Documente Academic

Documente Profesional

Documente Cultură

Loading Plan

Încărcat de

Iordache DumitruDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Loading Plan

Încărcat de

Iordache DumitruDrepturi de autor:

Formate disponibile

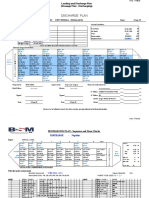

M.T.

STAVANGER BELL

Loading Plan

PORT OF: Yosu STS area Date Voyage no Grade

REMARK: VESSEL IS RESERVING THE RIGHT TO CHANGE THE 6 Oct 12 PRESENT PLAN ON RECEIVING THE CORRECT DENSITY AND 022 TEMPERATURE FROM TERMINAL. OR FOR ANY OTHER Sokol Crude Oil INSTRUCTIONS FROM CHARTERERS, RECEIVED AFTER COMMENCEMENT OF LOADING. FOR ANY OTHER LIMITATIONS Quantity to be loaded 93600 MT OF THE TERMINAL AS LINE DIAMETER OR NUMBER THE PLAN Est. Loading rate 5000 m3/hr CAN ALSO BE CHANGED Estimated load. Time 22 hrs Manifolds to be connected to cargo hoses: NO.1&2 x 12" Manifold crossovers 1, 2, 3 OPEN; Loading in 1W, 2W,3W, 4W,5W, Slop W.

Venting: All IG Inlets to be kept in open locked position, venting through mast riser.

STANDING C/O INSTRUCTIONS

1. Make rounds of the vessel and in pump room at appropriate intervals and log . 2. DESIGNATED OBSERVATION AREA IS MANIFOLD AREA. 3. Cargo room to be always manned by authorized persons during cargo operations. 4. Ensure the gangway (if used) is safe, moorings are well tended by minimum 2 persons, be aware of tide timings and pay particular attention to mooring and gangway at such times. Fire wire (if used) to be "NO SLACK ON DECK", 2m above water. 5. Cargo transfer connections should be monitored for tampering and in case of suspect connections, should be reported and investigated. Check readiness of fire-fighting equipment. 6. Cargo deck area, handling system and equipment should be monitored for tampering and in case of suspect spaces, equipment or systems should be reported and investigated. 7. Check the drafts at the end of every watch visually 8. The manifold and gangway should be manned at all times. 9. Particular interest by terminal staff or other involved parties in the nature of cargo, route, schedule, etc should be reported. 10. Fire wires (if used) to be adjusted by line connected to eye and not from weak link (if there is slack on deck), 11. Check that scuppers are plugged at all times, readiness of anti-pollution equipment. 12. Check regularly that no any leaking on deck or from all other unused manifolds, even at sea side. 13. Check ullages of all cargo tanks hourly, tanks not being loaded/discharged should also be checked hourly. 14. During ballasting / de-ballasting operations check soundings of all tanks regularly, visually check the overboard discharge while starting and at regular intervals. 15. Check and log stability condition hourly. 16. Maintain all logs and times regularly. Print out stability condition every four hours. 17. Gangway log to be maintained at all times. 18. Follow company and port regulations 19. Appropriate signals to be displayed. 20. Ensure deck is well illuminated at night. 21. Always I.S.G.O.T.T. requirements should be observed!

FOR ANY DOUBT CALL CHIEF OFFICER! Prepared by, Chief officer Second officer Third officer Master

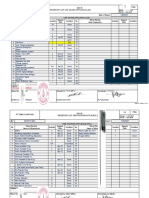

M.T. STAVANGER BELL TIME INITIAL TANK Cor. ULL % 1P 20.46 0.0 1S 20.46 0.0 2P 20.46 0.0 2S 20.47 0.0 3P 20.46 0.0 3S 20.46 0.0 4P 20.45 0.0 4S 20.47 0.0 5P 20.46 0.0 5S 20.46 0.0 SLOP(P) 20.47 0.0 SLOP(S) 20.45 0.0 QOB (Observed) 0 BALLAST TANK m3 % FP 1,233.8 95 1P 3,140.8 98 1S 3,140.8 98 2P 5,664.5 97 2S 5,664.5 97 3P 2,891.4 99 3S 2,891.4 99 4P 2,856.2 99 4S 2,856.2 99 5P 2,318.8 99 5S 2,108.0 90 AP 75.9 5 Total ballast (m3) 34,842.1 DRAFT F 6.05 DRAFT A 8.15 Trim 2.10 SF 39.0% BM 61.0% GoM 15.81 CHIEF OFFICER

