Documente Academic

Documente Profesional

Documente Cultură

CHAPTER 3 PSA Summary of Daily Report

Încărcat de

Balamuni PsaDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

CHAPTER 3 PSA Summary of Daily Report

Încărcat de

Balamuni PsaDrepturi de autor:

Formate disponibile

CHAPTER 3: SUMMARY OF INDUSTRIAL TRAINING Every polytechnics student must undergo Industrial Training before they are bestowed

with a Diploma. This Industrial Training should be undergone for 20 weeks and it is done in the fourth semester for Diploma courses. Each student is given a daily report book where they have to note down the activities done daily throughout the training in it. The summary of activities which I have done throughout my Industrial Training in SETIA AWAN HILDINGS SDN.BHD (MISI JUTARI SDN.BHD), works from 9 July 2012 until 7 December 2012 where I have arranged it according to weeks as in my daily report book. The Summary:Electrical HT/LT maintenance works ( VCB/OCB /RMU / TXs) Low Voltage Switch gear and switch board maintenance (ACB/OCB)

Below are the services that we provide: Servicing of 11KV System Shutter operation Busbar torque checks Cable termination checks Heater checks Insulation/ Bushings

Below are the services that we provide: Cable termination checks Insulation resistance Overall breaker operation Contact resistance Operation of mechanism Cleaning and lubrication

36

Overall breaker, metering / LV, busbar, cable compartments

Minor adjustment (if any)

Contact resistance Operation mechanism Insulation resistance Cleaning and lubrication Minor adjustment (if any) Vacuum interrupter test

Electrical spare parts supply

To supply ACB, MCCB, MCB, RCCB, ELR, EFR and UVR. To supply all kinds of bulbs, chokes, ballast, capacitor, ignitors, holders and new light sets

To supply PVC cables, armored cables, MICC cables and FRS cables To supply capacitors, power factor regulators, Ammeters, voltmeters and protection CTs

37

Figure 3.1.1: Electrical Parts Generator repair, services and part supply

Check diesel fuel level in tank and return piping for leakage Check coolant level and top up if necessary Check battery condition, battery terminal and connection Check battery electrolyte level and top up if necessary Check condition of hoses Check condition of fan belt and charger and alternator belt Check charging alternator Check governor condition - Mechanical /Electronic control Start up engine and warm up engine Check engine instrumentation Level engine protection system - LOP, HWT and OS Check for tightness of AMF switchboard and battery charger Frequency: 48 Hz - 55 Hz Oil pressure and water temperature. 38

Figure 3.1.2: Generator repair, services and part supply

39

Servicing of High Tension oil immersed Transformer To carryout oil purification and filtration for transformers. To carry out die-electric strength test before and after purification of oil

Servicing of High tension cast resin Transformer Insulation test Vector group test Reduce press test To carry out general inspection and cleaning of cast resin transformers

Associated works as below:Motor rewinding

Figure 3.1.3: Induction Motor 40

Single phase motor Capacitor start motor Rotor resistance motor Low and high speed motor 3 phase induction motor Re-calibrations of Earth Fault/ Over current Relays Electrical wiring - domestic industries Telephone wiring c/w JC 9 and cabinet

41

S-ar putea să vă placă și

- BBPP1203 Principles of Management For Non-Business Majors - Caug17 (Bookmark)Document148 paginiBBPP1203 Principles of Management For Non-Business Majors - Caug17 (Bookmark)VictoriaLim100% (7)

- SampleDocument2 paginiSampleBalamuni PsaÎncă nu există evaluări

- 15 ReferenceDocument1 pagină15 ReferenceBalamuni PsaÎncă nu există evaluări

- Ac Motors: An AC Motor Is An Driven by AnDocument18 paginiAc Motors: An AC Motor Is An Driven by AnBalamuni PsaÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Drag of A Disk Rotating in A Viscous FluidDocument50 paginiDrag of A Disk Rotating in A Viscous FluidBaptiste RéaudÎncă nu există evaluări

- Chapter25 PDFDocument8 paginiChapter25 PDFElizabeth DouglasÎncă nu există evaluări

