Documente Academic

Documente Profesional

Documente Cultură

Centrifugal Pump Troubleshooting Guide

Încărcat de

Fahad MaqsoodDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Centrifugal Pump Troubleshooting Guide

Încărcat de

Fahad MaqsoodDrepturi de autor:

Formate disponibile

Centrifugal Pump Troubleshooting Guide

Table 4-6 Troubleshooting Guide -- Centrifugal Process Pumps Symptoms Symptoms D C B A Insufficient Disch. Pressure . Intermittent Operation . Insufficient Capacity . No Liquid Delivery . Possible Causes # A B Pump Is Cavitating 1 2 1 (Symptom For Liquid Vaporizing In Suction System) -Horizontal Pumps C 1 D E F 9 Short Bearing Life Short Mech. Seal Life Vibration & Noise G 1 E F G A B C D Table 4-6 (cont.) Symptoms Insufficient Disch. Pressure . Intermittent Operation . Insufficient Capacity . No Liquid Delivery . Possible Causes Strainer Partially Clogged Pump Impeller Clogged Suction And/Or Discharge Valve(s) Closed Viscosity Too High # 7 8 9 A B 3 8 C D E F G Symptoms Short Bearing Life Short Mech. Seal Life Vibration & Noise Power Demand Excessive H # 7 8 9 Possible Remedies E F G H

Power Demand Excessive H H # Possible Remedies 1 * Check NPSHa/ NPSHr Margin

* Inspect And Clean * Check For Damage

And Clean

* If Pump Is Above

Liquid Level, Raise Liquid Level Closer To Pump

8 9

* Shut Down And Open

Valves

* If Liquid Is Above

Pump, Increase Liquid Level Elevation SUCTION PROBLEMS Insufficient 2 Immersion Of Suction Pipe Or Bell (VertTurbinePump) Pump Not Primed 3 1 1 1 1 2

10

4 10

* Heat Up Liquid To

Reduce Viscosity

* Lower

Suction Pipe Or Raise Sump Level

* Increase Size Of

HYDRAULIC SYSTEM Discharge Piping To Reduce Pressure Loss

* Increase System

Resistance 1 2 3

* Fill Pump And Suction

Piping Complete With Liquid

* Use Larger Driver Or

Change Type Of Pump Specific Gravity Too High Total System Head Lower Than Design Head Of Pump 11 12 4 11 2 11 3 12

* Eliminate High Points

In Suction

* Slow Pump Down * Check Design Specific

Gravity

* Remove All NonCondensibles (Air From Pump, Piping and Valves)

* Increase System

Resistance To Obtain Design Flow

* Eliminate High Points

In Suction Piping

* Check Design

Parameters Such As Impeller Size, Etc. Total System Head Higher Than Design Head Of Pump 13 6 5 4 10 2 13

* Check For Faulty Foot

Valve Or Check Valve HYDRAULIC SYSTEM Non-Condensibles In Liquid 4 2 3 1 4

* Decrease System

Resistance To Obtain Design Flow

* Check For Gas/Air

Ingress Through Suction System/Piping

* Check Design

Parameters Such As Impeller Size, Etc. Unsuitable Pumps In Parallel Operation 14 7 6 6 1 A B C D E F G H 14 15 #

* Install

Chamber Supply Tank Empty Obstructions In Lines Or Pump Housing Possible Causes 5 6 # 3 9 A B C 7 D E F 7 G H 5 6 #

Gas Separation

* Check Design

Parameters

* Refill Supply Tank * Inspect And Clear

Possible Remedies

Improper Mechanical 15 Seal Possible Causes #

* Check Mechanical

Seal Selection Strategy Possible Remedies

Centrifugal Pump Troubleshooting Guide

Table 4-6 (cont.) Symptoms D C B A Intermittent Operation . Insufficient Capacity . No Liquid Delivery . Possible Causes # A B Speed Too High 16 Speed Too Low Wrong Direction Of Rotation 17 4 18 5 4 C D E F Symptoms E F G

A C B D Symptoms Insufficient Disch. Pressure . Intermittent Operation . Insufficient Capacity . No Liquid Delivery . Possible Causes Mechanical Defects Worn, Rusted, Defective Bearings SYSTEM # A 25 B C D E F 5 G 8 Table 4-6 (cont.) Symptoms Short Bearing Life Short Mech. Seal Life Vibration & Noise Power Demand Excessive H # 10 25 Possible Remedies E F G H

