Documente Academic

Documente Profesional

Documente Cultură

API 651 Requirements For The Sand Pad Material

Încărcat de

mirzazubairDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

API 651 Requirements For The Sand Pad Material

Încărcat de

mirzazubairDrepturi de autor:

Formate disponibile

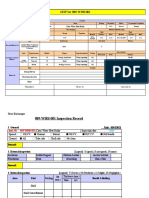

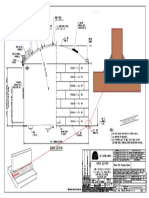

Please find below API 651 requirements for the sand pad material, my comments are in green. 5.3.2.

1 Sand Pad Material a. The sand should be clean, screened, and debris free (i.e., no wood, sticks, vegetation, paper, rocks; clay, silt, or other soil; welding rods or other metallic objects; etc.). b. Cleaning should be done at the supply source and is accomplished by mechanical washing with water that will not alter the chemical composition or electrical resistance of the sand material. CAUTION: A municipal potable water supply may not be acceptable because of chlorination which may produce high chloride levels. c. Masonry mortar quality sand is sometimes specified. d. Sand should conform to specifications such as one of the following: [sieve analysis shall be done according ASTM C136 and results shall evaluated as per these specifications; results must fall within specified ranges to be acceptable] 1) ASTM C 778 type 20-30 sand or equivalent, 2) ASTM C 778 graded sand or equivalent, or [preferred] 3) ASTM C 144 or equivalent. e. Portland cement, at an approximate 33:1 [2.9%] sand to cement ratio, or lime, at an approximate 95:5 [5%] sand to lime ratio, is sometimes added at the supply source to elevate pH levels and/or to facilitate good compaction. CAUTION: Do not use an excessive amount of portland cement or lime as the pad material should be somewhat yielding and not hard like concrete in order to allow the tank bottom to uniformly bear on the sand pad material when loaded and make intimate contact with it. [cement and lime content have to be also verified for this reason] f. Electrical resistivity of the sand material is a commonly used method for determining its corrosivity because it is relatively easy to measure. The resistivity of a soil depends on its chemical properties, moisture content, and temperature. The resistivity of the sand material may be determined in accordance with ASTM G 57, or equivalent. The results of the testing shall be forwarded to the cathodic protection designer. [CORRPRO specified 50 000 .cm in their technical offer.] g. Measuring pH indicates the hydrogen ion content of a soil. Corrosion of steel is fairly independent of pH when it is in the range of 5.0 to 8.0. [CONTRACTOR is advised not to exceed these limits, test results shall be forwarded to CORRPRO]The rate of corrosion increases appreciably when pH is < 5.0 and decreases when pH is > 8.0. pH may be determined in accordance with ASTM G 51 or equivalent. h. Chlorides will affect the resistivity of soil, and act as a depolarizing agent which will increase the current requirement for cathodic protection of steel. Pitting corrosion on steel can begin at chloride levels of 10 ppm [CONTRACTOR is advised not to exceed these limits, test results shall be forwarded to CORRPRO]. Chloride content may be determined in accordance with ASTM D 512 or equivalent. There is currently no industry consensus on an acceptable range for chloride levels, therefore the tank owner/operator should specify the acceptable chloride level. There are practical and possible economic limitations in achieving minimum levels of chloride content. i. Sulfate levels >200 ppm frequently indicate high concentrations of organic matter [CONTRACTOR is advised not to exceed these limits, test results shall be forwarded to CORRPRO] . Sulfate content may be determined in accordance with ASTM D 516 or equivalent. There is currently no industry consensus on an acceptable range for sulfate levels, therefore the tank owner/operator should specify the acceptable

sulfate level. There are practical and possible economic limitations in achieving minimum levels of sulfate content. j. Sulfide levels > 0.10 ppm, may indicate that sulfates have been reduced by bacteria. [CONTRACTOR is advised not to exceed these limits, test results shall be forwarded to CORRPRO] Sulfide content may be determined in accordance with EPA 0376.1 or equivalent. There is currently no industry consensus on an acceptable range for sulfide levels, therefore the tank owner/operator should specify the acceptable sulfide level. There are practical and possible economic limitations in achieving minimum levels of sulfide content.