25% Cor. ULL % 15.33 24.0 15.33 24.0 15.40 24.0 15.41 24.0 15.40 24.0 15.40 24.0 15.39 24.0 15.40 24.0 15.39 24.0 15.40 24.0 14.79 24.0 15.31 24.0 27,869 m3 % 1,233.8 95 1,922.9 60 1,922.9 60 3,795.8 65 3,795.8 65 1,898.4 65 1,898.4 65 1,875.3 65 1,875.3 65 1,639.5 70 1,639.5 70 75.9 5 23,573.5 7.43 9.47 2.04 22.0% 38.0% 13.47 SECOND OFFICER

50% Cor. ULL % 10.80 48.0 10.79 48.0 10.85 48.0 10.85 48.0 10.85 48.0 10.85 48.0 10.84 48.0 10.85 48.0 10.85 48.0 10.85 48.0 10.37 48.0 11.35 48.0 55,738 m3 % 389.6 30 961.5 30 961.5 30 1,751.9 30 1,751.9 30 876.2 30 876.2 30 865.5 30 865.5 30 983.7 42 1,077.4 46 75.9 5 11,436.8 8.63 10.85 2.22 17.6% 20.0% 7.95

PORT: DATE: 75% Cor. ULL % 6.65 70.0 6.64 70.0 6.68 70.0 6.68 70.0 6.68 70.0 6.68 70.0 5.72 75.0 5.73 75.0 5.73 75.0 5.73 75.0 5.50 75.0 7.04 75.0 84,121 m3 13.0 32.0 32.0 58.4 58.4 29.2 29.2 28.9 28.9 983.7 1,077.4 75.9 2,447.0 9.95 12.85 2.90 38.0% 30.0% 5.72 % 1 1 1 1 1 1 1 1 1 42 46 5

Yosu STS area 6-Oct-12 FINAL Cor. ULL % 1.79 96.0 1.79 96.0 1.75 96.0 1.75 96.0 1.75 96.0 1.75 96.0 1.74 96.0 1.75 96.0 1.75 96.0 1.75 96.0 1.72 96.0 2.05 96.0 111,475 m3 13.0 32.0 32.0 58.4 58.4 29.2 29.2 28.9 28.9 983.7 1,077.4 75.9 2,447.0 14.05 14.05 0.00 69.0% 62.0% 3.63 % 1 1 1 1 1 1 1 1 1 42 46 5

TIME TANK 1P 1S 2P 2S 3P 3S 4P 4S 5P 5S SLOP(P) SLOP(S) QOB (Observed) BALLAST TANK FP 1P 1S 2P 2S 3P 3S 4P 4S 5P 5S AP Total ballast (m3) DRAFT F DRAFT A Trim SF BM GoM

THIRD OFFICER

MASTER

M.T. STAVANGER BELL

PORT: DATE:

Yosu STS area

6-Oct-12

LOADING PROCEDURES

Cargo: Sokol Crude Oil API QTY. to be loaded: 93600 MT Tks to be loaded: 1W, 2W, 3W, 4W,5W, SlopW Tks not to be loaded at this port: Nil

36.3

REMARK: VESSEL IS RESERVING THE RIGHT TO CHANGE THE PRESENT PLAN ON RECEIVING THE CORRECT DENSITY AND TEMPERATURE FROM TERMINAL. OR FOR ANY OTHER INSTRUCTIONS FROM CHARTERERS, RECEIVED AFTER COMMENCEMENT OF LOADING. FOR ANY OTHER LIMITATIONS OF THE TERMINAL AS LINE DIAMETER OR NUMBER THE PLAN CAN ALSO BE CHANGED

