Documente Academic

Documente Profesional

Documente Cultură

Material Properties

Încărcat de

mialitaDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Material Properties

Încărcat de

mialitaDrepturi de autor:

Formate disponibile

Material Properties, Auto/Mil Specs

W W W. A R P L A N K . C O M

Material Physical Properties

Physical Property Average Density Comp Strength @ 25% @ 50% @ 75% Tensile Strength Tensile Elongation Tear Strength Comp Set @ 25% Comp Set @ 50% Buoyancy Thermal Conductivity Thermal Resistance Service Temp Water Absorption Comp Creep Flammability Chemical Resist Fuel Immersion ASTM-D3575 ASTM-D3575 ASTM-D3575 ASTM-D3575 ASTM-D3575 ASTM-D3575 ASTM-C177 ASTM-C177 ASTM-D3575 ASTM-D3575 ASTM-D3575 FMVSS-302 Various Coast Guard (CGD-770145) Fuel B Test Method ASTM-D3575 ASTM-D3575 psi psi psi psi % lbs/in % % pcf (K)BTU-in / ft 2-hr-F (R) @ 70 F F % 1000hr@1psi <4.0 in/min 1 hr exposure <5% change in volume 8 16 38 39 38 12 3 12 61.2 0.26 3.9 160 ~1.0 2.5 Pass Pass Pass 10 18 44 40 32 14 3 14 60.6 0.26 4 160 ~1.0 2.8 Pass Pass Pass 11 19 49 45 30 16 4 13 59.5 0.24 4.2 160 ~1.0 3.0 Pass Pass Pass 13 22 56 52 29 17 4 12 59.5 0.24 4.2 160 ~1.0 3.3 Pass Pass Pass 22 35 75 70 25 21 4 12 59.1 0.24 4.2 160 ~1.0 3.0 Pass Pass Pass 11 19 41 35 18 9 8 16 61 0.24 4.2 212 ~1.0 n/a Pass Pass Pass 14.5 23.5 45 38 16 10 8 14 60.5 0.24 4.2 212 ~1.0 n/a Pass Pass Pass 23.5 33.5 64 55.5 15 13 7 12 59.5 0.24 4.2 212 ~1.0 n/a Pass Pass Pass 42 54 111 67 14 16 7 12 59 0.24 4.2 212 ~1.0 n/a Pass Pass Pass 6 15 40 22 50 12 2 6 61 0.25 4.0 185 ~1.0 n/a Pass Pass Pass 23 35 79 27 13 19 5 9 n/a 0.265 3.8 212 ~1.0 n/a Pass Pass Pass pcf Unit 1.0 1.3 EPE 1.5 1.9 2.8 1.0 EPP 1.3 1.9 2.8 xEPE 1.5 P-EPP 2.8

The ARPLANK Materials

ARPLANK products are manufactured by JSP, one of the world's leading innovators and manufacturers of expanded plastic foam materials.

Expanded polypropylene products in the ARPLANK product line are made from ARPRO EPP. Used extensively in automotive and packaging applications where durability, multiple impact resistance and other demanding performance challenges must be met.

ARPEX is a good alternative to polyurethane foams. It maintains its cushioning properties indefinitely and produces minimal out-gassing.

ARPAK EPE is one of the premier packaging foam materials available today. and is ideal for applications requiring resiliences, non-abrasive surface, and outstanding cushioning for multiple impact energy management.

This unique form of EPP is comprised of expanding shaped beads to reduce weight while maintaining a high degree of EPP performance characteristics.

A PRODUCT OF

The above data reflects the performance of ARPLANK panels under controlled test conditions using limited product samples. There can be no assurance that similar results will be achieved in simulated tests or actual commercial use of ARPLANK panels. JSP makes no representation or warranty, and does not assume any liability, with respect to the accuracy or completeness of such information or the product performance in any particular instance. JSP makes no representation or warranty with respect to ARPLANK panels, express or implied, including, without limitation, any warranty of merchantability, fitness for a particular purpose, quality or conformity with any description or sample.