S-ar putea să vă placă și

- Calculation Inert AnodeDocument6 paginiCalculation Inert AnodeVIETLHÎncă nu există evaluări

- Cathodic Protection 2015Document21 paginiCathodic Protection 2015ainunÎncă nu există evaluări

- Leak Test Proce.-TankDocument7 paginiLeak Test Proce.-Tankpraveen 0064Încă nu există evaluări

- Double Deck - Floating RoofDocument7 paginiDouble Deck - Floating RoofDhia SlamaÎncă nu există evaluări

- Calculation Sheet: III. Calculation of Nozzle Neck Thickness Per UG-45Document3 paginiCalculation Sheet: III. Calculation of Nozzle Neck Thickness Per UG-45Fazri CME100% (1)

- Sacrficial Anode Requirement Calculation (+!!!!!!!!!!!!)Document1 paginăSacrficial Anode Requirement Calculation (+!!!!!!!!!!!!)Adis KaweÎncă nu există evaluări

- Paul Vinik State Structural Material Systems EngineerDocument7 paginiPaul Vinik State Structural Material Systems EngineerJoe BlagÎncă nu există evaluări

- Cathodic Protection Indian StandardDocument32 paginiCathodic Protection Indian StandardXiaohua ChenÎncă nu există evaluări

- Design Calculation Cathodic Protection Impressed Cureent SystemDocument13 paginiDesign Calculation Cathodic Protection Impressed Cureent Systemadeoye_okunoyeÎncă nu există evaluări

- Shell Corrosion Allowance For Aboveground Storage Tanks: Debra Tetteh-Wayoe, P.EngDocument8 paginiShell Corrosion Allowance For Aboveground Storage Tanks: Debra Tetteh-Wayoe, P.Engkhabiran100% (1)

- Fire Profing SpecificationDocument3 paginiFire Profing SpecificationMustafa Al-YasseriÎncă nu există evaluări

- Calculation Procedure For Ground Potentials With Multiple AnodesDocument17 paginiCalculation Procedure For Ground Potentials With Multiple AnodesIwan Husdiantama100% (1)

- Inspection Test Record (Itr) - A Jacket Pre-Loadout ST08-ADocument1 paginăInspection Test Record (Itr) - A Jacket Pre-Loadout ST08-AMomo ItachiÎncă nu există evaluări

- Syarikat Kejuruteraan Sistematik Sendirian BerhadDocument3 paginiSyarikat Kejuruteraan Sistematik Sendirian BerhadPat Lim100% (1)

- Ain Tsila Development Main EPC Contract A-CNT-CON-000-00282Document25 paginiAin Tsila Development Main EPC Contract A-CNT-CON-000-00282ZaidiÎncă nu există evaluări

- Tank Bottom Replacement and Membrane Placement: Chevron Specification TAM-MN-1-ADocument59 paginiTank Bottom Replacement and Membrane Placement: Chevron Specification TAM-MN-1-ABurak GülenÎncă nu există evaluări

- x5 Cathodic Protection Construction ProgramDocument10 paginix5 Cathodic Protection Construction ProgramNoor A Qasim100% (1)

- Chevron Nigeria Limited Escravos Gas Project - Phase 3 Development - Onshore Specification Number Egp3-02.01 Cathodic ProtectionDocument31 paginiChevron Nigeria Limited Escravos Gas Project - Phase 3 Development - Onshore Specification Number Egp3-02.01 Cathodic ProtectionNeo100% (1)

- SEIP For 089-WHB-001: Claus Waste Heat BoilerDocument6 paginiSEIP For 089-WHB-001: Claus Waste Heat BoilerThinh NguyenÎncă nu există evaluări

- VaconoDome Technical CommentaryDocument29 paginiVaconoDome Technical CommentaryOmar GRÎncă nu există evaluări

- Inspection and Repair of Storage Tanks 1710346228Document113 paginiInspection and Repair of Storage Tanks 1710346228Jayapal BhukyaÎncă nu există evaluări

- Cathodic Protection ProcedureDocument3 paginiCathodic Protection Procedurewhah11100% (2)

- API653 TankInspection FormDocument4 paginiAPI653 TankInspection FormAnbarasan PerumalÎncă nu există evaluări

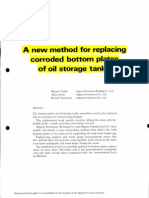

- Niigata - Replacing Bottom Plates of Oil Storage TanksDocument7 paginiNiigata - Replacing Bottom Plates of Oil Storage TanksJohnson Olarewaju100% (2)

- API Tank Settlement PDFDocument2 paginiAPI Tank Settlement PDFMuhammad BilalÎncă nu există evaluări

- Spark Gaps: Dehn (Uk) LTDDocument8 paginiSpark Gaps: Dehn (Uk) LTDElectromacnetist ElectrodÎncă nu există evaluări

- MQ SP I 7015 PDFDocument66 paginiMQ SP I 7015 PDFJaseelKanhirathinkalÎncă nu există evaluări

- Tank GADocument1 paginăTank GASubramanian100% (1)

