- A Road Map For Natural Capitalism by LovinsDocument3 paginiA Road Map For Natural Capitalism by LovinsClaire ElizabethÎncă nu există evaluări

- Plastic Bottle MachineDocument11 paginiPlastic Bottle MachineMelaku AssefaÎncă nu există evaluări

- Akhilesh Kumar Project ReportDocument8 paginiAkhilesh Kumar Project ReportRamesh Gupta86% (7)

- ID Studi Penggunaan Air Di PT Holcim IndoneDocument10 paginiID Studi Penggunaan Air Di PT Holcim Indonepascal sitanggangÎncă nu există evaluări

- Research Paper On Drip Irrigation PDFDocument7 paginiResearch Paper On Drip Irrigation PDFafnhkvmnemelfx100% (1)

- Puspawati 2019 IOP Conf. Ser. Earth Environ. Sci. 306 012019Document7 paginiPuspawati 2019 IOP Conf. Ser. Earth Environ. Sci. 306 012019Muhammad YunusÎncă nu există evaluări

- Project Report On Pet Recycling Unit (Pet Granules From Pet Waste)Document5 paginiProject Report On Pet Recycling Unit (Pet Granules From Pet Waste)EIRI Board of Consultants and Publishers100% (1)

- Pulp and Paper Technology 03602354: Smit Christian, LecturerDocument14 paginiPulp and Paper Technology 03602354: Smit Christian, LecturerSMIT CHRISTIANÎncă nu există evaluări

- Biermann's Handbook of Pulp and Paper - Cap 14Document13 paginiBiermann's Handbook of Pulp and Paper - Cap 14chau_riberÎncă nu există evaluări

- i-STP Independent Sewerage Treatment PlantDocument1 paginăi-STP Independent Sewerage Treatment PlantanierahÎncă nu există evaluări

- Social Solutions: Water ConservationDocument4 paginiSocial Solutions: Water ConservationNaghma AlamÎncă nu există evaluări

- Report On Reprocessing of Plastic and Manufacturing A Plastic GranulesDocument4 paginiReport On Reprocessing of Plastic and Manufacturing A Plastic GranulesKukaswadiya Ibrahim67% (3)

- Perth Residential Water Use StudyDocument40 paginiPerth Residential Water Use Studyp130324Încă nu există evaluări

- Icoseat (2022)Document8 paginiIcoseat (2022)Maulana ArifÎncă nu există evaluări

- Water Conservation in Sugar Industry: A Case Study of Lokmangal Sugar, Ethanol and Co-Generation Industries LTD, BhandarkavatheDocument7 paginiWater Conservation in Sugar Industry: A Case Study of Lokmangal Sugar, Ethanol and Co-Generation Industries LTD, BhandarkavatheIJIERT-International Journal of Innovations in Engineering Research and TechnologyÎncă nu există evaluări

- Iwwt BDocument2 paginiIwwt BBalvinder SinghÎncă nu există evaluări

- Save Water Presentation 2023Document80 paginiSave Water Presentation 2023Mehdi AcilÎncă nu există evaluări

- Mother Parkers Project Proposal - SNNP VersionDocument12 paginiMother Parkers Project Proposal - SNNP VersionMerga BeyeneÎncă nu există evaluări

- Water Efficient Building Design Guidebook PDFDocument77 paginiWater Efficient Building Design Guidebook PDFLinelle VisagieÎncă nu există evaluări

- Manthan SynopsysDocument3 paginiManthan Synopsystimepass4siteÎncă nu există evaluări

- Pulp and Paper IndustryDocument35 paginiPulp and Paper IndustryKlesh Padma Bhimrao Shrirame100% (1)

- Launching of A New ProductDocument23 paginiLaunching of A New ProductJello Valenzuela GonzalesÎncă nu există evaluări

- Spring Setting of Piping Connected To A CompressorDocument4 paginiSpring Setting of Piping Connected To A CompressorSharun SureshÎncă nu există evaluări

- Capr-I En229Document13 paginiCapr-I En229Anonymous WglGv0GÎncă nu există evaluări

- Criterion 6 Facilities and Technical Support 80: With Computer Systems GCC and JDK SoftwareDocument6 paginiCriterion 6 Facilities and Technical Support 80: With Computer Systems GCC and JDK SoftwareVinaya Babu MÎncă nu există evaluări