INNOVATION

SIMPLIFIED

W W W. J S P. C O M

Material Properties, Auto/Mil Specs

W W W. A R P L A N K . C O M

Military, Federal and International Material Property Test: JSP Molded Polyolefin Bead Foam Products

Authority Specification CID A-A-59135 JSP Materials EPP Low Density Sheets EPE Low Density Sheets Military Standard CID A-A-59136 PPP-C-1752 MIL-STD-2073 33 CFR 183.114 EPP Low Density Plank EPP Low Density Plank EPP & EPE Low Density Plank EPP & EPE Low Density Plank EPP & EPE Low Density All EPP (White) Federal Standards 49 CFR 571.302 EPP 1.3 pcf (Black) CAL-117 Underwriters Laboratories (UL) UL-94 (HBF) UL-94 (HF-1/HF-2) UL-94 (V-0/V-2) European Union (EU)/European Economic Committee (EEC) FR-EPP EPP Low Density (White) FR-EPP & FR-PEPP FR-EPP Federal Motor Vehicle Safety Standard (FMVSS) 302 Cigarette Burn Test UL Listed EPP (see UL website for details) UL Listed EPP (see UL website for details) High FR (Aircraft Grade) Details Class 2; Grade A, Type I, III, IV & V & Grade C, Type III Class 1; Grade A, Type I & III Class 2; Grade A & C Class 1; Grade A & C Obolete Standard Standard Practice for Military Packaging Coast Guard Standard CGD-77-145 Federal Motor Vehicle Safety Standard (FMVSS) 302

ARPLANK products are manufactured by JSP, one of the world's leading innovators and manufacturers of expanded plastic foam materials.

The ARPLANK Materials

Expanded polypropylene products in the ARPLANK product line are made from ARPRO EPP. Used extensively in automotive and packaging applications where durability, multiple impact resistance and other demanding performance challenges must be met.

2000/53/EC

All JSP EPP, EPE, xEPE & PEPP Products

European End-Of-Life Vehicle Directive (ELV) Class A Product per NFPA (per ASTM E-84) Class A Product per NFPA (per ASTM E-84) Class A Product per NFPA (per ASTM E-84)

ARPAK EPE is one of the premier packaging foam materials available today. and is ideal for applications requiring resiliences, non-abrasive surface, and outstanding cushioning for multiple impact energy management.

UBC 2602 Uniform Building Code (UBC) / International Building Code (IBC) IBC 2602.1 / International Residential Code IRC R318 (IRC)

FR-PEPP (Plank) FR-PEPP (Plank) FR-PEPP (Plank)

Note: The above test specifications reference a variety of test methods, including, but not limited to; ASTM, DIN, ISO, DIN, SAE, JIS, FMVSS, UL, as well as a variety of custom test methods specified by the specific customer.

ARPEX is a good alternative to polyurethane foams. It maintains its cushioning properties indefinitely and produces minimal out-gassing.

This unique form of EPP is comprised of expanding shaped beads to reduce weight while maintaining a high degree of EPP performance characteristics.

A PRODUCT OF

The above data reflects the performance of ARPLANK panels under controlled test conditions using limited product samples. There can be no assurance that similar results will be achieved in simulated tests or actual commercial use of ARPLANK panels. JSP makes no representation or warranty, and does not assume any liability, with respect to the accuracy or completeness of such information or the product performance in any particular instance. JSP makes no representation or warranty with respect to ARPLANK panels, express or implied, including, without limitation, any warranty of merchantability, fitness for a particular purpose, quality or conformity with any description or sample.

INNOVATION

SIMPLIFIED

W W W. J S P. C O M

Material Properties, Auto/Mil Specs

W W W. A R P L A N K . C O M

Automotive Industry (OEM) Material Property Test: ARPRO EPP

OEM Specification JSP Materials

GMP-PP-068 GMP-PP-092 GM7400M (Various) General Motors [GM-Holden] HN 2324 GMW3059 GM9685P GMN 8351 D a i m l e r-Chrysler D a i m l e r-Benz MS-DB50; Type A, B, C, D, E DBL 5460 DBL 5461 F o rd WSB-M4D815-A1/A2/A3 WSS-M99P29-A TSM5725G; Type 2A, 2B, 3, 4 & 5 To y o t a TSM5743G TSM0502G TSM0500G NES M0086 NES M0094 Nissan NES M0131 NES M0132 NES M0133 NES M0301 Mitsubishi Subaru/Isuzu (Fuji Heavy Industries) Honda ES-X60317; Type A, B, C & D ES-X60210 TS346-5-56 HES D2500 HES-C206 7117Z-SDA-P010-M1 VW 501 80 Vo l k s w a g e n A G TL-VW 1010 VW 440 45