- Coating Test With The ISOTEST Holiday Detector PDFDocument6 paginiCoating Test With The ISOTEST Holiday Detector PDFÖzgür TuştaşÎncă nu există evaluări

- Calculation Note - Cathodic Protection For 12in Pipeline - Section A & Section B - Sept 2019Document12 paginiCalculation Note - Cathodic Protection For 12in Pipeline - Section A & Section B - Sept 2019bagus handoko100% (4)

- Cathodic Protection Design of Pipelines: Pipeline InformationDocument2 paginiCathodic Protection Design of Pipelines: Pipeline Informationmtuanlatoi9704100% (1)

- VAI-ME-SPC-111 Pipe Insulation Technical Specification - Rev ADocument8 paginiVAI-ME-SPC-111 Pipe Insulation Technical Specification - Rev AAdvis100% (1)

- 025 - Guard Zinc Phosphate Epoxy PrimerDocument3 pagini025 - Guard Zinc Phosphate Epoxy PrimerBalgo BalgobinÎncă nu există evaluări

- 15250-194-EN04-SP-005-Rev 0 (Specification For Atmospheric Storage Tank)Document22 pagini15250-194-EN04-SP-005-Rev 0 (Specification For Atmospheric Storage Tank)sudokuÎncă nu există evaluări

- Geodesic Aluminum Dome & Cover Roof Specification API 650 Appendix GDocument6 paginiGeodesic Aluminum Dome & Cover Roof Specification API 650 Appendix GpassionÎncă nu există evaluări

- Above Ground TanksDocument6 paginiAbove Ground TanksGyanendra Narayan NayakÎncă nu există evaluări

- Dokumen - Tips Spherical Tanks Erection ProcedureDocument9 paginiDokumen - Tips Spherical Tanks Erection ProcedureAhmad Tedjo RukmonoÎncă nu există evaluări

- Cathode Protection Bullets & TanksDocument53 paginiCathode Protection Bullets & TanksGanga DharÎncă nu există evaluări

- Parches Handy Cap IPDocument2 paginiParches Handy Cap IPalvaro_sqsÎncă nu există evaluări

- Corrosion Rate CalculationDocument2 paginiCorrosion Rate CalculationPawan PatilÎncă nu există evaluări

- Cathodic Protection For Steel Water Storage Tanks Pocket Field GuideDocument15 paginiCathodic Protection For Steel Water Storage Tanks Pocket Field GuideBilel YoussefiÎncă nu există evaluări

- Sacrificial Anode Cathodic Protection Systems For The Interior Submerged Surfaces of Steel Water Storage TanksDocument32 paginiSacrificial Anode Cathodic Protection Systems For The Interior Submerged Surfaces of Steel Water Storage TanksChristian LeobreraÎncă nu există evaluări

- Gis 42-102Document38 paginiGis 42-102Felix JaimesÎncă nu există evaluări

- Tanks - Addition of Shell Nozzles by Hot TappingDocument2 paginiTanks - Addition of Shell Nozzles by Hot TappingJuan DelacruzÎncă nu există evaluări

- Api 650Document16 paginiApi 650cfpc10459Încă nu există evaluări

- An Overview of Cathodic Protection Potential MeasurementDocument7 paginiAn Overview of Cathodic Protection Potential MeasurementKhanh DTÎncă nu există evaluări

- Tank - Design and AnalysisDocument4 paginiTank - Design and Analysissammar_10Încă nu există evaluări

- Polyken 2000 High TempDocument2 paginiPolyken 2000 High TempKyaw Kyaw AungÎncă nu există evaluări

- GLACIER LAr Tank Design (Deliverable 2.2)Document76 paginiGLACIER LAr Tank Design (Deliverable 2.2)atiqulaÎncă nu există evaluări

- Cathodic Protection DesignDocument34 paginiCathodic Protection Designsouheil boussaid100% (2)

- Electrical Canle Trench SpecificationDocument12 paginiElectrical Canle Trench SpecificationSumit Kumar DattaÎncă nu există evaluări

- Single Col - Tank-2013Document35 paginiSingle Col - Tank-2013Hgagselim SelimÎncă nu există evaluări

- Spherical Pressure Vessels PDFDocument10 paginiSpherical Pressure Vessels PDFck19654840Încă nu există evaluări

- Tecnical Specification For Materials Division 9Document238 paginiTecnical Specification For Materials Division 9Julio Cesar ChiaÎncă nu există evaluări

- Marine Concrete Specs-HkDocument5 paginiMarine Concrete Specs-HkMohammed Faisal TÎncă nu există evaluări

