Documente Academic

Documente Profesional

Documente Cultură

Design Data Book PDF

Încărcat de

Dheeraj ShuklaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Design Data Book PDF

Încărcat de

Dheeraj ShuklaDrepturi de autor:

Formate disponibile

MADHAV INSTITUTE OF TECHNOLOGY & SCIENCE DEPARTMENT OF CHEMICAL ENGINEERING GWALIOR- 474005

DATA BOOK

PROCESS EQUIPMENT & DESIGN

DHEERAJ SHUKLA CHEMICAL ENGINEERING, 3rd YEAR CM10008

INDEX

Sr. No. 1. 2. 3. 4. 5. 6. 7. 8. 9.

Content Unit Conversion Design of Process Vessel under Internal Pressure Design of Head & Closure Design of Non-standard Flanges Design of Process Vessel & Pipes under External Pressure Compensation for opening in Process Vessel Design of Tall Vessel Design of Supports for Process Vessel Design of thick walled High Pressure Vessel

Page No. 2 5 10 17 27 32 39 47 63

UNIT CONVERSION

Conversion of units from existing units to S.I. Units: Quantity Length Existing Unit 1inch 1ft 1yd 1mile 1 1min 1hr 1day 1year 1oz 1lbm 1cwt 1ton 1in.2 1mm2 1cm2 1ft2 1yd2 1kg/l 1lb/ft3 1lb/UK gal 1ib/US gal 1g/cm3 1cm/s2 1ft/s2 1erg 1ft pdl 1ft lbf 1cal 1kgf m 1Btu 1Chu 1hp-hr(metric) 1hp-hr(British) 1kW h 1 dyne S.I. Unit 0.0254m 0.3048m 0.9144m 1.6093m 10-10m 60s 3600s 86.4*103s 31.5*106s 28.352*10-3kg o.454kg 50.8023kg 1016.06kg 645.16*10-6m2 1*10-6m2 1*10-4m2 9.2903*10-2m2 8.3613*10-1m2 1*103kg/m3 16.018kg/m3 99.779kg/m3 119.83kg/m3 103kg/m3 1*10-2m/s2 0.3048m/s2 1*10-7J 4.2139*10-2J 1.3558J 4.1868J 9.8067J 1055.1J 1.8991*103J 2.6477*106J 2.6845*106J 3.6*106J 1*10-5N

Time

Mass

Area

Density

Acceleration Energy(Torque)

Force

Volume

Velocity

Viscosity(dynamic)

Frequency Specific heat capacity

Temperature Difference

Thermal Conductivity

Power

Pressure(Stress)

1 pdl 1lbf 1kgf 1tonnef 1tonf 1in3 1 US gal 1 UK gal 1ft3 1 barrel(petroleum US) 1 lube oil barrel 1 yd3 1 ft/h 1 ft/min 1ft/s 1 mile/h 1 mN s/m2(cp) 1 lb/ft h 1g/cm s (poise P) 1 lb/ft s 1 c/s 1 cal/gm C 1 Btu/lb F 1 Chu/l bC 1 C 1 C 1R 1 Btu/h ft2(F/in) 1 kcal/h m C 1 Btu/h ft F 1 cal/s cm C 1 ftlbf/min 1 ftlbf/s 1 m kgf/s 1 hp (metric) 1 hp (British) 1 dyne/cm2 1 Pascal 1 kgf/m2 1 mm water 1lbf/ft2

1.3825*10-1N 4.4482N 9.8067N 9.8067*103N 9.9640*103N 1.6387*10-5m3 3.7853*10-3m3 4.546*10-3m3 2.8317*10-2m3 0.15898m3 0.20819m3 0.76455m3 8.4667*10-5m/s 5.08*10-3m/s 0.3048m/s 0.44704m/s 1*10-3N s/m2 4.1338*10-4N s/m2 0.1 N s/m2 1.4882N s/m2 1Hz 4.1868*103J/kg K 4.1868*103J/kg K 4.1868*103J/kg K 1K 5/9 K 5/9 K 0.14423J/s m K 1.163J/s m K 1.7308J/s m K 418.68J/s m K 2.2597*10-2J/s 1.3558J/s 9.8065J/s 7.3548*102J/s 7.457*102J/s 0.1N/m2 1 N/m2 9.8067 N/m2 9.8067 N/m2 47.88 N/m2

Moment of inertia Momentum Angular momentum Viscosity(kinematic)

1 cm water(gf/cm2) 1 mbar 1 matm 1torr(mmHg) 1 in water 1 ft water 1 in Hg 1 lbf/in2(psi) 1 m water 1 2 at(kgf/cm orkp/cm2) 1 bar 1 atm 1N/mm2 1tonf/in2 1 lbft2

98.0671 N/m2 100 N/m2 101.33 N/m2 133.33 N/m2 249.09 N/m2 2.9891*103 N/m2 3.3866*103 N/m2 6.8948*103N/m2 9.8067*103 N/m2 9.8067*104 N/m2 1*105 N/m2 1.0133*105N/m2 1*106 N/m2 1.5444*107 N/m2 0.04214 kg/m2

1 lbft/s 1 lb ft2/s 1 S(stokes) 1 ft2/h

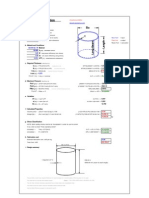

Design of process vessel under internal Pressure

Cylindrical Spherical

Design of cylindrical and spherical vessels under internal pressure Thin wall thickness

(a) If (b) If 0.25 then thin wall thickness vessels is required. 1.5 then thin wall thickness vessels is required. Thin wall thickness for cylindrical shell (i) Internal pressure

P=

(ii) Minimum wall thickness

or

t =

or

(iii) Circumferential stress

=

(iv) Longitudinal stress

z =

Thin wall thickness for spherical shell (i)Internal pressure

P=

or

(ii) Minimum thickness of wall

t=

or

(iii)Circumferential and longitudinal stress

= z =

Where,

or

P = Internal design pressure P = 1.05 * max working pressure J = Joint efficiency factor J= 0.85 double welded butt joint with full penetration J= 0.8 single welded butt joint with backing strip F=design stress for the material specified c = corrosion allowance t=thickness of wall without corrosion allowance

t = t + c

t = thickness with corrosion allowance D = mean diameter =

= outer diameter = inner diameter

THICK WALL VESSEL PRESSURE

There are three stresses applied (i) (ii) (iii) Longitudinal stress Radial stress Hoop stress

(1) Longitudinal stress

=

(2) Radial stress = Where, D = diameter of shell where stress is to be calculated (3) Hoop stress =

Stress at internal surface (i) Longitudinal stress

= =

In this case Po = 0 , If Do = 0 then = Pi

(ii)

Radial stress

= Where, K =

(iii) Hoop stress

Stress for external pressure

= 0 = =

The maximum shear stress at any point in the cylinder

zi

= = =

Theory of failure (1) Maximum shear stress theory

= Where, =yield stress Pi = Internal pressure K=

(2)Maximum strain theory

= Poisson ratio, is obtain by table 1 (3)Maximum strain energy theory

10

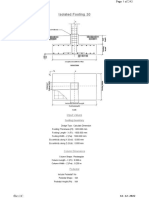

Design of Head and Closures

Design of flat head Thickness of flat head t = C De , De = effective diameter =Di

F= allowable stress of material. Design of cylindrical and spherical vessels under C = design pressure constant internal

C depends on the method of attachments to the shell. Cases follow: I. II. III. IV. Flanged flat head butt welded to shell Plates welded to the inside of the shell Plates welded to the end of the shell (no inside welding) Covers riveted or bolted with full face gaskets to shell flanges or side plates Covers with a narrow fane bolted flanged joint is placed within the bolts holes ( )

V.

Fb = bolt load VI. Plates welded to the end of the shell with an additional fillet weld on the inside. This thickness is theoretically calculated to this 2mm thickness. Corrosion allowance is to be added and another say 6% is to be added to take care of the reduction in thickness at the torus section. This gives a practically required min. thickness. The value of C is generally taken as 0.45.

11

TORI-SPHERICAL HEADS

Thickness of head t= C is the safe or stress concentration factor Assume (i)Safe factor C depend upon or for the head without any opening or with fully compensated opening or reinforced opening (ii) C depend upon or

for uncompensated opening

If Sf is very less , he = ho ho= Unreinforced opening ho= Where, he = Effective external height of head without straight flange ho = outside height of flange hi = inside height of flange Sf = flange height Sf = 40mm

12

ri and ro inside and outside knuckle radius Ri and Ro inside and outside crown radius d is the diameter of the largest uncompensated opening in the head For C t/D0C =P/2fJ now find value of C from he/D0 and t/D0 by trial & error method using table 2 C for formed head without opening or fully compensated opening is given in table 2 R0=D0 Blank diameter = D0+(D0/42)+(2/3)ri+2Sf For ,t 25mm =D0+(D0/42)+(2/3)rI+2Sf+t ,For , t 25mm External height of the excluding straight flange h0 =R0 ( ) for ,ri= .06 Di

V, Excluding straight flange = 0.0847 =0.1313

, for ,2:1 ellipsoidal or deep dished head

For accuracy it is suggested to recalculate h0 by putting new value for he/D0 another method would we assumed some value of t & check the same from t= PDOC/2fJ

13

ELLIPSOIDAL HEADS

Neglecting thinning effect C = 2fJt / PD0 , J=1 D0 = outer diameter of shell For, 2:1, ellipsoidal, he=h0=0.25D0 hi=0.25Di he/D0=0.25 , by table 3 obtain d/ Volume of elliptical dished head Vn = ( /4) (D0/6) = /24