Insufficient Disch. Pressure . Short Bearing Life Short Mech. Seal Life Vibration & Noise G

Power Demand Excessive H H # Possible Remedies 1 16 * Check Motor Voltage Slow Down Driver 17 6 18

2 3

* Consult Driver

Troubleshooting Guide

Inspect Parts For Defects - Repair Or Replace. Use Bearing Failure Analysis Guide

*

Unbalance - Driver 26 5 7 9 26

* Check Rotation With

Arrow On Casing Reverse Polarity On Motor

Check Lubrication Procedures

Impeller Installed Backward (Double Suction Imp.) Misalignment MECHANICAL SYSTEM

19

10

12 19

* Inspect * Check Angular And

Parallel Alignment Between Pump And Driver

MECHANICAL

Run Driver Disconnected From Pump Unit - Perform Vibration Analysis

Unbalance - Pump Motor Troubles Possible Causes

27 28 # A B C D

4 6 E

27

Investigate Natural Frequency

20

7 20

8 10 11 28 F G H #

* Consult Motor

Troubleshooting Guide Possible Remedies

Casing Distorted From Excessive Pipe Strain

21

21

* Check For

Misalignment

* Check Pump For

Wear Between Casing And Rotating Elements

Inadequate Grouting Of Base Bent Shaft

22 23 3 4

6 7

22 8 23

* Analyze Piping Loads * Check Grouting And

Regrout If Required

* Check Deflection

(Should Not Exceed 0.002"). Replace Shaft And Bearings If Necessary

1-800-767-6700

This material was reproduced from Practical Machinery Management for Process Plants: Machinery Failure Analysis and Troubleshooting by Heinz P. Bloch and Fred K. Geitner by permission of the publisher Butterworth Heinemann of 225 Wildwood Avenue, Woburn MA 01801 (www.bh.com). 10% Discount on copies of this book will be offered with this sheet.

Internal Wear Possible Causes

24 # A B C

8 D E F G

9 24 H #

* Check Impeller

Clearances Possible Remedies

S-ar putea să vă placă și

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineDe la EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineEvaluare: 5 din 5 stele5/5 (1)

- Listings of Texas A&M Pump Users Symposiums Proceedings From 1984 To 2013Document116 paginiListings of Texas A&M Pump Users Symposiums Proceedings From 1984 To 2013jehodgsonÎncă nu există evaluări

- Plant Maintenance A Complete Guide - 2020 EditionDe la EverandPlant Maintenance A Complete Guide - 2020 EditionÎncă nu există evaluări

- Mark 3 ASME Pumps PDFDocument94 paginiMark 3 ASME Pumps PDFInf IngÎncă nu există evaluări

- Schroedahl ArvDocument19 paginiSchroedahl ArvfadzilharmanÎncă nu există evaluări

- Centrifugal Pump - Troubleshooting MatrixDocument1 paginăCentrifugal Pump - Troubleshooting MatrixSuresha Pd100% (1)

- Instructions On Installation, Operation and Maintenanace For Sam Turbo Pump TypeDocument30 paginiInstructions On Installation, Operation and Maintenanace For Sam Turbo Pump TypeSai RamÎncă nu există evaluări

- Dynamic Seal in The Fertilizer Industry 11-09Document9 paginiDynamic Seal in The Fertilizer Industry 11-09Souvik Singha RoyÎncă nu există evaluări

- Centrifugal Pump Set Failure ModesDocument70 paginiCentrifugal Pump Set Failure ModesArif WidyatamaÎncă nu există evaluări

- Persatuan Insinyur Indonesia (PII) Badan Koordinasi Mesin (BKM)Document19 paginiPersatuan Insinyur Indonesia (PII) Badan Koordinasi Mesin (BKM)HaryadiÎncă nu există evaluări

- Boiler Feed Pump New 1Document39 paginiBoiler Feed Pump New 1789krishnaÎncă nu există evaluări

- Pumps CentrifugalDocument44 paginiPumps CentrifugalEhab Abowarda100% (1)

- Cavitation and PUmp NPSHRDocument39 paginiCavitation and PUmp NPSHRRaheel Sultan100% (1)

- Pitfalls of Pump PipingDocument3 paginiPitfalls of Pump PipingChris PeramunugamaÎncă nu există evaluări