- CRD c662Document6 paginiCRD c662Veio MacieiraÎncă nu există evaluări

- Determining The Potential Alkali-Silica Reactivity of Combinations of Cementitious Materials and Aggregate (Accelerated Mortar-Bar Method)Document5 paginiDetermining The Potential Alkali-Silica Reactivity of Combinations of Cementitious Materials and Aggregate (Accelerated Mortar-Bar Method)smanoj354Încă nu există evaluări

- SRPC Khaleej PCDocument2 paginiSRPC Khaleej PCUnited Construction Est. TechnicalÎncă nu există evaluări

- Aggregatewater and SlumpDocument1 paginăAggregatewater and SlumpTharindu Sampath WeerasingheÎncă nu există evaluări

- Concrete TestDocument9 paginiConcrete TestVelmurugan BalasubramanianÎncă nu există evaluări

- Department of Accounting and Finances Accounting and Finance ProgramDocument3 paginiDepartment of Accounting and Finances Accounting and Finance Programwossen gebremariamÎncă nu există evaluări

- Zencrack Installation and ExecutionDocument48 paginiZencrack Installation and ExecutionJu waÎncă nu există evaluări

- Fluid Mechanics and Machinery Laboratory Manual: by Dr. N. Kumara SwamyDocument4 paginiFluid Mechanics and Machinery Laboratory Manual: by Dr. N. Kumara SwamyMD Mahmudul Hasan Masud100% (1)

- Analisis Perencanaan Rekrutmen Aparatur Sipil Negara Kabupaten Mamuju UtaraDocument11 paginiAnalisis Perencanaan Rekrutmen Aparatur Sipil Negara Kabupaten Mamuju UtarafitriÎncă nu există evaluări

- Micron Serial NOR Flash Memory: 3V, Multiple I/O, 4KB Sector Erase N25Q256A FeaturesDocument92 paginiMicron Serial NOR Flash Memory: 3V, Multiple I/O, 4KB Sector Erase N25Q256A FeaturesAEÎncă nu există evaluări

- IDR PresentationDocument11 paginiIDR Presentationparthesh laheriÎncă nu există evaluări

- Install Sensor Lsi Fl061Document14 paginiInstall Sensor Lsi Fl061AlterSon Grafi KalayÎncă nu există evaluări

- Frankenstein ExtractDocument1 paginăFrankenstein ExtractAnneÎncă nu există evaluări

- Yusof Ishak Secondary School Humanities Study Tour Ho Chi Minh City, VietnamDocument19 paginiYusof Ishak Secondary School Humanities Study Tour Ho Chi Minh City, Vietnamadamant751Încă nu există evaluări

- Hamilton-Resume 4Document1 paginăHamilton-Resume 4api-654686470Încă nu există evaluări

- Data Sheet 6GK5213-3BB00-2TB2: Transfer RateDocument6 paginiData Sheet 6GK5213-3BB00-2TB2: Transfer RateClaudiu VlasceanuÎncă nu există evaluări

- Getting Started HANADocument86 paginiGetting Started HANAAr RazaÎncă nu există evaluări

- Jackson R. Lanning: Profile StatementDocument1 paginăJackson R. Lanning: Profile StatementJacksonLanningÎncă nu există evaluări

- GSM Rtu Controller Rtu5011 v2 PDFDocument27 paginiGSM Rtu Controller Rtu5011 v2 PDFAbdul GhaniÎncă nu există evaluări

- Safety Data Sheet: Section 1. IdentificationDocument10 paginiSafety Data Sheet: Section 1. IdentificationAnonymous Wj1DqbEÎncă nu există evaluări

- Bird Beak Adaptations: PurposeDocument9 paginiBird Beak Adaptations: PurposelilazrbÎncă nu există evaluări

- Ajol File Journals - 404 - Articles - 66996 - Submission - Proof - 66996 4813 136433 1 10 20110608Document12 paginiAjol File Journals - 404 - Articles - 66996 - Submission - Proof - 66996 4813 136433 1 10 20110608Lovely Joy Hatamosa Verdon-DielÎncă nu există evaluări

- Concept of InsuranceDocument4 paginiConcept of InsuranceNazrul HoqueÎncă nu există evaluări

- Grade 8 Mock 1Document11 paginiGrade 8 Mock 1yutika GhuwalewalaÎncă nu există evaluări

- Income Tax - MidtermDocument9 paginiIncome Tax - MidtermThe Second OneÎncă nu există evaluări

- Chapter 3 Rotation and Revolution NotesDocument12 paginiChapter 3 Rotation and Revolution NotesMERLIN ANTHONYÎncă nu există evaluări