ELLIPTICAL HEAD

Thickness of elliptical head

tn= PDV/2fJ

where , P=internal pressure D=major axis V=stress intensification factor = (2+K2) K=major axis =272.6

HEMISPHERICAL HEAD

Neglecting thinning effect C = 2fJt / PD0 , J=1 D0 = outer diameter of shell he/D0 = 0.5 ,From table 3 obtain d/

14

Volume of elliptical dished head Vn = ( /4) (D0/6) = /24

Total volume contain in vessel where D is internal diameter Vvessel=[{ }2+{ }2]

Volume of torispherical dished head to straight flange V=0.000049 Where, di=inside diameter of vessel in inches

CONICAL HEAD

(1)

Thickness of conical head at junction t= Where De is the outer diameter P is design pressure J is the factor to be taken at joint =0.85 Where Z is the factor to be Z 20 1.00 30 1.35 Surface area , A = (1/2) Volumetric capacity= (1/3)

(2)

45 2.05

60 3.20

(h/4)

thickness away from the junction t= ( )

, P=design pressure Dk=internal diameter of cone at a distance L

15

L=(1/2) t = thickness of shell+corrosion allowance From the junction, Dk=Di 2Lsin J =0.85 Di=Do 2t ,Do and Di= external and internal diameter

Table 1 Material Aluminium Brass Copper Iron Nickel Steel Specific weight ( 2.65 8.35 8.74 7.74 8.74 7.70 Poisson ratio = /E 0.34 0.35 0.35 0.28 0.36 0.30

Table 2 Stress concentration factor C for formed heads without opening or with fully compensated opening t/D0 hE/D0 0.002 0.005 0.01 0.02 0.04 0.15 4.55 2.66 2.15 1.95 1.75 0.20 2.30 1.70 1.45 1.37 1.32 0.25 1.38 1.14 1.0 1.00 1.00 0.30 0.92 0.77 0.77 0.77 0.77 0.40 0.59 0.59 0.59 o.59 0.59 0.50 0.55 0.55 0.55 0.55 0.55

16

Table 3 Stress concentration factor C for formed heads with uncompensated opening hE/D0 0.15 0.20 0.25 0.30 0.50 0.5 1.67 1.28 1.00 0.83 0.60 1.0 1.86 1.45 1.15 1.00 0.80 d/ 2.0 2.15 1.85 1.60 1.45 1.10 3.0 2.65 2.30 2.05 1.88 1.50 4.0 3.10 2.75 2.50 2.28 1.85 5.0 3.60 3.25 2.95 2.70 2.15

Note: values can be interpolated

17

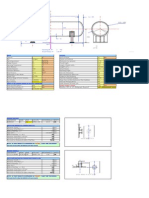

Design of Non-standard flanges

Gasket dimensions do/di = [ ( Y pm ) / { Y p (m+1) } vessels ] Design of cylindrical and spherical under Where, internal pressure di = inside diameter of gasket do= outside diameter of gasket Y = minimum design gasket seating stress p = internal design pressure

1/2

(Residual gasket force) = (gasket seating force) (hydrostatic pressure force) TABLE1 Gasket thickness and width of gasket Thickness (mm) 3 4 5 Width (mm) Up to 20 Over 20 and up to 30 Over 30

Thickness smaller than 3 mm can be used, if larger gasket seating stress is desired. The values of Y and m can be determined from table 1. 1. Minimum Gasket width N = (do di)/2

2. Gasket seating width bo = N/2

18

3. Effective gasket seating width

(a)

b = bo 1/2 (b) b = 2.5 ( bo )

when bo 6.3 mm when bo> 6.3 mm

4. Diameter at location of gasket load G (a) G=di + N when b < 6.3 mm (b) G=do 2b when b 6.3 mm 5. Maximum bolt space = [2d + {6t / (m + 0.5) } ] Where, d = bolt diameter, m = gasket factor, t = flange thickness. The minimum bolt spacing should not be less than 2.5 d for smaller bolt diameter.

6. Minimum bolt circle diameter C = B + 2 (g + R) or C = n Bs/ Where, C = bolt circle diameter, B = inside diameter of flange, g= thickness of hub at back of flange, R = radial clearance from bolt circle to point of connection of hub or nozzle and back of flange, n = actual number of bolts, Bs= bolt spacing.

19

Estimation of Bolt Loads:

1. Load due to design pressure: H=G2p/4 Where; H=Load due to design pressure, MN G= Dia at location of gasket load reaction, m P= design pressure, MN/m2 2. Load to keep joint tight under operation: Hp=G (2b) mp Where; p= design pressure m= gasket factor G=Diameter at location of gasket load b = effective gasket seating width 3. Total operating load: Wo = H + Hp

4. Load to seat gasket under bolting up condition : Wg= Gboy y=minimum gasket seating stress (table 2)

20

5. Controlling load ; If WO > Wg, then controlling load = WO If WO < Wg, then controlling load = Wg 6. Determination of minimum bolt area : Under operating condition Am is :( Am= Ao) Ao = Wo/So Under bolting up condition Ag = Wg/Sg Where: Ao is the bolt area required under operating condition Ag is the area required under bolting up condition So is allowable stress for bolting material at design pressure (table 2) Sg is allowable stress for bolting material at atmosphere temperature (table 2)

7. Calculation of flange outside diameter (A) . A= C+ bolt dia +0.02 meters (Use Table 3)

21

Check for gasket width:To prevent damage to gasket during bolting up condition following condition to be satisfied

Ab Sg / GN < 2y

(From table 3)

Determination of flange moments

(a) Operating condition 1. Total Load Wo = W1 + W2 + W3 W1 = ( B / 4) p W2 = H W1 W3 = WO H =Hp Where; W1 Hydrostatic end force on area inside of flange H- Load due to design pressure Hp- Load to keep joint tight under operation 2. Total flange moment Mo = W1 a1+ W2a2 + W3a3 The values of a1, a2 and a3 for different flange type Assume lap joint flange and use Table 5

22

(b) Bolting up condition 1. Total flange moment Mg = W a3 Where; W = (Am + Ab) Sg / 2 a3 = (C G)/ 2

TABLE 2 Allowable Stresses for Bolting Materials in MN/m2 Allowable stress MN/ m2 for design metal temperature not exceeding (0C)

Material Hot rolled carbon steel 5% Cr Mo steel 13.8%Cr Ni steel 13% Cr Ni steel 18% Cr 2 Ni steel

50 57.3

100 55.1

200 53.5

250 47.6

300

350

400

138.0 138.0 138.0 138.0 138.0 138.0 138.0 129.0 109.0 85.0 78.5 76.0 73.2 72.0

176.0 162.0 140.5 134.0 126.5 119.0 104.5 212.0 195.0 170.0 161.0 152.0 144.0 127.0

23

TABLE 3 FLANGES Bolt size Root area Min. no.of bolts Actu al no of bolts (n) 52 44 36 R(m) Bs (m) C= nBs/ (m) 1.24 1.05 0.86 C=ID+2(1.4 15go+R) (m)

M 16 x 1.5 1.54 x 104

50.8 43-7 33.7

0.025 0.027 0.030

0.07 5 0.07 5 0.07 5

1.0583 1.0623 1.0683

M 18 x 2 M 20 x 2

1.54 x 104

2 x 10-4

TABLE 4 I. loose type flange 1.lap joint flange 2. Raised face with hub II. Integral type 1.ring only plane face 2. lap weld hub raised face III. Optional type 1. plane face with weld hub 2, Ring only type raised face Outside dia Outside dia g1=21/2 g0 g1=g0 Outside dia Outside dia g1= g1 g1=21/2 g0 B Outside dia. Outside dia g1 g1=g0 g1=0.5 g0

24

Table 5 Moment arms for flange loads under operating conditions Type of flange Internal type flanges Loose type except lap joint flanges Lap joint flanges a1 R + (g1/2) ( C B)/ 2 ( C B)/ 2 a2 (R + g1 + a3) / 2 (a+ a)/2 ( C G)/ 2 a3 ( C G)/ 2 ( C G)/ 2 ( C G)/ 2

Calculation of flange thickness: t2 = (MCFY/BST) =(MCFY/BSFO) Where, CF = bolt pitch correction factor. CF = (BS/ (2d+t))1/2 M = MO And Y = Bt2SFO/M

Gasket material

Gasket factor m 1.00

Vulcanized rubber sheet hardness above 70 IHRD } Asbestos 3.2mm with a Thick suitable binder for 1.6mm operating conditions

Min. design seating stress, Y ,MN/m 1.38

Min. actual gasket width (mm) 10

2.00

11.00

10

2.75

25.50

10

25

0.8mm

3.50

44.85

10

Rubber with cotton fabric insertion } Rubber with 3asbestos fabric ply insertion, with or without wire reinforcement 2ply

1.25

2.76

10

2.25

15.25

10

2.50

20.00

10

2.75 1ply Vegetable fibre Spiral} Carbon wound steel metal, asbestos S.S.ormonel filled metal Corrugated } metal, asbestos Soft Al inserted or Soft asbestos filled Cu/brass corrugated Iron/soft metal jacket steel Monel metal S.S. } Corrugated metal Soft Al Soft Cu/brass Iron/soft steel Monel metal S.S. 1.75 2.50 3.00

25.50

10

7.56 20.00 31.00

10 10 10

2.50 2.75 3.00 3.25 3.50

20.00 25.00 31.00 38.00 45.00

10 10 10 10 10

2.75 3.00 3.25 3.50 3.75

25.50 31.00 38.00 45.00 52.00

10 10 10 10 10

26

Asbestos filled } flat metal jacket

Solid flat metal

Ring joint

Soft Al Soft Cu/brass Iron/soft steel Monel metal S.S. } Soft Al Soft Cu/brass Iron/soft steel Monel metal S.S. Iron/soft steel Monel metal S.S.