- Bombas Sumergibles KSBDocument92 paginiBombas Sumergibles KSBArturPÎncă nu există evaluări

- Mechanical Seals (Compatibility Mode)Document81 paginiMechanical Seals (Compatibility Mode)mechanikyÎncă nu există evaluări

- Boletin Non ClogDocument12 paginiBoletin Non ClogulisesgeÎncă nu există evaluări

- Starting and Operating Centrifugal PumpsDocument5 paginiStarting and Operating Centrifugal PumpskevinGojiÎncă nu există evaluări

- Flowserve PumpsDocument16 paginiFlowserve Pumpsdavidgaro12100% (1)

- P 10 500 Ea4 PDFDocument36 paginiP 10 500 Ea4 PDFDanielÎncă nu există evaluări

- POSITIVE DISPLACEMENT AND CENTRIFUGAL PUMP TROUBLESHOOTING GUIDEDocument6 paginiPOSITIVE DISPLACEMENT AND CENTRIFUGAL PUMP TROUBLESHOOTING GUIDESyed Abdullah FaizÎncă nu există evaluări

- PumpsDocument45 paginiPumpsMehmood Ul Hassan100% (1)

- Desalination pump design bookletDocument14 paginiDesalination pump design bookletBenicio Joaquín Ferrero BrebesÎncă nu există evaluări

- OHH OHHL E00697 (Pump Zulzer)Document6 paginiOHH OHHL E00697 (Pump Zulzer)Jose Sosa CojÎncă nu există evaluări

- Positive Displacement PumpsDocument6 paginiPositive Displacement PumpsVignesh DuraiÎncă nu există evaluări

- Roots Blower Booster Vacuum Pump OilDocument9 paginiRoots Blower Booster Vacuum Pump OilsupervacoilsÎncă nu există evaluări

- Impeller and Centrifugal Pump OutputDocument2 paginiImpeller and Centrifugal Pump Outputejzuppelli8036Încă nu există evaluări

- Compressors Course-Chapter 8Document3 paginiCompressors Course-Chapter 8vela vanÎncă nu există evaluări

- Troubleshooting Centrifugal Pumps July04!28!34Document7 paginiTroubleshooting Centrifugal Pumps July04!28!34ho-faÎncă nu există evaluări

- SEALDocument6 paginiSEALkishorsinghÎncă nu există evaluări

- Vertical Turbine Pumps Engineering Data: Effective April 1, 2003Document11 paginiVertical Turbine Pumps Engineering Data: Effective April 1, 2003Israel CastilloÎncă nu există evaluări

- Vertical Turbine PumpsDocument6 paginiVertical Turbine PumpsadehriyaÎncă nu există evaluări

- Pump Life Cycle Cost 4 Inventory Cost ReductionDocument24 paginiPump Life Cycle Cost 4 Inventory Cost ReductionRafael OrjuelaÎncă nu există evaluări

- ANSI Vs APIDocument2 paginiANSI Vs APIMohd Effiezool YaserÎncă nu există evaluări

- Tubular Casing Pumps by KSBDocument16 paginiTubular Casing Pumps by KSBGogy0% (1)

- Horizontal & SuHorizontal & Sump Pumpmp PumpsDocument105 paginiHorizontal & SuHorizontal & Sump Pumpmp PumpsAnonymous dHLFEZuhBa50% (2)

- Centrifugal Pump Operating Range As Per API 610 - LinkedInDocument2 paginiCentrifugal Pump Operating Range As Per API 610 - LinkedInragulÎncă nu există evaluări

- Sundyne Pumps & Compressors Training Course: THREE DAYS (Theoretical and Practical)Document3 paginiSundyne Pumps & Compressors Training Course: THREE DAYS (Theoretical and Practical)önder KarakayaÎncă nu există evaluări

- Engineered Seal Chamber With Vane Particle Ejector For Process PumpsDocument4 paginiEngineered Seal Chamber With Vane Particle Ejector For Process PumpsMarlon QuinteroÎncă nu există evaluări

- Guide To Measure Rotating EquipmentDocument18 paginiGuide To Measure Rotating EquipmentMDRÎncă nu există evaluări

- Illustration and Analysis of Seal Face Damage PatternsDocument12 paginiIllustration and Analysis of Seal Face Damage PatternsЭдуардс КеистерсÎncă nu există evaluări