After issuing of 'OBQ Certificate' and hoses connection, start ship's lining-up preparations for loading. SAMPLING AND/OR ALL OTHER CARGO OPERATIONS SHOULD BE DONE IN CLOSED SYSTEM ONLY! OOW TO CHECK MANIFOLD BEFORE CONNECTION. OOW will attend manifold connections and will watch for all bolts in position if these kind of connection are used. For manifold connection and for any other operation, on board unsparkling tools only to be used. Hose(s) or arm(s) to be connected as follows: NO.1&2 x 12" When ready to start loading , open manifold and local drop valves to nos. 1P and 1S C.O.Ts. And call for start loading with initial rate requested by ship. Check if cargo come into nos. 1P and 1S C.O.Ts. Check all other tanks, lines and manifolds at both sides. If no abnormality open other tanks that are to be loaded and ask the terminal to increase the rate to max. DURING BALLASTING OR DEBALLASTING OPERATIONS, OOW WILL CHECK THE WATER BALLAST QUALITY AT THE FREQUENCY BASIS, NOT EXCEEDING ONE HOUR.

INSPECTION WILL BE CARRIED OUT VISUALLY. IF ANY SPOT OR DIRTY WATER WILL BE OBSERVED, STOP BALLASTING OR DEBALLASTING AND CALL CHIEF OFFICER.

CHIEF OFFICER THIRD OFFICER SECOND OFFICER

MASTER

M.T. STAVANGER BELL

PORT: DATE:

Yosu STS area 6-Oct-12

STOWAGE PLAN

ARRIVAL CONDITION CARGO: NIL 1P CARGO: NIL QUANTITY (MT): M3 2P CARGO: Nil QUANTITY (MT): M3 3P CARGO: Nil QUANTITY (MT): M3 4P CARGO: NIL QUANTITY (MT): M3 5P CARGO: Nil QUANTITY (MT): M3 CARGO: Nil QUANTITY (MT): M3 SLOP (S) CARGO: NIL QUANTITY (MT): M3 0.00 0.00 CHIEF OFFICER CARGO: NIL QUANTITY (MT): M3 5S CARGO: Nil QUANTITY (MT): M3 4S CARGO: Nil QUANTITY (MT): M3 3S CARGO: NIL QUANTITY (MT): M3 2S 1S

0.0 0.0

0.0 0.0

0.0 0.0

0.0 0.0

0.0 0.0

0.0 0.0

0.0 0.0

0.0 0.0

0.0 0.0 SLOP (P)

0.0 0.0

CARGO: NIL QUANTITY (MT): M3

0.0 0.0

0.0 0.0

CARGO (MT)= CARGO (bbls-obs)=

M.T. STAVANGER BELL

PORT: Yosu STS area DATE: 10/6/2012

STOWAGE PLAN

ARRIVAL CONDITION CARGO: Sokol Crude Oil 1P 1S CARGO: Sokol Crude Oil QUANTITY (MT): 7265.0 M3 8674.4 2S CARGO: Sokol Crude Oil QUANTITY (MT): 8335.0 M3 9916.6 3S CARGO: Sokol Crude Oil QUANTITY (MT): 8335.0 M3 9916.6 4S CARGO: Sokol Crude Oil QUANTITY (MT): 8335.0 M3 9916.6 5S CARGO: Sokol Crude Oil QUANTITY (MT): 8335.0 M3 9916.6 SLOP (S) CARGO: Sokol Crude Oil QUANTITY (MT): 5840.0 M3 6948.1 93645.00 111475.10 CHIEF OFFICER

CARGO: Sokol Crude Oil QUANTITY (MT): 7259.0 M3 8666.5 2P CARGO: Sokol Crude Oil QUANTITY (MT): 8335.0 M3 9916.6 3P CARGO: Sokol Crude Oil QUANTITY (MT): 8335.0 M3 9916.6 4P CARGO: Sokol Crude Oil QUANTITY (MT): 8335.0 M3 9916.6 5P CARGO: Sokol Crude Oil QUANTITY (MT): 8335.0 M3 9916.6 SLOP (P) CARGO: Sokol Crude Oil QUANTITY (MT): 6601.0 M3 7853.3 CARGO (MT)= CARGO (M3-obs)=