- Corresponds To The Correct Answer. Write You Answers On The Space Before Each NumberDocument2 paginiCorresponds To The Correct Answer. Write You Answers On The Space Before Each NumberJESSA SUMAYANGÎncă nu există evaluări

- A Companion To Fourier Analysis For Physics Students: Gol Mohammad NafisiDocument25 paginiA Companion To Fourier Analysis For Physics Students: Gol Mohammad NafisiIridian ÁvilaÎncă nu există evaluări

- Applications of Solar Energy PDFDocument42 paginiApplications of Solar Energy PDFpallav guptaÎncă nu există evaluări

- La Teoria SintergiaDocument17 paginiLa Teoria SintergiaCarlos CárdenasÎncă nu există evaluări

- Learn CBSE: To Measure Diameter of A Given Wire Using Screw GaugeDocument4 paginiLearn CBSE: To Measure Diameter of A Given Wire Using Screw GaugeSuman SamantaÎncă nu există evaluări

- Daikin Individual Control Systems Technical Data BookDocument37 paginiDaikin Individual Control Systems Technical Data BooktonylyfÎncă nu există evaluări

- Matter and Consciousness - Iain McGilcristDocument34 paginiMatter and Consciousness - Iain McGilcristmalcrowe100% (1)

- The Klein-Gordon EquationDocument22 paginiThe Klein-Gordon EquationAnderson CalistroÎncă nu există evaluări

- Spring 2011 Portfolio Unit PlanDocument48 paginiSpring 2011 Portfolio Unit PlanJack MoselÎncă nu există evaluări

- Cows and ChickensDocument9 paginiCows and Chickensapi-298565250Încă nu există evaluări

- ChapterDocument18 paginiChapterSharaf HantooshÎncă nu există evaluări

- Bionanotechnology - E. Papazoglou, A. Parthasarathy (2007) WWDocument148 paginiBionanotechnology - E. Papazoglou, A. Parthasarathy (2007) WWbicarbonat100% (2)

- NES 838 Part2Document42 paginiNES 838 Part2QTESÎncă nu există evaluări

- Adaptive Control by LandauDocument6 paginiAdaptive Control by LandauSabit RashidÎncă nu există evaluări

- 2017 Specimen Markscheme 1Document14 pagini2017 Specimen Markscheme 1Bassem Khalid YasseenÎncă nu există evaluări

- Electronique - Audio - Microphone Valve PreampDocument7 paginiElectronique - Audio - Microphone Valve PreampkoukihamedÎncă nu există evaluări

- "Quantum Physics" - S. GasiorowiczDocument522 pagini"Quantum Physics" - S. Gasiorowicz11111__11__1111100% (2)

- Atomic Absorption SpectrometryDocument36 paginiAtomic Absorption SpectrometryZubair KambohÎncă nu există evaluări

- Timoshenko Beam ElementDocument11 paginiTimoshenko Beam ElementMahmoud M.S. DwaikatÎncă nu există evaluări

- 6.1.5 - Well Control Worksheet & Pump DataDocument4 pagini6.1.5 - Well Control Worksheet & Pump DatadagingoÎncă nu există evaluări

- Full Lab Report #8Document13 paginiFull Lab Report #8Joe Morrison100% (2)

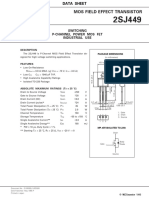

- 2SJ 449 - NecDocument9 pagini2SJ 449 - NecStevenÎncă nu există evaluări

- DiodeDocument36 paginiDiodeJacobÎncă nu există evaluări

- TDS 188-2 - RGA - CatalogueDocument20 paginiTDS 188-2 - RGA - CatalogueClausio Junior MeloÎncă nu există evaluări

- 24-Fracturing Horizontal Wells PDFDocument37 pagini24-Fracturing Horizontal Wells PDFmorcaronte08Încă nu există evaluări

- BillDipenser NCR 5633Document166 paginiBillDipenser NCR 5633Amanda Brown100% (1)

- 2008 Bruce VandermeerDocument11 pagini2008 Bruce Vandermeermadhumster1240Încă nu există evaluări

- Hveem Design Method For HMADocument8 paginiHveem Design Method For HMASaif LlÎncă nu există evaluări