3.25 3.50 3.75 3.50 3.75

38.00 45.00 52.00 55.00 62.50

10 10 10 10 10

4.00 4.75 5.50 6.00 6.50

61.00 90.00 125.00 150.00 180.00

6 6 6 6 6

5.50 6.00 6.50

125.00 150.00 180.00

6 6 6

27

Design of process vessel and pipes under external pressure

(1) CRITICAL LENGTH BETWEEN Design of cylindrical andSTIFFENERS: spherical vessels under internal pressure = 0.3 for steel vessel D= outer diameter of shell t = thickness of shell

(2) OUT OF ROUNDNESS OF SHELLS (U): (a)For oval shape

(b)For dent or flat spots

Where, a = depth of dent or flat spots (maximum value is to be taken). U = Out of roundness factor, 1.5% for new vessel

(3) DETERMINATION OF SHELL THICKNESS WITH OUT STIFFENER RING: Design is to be check for elastic instability or plastic deformation

28

If type of head and closures are not given then consider the vessel has torispherical head (standard dished head) at the both end of shell having R =D0 and r=0.1D0 where R crown radius and r knuckle radius, D0 outside shell diameter Inside depth h for tori spherical head Where:

Effective length of tower without stiffener L= tangent to tangent length + 1/3(inside height of head) + 1/3(inside height of closures) Or L= tangent to tangent length + 2/3h (inside height of head and closures)

Determination of safe pressure against elastic failure:

Where; p safe external pressure E = modulus of elasticity at design temperature t = shell thickness, D0=outside dia

29

Value of K and m as a function of D0/L ratio of given in table below D0/L 0 0.1 0.2 0.3 0.4 0.6 0.8 1.0 1.5 2.0 3.0 4.0 5.0 K 0.733 0.185 0.224 0.229 0.246 0.516 0.660 0.879 1.572 2.364 5.144 9.037 10.359 M 3.00 2.60 2.54 2.47 2.43 2.49 2.48 2.49 2.52 2.54 2.61 2.62 2.58

Checking for plastic deformation If D0/L 5 or ( )

( ( )

, then

= allowable compressive stress U= out of roundness factor

If D0/L>5, i.e. L<0.2D0, then

If p > external design pressure than calculated thickness from elastic instability is correct otherwise thickness is not safe that calculated thickness against plastic deformation.

30

(4)DETERMINATION OF THICKNESS USING STIFFENER RING: Given if stiffener is use effective length of tower will be the trace facing, else the critical length between stiffeners is to be consider. So again calculate D0/L and find the value of K and m and calculate the shell thickness for elastic instability Checking for Plastic deformation If D/L5

If D/L>5

(5)DESIGN OF CIRCUMFERENTIAL STIFFENING RING: Design of stiffening ring involve first to select a standard structure and then to check for required moment of inertia of structure

Where, I= required moment of inertia f=allowable stress As=cross-section area of one circumferential stiffener E= modulus of elasticity at temperature L= distance between stiffener t = corroded shell thickness

31

Now, Select a 18 cm channel of following specification Weight (Wt) =14.6 kg As= 1.84 I=8.9 , m

No. of stiffener required = 5 Total weight of ring = DoWt no. of stiffener rings Saving in shell material for using stiffening rings: = D0 (t-ts) L = tangent to tangent length

32

COMPENSATION FOR OPENINGS IN PROCESS VESSEL

Design of cylindrical and spherical vessels under internal pressure

Where, d = internal diameter of nozzle,m = (outside dia of nozzle - 2thickness of nozzle) c = corrosion allowance,m reinforcement thickness. Where,

1. Area to be compensated

D = outside diameter of the shell 2. Area available from Shell for reinforcement:

Where, is the actual shell thickness. 3. Area available from nozzle for reinforcement: A = An ( no inside protution)

Where,

And

33

If nozzle length outside the vessel is larger than H1, the boundary limit the n above value of H1 will be taken. If, on the other hand, the nozzle length outside the vessel surface is less than or equal to the height of the boundary limit, then, H1 = actual length of nozzle 4. Area of the nozzle inside the vessel available for compensation:

Where, tn is the nozzle wall thickness. And If the inside protrusion of the nozzle goes beyond the boundary zone, then, On the other hand if the inside protrusion is less or equal, then, H2 = actual length of produced portion. Excess area available in the nozzle for reinforcement:

5. Reinforcement area everywhere from shell and nozzle:

If it is found that If

, then no other external reinforcement necessary. , the difference in area ring pad weldments is to be provided with

6. Area available from ring pad and weldmentsn within boundary limits:

2 ( d + 2c ) (d + 2c + 2 )} tp , tp= thickness of the ring pad, Ring pad dimensions:

34

Inner diameter = d Outer diameter = 2( d + 2c )

7. Area of compensation within the boundary limit:

Area of compensation within the boundary limit should not be less than the basic area removed from the shell during opening. i.e., AA. If material of construction for nozzle and ring pad having different allowable stress values for shell then area of compensation within the boundary limits:

Where, is allowable stress for shell material. is allowable stress for nozzle material. is allowable stress for ring pad material.

35

UNCOMPENSATION FOR OPENINGS IN PROCESS VESSEL

Uncompensated Opening

Design of cylindrical and spherical vessels under K factor: internal pressure

Then, According to IS: 2825-1969, near the opening above equation becomes:

If If

or a little over 1, an opening diameter up to 0.05m need not be compensated. , larger opening diameter up to 0.2m can remain unreinforced depending upon the shell diameter.

Weakening factor:

Where, is pressure required to cause 0.2% permanent deformation near the opening. Pressure required yielding the unpierced shell. Theoretical shell thickness for uncompensated opening:

If opening is made away from welded joints, J=1.

36

Table 1 0.0 0.25 0.5 0.75 1.0 1.5 2.0 2.5 3.0 3.5 1.000 0.900 0.785 0.700 0.645 0.545 0.465 0.390 0.340 0.285

4.0 4.5 5.0 5.5 6.0 6.5 7.0 7.5 8.0 0.245 0.215 0.180 0.155 0.130 0.115 0.090 0.080 0.075

Where, D0 is the shell outside diameter. d0 is the opening diameter. ts is the actual shell thickness. c is the corrosion allowance. weakening factor.

Determination of Compensation Requirement for Openings in Heads (a) For dished and hemisphere ends: If the opening and its compensation are located entirely within the spherical portion of a dished end, tr is the thickness required for a sphere having a radius equal to crown radius.

37

(b) For semi-ellipsoidal end: When the opening and its compensation are in ellipsoidal end and are located entirely within a circle having a radius, measured from the centre of the end, of 0.40 of the shell diameter, tr is the thickness required for a sphere having a radius R, derived from the following table: Table 2 0.167 0.178 0.192 0.207 0.227 0.25 1.36 1.27 1.18 1.08 0.99 0.90 0.277 0.312 0.357 0.40 0.45 0.50 0.81 0.73 0.65 0.59 0.54 0.50

Compensation for Multiple Openings Interaction between two openings, if their edge distance is roughly Where L is the pitch andd is the inside diameter of the large opening. Interaction between two openings is virtually negligible when, As per IS: 2825-1969 the openings spaced apart a distance not less than :

But in no case less than twice the diameter of the larger opening may be regarded as isolated opening. Effective cross sectional area for nozzle type reinforcement:

38

) (a)If the openings are along longitudinal direction:

(b)If openings are along circumference or on sphere:

39

DESIGN OF TALL VESSELS

1. Determination of shell thickness: ts = PDO / (2fJ+p)+C Design of cylindrical and spherical vessels Where, internal ts = thickness of shell under pressure J= joint efficiency (0.85) P= design pressure f = allowable stress (from table A-1) DO = outside diameter of shell 2. Determination of longitudinal stress: a) The axial stress (tensile or compressive) due to pressure in: Zp = P D2/4t(Di+t) , D = Di+t And, Zp =PD/4t , [{DO= Di+t =Di}]

Where,D=Di for internal pressure D=DO for vaccum(inclusive of insulation thickness) t= corroded shell thickness(thickness w/o corrosion allowance) b)The axial stress (compressive) due to dead loads: a) The stresses induced by shell wt. at X meter height from top: Zp=WS/ t(Di+t) Where, WS= (DtXS) Where, S=specific wt.(from table given below) WS=wt. of shell of length X meter t= shell thickness at the point under consideration

40

Material Aluminium Brass Copper Iron Nickel Steel

Specific wt. N/m3 2.65x104 8.35x104 8.79x104 7.74x104 8.74x104 7.70x104

Poissons ratio 0.34 0.35 0.35 0.28 0.36 0.30

b) The stress induced in the shell due to a distance X meters from the top: Zi= Wi/t(DI+t) Where, Wi=(Dtinsins ){wt. of insulation up to a distance for a length of X meters from the top} tins= insulation thickness ins= Specific weight of insulation (from table 1.1 given below) c) The stress induced by the weight of the liquid supported by the inner arrangement like tray for a distance X meter from the top is: No. Of tray, N= [(X-top spacing)/tray spacing] + 1 Zi = Wl/t(Di+t) Wl= (/4)D2(weir height)(sp. Gravity of water)(no. Of trays) Wl=Wt. of liquid supported for distance X meters from the top d) The axial stress due to the weight of attachments like trays,overhead condensers, top head, platforms and ladders for a distance X meter from the tpo is: za= Wa/t(Di+t) where, Wa= Wt of head + wt. of ladders + wt. of platform + wt. of liquid or trays Wt. of ladder =37X Wt. of platform = (/4)(dia. of platform)2(platform loading) Wt. of trays = (/4)(tray loading)(no. Of trays)

41

*for the design calculation weight of steel ladders plateforms,caged ladders ,plain ladders and trays (including liquid hold up)may be taken as given in the following data: steel ladder(caged)=37kgf per meter linear length steel ladder (plane) = 15kgf per meter length steel platform = 170 kgf per sq. Meter area Distillation tray wt. (inclusive of liquid hold up) = 122kgf per sq. Meter area

Total dead load stress, Zw, acting along the axial direction of shell at the point is given by: Zw=Zs + Zi + Zl + Za for vessel which does not contain internal attachments like tray but consists only of shell insulations, heads,minor attachments like nozzles,man holes,etc.the additional load may be approx. Equal to 18% of the weight of a steel shell.