M.T. STAVANGER BELL

PORT: Yosu STS area DATE: 6/Oct/12

PRE-LOADING MEETING

AGENDA: 1 2 3 4 5 6 7 8 9 Contamination issues: Sampling procedures: Nature of cargo: Any defects in the cargo / ballast system: Rest periods / watchkeeping: Bunkering: Stores: Surveys: MOC inspections: VESSEL WILL LOAD Sokol Crude Oil in : 1W, 2W,3W, 4W,5W, SlopW CLOSED METHOD, AS PER SURVEYOR INSTRUCTION Crude Oil NIL AS PER STANDING INSTRUCTION NO NO NO NO

DURING THE ABOVE VOYAGE NO BREACH WHATSOEVER HAS TAKEN PLACE OF MARPOL REQUIREMENTS BY SHIP'S PERSONNEL

RANK Ch. Off. 2nd Off. 3rd Off. P/man

NAME Iordache Dumitru Radu Popescu Pascale Alexandru Tayag Renante

SIGNATURE

MASTER

S-ar putea să vă placă și

- Voy 038D Callao - TalaraDocument35 paginiVoy 038D Callao - TalaraHendra TambunanÎncă nu există evaluări

- SEEMPDocument19 paginiSEEMPswapneel_kulkarniÎncă nu există evaluări

- Tonnage Calculations: M/V Ottawa IvDocument6 paginiTonnage Calculations: M/V Ottawa Ivtahtoh25Încă nu există evaluări

- Deck FormsDocument81 paginiDeck FormsRose AriantiÎncă nu există evaluări

- List of Required Plans and Manuals (Tankers)Document2 paginiList of Required Plans and Manuals (Tankers)Baba Ghanoush50% (2)

- Draft Survey CalculationDocument5 paginiDraft Survey CalculationFarrukh Ali Kazim100% (1)

- Green Dolphin - Brochure - tcm4-518925Document12 paginiGreen Dolphin - Brochure - tcm4-518925GregoryPapoutsakisÎncă nu există evaluări

- VOY 13-14 Passage Plan Merak SurabayaDocument11 paginiVOY 13-14 Passage Plan Merak SurabayaRaden Mas Farih100% (1)

- NAV 1 - Passage Plan XLSDocument85 paginiNAV 1 - Passage Plan XLSGaurav Shresth100% (2)

- SD 1.3.3 Bulk CarriersDocument36 paginiSD 1.3.3 Bulk CarriersMphil Averomar100% (1)

- TEC 08 - Bunkering Operations Checklist PDFDocument5 paginiTEC 08 - Bunkering Operations Checklist PDFnmospan100% (1)

- Disch Plan VOY 89 Disch at Sendai, Japan - 20 KLDocument17 paginiDisch Plan VOY 89 Disch at Sendai, Japan - 20 KLRahul GuptaÎncă nu există evaluări

- Tank Sounding Trim CorrectionDocument44 paginiTank Sounding Trim Correctionfnu maliki100% (1)

- United Arab Shipping Company (S.A.G.) : M.V. Al Hilal Pilot CardDocument3 paginiUnited Arab Shipping Company (S.A.G.) : M.V. Al Hilal Pilot CardAamir Sirohi100% (2)

- Draught Survey Code by UNECEDocument19 paginiDraught Survey Code by UNECEHobbyLogicÎncă nu există evaluări

- Noon Report 55Document4 paginiNoon Report 55Amar SinghÎncă nu există evaluări

- IBS - IMO SEEMP Part II - Template (Blank Form)Document10 paginiIBS - IMO SEEMP Part II - Template (Blank Form)sakis papasÎncă nu există evaluări

- Deterministic Damage Stability PDFDocument44 paginiDeterministic Damage Stability PDFUngke KansilÎncă nu există evaluări

- Stability Calculation Form For MV MaineborgDocument9 paginiStability Calculation Form For MV MaineborgtrananhnganÎncă nu există evaluări