- FConvert Free YouTube Converter Downloader Convert To MP3, MP4Document2 paginiFConvert Free YouTube Converter Downloader Convert To MP3, MP4FConvert Free YouTube ConverterÎncă nu există evaluări

- 6.3. Example of Transmission Ratio Assessment 6.3.1. Power-Split Hydro-Mechanical TransmissionDocument2 pagini6.3. Example of Transmission Ratio Assessment 6.3.1. Power-Split Hydro-Mechanical TransmissionNita SebastianÎncă nu există evaluări

- Mechanical and Micro Structure of MDF Processed MaterialDocument8 paginiMechanical and Micro Structure of MDF Processed MaterialSharath P CÎncă nu există evaluări

- Marketing Information Systems & Market ResearchDocument20 paginiMarketing Information Systems & Market ResearchJalaj Mathur100% (1)

- Shannons ModelDocument2 paginiShannons ModelransÎncă nu există evaluări

- Liquid Penetrant Test Procedure: Document No.: SP-1.5 Rev. 1.2Document12 paginiLiquid Penetrant Test Procedure: Document No.: SP-1.5 Rev. 1.2Anas PratamaÎncă nu există evaluări

- CAC - Agile Certification BrochureDocument40 paginiCAC - Agile Certification BrochureAgility4AllÎncă nu există evaluări

- 4L60E SwapguideDocument3 pagini4L60E Swapguideericproffitt100% (3)

- Content:: Saudi Arabian Oil Company (Saudi Aramco) General Instruction ManualDocument3 paginiContent:: Saudi Arabian Oil Company (Saudi Aramco) General Instruction Manualmalika_00Încă nu există evaluări

- BETA-2 Pancake Geiger TubeDocument4 paginiBETA-2 Pancake Geiger TubeqqazertyÎncă nu există evaluări

- Jaipur Foot 2014 India Business ConferenceDocument22 paginiJaipur Foot 2014 India Business Conferencepratt100% (1)

- Window/ Water Curtain Nozzle: Model CN & CnsDocument4 paginiWindow/ Water Curtain Nozzle: Model CN & CnsWirat WitaphanÎncă nu există evaluări

- IPv6 RoutingDocument27 paginiIPv6 RoutingTtmManÎncă nu există evaluări

- 15ME11E - Solar PV - Question BankDocument15 pagini15ME11E - Solar PV - Question BankvigneshÎncă nu există evaluări

- Samsung SSD 850 EVO M2 Data Sheet Rev2Document4 paginiSamsung SSD 850 EVO M2 Data Sheet Rev2Piyush ShrivastavaÎncă nu există evaluări

- Chapter 6 Tutorial PDFDocument4 paginiChapter 6 Tutorial PDFAhmad NAz RaInÎncă nu există evaluări

- LX Capacity Chart Hydrogen SCFM 10-2008 PDFDocument5 paginiLX Capacity Chart Hydrogen SCFM 10-2008 PDFZack AmerÎncă nu există evaluări

- Spare Parts List: Hand-Held Gas Saw DS HS80-14"Document20 paginiSpare Parts List: Hand-Held Gas Saw DS HS80-14"mayoo1986Încă nu există evaluări

- En Mirage Classic Installation GuideDocument4 paginiEn Mirage Classic Installation GuideMykel VelasquezÎncă nu există evaluări

- CATIA Cloud of PointsDocument141 paginiCATIA Cloud of Points4953049530100% (1)

- Data Loss PreventionDocument24 paginiData Loss PreventionhelmaaroufiÎncă nu există evaluări

- Medium Voltage Application Guide en IECDocument224 paginiMedium Voltage Application Guide en IECJag Jagdish0% (1)

- Oracle Mid Exam Sem 1Document2 paginiOracle Mid Exam Sem 1Ardie Gucci100% (1)

- ALR Compact Repeater: Future On DemandDocument62 paginiALR Compact Repeater: Future On DemandmickycachoperroÎncă nu există evaluări

- Xample Program in C++ Using File Handling To Perform Following OperationsDocument6 paginiXample Program in C++ Using File Handling To Perform Following OperationsNamita SahuÎncă nu există evaluări

- IEEE Conf 2018 TrackNet - A - Deep - Learning - Based - Fault - Detection - For - Railway - Track - InspectionDocument5 paginiIEEE Conf 2018 TrackNet - A - Deep - Learning - Based - Fault - Detection - For - Railway - Track - InspectionkaruldeepaÎncă nu există evaluări