EPP; Low and Mid Density EPP; High Density EPP; Various Densities EPP; Various Densities EPP, xEPE; Various Densities EPP; Various Densities EPP, xEPE; Various Densities EPP; Low and Mid Densities EPP; Various Densities EPP; Various Densities EPP; Low and Mid Densities EPP; Low Densities EPP; Low and Mid Densities EPP, PEPP; Low Densities EPP; Various Densities EPP; Various Densities EPP; Various Densities EPP; Various Densities EPP; Various Densities EPP; Various Densities EPP; Various Densities EPP; Various Densities EPP; Low and Mid Density EPP; Various Densities EPP; Low and Mid Density EPP; Various Densities EPP; Various Densities EPP; Various Densities EPP; Various Densities EPP; Various Densities EPP; Various Densities

ARPLANK products are manufactured by JSP, one of the world's leading innovators and manufacturers of expanded plastic foam materials.

The ARPLANK Materials

Expanded polypropylene products in the ARPLANK product line are made from ARPRO EPP. Used extensively in automotive and packaging applications where durability, multiple impact resistance and other demanding performance challenges must be met.

ARPAK EPE is one of the premier packaging foam materials available today. and is ideal for applications requiring resiliences, non-abrasive surface, and outstanding cushioning for multiple impact energy management.

ARPEX is a good alternative to polyurethane foams. It maintains its cushioning properties indefinitely and produces minimal out-gassing.

Note: The above test specifications reference a variety of test methods, including, but not limited to; ASTM, DIN, ISO, DIN, SAE, JIS, FMVSS, UL, as well as a variety of custom test methods specified by the specific customer.

This unique form of EPP is comprised of expanding shaped beads to reduce weight while maintaining a high degree of EPP performance characteristics.

ARPRO, ARPEX and ARPAK is a registered trademark of JSP Licenses LLC. Publication JSP-Material properties, Auto/Mil Specs-2006/06

A PRODUCT OF

The above data reflects the performance of ARPLANK panels under controlled test conditions using limited product samples. There can be no assurance that similar results will be achieved in simulated tests or actual commercial use of ARPLANK panels. JSP makes no representation or warranty, and does not assume any liability, with respect to the accuracy or completeness of such information or the product performance in any particular instance. JSP makes no representation or warranty with respect to ARPLANK panels, express or implied, including, without limitation, any warranty of merchantability, fitness for a particular purpose, quality or conformity with any description or sample.

INNOVATION

SIMPLIFIED

W W W. J S P. C O M

S-ar putea să vă placă și

- Nuclear Power Plant Safety and Mechanical Integrity: Design and Operability of Mechanical Systems, Equipment and Supporting StructuresDe la EverandNuclear Power Plant Safety and Mechanical Integrity: Design and Operability of Mechanical Systems, Equipment and Supporting StructuresEvaluare: 5 din 5 stele5/5 (1)

- WhitePaper - Laser Scanning For Industrial PlantsDocument14 paginiWhitePaper - Laser Scanning For Industrial PlantsmialitaÎncă nu există evaluări

- SAEJ1344 V 001Document25 paginiSAEJ1344 V 001Juan VegaÎncă nu există evaluări

- Fluid Power Seal GuideDocument424 paginiFluid Power Seal GuideDillibabu RÎncă nu există evaluări

- O RingDocument424 paginiO Ringhemantabhale100% (1)

- Fluid Power Seal Design Guide: Catalog EPS 5370Document424 paginiFluid Power Seal Design Guide: Catalog EPS 5370Nicolas Darrel Pua BulnesÎncă nu există evaluări

- Parker O RingDocument0 paginiParker O RingRazvan C GoranÎncă nu există evaluări

- Rotary Seal Design GuideDocument434 paginiRotary Seal Design GuideBhargav Suvagiya100% (3)

- Arc Insulations BrochureDocument5 paginiArc Insulations BrochureacompositesÎncă nu există evaluări