- E04-Ship Geometry & Hydrostatic CalculationsDocument2 paginiE04-Ship Geometry & Hydrostatic Calculationsarise tettehÎncă nu există evaluări

- ABS Matrix of Regulation - Updated May 2019Document37 paginiABS Matrix of Regulation - Updated May 2019Claudio SantellanesÎncă nu există evaluări

- A.601 (15) IMO Res On Display of Manoeuvring Info Onboard ShipsDocument14 paginiA.601 (15) IMO Res On Display of Manoeuvring Info Onboard ShipsmanojÎncă nu există evaluări

- Doc-01 Voyage ReportDocument1 paginăDoc-01 Voyage ReportopytnymoryakÎncă nu există evaluări

- NSRP Ship Vetting PolicyDocument11 paginiNSRP Ship Vetting PolicyNgôThếLạcÎncă nu există evaluări

- Fuel Oil Consumption Data Collection Plan SampleDocument2 paginiFuel Oil Consumption Data Collection Plan SampleJCAÎncă nu există evaluări

- Determining Critical Wind Velocity For Dragging AnchorDocument2 paginiDetermining Critical Wind Velocity For Dragging AnchorOctavianÎncă nu există evaluări

- Ballast Water Reporting Form PORT HEALTH VOY 4Document2 paginiBallast Water Reporting Form PORT HEALTH VOY 4anilÎncă nu există evaluări

- CNE 05221 Dart M/V Ocean Wealth 266 M/V Ocean Wealth SingaporeDocument16 paginiCNE 05221 Dart M/V Ocean Wealth 266 M/V Ocean Wealth SingaporeDavid c. PocongÎncă nu există evaluări

- Cargo PBLMDocument7 paginiCargo PBLMmeghna c binu100% (1)

- Noon Report 26 Agustus 2021Document12 paginiNoon Report 26 Agustus 2021arthur kadangÎncă nu există evaluări

- 8.W LSA FFA EquipmentDocument12 pagini8.W LSA FFA EquipmenttyoÎncă nu există evaluări

- Wheelhouse Poster: Bulkc12LDocument3 paginiWheelhouse Poster: Bulkc12LTrucMaiÎncă nu există evaluări

- ExxonMobil VPQ Review FormDocument30 paginiExxonMobil VPQ Review FormTruong's100% (3)

- VESSEL Draft Survey ReportDocument1 paginăVESSEL Draft Survey ReportSailee Korde100% (1)

- Ship'S Particulars of " Opal Leader ": Opal Leader C6VT8 1A1 Car Carrier, Ro/Ro, Eo, Naut-Oc, Tmon Bahamas NassauDocument2 paginiShip'S Particulars of " Opal Leader ": Opal Leader C6VT8 1A1 Car Carrier, Ro/Ro, Eo, Naut-Oc, Tmon Bahamas NassauMaksym KovalÎncă nu există evaluări

- Baltic QuestionnaireDocument6 paginiBaltic QuestionnaireYnaffit Alteza UntalÎncă nu există evaluări

- Loading Plan + Sfops 8Document9 paginiLoading Plan + Sfops 8nivasmarine100% (3)

- Dra Aft Surve Ey: Proc Cedures and Cal Lculation N: Readi Ing The Draf Ftmark of TH He ShipDocument4 paginiDra Aft Surve Ey: Proc Cedures and Cal Lculation N: Readi Ing The Draf Ftmark of TH He ShiprubinoestelaÎncă nu există evaluări

- SQE MARINE Preparation For Arrival at Port 2018 04Document3 paginiSQE MARINE Preparation For Arrival at Port 2018 04David NazarethÎncă nu există evaluări

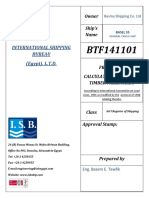

- BTF141101 Freeboard Basel S5Document16 paginiBTF141101 Freeboard Basel S5tahtoh25100% (1)

- Free BoardDocument4 paginiFree BoardIan StefanusÎncă nu există evaluări

- Oil Transfer Procedures - SitakathrineDocument12 paginiOil Transfer Procedures - SitakathrineAmit Pandey100% (1)