3. The longitudinal bending stresses due to dynamic loads: a) The axial stress (tensile & compressive) due to wind loads in self-supporting tall vessels: The wind load on a vessel is given by: PW = (1/2)CD V2 A Where ,CD =drag coefficient = density of air V= wind velocity A = projected area normal to the direction of the wind The wind load on tall cylinder vertical vessel can be calculated from the following empirical formula (for a shape factor of ew =0.7) pw= 0.05 V2 Where,pw= wind stress in N/m2 or min. Wind pressure

42

V= wind velocity in Km/hour The wind pressure for the bottom part & the rest of the upper part can be directly obtained from the following table depending upon the zone of insulation of the vessel. TABLE.2 Wind pressure (kN/m2) Region Coastal area Area with moderate wind At, H =20m 0.7-1.0 0.4 At, H=100m 1.5-2.0 1.0

The total load due to wind acting on the bottom and upper parts of the vessel are determined from the following equations: Pbw=k1k2p1h1D0 Puw= k1k2p2h2D0

Pbw=total force due to wind load acting on the bottom parts of the vessel with height equal to or less than 20 meter Puw=total force due to wind load acting on upper part above 20 meter h1= height of the bottom part of the vessel equal to or less than 20 meter h2= height of the upper part above 20 meter p1= wind pressure for the bottom part of the vessel (from table 2,value given for H=20 meter)

43

p2= wind pressure for the bottom part of the vessel(to be determined from table 2 for mid point of upper part of vessel by interpolation of data given) D0=outer dia. including insulation as the case may be K1=coefficient depending upon shape factor = 90 degree to the wind = 0.7 for cylindrical surface K2= coefficient depending upon the period of one cycle of vibration of the vessel =1 (if period of vibration T is 0.5 second or less) = 2(if period exceeds 0.5 seconds)

The period of vibration T is given as T=6.35 x 10-5(H/D)3/2(W/t)1/2 Where, H= tangent to tangent height +skirt height W= total weight of shell W= WS + Wi +Wl + Wa Ws= weight of shell Wi= weight of insulation Wl= weight of liquid in tray Wa= weight of attachments If vessel height is less than 20 meter, then wind load Pw Pw=k1k2 (pw)D0X Where , pw= wind pressure or wind stress D0= Di+(2XTins)

44

* The bending moment at the base of the vessel due to wind load is determined from the following equation: a)If for the vessel H is less than or equal to 20 meter Mw = Pbw(H/2) b)for the vessel with H>20meter Mw=Pbw (h1/2)+Puw(h1+h2/2) The resulting bending stress in the axial direction is computed from the following correlation: zwm= 4 Mw/t(Di+t)Di Where, zwm=longitudinal stress due to wind moment(compressive on down wind side & tensile on up upwind side), Mw= bending moment due to wind load Di=inner dia. of the shell t= corroded shell thickness

4.Determination of resultant longitudinal stresses : a)The resultant tensile stress (on upwind side)in the cross section of the vessel at distance X meter from the top in absence of eccentric loads will be: For internal pressure, z = zp + zwm - zw z,tensile(maximum)= fJ forv external pressure z=( zwmor zsm )- zp - zw b) The resultant compressive stress (on downwind side) is given by: For internal pressure:z= zwm + zw - zp

45

z,compressive,(maximum) = 0.125E(t/Do) Where,E =modulus of elasticity For external pressure:z= (zwm or zsm) + zw + zp Check : (safe design) Equivalent stress , e = (e2 - e z + z2 )1/2 Here, e = hoop stress =P(Di+t)/2t or P(Do-t)/2t z= tensile stress Now calculate the value of z from: z = zp + zwm - zw And substitute the value of zp & e in the equation of equivalent stress and then check it from, e = fJ if e (calculated)< e (check design condition) then our calculated thickness is correct here e is calculated by putting X = height of tower height of skirt or tangent to-tangent height

Check for safe design: At design conditions, 1) e < Fj 2) (tensile)< fJ 3) z(compressive)< 0.125E(t/Do) At test conditions, 1) z < 1.3 fJ 2) z(tensile) <faJ 3) Z(compressive) <0.125Ea(ta/Do)

46

*Now calculate the value of z from: z = zp + zwm - zw and substitute the value of z and e in equation of equivalent stress and then check it from e= fJ *if e (calculated) is < w (checked design condition),then our calculated thickness is safe.

TABLE 1 Specific Weight of insulating Material Material Apparent sp. Wt. KN/m3 5.64 15.00 20.70 0.78 1.57 1.45 2.70 Thermal conductivity

Asbestos 0.496 Chalk 0.692 Plaster ,artificial 0.742 Cotton wood 0.042 Cork board 0.043 Cork ground 0.043 Diatomaceous earth Powder 0.069 ,fine Wool 1.08 0.036 Felt , wool 3.26 0.052 Graphite, powdered 4.78 0.180 Magnesia,molded& dry 12.20 0.432 Mineral,wood 7.84 0.605 Rubber,hard 11.70 0.150 Sawdust 1.88 0.052 Silk 0.99 0.045 D.Q Kern process heat transfer McGraw-Hill Book Co. Inc,New york

47

DESIGN OF SUPPORTS FOR PROCESS VESSELS

(1)

Thickness of shell for internal pressure in given by

Design of cylindrical and spherical vessels t= under internal pressure

Where, P= design pressure f= allowable stress j= joint efficiency factor = outer dia of shell C= corrosion allowance SUPPORTS 1] Skirt Support

1) The tensile stress in the skirt will be maximum when the dead load(weight) is minimum i.e. the shell of the vessel is just erected and the shell is empty without any internal attachment. 2) The compressive stress is to be determined when the vessel is filled up with water for hydraulic test. Maximum load may be expected at any time and this factor is always to be considered. The maximum weight of the vessel with two heads and shell will be = +

Where, Ws= Wt. of shell = ( ) (H - 4) = Wt. of Head = 2(Wt. of each head) = outer dia. Of shell = shell thickness, with corrosion allowance = specific weight of shell material from (table A-8) in H= total height (tangent to tangent ht. + skirt height)

48

= Ws + Wi + Wl + Wa The value of Ws, Wi, Wl, Wa can be taken from Tall vessel Now period of vibration at minimum dead weight is

Where, H= Total height of vessel D= Outer dia of vessel ta = shell thickness with corrosion allowance If Tmin 0.5 then K2 =1 Tmin > 0.5 then K2 = 2

Similarly, Period of vibration at maximum dead weight is given by

Now if total height of vessel is 20m or less than 20 m, then the wind load is determined as:

For maximum wind load:

Where , Pw =wind pressure = 0.05 Vw2 (Vw = wind velocity) D0 = outer dia of shell + 2 (thickness of insulation) K1 = 0.7 for cylindrical surface = 1.4 for flat surface 90 to wind

49

For minimum wind load: (PW) min = K1 K2 PW H D0

Minimum and maximum wind moments are given by: (Mw)min = (Pw)min . H/2 (Mw)max = (Pw)max . H/2

If the total height of vessel is greater than 20m then (Pbw) min = K1 K2 P1 h1 D (Puw) min = K1 K2 P2 h2 D Where, P1 = wind pressure at height h1 = 20m P2 = wind pressure at h2 > 20m D= outer dia of shell Similarly, (Pbw) max = K1 K2 P1 h1 D (Puw) max = K1 K2 P2 h2 D Where, K1, K2, h2, h1, P1, P2 are as before D= outer dia of shell +2x insulation thickness Maximum & minimum wind moment is given by: (Mw) max = (Pbw) max (h1/2) + (Puw) max (h1 + h2 /2) (Mw) min = (Pbw) min (h1/2) + (Puw) min (h1 + h2 /2)

50

As the thickness of skirt is excepted to be small assume Di = D0 Now, minimum longitudinal stress due to minimum wind moment is: Where, D = outer dia of skirt ( outer dia of shell when skirt support is cylindrical) ts = thickness of skirt Maximum longitudinal stress due to maximum wind moment is:

Minimum & maximum dead load stresses o the skirt is given by: Where; D = D0 when skirt is cylindrical Now maximum tensile stress w/o any eccentric load max max

For safe tensile stress:

Where; f = allowable stress J = joint efficiency factor (0.7 for double welded butt joint forclass3 cons)

51

(0.85 for double welded butt joint for class 2 cons) To find thickness, equate ..(1) Maximum compressive stress due to maximum load is computed as: max For safe compressive stress: max

Where; E = youngs modulus at design temp. ts = skirt thickness D0 = dia. Of skirt (outer dia of shell when skirt is cylindrical) = half the top angle of conical skirt (100maximum) (00 for cylindrical skirt) To find thickness Equate max (2)

The thickness which is maximum for (1) & (2) is considered as per IS 2852 1969, minimum corroded thickness of skirt is 7mm and taking 1mm as corrosion allowance. DESIGN OF SKIRT BEARING PLATE The maximum compressive stress b/w the bearing plate and the concrete foundation is given by (Max)= A= ( + l)l

Where, A = area of contact b/w bearing plate and concrete foundation is given by = outer dia of skirt

52

l = outer radius of bearing plate outer radius of skirt Z= l =( - l)/ 2

The allowable compressive strength of concrete foundation varies from 5.5 MN/ to 9.5MN/ Substitute (max) = 5.5NM/ and calculate l (max)

By substituting the value of l again in same equation and calculate

Thickness of bearing plate w/o gussets: = l M (max) = For b=1 M (max) = bl( ) =

(max)

If bearing plate thickness is equal to or less than 12 to 20mm , no gussets are required otherwise gussets are required to reinforce the plate from table 10.1 ,1/b=1 M (max) = M y = -.119 =

53

ANCHOR BOLT DESIGN:

J = Wmin R / Mw (min) If j < 1.5 then vessel is not steady by its own weight, Therefore anchor bolt are used. P bolt (n) = A Where P bolt = load on bolt N= no. of bolt A= area of contact b/w bearing plate and foundation (a r n) f =n P bolt Where ar is root area of bolt For f of bolt use table 7.5

SKIRT SUPPORT 1. Stress due to dead weight = Where, = skirt thickness, = outer dia or dia of vessel

2.