- DNA Structure and Replication: Chapter Nine Khalid HussainDocument49 paginiDNA Structure and Replication: Chapter Nine Khalid HussainKhalid HussainÎncă nu există evaluări

- Research InstrumentsDocument28 paginiResearch InstrumentsAnjeneatte Amarille AlforqueÎncă nu există evaluări

- Board of DirectorsDocument2 paginiBoard of DirectorsjonahsalvadorÎncă nu există evaluări

- WikipediaDocument29 paginiWikipediaradhakodirekka8732Încă nu există evaluări

- Entrance 2021: Indira Gandhi Rashtriya Uran AkademiDocument2 paginiEntrance 2021: Indira Gandhi Rashtriya Uran Akademird meshramÎncă nu există evaluări

- Angles - of - Elevation - and - Depression Lesson STEMDocument18 paginiAngles - of - Elevation - and - Depression Lesson STEMmheojhun0% (1)

- Sample Barista Offer LetterDocument2 paginiSample Barista Offer LetterMohammed Albalushi100% (2)

- Executing and Releasing Value (V4.0.4.1) - A4Document27 paginiExecuting and Releasing Value (V4.0.4.1) - A4V100% (1)

- G5 Series User ManualDocument22 paginiG5 Series User ManualDaniel MekonnenÎncă nu există evaluări

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedDe la EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedEvaluare: 5 din 5 stele5/5 (1)

- A Place of My Own: The Architecture of DaydreamsDe la EverandA Place of My Own: The Architecture of DaydreamsEvaluare: 4 din 5 stele4/5 (242)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionDe la EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionEvaluare: 4.5 din 5 stele4.5/5 (2)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda Cans (Father's Day Gift for Science and Engineering Curious Dads)De la EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda Cans (Father's Day Gift for Science and Engineering Curious Dads)Încă nu există evaluări

- Building Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesDe la EverandBuilding Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesÎncă nu există evaluări

- The Aqua Group Guide to Procurement, Tendering and Contract AdministrationDe la EverandThe Aqua Group Guide to Procurement, Tendering and Contract AdministrationMark HackettEvaluare: 4 din 5 stele4/5 (1)

- Building Construction Technology: A Useful Guide - Part 1De la EverandBuilding Construction Technology: A Useful Guide - Part 1Evaluare: 4 din 5 stele4/5 (3)

- Real Life: Construction Management Guide from A-ZDe la EverandReal Life: Construction Management Guide from A-ZEvaluare: 4.5 din 5 stele4.5/5 (4)

- Principles of Welding: Processes, Physics, Chemistry, and MetallurgyDe la EverandPrinciples of Welding: Processes, Physics, Chemistry, and MetallurgyEvaluare: 4 din 5 stele4/5 (1)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansDe la EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansEvaluare: 4.5 din 5 stele4.5/5 (21)

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsDe la EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsÎncă nu există evaluări

- To Engineer Is Human: The Role of Failure in Successful DesignDe la EverandTo Engineer Is Human: The Role of Failure in Successful DesignEvaluare: 4 din 5 stele4/5 (138)

- Civil Engineer's Handbook of Professional PracticeDe la EverandCivil Engineer's Handbook of Professional PracticeEvaluare: 4.5 din 5 stele4.5/5 (2)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialDe la EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialÎncă nu există evaluări

- Rocks and Minerals of The World: Geology for Kids - Minerology and SedimentologyDe la EverandRocks and Minerals of The World: Geology for Kids - Minerology and SedimentologyEvaluare: 4.5 din 5 stele4.5/5 (5)

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetDe la EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetEvaluare: 4.5 din 5 stele4.5/5 (10)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ADe la EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AÎncă nu există evaluări

- Piping Engineering Leadership for Process Plant ProjectsDe la EverandPiping Engineering Leadership for Process Plant ProjectsEvaluare: 5 din 5 stele5/5 (1)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideDe la Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideEvaluare: 3.5 din 5 stele3.5/5 (7)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsDe la EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsEvaluare: 3.5 din 5 stele3.5/5 (3)

- Troubleshooting and Repair of Diesel EnginesDe la EverandTroubleshooting and Repair of Diesel EnginesEvaluare: 1.5 din 5 stele1.5/5 (2)

- Construction Management: Document to Reduce RiskDe la EverandConstruction Management: Document to Reduce RiskÎncă nu există evaluări

- Starting Your Career as a Contractor: How to Build and Run a Construction BusinessDe la EverandStarting Your Career as a Contractor: How to Build and Run a Construction BusinessEvaluare: 5 din 5 stele5/5 (3)

- The Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyDe la EverandThe Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyEvaluare: 4 din 5 stele4/5 (1)