- Calculation-of-Displacement-LWT-and-DW BUDI OKEDocument28 paginiCalculation-of-Displacement-LWT-and-DW BUDI OKEBudi PrayitnoÎncă nu există evaluări

- Schokland - Vessel DescriptionDocument2 paginiSchokland - Vessel DescriptionEnrique Domínguez DomínguezÎncă nu există evaluări

- Stability and Trim From Ian v.Document44 paginiStability and Trim From Ian v.Trizha Dela Gente100% (1)

- Survey Planning Questionnaire For Oil Tanker - CASDocument4 paginiSurvey Planning Questionnaire For Oil Tanker - CASrays100% (1)

- Surveyors 1Document86 paginiSurveyors 1shilparabÎncă nu există evaluări

- 2 Ships Particulas MV HC Jette-MaritDocument2 pagini2 Ships Particulas MV HC Jette-MaritWILLINTON HINOJOSA100% (2)

- Stowage PlanDocument1 paginăStowage PlanJohn BavoÎncă nu există evaluări

- Towing Arrangement BDocument2 paginiTowing Arrangement BDevi Ratna PratiwiÎncă nu există evaluări

- MV Toronto TraderDocument3 paginiMV Toronto TraderPapitas FritasÎncă nu există evaluări

- Load Line: Ship DesignDocument89 paginiLoad Line: Ship DesignMuhammed Talha ÖzdenoğluÎncă nu există evaluări

- Ship Inspection Form F P - R: 1. G I / S DDocument6 paginiShip Inspection Form F P - R: 1. G I / S DRonachai FuangfoongÎncă nu există evaluări

- Voy. Abstract SampleDocument11 paginiVoy. Abstract SampleAAjay SharmaÎncă nu există evaluări

- SD-1.4.1-Container Carriers PDFDocument26 paginiSD-1.4.1-Container Carriers PDFTommyVercetti100% (1)

- Light Ship and Tonnage Check ListDocument9 paginiLight Ship and Tonnage Check ListLegend AnbuÎncă nu există evaluări

- '059-H - LSA, FFA, LBA Inventory List 11novDocument4 pagini'059-H - LSA, FFA, LBA Inventory List 11novraja bader100% (1)

- Visibility CalculatorDocument2 paginiVisibility CalculatorJeet SinghÎncă nu există evaluări

- Chintana Naree BriefDocument11 paginiChintana Naree BriefWinston Rodrigues100% (1)

- Muster List EngDocument2 paginiMuster List Engpiotr21167% (9)

- Bahasa Inggris Kerja KelompokDocument4 paginiBahasa Inggris Kerja KelompokJosua Albert Butar ButarÎncă nu există evaluări

- Coc Class 3 Deck Officer - : Preparatory Course Application FormDocument4 paginiCoc Class 3 Deck Officer - : Preparatory Course Application FormAbu Syeed Md. Aurangzeb Al MasumÎncă nu există evaluări

- Instructor ManualDocument108 paginiInstructor ManualJose Ariel Chejanovich100% (1)

- 0404 - A - Complete The Annual Servicing On Both Gyro Compass UnitsDocument3 pagini0404 - A - Complete The Annual Servicing On Both Gyro Compass UnitsYaw AndersonÎncă nu există evaluări

- Container Losses in Rough Weather: Karan Doshi, Sharad DhavalikarDocument47 paginiContainer Losses in Rough Weather: Karan Doshi, Sharad DhavalikarDilip SarangdharÎncă nu există evaluări

- New Form - Deck Performance and Appraisal Report As of Oct. 14, 2019Document1 paginăNew Form - Deck Performance and Appraisal Report As of Oct. 14, 2019Kevin FrutoÎncă nu există evaluări

- Aramco Officer CV Package Checklist - Rev. 04 Aug 2021 - REVISED - Angus MackinnonDocument1 paginăAramco Officer CV Package Checklist - Rev. 04 Aug 2021 - REVISED - Angus Mackinnonmohammed kasidÎncă nu există evaluări