Stress due to wind load = Where = bending moment due to wind at base of vessel = = + for height up to ( + 20m

) for height > 20m

54

Where, =k = K P2 h2 D0 = D20 tsk Where, h2= (height of Bessel + height of skirt) 20m h1= ht. Up to 20m K= 0.7 P1&P2 = wind pressure 3. Stress due to seismic load fsb=

( )

Where, Msb= C W H & C =0.08 4. Maximum tensile stresss Fmax= fwb - fd Where, Fmax = permissible tensile stress 5. Max. Compressive stress fc(max)= fwb + fd fc yield point ( table A-1) Calculate value of tsk from above two formulae by equating the value of fc & ft

SADDLE SUPPORT Horizontal cylindrical vessels are supported on saddles. A cylindrical vessel with closure at the ends may be treated an equivalent cylinder having a (1) Length Length H = depth of closure L = length of tangent lines

55

(2)

Load on support w = uniformly distributed load

(3)

Bending moment at the support

Where, A = distance between support nearest end of vessel. H = height of head L = tangent to tangent length R = radius of tank

(4)

Bending moment at centre

(5) (a) If in case the stiffness is enough to maintain a circular cross section (i.e. A< 0.5R) the whole cross section is effective and therefore the stress due to bending is given by:(i)At the topmost fibre of the cross-section

(ii)At the bottom most fibre of the cross-section

Where: t = thickness of the shell K1 = K2 = 1

56

(b) For A > 0.5R the shell is not sufficiently stiffened by the end . The value of the factor:K1 = 0.107 = 120 K1 = 0.161 = 150 K2 = 0.192 = 120 K2 = 0.279 = 150 Stress in the shell at the mid span:The stress at the mid span

Arial stress in the vessel shell due to internal pressure

For design all these stresses are considerably than the permissible stress of material. And the combined stresses (fp+f1), (fp f2) and (fp+f3) should be within permissible stress

BRACKET SUPPORT OR LUG SUPPORT 1) Maximum compressive load due to wind: Where K = K1K2 = const. Pw can be calculated for height in same manner as in skirt support. The main load on the bracket support is the dead weight of the vessel with its contents & the wind load The maximum total compressive load on the support is given by } Where, p = total forces due to wind load acting on vessel. H=height of the vessel above foundation. F= vessel clearance from foundation to vessel bottom. Db= diameter of the bolt circle.

57

2)

W= max. wt. of vessel with attachments and its contents. Wmax = Ws + Wi + W1 + Wa n = no. of brackets. Bracket (thickness of base plate) : From table 13.2 Vessel dia. (D) = (given) v/s A=? No. of brackets = (given) v/s B=? Where B= length of the base plate.

Average pressure on the base plate is given by

Where P= total load a = (140mm) Maximum stress in a plate subjected to a pressure Pav & fixed at the edges is ..(1) Where f= bending stress (given) In this case the load is only distributed on the surface of contact between the base plate & the supporting beam; the actual stress may be taken as 40% more. .(2) For finding thickness of base plate T1 equation (2) is always used. 3) Thickness of web plates (gussets plates ): There are two web plates for each bracket. The bending moment for each plate is = PC/2 C= (A dia of tank) / 2 Stress at the edge of (3) Where, h=H(in c.m) from table 13.3 f=bending stress (given) 3PC=bending moment calculated above. Calculate T2 from eq.(3) T2 may be taken as 4 to 6mm.

58

4) Column support for bracket: It is proposed to use a channel section as column. The size chosen is ISMC 150 (from table c-3) bhatt) Size =150 75 Area of cross section (A) =? (From table c-3) Modulus of section (Zyy) =90.4cm.3 Radius of gyration (ryy) =? (From table c-3) Weight (W) =164 N/m Height from foundation (l) =given in question Equivalent length for fixed ends (Ie) = Slenderness ratio= Ie/ryy f = (P/A) + (P width of flange/modules of section) fc = (P/A)[1+(1/ )(le/r)] + (P width of flange/modules of section) Where, Density of material (steel) 5) Base plate for column: Size of column= _______150_______ _____20__________ Assume the base plate extend in mm. on either side of channel Side B= 0.8 (width of flange) + 2 (extend length) Side C=0.95 (depth of section) + 2 (extend length) Extended length is always taken as 20mm. Bearing pressure Pb = (P/number of brackets)(1/C) (C=side C) Pb should be less than the permissible bearing pressure for concrete. Stress in the plate f = [(side C/2) (extended lengtht2/10)]/(t2/6) f= bending stress given Calculate t (t is usually 4 to 6mm. thick.) SADDLE SUPPORT FOR HORIZONTAL VESSEL (1) Longitudinal bending moment at the support is [ ( ) ]

59

Where A = distance b/w support and its nerest end of vessel. H = height of head. L = tangent to tangent height. R = radius of tank. The value of A, H is taken from table 13.3 ( ) W = uniformly distributed load. Similarly the bending moment at the center of the span

( )

)[

(2)Longitudinal bending stress in shell at saddles a) when supports are near the end of the vessel, so that A < 0.5 R Then, (i) At the top most point of the cross section f2 = (ii) At the bottom most fiber of cross section f2 = Values of Factors K1 & K2

Condition shell stiffened by end or rings (i.e. A < R/2 or rings provided)

Saddle Angle 120 150

K1 1 1

K2 1 1

shell unstiffened by end or rings (i.e. A > R/2 or no rings provided)

120 150

0.107 0.161

0.192 0.279

60

(3)Longitudinal bending stresses at mid span (a) At the highest point of the cross section, f1 =

(b) At the lowest, f1 =

Tangential shearing stresses Case 1: shell not stiffened by vessel end (A > R/2) Maximum tangential stress is given by: ( )

It is not applicable if A > L/4 Value of K3 is depends on presence or absence of supporting rings and on the saddle angle and is given by table below Values of Factors K3 & K4

Condition A > R/2 and shell unstiffened by rings A > R/2 and shell stiffened by rings in

Saddle Angle ( ) 120 150 120 150 plane of saddles 120 150 adjacent to saddles

K3 1.171 0.799 0.319 0.319

K4

A > R/2 and shell stiffened by rings

1.171 0.799

61

Shell stiffened by end of vessel

120 150 120 150

0.880 0.485 0.880 0.485

0.401 0.279 0.880 0.485

Circumferential stresses (a) At the lowest point of the cross section,

(b) At the horn of the saddle, If L/R > 8, f4 = If L/R < 8, f4 = Stress can be reduced by welding a reinforcing backing plate. If width of this plate > B + 10t and if its angle from the centre of cylinder > ( + 12) degree, Then, substitute t with t + t1 Where, t1 = thickness of backing plate Value of K5 & K6 are given below K5 = 0.760 for = 1200 K5 = 0.673 for = 1500 Values of K6

A/R 0 0.5 0.6 0.7 0.8

= 1200 0.013 0.018 0.030 0.034

= 1500 0.007 0.010 0.017 0.021

62

0.9 1.0 1.1- 3.0

0.047 0.052 0.055

0.028 0.031 0.033

Ring stiffeners Ring stiffener is designed from the following correlation:

f = allowable compressive stress Ar = cross section area of the stiffening ring, (thickness width of rectangular cross section), Z = section modulus of ring cross section. Values of K7 & K8 as a function of saddle angle, , are given below Values K7 and K8

Saddle Angle ( ) 120 150

K7 0.0560 0.0210

K8 0.0528 0.0316

Design of Saddle Horizontal component of all radial loads may be determined by following equations F = K9 W1 Where, K9 = 0.204 for = 1200 0.260 for = 1500

63

DESIGN OF THICK WALLED HIGH PRESSURE VESSEL

1.Stresses in a thick cylinder:-

Design of cylindrical and spherical vessels = piDi2 p0D02/ D02 Di2 under internal pressure = [p D 2 p D 2/ D 2 D 2] [(p -p )D 2D 2/D2(D 2-D 2)] ,

i i 0 0 0 i i 0 i 0 o i

=[piDi2 p0D02/ D02 Di2]+[(pi-p0) Di2D02/D2(Do2-Di2)]] Where, = y/F =stress, D= any diameter where stress is evaluated Di= internal diameter Do= external diameter P0=pressure acting inside the jacket Pi=the inside shell pressure And , D0=Di+2t Or , D=Di, For maximum stress , K=D0/Di

For external jacket thickness, = p0(K2+1)/(K2-1) Where, D0=Jacket outside diameter Di= jacket inner diameter Again for,maximum stress ,D=Di,K= (D0/Di)