- 2011-JAN ES-E SM-0128 US RevBDocument2 pagini2011-JAN ES-E SM-0128 US RevBpclaptopsusÎncă nu există evaluări

- Ficha Informativa 1204Document1 paginăFicha Informativa 1204IQCALLANÎncă nu există evaluări

- Oring Guide Europe Ord 5712ukDocument0 paginiOring Guide Europe Ord 5712ukramchandra rao deshpandeÎncă nu există evaluări

- 105 Ta D411-350Document3 pagini105 Ta D411-350isaacalvareztejanoÎncă nu există evaluări

- 2013.1.26 8.19.59 7545Document86 pagini2013.1.26 8.19.59 7545titanium_er88coolÎncă nu există evaluări

- Plexiglas MCDocument2 paginiPlexiglas MCMarco Ngawang KeelsenÎncă nu există evaluări

- NORMAPLAST en PDFDocument19 paginiNORMAPLAST en PDFmkalamarasÎncă nu există evaluări

- Chemical Resistance Guide FPMDocument26 paginiChemical Resistance Guide FPMjeanmarcauerÎncă nu există evaluări

- Adhesives&Sealants PVCDocument2 paginiAdhesives&Sealants PVCkaiserasraelÎncă nu există evaluări

- BUL Marine 3000 - 0409Document4 paginiBUL Marine 3000 - 0409Muhammad FerialÎncă nu există evaluări

- Explosive DecompressionDocument11 paginiExplosive DecompressionAndrey EkkertÎncă nu există evaluări

- FRP Cable Tray 1Document37 paginiFRP Cable Tray 1Vikas TanejaÎncă nu există evaluări

- FDM Materials - Overview 2015Document2 paginiFDM Materials - Overview 2015bloodterry2284Încă nu există evaluări

- AOC Corrosion Guide Listing UpdatedDocument32 paginiAOC Corrosion Guide Listing UpdatedYap HS100% (1)

- Parker Seals FAQDocument5 paginiParker Seals FAQmuditmmittalÎncă nu există evaluări

- (VESBO) Catalog en 100317Document55 pagini(VESBO) Catalog en 100317AnhNguyen100% (1)

- Vespel: Shapes: SP Polyimide Machining StockDocument8 paginiVespel: Shapes: SP Polyimide Machining StockFriedrich GaussÎncă nu există evaluări

- Operator'S Manual Px15P-Xxx-Xxx-Axxx: 1-1/2" Diaphragm PumpDocument12 paginiOperator'S Manual Px15P-Xxx-Xxx-Axxx: 1-1/2" Diaphragm PumpNashrullah AhmadÎncă nu există evaluări

- Erapol EHP70DDocument2 paginiErapol EHP70DqwepoolÎncă nu există evaluări

- Alp General ACCESORIESDocument74 paginiAlp General ACCESORIESsas_uu100% (1)

- Section G - Cable TiesDocument15 paginiSection G - Cable TiesOtto AcnÎncă nu există evaluări

- 5370Document300 pagini5370Arnaldo BenitezÎncă nu există evaluări

- Fluid Power Seal Design Guide - Catalog EPS 5370Document300 paginiFluid Power Seal Design Guide - Catalog EPS 5370SasankÎncă nu există evaluări

- Amerlock 400 GFADocument4 paginiAmerlock 400 GFASherif AbdelhameedÎncă nu există evaluări

- HDP Pipe and Fittings CatalougeDocument64 paginiHDP Pipe and Fittings CatalougeThiruvengadamÎncă nu există evaluări

- FRP Catalogue 04.2021Document84 paginiFRP Catalogue 04.2021Bilel MahjoubÎncă nu există evaluări

- AgHT 10Document1 paginăAgHT 10Muhammad Sa'ad BashirÎncă nu există evaluări

- Parker O-Ring GuideDocument96 paginiParker O-Ring GuideJason ZhaoÎncă nu există evaluări

- Catalog O Ring Guide ODE5712 GB 0704Document88 paginiCatalog O Ring Guide ODE5712 GB 0704Ashwanth RameshÎncă nu există evaluări

- Data Sheet: Series E Electronic Metering PumpsDocument2 paginiData Sheet: Series E Electronic Metering PumpsShesharam ChouhanÎncă nu există evaluări

