Documente Academic

Documente Profesional

Documente Cultură

Cost Control

Încărcat de

Nishit PatelDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Cost Control

Încărcat de

Nishit PatelDrepturi de autor:

Formate disponibile

COST CONTROL Introduction The cost of power supplied to the end consumer comprises of components like cost of setting

up the plant, operational cost, cost of transmission and cost of distribution. If the cost of power supplied to a consumer were to be reduced, the cost associated with each component would need to be reduced. If we focus on set up cost of power projects, it not only involves substantial capital investment but also the gestation period is longer compared to other industries. The project capital cost is one of the important parameter on which the unit cost of power is worked out. For the same reason, emphasis is being given on reduction of this cost and various ways has been suggested from time to time. One of the ways to achieve this is, by proper designing and executing power projects using standardization technique. The purpose of this paper is to discuss practically all aspects related to standardization of a Gas Based Power Project. Though the paper details practically every aspect related with the standardization, focus will be on the capital cost optimisation from the viewpoint of owner, as it is a major factor in deciding the unit cost of power to be supplied to end consumer. To begin with, highlights the benefits of standardization.

Benefits of standardization 1. Savings in cost & time: Through bulk procurement of identical equipment & materials, which constitutes the major part of project, owner could negotiate lower supplier pricing for them. Also the home office job-hours required to specify and procure would be extended only on an initial project. The evolutionary design process leads to a family of plants, which can transfer experience from one project to the next. Standardization, which is inherent in a family of nearly identical plants, plays a significant role in reducing construction and start-up costs and time. Substantial cost and schedule improvements are realized during construction as techniques are passed on, rework is reduced, more efficient methods are developed and familiarity with the design increases. This is evident at multi-unit sites where the subsequent units are completed in shorter times. While influential in reducing

construction cost, this shortened schedule also provides a quicker return on investment for the plant owner. The significant cost benefits from series development is the savings in design and engineering job hours/cost by standardizing designs of major systems.

2. Assured Innovation: Standardization based on proven technology guarantees a plant performance that leads to a reduced financial risk for the project.

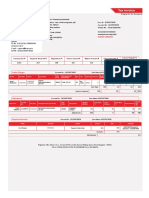

Capital Cost of the projects 1. Land & Site development = 2. Building Costs = 3. Plant & Machinery Inc. spares = (a) Imported = (b) Indigenous = (c) Spares & installation = 4. Process Know-how fee & Detailed Eng. & Consultancy Services (Including basic and Review Eng.= 5. Expenses on erection Supervision training & startup = 6. Margin Money for working Capital= Total Project Cost =

(Rs. Crores) 10.00 16.00 325.00 100.00 200.00 25.00

22.00

40.00

7.00 420.00

Source of finance 1. Secured / Long term loans = 2.Unsecured loan 3. Owners capital TOTAL = 315.00 85.00 20.00 420.00

Year-wise Capacity: Utilization% 1st Year = 2nd Year = 3rd Year = 60% 70% 80%

Cost of Gas = (At 100% capacity)

175.00

Utilities =

4.80

Manpower (Total = 70) (Direct-84, Contract -6) = 85.00

Cost of Power 1st year = 2nd year = 3rd year = Rs. 80.29 Rs. 105.47 Rs. 125.70

Revenue Realization (Power Transmitted) 1st year = 2nd year = 3rd year = Rs. 220.43 Rs. 270.67 Rs. 320.91

Gross Profit (before interest & depreciation) 1st year = 2nd year = 3rd year = Rs. 85.14 Rs. 100.20 Rs. 115.20

Operating Profit (after interest & depreciation) 1st year = 2nd year = 3rd year = Rs. 35.94 Rs. 45.35 Rs. 55.14

Return on Investment, % 1st year = 2nd year = 3rd year = Rs. 15.55 Rs. 25.44 Rs. 35.23

Break Even Point, % i. At Installed Capacity (100%) = ii. At Optimum Capacity (80%) = Rs. 25.50 Rs. 40.37

Debt Service Coverage Ratio (DSCR) Average = 1.68

Conclusion The owner can save almost 15% -18% of total capital cost through standardization, undoubtedly a powerful cost saving technique, but requires large capital investment. This capital investment in power sector in any country will attract taxes and duties concessions from the local government, further improving saving in capital cost. Standardization would help the organizations to successfully implement its strategy to develop large projects while reducing execution costs and providing faster speed to market and greater certainty of outcome. With this standard plant technique, owner is bound to gain an important position and a competitive edge in EPC market.