64

2.Theories of elastic failure:a)Maximum principal stress theory:(max) = y/F=pi(k2+1)/(k2-1) Where, e=yield point of the material P= internal pressure And,K= (D0/Di) Than calculate ,t(thickness). b)Maximum strain theory:(max) = y/F=pi [(1- )+(1+ )k2/(k2-1)] Where, =poissions ratio And, K= (D0/Di) Than calculate ,t. c)Maximum strain energy theory: = y/F=Pi(6+10k4)1/2/2(k2-1) And, K= (D0/Di) Than calculate ,t. d) Maximum shear theory:(i) when maxi. Shear stress equals to the shear stress set up in the material at elastic limit:=1/2(- r)=1/2 y or, y/F = [2k2/(k2-1)]Pi=2 (max) (ii) when elastic break down by maximum shear := y/pi = (3)1/2k2/(k2-1)

65

DESIGN OF STORAGE TANK

SHELL DESIGN:

1.Head of liquid (or height of tank) is calculated as:

Design of cylindrical and spherical vessels under internal pressure H = V/r2

Where, H= head of liquid (m) V = volume (capacity) of tank (m3) R = Di/2 = inner radius (m) [R can be calculated from table] [if only V is given ,H and R can be calculated from the table]

2. Number of layers of plates in shell: n = H/Width of plate Where , H = height of tank (m) Width of plate = 1.8 (from standard dimensions 6.3mx1.8mx1m)

3.Number of plates in a single layer: =Di /length of plate Where, Di = inner dia. of shell(m) Length of plate = 6.3m(standard)

66

4. Total number of plates used in shell: =number of layers x plates used in a single layer

5. Internal pressure of shell P= (H-0.3)g Where, P= internal pressure in N/m2 = density of liquid in Kgf/m3 H=height of tank in (m) g= accelaration due to gravity(10 m/s2) 6.Thickness of plate We can calculated the thickness of plates for each layer of the tank up to the total height of tank by the following formula:t= [50 (He-0.3)x DiG/fJ] +C Where, t=thickness 6. Average thickness of shell plates tavg = (t1 + t2 + t3 + + tn) / n Where, t1, t2, t3, tn the thickness of the respective layers and n is the number of layers 8.Stability check If H1 > H then our calculated thickness is correct Where, H = height of tank in m And H1 = 1500 [tavg / P] [tavg /Di]3/2 (m)

67

Where, P = superimposed load, wind load, sum of all external pressure acting on the tank in kg/ m2. Di = inner dia of tank in m. Tavg =average thickness in mm. BOTTOM DESIGN: 1. Thickness of bottom plate Tank diameter >12 m <12 m From IS Code 803-1976 thickness of bottom plate 6 mm 8 mm

2. bottom diameter (Db) Since diameter of the bottom of tank extends deyond the shell by65 mm

3. Circumference of Bottom = Db

4. Number of stiffening rings For increasing the thickness of shell stiffeners provided, around the shell No. of rings = Db / 6.3

ROOF DESIGN There are two cases in the roof designing Case1 Case2 When 370 When > 370 Self Supported Roof Supprted Roof

68

Where = roof curb angle For determining act, first we should assume roof as self supporting conical roof for which = 370 1. Thickness of Roof Plate t = Di / 5 sin Where, Di = inner dia of shell in m = Roof curb angle (370) t = Thickness of roof plate in m.

2. Dead load on Roof Dead load = (Thickness of roof plate in m) . (density of plate material in kg/m3

3. Total load on Roof Total load = super imposed load in kg / m2 + Dead lad in kg /m2

4. Actual Slope of Roof sin act = [Di/ t] [P / 0.202 E]1/2 where , Di = inner dia of shell in m t = thickness of roof plate in m P = total load on roof in kg / m2 E = Modulus of elasticity in kg / m2 (table no.) From here act can be calculated compare act that either > 37 or 37 and decide what roof will be allowable as given in earlier conditions.

69

SELF SUPPORTING ROOF DESIGN 1. Actual thickness of Roof plate If actual is less than or equal to 37 then we calculate actual thickness of the roof plate as given below tact = Di / 5 sin act Where, Di = inner dai of shell in m act = actual Roof Curb Angle tact = Actual Roof Plate thickness in mm 1. Roof Loading For self supporting roofs a uniform load of 125 kgf / m2is assumed 2. Internal pressure 1. 2. 3. 3. ROOF SHAPE The roof shape may have the following forms (a) Cone roof (b) Dome roof (c) Umbrella roof An internal pressure equivalent to 75 kg / m2 for non pressure tanks 200 kg / m2 for class A tanks 550 kg / m2 for class B tanks

SUPPORTED ROOF DESIGNS

1)

NO. of rafter on outer periphery = circumference / rafter spacing = d / 2 m ( assumed ) Where D = dia of shell in m Actual spacing between two rafters = circumference / no. of rafters = D/ no. of rafters

2) 3)

Selection of central support IS Code 803 1976

70

Diameter of tank 6 -12.5 m 12.5 15 m 15.20 m 20.25 m 25.30 m

type of central support one centre column circular square pentagonal hexagonal

4)

No. of rafter plate girder = total no. of rafters / no. of girders (sides of polygon)

5)

LENGTH OF SIDE OF POLYGON(a) a= D/cosec(180/n) Where, D= dia of the circle which contains the polygon n= no. Of sides of polygon

6)

Length of rafter According to IS Code 803-1976, we cannot take a rafter of length greater than 7.5m. But in the case of tank of radius greater than 7.5 m it creates problem. Therefore we have to spilt the rafter into two such parts that no one should be greater than 7.5 m. Hence choose the internal support under a circle which divides the radius of tank into two parts that they are always less than 7.5m

1) 2)

Length of inner rafter = Length of outer rafter =

Where D = dia of tank in m D1 = dia of inner circle in m

7)

Perimeter of polygon = no. of sides Area of polygon

length of a side

8)

A= n . a2 .Cot[ 180/n]

71

Where , A= area of polygon in m2 n= number of sides (grider) a= length of aside of a polygon in m

9)

No. of inner rafter = periphery of polygon (n.a) / inner rafter spacing (2m)

10) Actual rafter spacing

= periphery of polygon / no. of inner rafters

11) No. of inner rafter per girder

= no. of inner rafter / no. of sides of polygon

12) Total load on roof

= surface area of cone density of roof material = ( R L t) KGf Surface area of cone = R L thickness of plate

Where, R= D/2 = radius of tank in m L= H = R/16 = height of cone roof Density (p) of roof material in Kg/m3 Thickness (t) of roof plate = 6mm (from IS Code 803- 1976)

13) Load on polygon (Kgf)

= area of polygon density of roof material thickness of roof plate

14) Load on outer rafter = total load ioad on polygon 15) Load per outer rafter

= load on outer rafter / no. of inner rafter

16) Load on inner rafter =load on polygon 17) Load per inner rafter = load on inner rafter / no. of inner rafter

72

18) Load per grider = total load on roof (W) / 2n

Where, n = no. of sides of polygon

19) Bending moment (m) = WL2 / 8 (Kgf m2)

Where, W= total load on roof in Kgf L= in m

20) Section of modules (z) = B M / stress = M / F

With the help of Z and M by using steel plate we can find out the greater size.

S-ar putea să vă placă și

- Bolted Flange Design According To ASME Section VIII Division 1Document18 paginiBolted Flange Design According To ASME Section VIII Division 1LORENA REISÎncă nu există evaluări

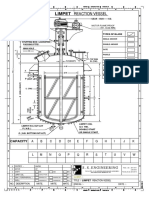

- Limpet Reaction Vessel PDFDocument1 paginăLimpet Reaction Vessel PDFarajamani78Încă nu există evaluări

- Technical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionDe la EverandTechnical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionÎncă nu există evaluări

- Design of Pressure Vessel by Group 4Document46 paginiDesign of Pressure Vessel by Group 4anteneh tesfayeÎncă nu există evaluări

- Application For The Static Equipment Design EngineerDocument3 paginiApplication For The Static Equipment Design EngineerTejas ShahÎncă nu există evaluări

- PVP2014-28729 Large Openings in Cylindrical Pressure Vessels-An Assessment Based On Absolute Size 2014 PDFDocument6 paginiPVP2014-28729 Large Openings in Cylindrical Pressure Vessels-An Assessment Based On Absolute Size 2014 PDFmatteo_1234Încă nu există evaluări

- Pipe Support DetailsDocument8 paginiPipe Support DetailsGodwinÎncă nu există evaluări

- Actual Plate Thickness: Material H/LDocument8 paginiActual Plate Thickness: Material H/LSruthish SasindranÎncă nu există evaluări

- Design of Reactor With Agitator Shaft 1Document40 paginiDesign of Reactor With Agitator Shaft 1gholiÎncă nu există evaluări

- Dimpled Jacket 2Document4 paginiDimpled Jacket 2grincheu7050% (2)

- Checking of Collar Bolts in Shear & Bearing: Client: India Eqpt.: Job No. DR No. Rev. Document NumberDocument1 paginăChecking of Collar Bolts in Shear & Bearing: Client: India Eqpt.: Job No. DR No. Rev. Document NumbershazanÎncă nu există evaluări

- NTIW Tube Sheet PaperDocument10 paginiNTIW Tube Sheet PaperPankaj SinglaÎncă nu există evaluări

- Design and Analysis of Vertical Pressure VesselDocument12 paginiDesign and Analysis of Vertical Pressure Vesselkumar31052003Încă nu există evaluări

- Manual On Chilled Water Pump CalculationsDocument18 paginiManual On Chilled Water Pump CalculationsImas Mnu AbdÎncă nu există evaluări