- CatalogDocument36 paginiCatalogBhurman Pratama PutraÎncă nu există evaluări

- Aral Supertronic K 5w-30 Global English PDB 470247Document2 paginiAral Supertronic K 5w-30 Global English PDB 470247viktor chervonenkoÎncă nu există evaluări

- Fluid Resistant Epoxy Primer Lead and Cadmium Free: Technical Data SheetDocument4 paginiFluid Resistant Epoxy Primer Lead and Cadmium Free: Technical Data SheetFrancisco RodríguezÎncă nu există evaluări

- PALSUN Flat Solid Polycarbonate SheetsDocument28 paginiPALSUN Flat Solid Polycarbonate SheetsGirish DhawanÎncă nu există evaluări

- Especificaciones Vinil Polyflor Mystique PP Oct 2013Document1 paginăEspecificaciones Vinil Polyflor Mystique PP Oct 2013Henry ValenciaÎncă nu există evaluări

- EL EAM BrochureDocument10 paginiEL EAM BrochureParlin AmbaritaÎncă nu există evaluări

- 22 Dead-End & Suspension InsulatorsDocument16 pagini22 Dead-End & Suspension Insulatorsrye_eeÎncă nu există evaluări

- Operator'S Manual Px10P-Xxs-Xxx-Axxx: 1" Diaphragm PumpDocument12 paginiOperator'S Manual Px10P-Xxs-Xxx-Axxx: 1" Diaphragm PumpjarosÎncă nu există evaluări

- BT DataDocument2 paginiBT DatasoudchoudhuryÎncă nu există evaluări

- Automotive Buzz, Squeak and Rattle: Mechanisms, Analysis, Evaluation and PreventionDe la EverandAutomotive Buzz, Squeak and Rattle: Mechanisms, Analysis, Evaluation and PreventionEvaluare: 5 din 5 stele5/5 (3)

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionDe la EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionÎncă nu există evaluări

- Issue #9 Printing and Graphics Science Group NewsletterDe la EverandIssue #9 Printing and Graphics Science Group NewsletterÎncă nu există evaluări

- Geotextiles and Geomembranes HandbookDe la EverandGeotextiles and Geomembranes HandbookT.S. IngoldEvaluare: 5 din 5 stele5/5 (1)

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965De la EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Încă nu există evaluări

- GRP and Buildings: A Design Guide for Architects and EngineersDe la EverandGRP and Buildings: A Design Guide for Architects and EngineersÎncă nu există evaluări

- Applications of Fluoropolymer Films: Properties, Processing, and ProductsDe la EverandApplications of Fluoropolymer Films: Properties, Processing, and ProductsÎncă nu există evaluări

- Process Design ThinkingDocument48 paginiProcess Design ThinkingmialitaÎncă nu există evaluări

- Part and Mold Design Guide (2005)Document174 paginiPart and Mold Design Guide (2005)naitikpanchal100% (4)

- Company: Person in Charge: Dispatched Location: Dispatched Staff: Position: Period: Working Day / TimeDocument1 paginăCompany: Person in Charge: Dispatched Location: Dispatched Staff: Position: Period: Working Day / TimemialitaÎncă nu există evaluări

- Dimension IngDocument26 paginiDimension IngmialitaÎncă nu există evaluări

- Technical Drawing SpecificationsDocument21 paginiTechnical Drawing SpecificationsmialitaÎncă nu există evaluări

- ISO StandardsDocument4 paginiISO StandardsmialitaÎncă nu există evaluări

- Acrawax C Dispersing Agent For Colour MasterbatchDocument2 paginiAcrawax C Dispersing Agent For Colour MasterbatchcharliesÎncă nu există evaluări

- Effect of Polymer Morphology On Photodegradation Kinetics 411Document13 paginiEffect of Polymer Morphology On Photodegradation Kinetics 411Marister OliveiraÎncă nu există evaluări

- Review Raw Natural Fiber Based Polymer CompositesDocument17 paginiReview Raw Natural Fiber Based Polymer CompositeswaleedsikandryÎncă nu există evaluări

- Welding Methods For Joining Thermoplastic Polymers For The Hermetic Enclosure of Medical DevicesDocument10 paginiWelding Methods For Joining Thermoplastic Polymers For The Hermetic Enclosure of Medical Deviceskaliappan45490Încă nu există evaluări