Reference: http://www.projectcontrolsonline.com/Blogs/tabid/103/EntryId/4/Capital-Cost-OptimizationOn-Gas-Fired-Power-Projects-Through-Standardization.aspx GAS based power plant UP.pdf

S-ar putea să vă placă și

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Invoice Act May 2022Document2 paginiInvoice Act May 2022Pavan kumarÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Accounting 206Document3 paginiAccounting 206Evan MiñozaÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- The Advanced Guide To Equity Research Report WritingDocument23 paginiThe Advanced Guide To Equity Research Report Writingsara_isarÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- HR Policies and Challenges: - by Dr. Deepakshi JaiswalDocument9 paginiHR Policies and Challenges: - by Dr. Deepakshi JaiswalAyushi GargÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Planning - Case StudiesDocument11 paginiPlanning - Case Studiesfathima hamnaÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Nestle SpeechDocument3 paginiNestle Speechkapil chandwaniÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Sustainability LeadershipDocument8 paginiSustainability Leadershiprocky100% (1)

- Capstone ProjectDocument10 paginiCapstone ProjectLifeStacksÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- PR - SEBI Cautions Public To Deal With Only SEBI Registered Investment Advisers and Research AnalystsDocument2 paginiPR - SEBI Cautions Public To Deal With Only SEBI Registered Investment Advisers and Research AnalystsShyam SunderÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Quomundo LTD - Brochure-RevDocument14 paginiQuomundo LTD - Brochure-RevHeryanto GeoÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Instructions: Find, Read and Attach An Opinion-Editorial (Op-Ed) Article Instructions: Find, Read and Attach An Opinion-Editorial (Op-Ed) ArticleDocument2 paginiInstructions: Find, Read and Attach An Opinion-Editorial (Op-Ed) Article Instructions: Find, Read and Attach An Opinion-Editorial (Op-Ed) ArticleAriell EmraduraÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- LISA Transfer Authority Form PDFDocument2 paginiLISA Transfer Authority Form PDFAnonymous lHIUIweVÎncă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Writing Business Proposals, Business Plan and Case ReportsDocument47 paginiWriting Business Proposals, Business Plan and Case ReportsAbhishek Agarwal100% (2)

- The Valuation of Olive Orchards: A Case Study For TurkeyDocument4 paginiThe Valuation of Olive Orchards: A Case Study For TurkeyShailendra RajanÎncă nu există evaluări

- Indian Institute of Management Lucknow Post Graduate Programme, 2012-13Document3 paginiIndian Institute of Management Lucknow Post Graduate Programme, 2012-13Vikas HajelaÎncă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- BUS 2201 Principles of Marketing Unit 2 DADocument5 paginiBUS 2201 Principles of Marketing Unit 2 DAMamu KamÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Cambria Tail Risk ETF: Strategy Overview Fund DetailsDocument2 paginiCambria Tail Risk ETF: Strategy Overview Fund Detailscena1987Încă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Chapter Three: Valuation of Financial Instruments & Cost of CapitalDocument68 paginiChapter Three: Valuation of Financial Instruments & Cost of CapitalAbrahamÎncă nu există evaluări

- Unit 3 - Security AnalysisDocument33 paginiUnit 3 - Security AnalysisWasim DalviÎncă nu există evaluări

- Senyo Thesis Power Point 2Document25 paginiSenyo Thesis Power Point 2Eghan MarkÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- MCR 21 Jan 22Document37 paginiMCR 21 Jan 22Ivan FirmandaÎncă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1091)

- JPMorgan Chase London Whale HDocument12 paginiJPMorgan Chase London Whale HMaksym ShodaÎncă nu există evaluări

- Oracle 11: Drop ShipmentDocument69 paginiOracle 11: Drop ShipmentShivangiSinghMadnaniÎncă nu există evaluări

- APT ExerciseDocument3 paginiAPT Exercise노긔0% (1)

- Presidential Decree No 772Document14 paginiPresidential Decree No 772Juan Luis LusongÎncă nu există evaluări

- Benefits of Sole PropDocument12 paginiBenefits of Sole PropRisha Mae SalingayÎncă nu există evaluări

- Pathfinder May 2018 SkillsDocument155 paginiPathfinder May 2018 SkillsOgunmola femiÎncă nu există evaluări

- Tax Ordinance-Books 1-30 FCTBDocument51 paginiTax Ordinance-Books 1-30 FCTBRaiha MoriyomÎncă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Quiz 1 Bank TARGET FinalDocument6 paginiQuiz 1 Bank TARGET FinalSEERAT HASSAN AHMEDÎncă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)