- Plate Fabricated Pipe Calculation Sample PDFDocument4 paginiPlate Fabricated Pipe Calculation Sample PDFSakthi VelÎncă nu există evaluări

- Design and Static Analysis of Different Pressure Vessels and Materials Using Fem MethodDocument7 paginiDesign and Static Analysis of Different Pressure Vessels and Materials Using Fem MethodSuryaprakashÎncă nu există evaluări

- Report Vibration Analysis For - Support Agitator v-410Document54 paginiReport Vibration Analysis For - Support Agitator v-410CaptainToniesÎncă nu există evaluări

- Stresses in Large Horizontal Cylindrical Pressure Vessels On Two Saddle SupportsDocument12 paginiStresses in Large Horizontal Cylindrical Pressure Vessels On Two Saddle SupportsAlexander BlackÎncă nu există evaluări

- Pressure Vessel Design (Basic)Document10 paginiPressure Vessel Design (Basic)Jason Gibbs100% (1)

- Nozzle Load CheckDocument4 paginiNozzle Load CheckpipestressÎncă nu există evaluări

- BS 4504 Slip On Flanges PDFDocument7 paginiBS 4504 Slip On Flanges PDFMaclean ArthurÎncă nu există evaluări

- Shell Thickness CalcDocument1 paginăShell Thickness CalcDidi KurniadiÎncă nu există evaluări

- PED-Design Preliminaries-Mechanical Aspects - MergedDocument87 paginiPED-Design Preliminaries-Mechanical Aspects - Mergedsudhanshu shekharÎncă nu există evaluări

- Agitator - Mixer For VesselsDocument26 paginiAgitator - Mixer For VesselsSri AmshaÎncă nu există evaluări

- Top Pipe MomentDocument2 paginiTop Pipe MomentrsubramaniÎncă nu există evaluări

- PV Elite BrocDocument6 paginiPV Elite BrocprasadgssÎncă nu există evaluări

- PHE SpecificationDocument2 paginiPHE SpecificationPaulusIwanÎncă nu există evaluări

- Development of Hot Cells and Their Embedded PartsDocument3 paginiDevelopment of Hot Cells and Their Embedded PartsK. JayarajanÎncă nu există evaluări

- Head Surface AeaDocument7 paginiHead Surface AeaShashi Kant KumarÎncă nu există evaluări

- BN-DS-T29 Collar Bolts For Removable Bundle Heat ExchangerDocument1 paginăBN-DS-T29 Collar Bolts For Removable Bundle Heat ExchangerAlexDdd123Încă nu există evaluări

- Is 4894 1987Document18 paginiIs 4894 1987sajay2010Încă nu există evaluări

- 1 - Design Helical Coil Heat ExchangerDocument6 pagini1 - Design Helical Coil Heat ExchangerNathan Van Betuw100% (1)

- eBroc-Shell and Tube Heat Exchangers Model Series and Customer Oriented Solutions, FunkeDocument18 paginieBroc-Shell and Tube Heat Exchangers Model Series and Customer Oriented Solutions, FunkeMoly69xÎncă nu există evaluări

- PR VESSEL FABRICATION - Awareness Session - 16.11.19Document50 paginiPR VESSEL FABRICATION - Awareness Session - 16.11.19avik100% (1)

- Heat Transfer FundamentalsDocument6 paginiHeat Transfer FundamentalsMuhammad FahadÎncă nu există evaluări

- Pressure Drop CalculationDocument1 paginăPressure Drop CalculationCak NhassÎncă nu există evaluări

- Sample of Expansion LoopDocument1 paginăSample of Expansion LoopalvinchuanÎncă nu există evaluări

- Sight Glass Selection Guide PDFDocument7 paginiSight Glass Selection Guide PDFani_datÎncă nu există evaluări

- PV Enineering EHX - OutDocument144 paginiPV Enineering EHX - Out9913489806Încă nu există evaluări

- Comparison of Design and Analysis of Tube Sheet Thickness by Using Uhx Code-2/comparison of Design and Analysis of Tube Sheet Thickness by Using Uhx Code-2 PDFDocument13 paginiComparison of Design and Analysis of Tube Sheet Thickness by Using Uhx Code-2/comparison of Design and Analysis of Tube Sheet Thickness by Using Uhx Code-2 PDFruponline1Încă nu există evaluări

- Shell: Working Pressure of Shell (As Per Ibr 270 & 271 New Amendment)Document1 paginăShell: Working Pressure of Shell (As Per Ibr 270 & 271 New Amendment)Karthic KeyanÎncă nu există evaluări

- Ansi B16.9-16.28-MSS SP-43Document3 paginiAnsi B16.9-16.28-MSS SP-43vangie3339515Încă nu există evaluări

- Design, Analysis and Optimization of Non Standard Weld Neck Body Flange in Small Pressure VesselDocument7 paginiDesign, Analysis and Optimization of Non Standard Weld Neck Body Flange in Small Pressure VesselGRD JournalsÎncă nu există evaluări

- 03 Metal Packing Support PlatesDocument3 pagini03 Metal Packing Support PlatesypatelsÎncă nu există evaluări

- Nitrile Rubber InsulationDocument2 paginiNitrile Rubber Insulationavid_ankurÎncă nu există evaluări

- What Is Design Interpretation?Document17 paginiWhat Is Design Interpretation?Qaisir MehmoodÎncă nu există evaluări

- Pressure VesselsDocument63 paginiPressure Vesselsكرار نعيمÎncă nu există evaluări

- Finned Tube Heat ExchangerDocument15 paginiFinned Tube Heat ExchangerAna Quintana0% (1)

- Blind Flanges - ANSI B16.5Document7 paginiBlind Flanges - ANSI B16.5Paul SolorzanoÎncă nu există evaluări

- Heat Exchanger Design2Document35 paginiHeat Exchanger Design2YunardiÎncă nu există evaluări

- Mini Kin Design Book 4 The DitionDocument36 paginiMini Kin Design Book 4 The Ditionhalder_kalyan9216Încă nu există evaluări

- Mechanical Equipment DesignDocument60 paginiMechanical Equipment Designzuber2111Încă nu există evaluări

- Laboratory Manual - Process Equipment Design PDFDocument24 paginiLaboratory Manual - Process Equipment Design PDFMd NoorÎncă nu există evaluări

- Design of Vertical Pressure VesselsDocument15 paginiDesign of Vertical Pressure VesselsMohit SinghÎncă nu există evaluări

- 26 Pressure Vessel.Document21 pagini26 Pressure Vessel.mishtinil93% (14)

- Weight Estimation of Vessels AppsDocument28 paginiWeight Estimation of Vessels AppsAlvin Smith60% (5)

- 26 Pressure VesselDocument21 pagini26 Pressure VesseljnmanivannanmechÎncă nu există evaluări

- API 650 Tank Design CalculationDocument9 paginiAPI 650 Tank Design CalculationSunday PaulÎncă nu există evaluări

- 20th NCE ProspectusDocument22 pagini20th NCE Prospectusvivek bajpaiÎncă nu există evaluări

- 19th Exam Advertisement PDFDocument1 pagină19th Exam Advertisement PDFDheeraj ShuklaÎncă nu există evaluări

- Online Application For DegreeDocument1 paginăOnline Application For DegreeankitrajeÎncă nu există evaluări

- Birla Cellulose, Kosamba (Aditya Birla Group)Document3 paginiBirla Cellulose, Kosamba (Aditya Birla Group)Dheeraj Shukla100% (1)

- Online Application For DegreeDocument1 paginăOnline Application For DegreeankitrajeÎncă nu există evaluări

- 19th Exam Advertisement PDFDocument1 pagină19th Exam Advertisement PDFDheeraj ShuklaÎncă nu există evaluări

- Philosophy: 1. Loss PreventionDocument3 paginiPhilosophy: 1. Loss PreventionDheeraj ShuklaÎncă nu există evaluări

- ZV 2 Usj/TDocument1 paginăZV 2 Usj/TDheeraj ShuklaÎncă nu există evaluări

- Discussion Invitation: Building Customer LoyaltyDocument1 paginăDiscussion Invitation: Building Customer LoyaltyDheeraj ShuklaÎncă nu există evaluări

- 1Q 3Document7 pagini1Q 3Dheeraj ShuklaÎncă nu există evaluări

- Print ERS Without Advertisements (X)Document2 paginiPrint ERS Without Advertisements (X)Dheeraj ShuklaÎncă nu există evaluări

- Current Affairs Pocket PDF - May 2016 by AffairsCloudDocument33 paginiCurrent Affairs Pocket PDF - May 2016 by AffairsCloudKandikunnta MalavikaÎncă nu există evaluări

- Print ERS Without Advertisements (X)Document2 paginiPrint ERS Without Advertisements (X)Dheeraj ShuklaÎncă nu există evaluări

- Model Question Paper - 2006 National Certification Examination Energy Managers & Energy AuditorsDocument7 paginiModel Question Paper - 2006 National Certification Examination Energy Managers & Energy AuditorsimkamleshÎncă nu există evaluări

- Police LawsDocument21 paginiPolice LawsMohd Usmaan KhanÎncă nu există evaluări

- 1QDocument6 pagini1QRajil NaikÎncă nu există evaluări

- Lecture 2 Hatchery and Design ConsiderationsDocument22 paginiLecture 2 Hatchery and Design ConsiderationsDheeraj ShuklaÎncă nu există evaluări

- Pressure Piping Thickness and Flange Rating CalculationDocument10 paginiPressure Piping Thickness and Flange Rating Calculationpradip panthaÎncă nu există evaluări

- P&IDDocument18 paginiP&IDhectornicolauÎncă nu există evaluări

- 3Q 2Document4 pagini3Q 2Dheeraj Shukla100% (1)