- Responsibilities & Obligation of Master & All Crew MembersDocument22 paginiResponsibilities & Obligation of Master & All Crew MembersNice HappyForestÎncă nu există evaluări

- Key Word Transformations For b1 Connect Series Wordsearches 74164Document2 paginiKey Word Transformations For b1 Connect Series Wordsearches 74164Evsenkova NadezhdaÎncă nu există evaluări

- Listing of Current IMO PublicationsDocument9 paginiListing of Current IMO PublicationsThuat NguyenÎncă nu există evaluări

- Instant Download Essentials of Statistics For Business and Economics 7th Edition Anderson Solutions Manual PDF Full ChapterDocument33 paginiInstant Download Essentials of Statistics For Business and Economics 7th Edition Anderson Solutions Manual PDF Full Chapterbrianhue3zqkp100% (9)

- Anchoring: Factors To Bear in Mind While Determining Safe Anchorage / Anchor PlanningDocument39 paginiAnchoring: Factors To Bear in Mind While Determining Safe Anchorage / Anchor Planningmaneesh0% (1)

- ABAÖNDON SHIP & Lower RESCUE BOATDocument2 paginiABAÖNDON SHIP & Lower RESCUE BOATAbu Syeed Md. Aurangzeb Al MasumÎncă nu există evaluări

- Activity 1: Listen To The Information and Fill in The BlanksDocument3 paginiActivity 1: Listen To The Information and Fill in The BlanksBettoPerverttÎncă nu există evaluări

- Muster List EngDocument1 paginăMuster List Engpauli100% (1)

- Cargo Operation Standing OrderDocument1 paginăCargo Operation Standing OrderAung Htet Kyaw100% (1)

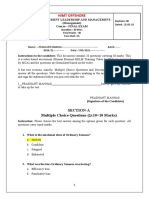

- Himt Offshore: Section-A Multiple Choice Questions (1x10 10 Marks)Document6 paginiHimt Offshore: Section-A Multiple Choice Questions (1x10 10 Marks)prashant manhasÎncă nu există evaluări

- Chief Mate Unlimited Coc ExamDocument2 paginiChief Mate Unlimited Coc ExamRecca Pirrip0% (1)

- The Secret SharerDocument3 paginiThe Secret ShareranbarasiÎncă nu există evaluări

- 1521511558maritime Law - Capt. Ashish Kapoor PDFDocument104 pagini1521511558maritime Law - Capt. Ashish Kapoor PDFSharma GowthamanÎncă nu există evaluări

- 1552536990phase I Complete Q.Set Till Jan19 PDFDocument219 pagini1552536990phase I Complete Q.Set Till Jan19 PDFAnaz NazarÎncă nu există evaluări

- Vessel Selection Policy and MSC Above 10 KT DWTDocument16 paginiVessel Selection Policy and MSC Above 10 KT DWTBoris VukovicÎncă nu există evaluări

- Unit 1 - Anchoring PDFDocument18 paginiUnit 1 - Anchoring PDFClaudiuAlex100% (1)

- NTSB Safer Seas Digest 2021 2022 10Document96 paginiNTSB Safer Seas Digest 2021 2022 10Jose AlvarezÎncă nu există evaluări

- Value Added Courses: Sr. No. Course NameDocument3 paginiValue Added Courses: Sr. No. Course Namerishabh srivastavaÎncă nu există evaluări

- ATT III - 17. Application of Leadership and Teamworking SkillsDocument6 paginiATT III - 17. Application of Leadership and Teamworking Skillsedwin90276Încă nu există evaluări

- Nav Arc 2 - StabilityDocument103 paginiNav Arc 2 - StabilityDinchak RRAHÎncă nu există evaluări

- Investigarea Unui Incendiu La Bordul NaveiDocument5 paginiInvestigarea Unui Incendiu La Bordul NaveiSilviu NistorÎncă nu există evaluări

- Information Bulletin No. 104 - Issue of Bahamas National Certificates and Endorsements Rev2 PDFDocument29 paginiInformation Bulletin No. 104 - Issue of Bahamas National Certificates and Endorsements Rev2 PDFvlcktorÎncă nu există evaluări