- Evironmental Issues PlasticDocument8 paginiEvironmental Issues PlasticDafa FadilahÎncă nu există evaluări

- Effects of Fibers On The Glass Transition Temperature of Polyphenylene Sulfide CompositesDocument5 paginiEffects of Fibers On The Glass Transition Temperature of Polyphenylene Sulfide CompositesTC Onur ÇobanÎncă nu există evaluări

- Jan 11Document66 paginiJan 11c_nghia100% (2)

- 1 PCRDocument78 pagini1 PCRTressa SoÎncă nu există evaluări

- Shenoy 1986Document58 paginiShenoy 1986Miguel Alberto CasabÎncă nu există evaluări

- Design and Automation of Plastic Injection Molding Machine: Under The Valuable Guidance ofDocument49 paginiDesign and Automation of Plastic Injection Molding Machine: Under The Valuable Guidance ofAniket ChavanÎncă nu există evaluări

- Biofuel From PlasticDocument4 paginiBiofuel From PlasticNaveen BPÎncă nu există evaluări

- Basic MethodDocument13 paginiBasic MethodGagan H PÎncă nu există evaluări

- SABIC® PP - FPC70T - Asia - Technical - Data - SheetDocument2 paginiSABIC® PP - FPC70T - Asia - Technical - Data - SheetJuan PabloÎncă nu există evaluări

- Non-Hydrolyzable Plastics - An Interdisciplinary Look at Plastic Bio-OxidationDocument12 paginiNon-Hydrolyzable Plastics - An Interdisciplinary Look at Plastic Bio-Oxidationtiffany charlottaÎncă nu există evaluări

- PolymersDocument92 paginiPolymersShahid MehmudÎncă nu există evaluări

- Cartridge English PDFDocument20 paginiCartridge English PDFkunto prÎncă nu există evaluări

- Psi Fiberstrand Multi-Mix 80: Polypropylene MicrofiberDocument2 paginiPsi Fiberstrand Multi-Mix 80: Polypropylene Microfibercaleb pazÎncă nu există evaluări

- Topilene J800Document1 paginăTopilene J800KevinGarciaÎncă nu există evaluări

- Forbo ConveyorsDocument14 paginiForbo ConveyorsMiguel AngelÎncă nu există evaluări

- Flexitanks PresentationDocument13 paginiFlexitanks PresentationOchoa ErickÎncă nu există evaluări

- 5packaging of Pharmaceutical Dosage FormsDocument19 pagini5packaging of Pharmaceutical Dosage FormsTrii SakttiÎncă nu există evaluări

- CCS Series Ink LineupDocument2 paginiCCS Series Ink LineupJesus LozanoÎncă nu există evaluări

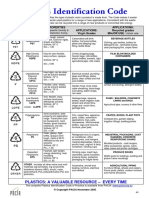

- Plastic Identification CodesDocument1 paginăPlastic Identification CodesMuhammad Adnan HafeezÎncă nu există evaluări

- DEP 31.40.30.37-Gen-Feb-2020 EXTERNAL FIELD JOINT AND REHABILITATION COATINGDocument75 paginiDEP 31.40.30.37-Gen-Feb-2020 EXTERNAL FIELD JOINT AND REHABILITATION COATINGDevam RajÎncă nu există evaluări

- NFT-58-000 Tolerances Applicable To Moulded PlasticDocument10 paginiNFT-58-000 Tolerances Applicable To Moulded PlasticTrexa Gyreue0% (1)

- Inhibitors For Unsaturated Polyester Resines. Parker 1963Document4 paginiInhibitors For Unsaturated Polyester Resines. Parker 1963Guz UchihaÎncă nu există evaluări

- A Study in The Effect of Different Nozzle Shapes and Fibre Reinforcement in 3D Pritable MortarDocument23 paginiA Study in The Effect of Different Nozzle Shapes and Fibre Reinforcement in 3D Pritable MortarManu K MohanÎncă nu există evaluări

- Use of Plastic Waste in Road ConstructionDocument28 paginiUse of Plastic Waste in Road ConstructionKunreddy Naresh Reddy100% (2)