- Changes Between IPC Law Commission Reports JVC and 2013 ActDocument72 paginiChanges Between IPC Law Commission Reports JVC and 2013 ActDheeraj ShuklaÎncă nu există evaluări

- Revised Bus Time Table W.E.F. 4.8.15: Schedule of Bus TimingsDocument4 paginiRevised Bus Time Table W.E.F. 4.8.15: Schedule of Bus TimingsDheeraj ShuklaÎncă nu există evaluări

- Bombay Police Act 1951Document73 paginiBombay Police Act 1951Gabriella RuhilÎncă nu există evaluări

- Ammonia and Urea ProductionDocument10 paginiAmmonia and Urea Productionwaheed_bhattiÎncă nu există evaluări

- Notification 15052016Document6 paginiNotification 15052016Dheeraj ShuklaÎncă nu există evaluări

- 1 Why HalmateDocument24 pagini1 Why HalmateDheeraj ShuklaÎncă nu există evaluări

- Notification 15052016Document6 paginiNotification 15052016Dheeraj ShuklaÎncă nu există evaluări

- Interesting Panther FactsDocument6 paginiInteresting Panther FactsDheeraj ShuklaÎncă nu există evaluări

- Name Pack Size Used/batch Total Vol of Batch Percentage MakingDocument2 paginiName Pack Size Used/batch Total Vol of Batch Percentage MakingDheeraj ShuklaÎncă nu există evaluări

- Fail (Invalid Getgatewaypostingamount) : Dear CandidateDocument1 paginăFail (Invalid Getgatewaypostingamount) : Dear CandidateDheeraj ShuklaÎncă nu există evaluări

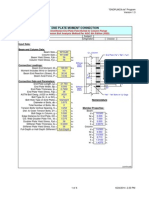

- Conxtech Conxl Moment Connection: 10.1. GENERALDocument24 paginiConxtech Conxl Moment Connection: 10.1. GENERALPaola DoradoÎncă nu există evaluări

- Calculation For Moment Connection - Type ADocument15 paginiCalculation For Moment Connection - Type ANitesh SinghÎncă nu există evaluări

- CIA - CPN24 Design-of-Joints-in-Concrete-Structures PDFDocument20 paginiCIA - CPN24 Design-of-Joints-in-Concrete-Structures PDFdjay101Încă nu există evaluări

- ARC2401-Jencks Charles-The Language of Post-Modern Architecture-The Modes of Architectural Communication-Pp39-80 PDFDocument51 paginiARC2401-Jencks Charles-The Language of Post-Modern Architecture-The Modes of Architectural Communication-Pp39-80 PDFSimonÎncă nu există evaluări

- Case Studies - Concrete Mixed Use Buildings - Infinity Tower, Dubai, UAE - Portland Cement Association (PCA) PDFDocument2 paginiCase Studies - Concrete Mixed Use Buildings - Infinity Tower, Dubai, UAE - Portland Cement Association (PCA) PDFMara Tom100% (1)

- GS Foundation 1205 en - T3-Model PDFDocument1 paginăGS Foundation 1205 en - T3-Model PDFLavender HoneyÎncă nu există evaluări

- Design Analysis & Comparsion of Intze Type Water Tank For Different Wind Speed and Seismic Zones As Per Indian CodesDocument10 paginiDesign Analysis & Comparsion of Intze Type Water Tank For Different Wind Speed and Seismic Zones As Per Indian CodesAnonymous oVmxT9KzrbÎncă nu există evaluări

- Pinned Base PlatesDocument61 paginiPinned Base PlatesDarren TurnerÎncă nu există evaluări

- Formwork PDFDocument27 paginiFormwork PDFKandarp Rajyaguru100% (1)

- Effect of Floating Column Position On Multi Storied RCC Structures Subjected To Dynamic LoadsDocument10 paginiEffect of Floating Column Position On Multi Storied RCC Structures Subjected To Dynamic LoadsKarthik SampathÎncă nu există evaluări

- Structural Engineering by Way of BIM PDFDocument12 paginiStructural Engineering by Way of BIM PDFcharvi shiny100% (1)

- ErectionDocument20 paginiErectionpulilathaÎncă nu există evaluări

- Behavior of Biaxially Loaded Concrete-Encased Composite Columns by Pedro R. Munoz Member, ASCE, and Cheng-Tzu Thomas Hsu/ Fellow, ASCEDocument9 paginiBehavior of Biaxially Loaded Concrete-Encased Composite Columns by Pedro R. Munoz Member, ASCE, and Cheng-Tzu Thomas Hsu/ Fellow, ASCEvardhangargÎncă nu există evaluări

- End Plate Moment ConnectionDocument4 paginiEnd Plate Moment Connectionmahhor82_635643838Încă nu există evaluări

- Flat SlabsDocument8 paginiFlat Slabsnahzem100% (1)

- Rockwood 6 and 8 Inch ClassicDocument4 paginiRockwood 6 and 8 Inch ClassicWorld Outdoor EmporiumÎncă nu există evaluări

- Column K PDFDocument27 paginiColumn K PDFAngelika Caguioa BiayÎncă nu există evaluări

- Ghosh The Development of Buddhist Art in South IndiaDocument14 paginiGhosh The Development of Buddhist Art in South IndiaRoberto E. GarcíaÎncă nu există evaluări

- Footing ReportDocument15 paginiFooting ReportSHAH JILÎncă nu există evaluări

- Rules of ThumbDocument10 paginiRules of ThumbYazuraPoyoÎncă nu există evaluări

- Seismic Evaluation of Existing Buildings and Strengthening TechniquesDocument12 paginiSeismic Evaluation of Existing Buildings and Strengthening TechniquesSujan ShresthaÎncă nu există evaluări

- Human Activity SAP ExamplesDocument10 paginiHuman Activity SAP ExamplesmnalnoussÎncă nu există evaluări

- Steel Structures 3 - Composite Steel-Concrete Structures - Slides Lecture 4 To 6Document46 paginiSteel Structures 3 - Composite Steel-Concrete Structures - Slides Lecture 4 To 6iSoK11Încă nu există evaluări

- Case Study: Sheraton Hotel, Bilbao, SpainDocument13 paginiCase Study: Sheraton Hotel, Bilbao, Spainfloi dÎncă nu există evaluări

- Structural Analysis and Design of Hospital Building and Associated Structures Surkhet Block "A" and "B" RampDocument88 paginiStructural Analysis and Design of Hospital Building and Associated Structures Surkhet Block "A" and "B" RampSudip ShresthaÎncă nu există evaluări

- Equivalent Frame MethodDocument34 paginiEquivalent Frame MethodMarlo Aristorenas100% (3)

- Analysis and Design of Pump HouseDocument9 paginiAnalysis and Design of Pump HouseKandousi YassineÎncă nu există evaluări

- 1995 The Structural Design of Tianjin Goldin Finance 117 TowerDocument12 pagini1995 The Structural Design of Tianjin Goldin Finance 117 TowerNadya Pricilia100% (1)

- Board Exam Problems-SteelDocument5 paginiBoard Exam Problems-SteelAngela Mae Francisco100% (1)

- Bolts in CADWorx Specifications (Excerpt)Document45 paginiBolts in CADWorx Specifications (Excerpt)CastorNoroñoÎncă nu există evaluări

- Marine Structural Design CalculationsDe la EverandMarine Structural Design CalculationsEvaluare: 4.5 din 5 stele4.5/5 (13)

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresDe la EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresEvaluare: 1 din 5 stele1/5 (2)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsDe la EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsÎncă nu există evaluări

- Predicting Lifetime for Concrete StructureDe la EverandPredicting Lifetime for Concrete StructureÎncă nu există evaluări

- Pocket Guide to Flanges, Fittings, and Piping DataDe la EverandPocket Guide to Flanges, Fittings, and Piping DataEvaluare: 3.5 din 5 stele3.5/5 (22)

- Advanced Modelling Techniques in Structural DesignDe la EverandAdvanced Modelling Techniques in Structural DesignEvaluare: 5 din 5 stele5/5 (3)

- To Engineer Is Human: The Role of Failure in Successful DesignDe la EverandTo Engineer Is Human: The Role of Failure in Successful DesignEvaluare: 4 din 5 stele4/5 (138)

- Green Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsDe la EverandGreen Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsÎncă nu există evaluări

- Structural Cross Sections: Analysis and DesignDe la EverandStructural Cross Sections: Analysis and DesignEvaluare: 4.5 din 5 stele4.5/5 (19)

- Pile Design and Construction Rules of ThumbDe la EverandPile Design and Construction Rules of ThumbEvaluare: 4.5 din 5 stele4.5/5 (15)

- Climate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingDe la EverandClimate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingÎncă nu există evaluări

- Flow-Induced Vibrations: Classifications and Lessons from Practical ExperiencesDe la EverandFlow-Induced Vibrations: Classifications and Lessons from Practical ExperiencesTomomichi NakamuraEvaluare: 4.5 din 5 stele4.5/5 (4)

- Bridge Engineering: Classifications, Design Loading, and Analysis MethodsDe la EverandBridge Engineering: Classifications, Design Loading, and Analysis MethodsEvaluare: 4 din 5 stele4/5 (16)

- Design and Construction of Soil Anchor PlatesDe la EverandDesign and Construction of Soil Anchor PlatesEvaluare: 5 din 5 stele5/5 (1)

- Engineering for Kids: Building and Construction Fun | Children's Engineering BooksDe la EverandEngineering for Kids: Building and Construction Fun | Children's Engineering BooksEvaluare: 3 din 5 stele3/5 (2)

- Modeling and Dimensioning of Structures: An IntroductionDe la EverandModeling and Dimensioning of Structures: An IntroductionÎncă nu există evaluări