- Centrifugal Pump Axial ThrustDocument4 paginiCentrifugal Pump Axial Thrustfawmer61100% (1)

- Multistage Boiler Feed Water PumpDocument12 paginiMultistage Boiler Feed Water Pumpbalaji_jayadeva9546100% (1)

- 2012 Paper Screw CompressorsDocument25 pagini2012 Paper Screw CompressorsravisankarÎncă nu există evaluări

- Deepwell Submersible Motor 50HzDocument38 paginiDeepwell Submersible Motor 50HzSujanto WidjajaÎncă nu există evaluări

- Vibrations in Reciprocating CompressorsDocument15 paginiVibrations in Reciprocating Compressorschaitanya_kumar_13Încă nu există evaluări

- BB5Document16 paginiBB5Roozbeh PÎncă nu există evaluări

- Lawrence Pumps VPL3600: Vertical Lineshaft, Slurry PumpDocument8 paginiLawrence Pumps VPL3600: Vertical Lineshaft, Slurry PumpjnÎncă nu există evaluări

- Centrifugal PumpsDocument24 paginiCentrifugal PumpsHari Babu DharmavarapuÎncă nu există evaluări

- FLOWSERVE CPXV AP73611BDocument48 paginiFLOWSERVE CPXV AP73611Broyert80Încă nu există evaluări

- Centrifugal Pump Books PDFDocument1 paginăCentrifugal Pump Books PDFyusufÎncă nu există evaluări

- Model A7 With Mechanical Seal: Installation, Operation, Maintenance and Storage ManualDocument38 paginiModel A7 With Mechanical Seal: Installation, Operation, Maintenance and Storage ManualDan-jones TudziÎncă nu există evaluări

- Microproject Report HPCDocument7 paginiMicroproject Report HPCkadamnavadeep5863Încă nu există evaluări

- Top Entry Mixer Features For EkatoDocument2 paginiTop Entry Mixer Features For EkatoShankarÎncă nu există evaluări

- Centrifugal Compressor Vibrations: Oil & Gas Customer Training CenterDocument44 paginiCentrifugal Compressor Vibrations: Oil & Gas Customer Training CenterBrahim Rostane100% (1)

- P178Document9 paginiP178keepmoshingÎncă nu există evaluări

- Operation & Maintenance ManualDocument22 paginiOperation & Maintenance ManualAnivaryaPumpsÎncă nu există evaluări

- SideWinder 40 60 80 CHMCL PMP BrchreDocument4 paginiSideWinder 40 60 80 CHMCL PMP BrchreSH McÎncă nu există evaluări

- Preventive Maintenance Introduction: For Centrifugal Pump SystemsDocument13 paginiPreventive Maintenance Introduction: For Centrifugal Pump SystemsZaenal AripinÎncă nu există evaluări

- Maintenance Schedule Trailer PumpsDocument8 paginiMaintenance Schedule Trailer PumpsGhabriÎncă nu există evaluări

- Instrumentation Technician ResumeDocument2 paginiInstrumentation Technician ResumeFahad MaqsoodÎncă nu există evaluări

- Ohsms Example For Safety PDFDocument17 paginiOhsms Example For Safety PDFShoaib BokhariÎncă nu există evaluări

- 1079 PDFDocument7 pagini1079 PDFFahad MaqsoodÎncă nu există evaluări

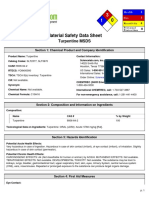

- Msds PDFDocument6 paginiMsds PDFFahad Maqsood100% (1)

- Specification and Test Methods for White SpiritDocument1 paginăSpecification and Test Methods for White SpiritFahad MaqsoodÎncă nu există evaluări

- A01 4012 11e08Document30 paginiA01 4012 11e08Fahad MaqsoodÎncă nu există evaluări

- Rotary Piston VacuumKinney KDH Series ManualDocument26 paginiRotary Piston VacuumKinney KDH Series ManualFahad Maqsood100% (1)

- Affinity DiagramDocument1 paginăAffinity DiagramFahad MaqsoodÎncă nu există evaluări

- ViscosityDocument20 paginiViscosityOnur CelikkanÎncă nu există evaluări

- Safety Uchicago Edu PP Emergency Fire SHTMLDocument5 paginiSafety Uchicago Edu PP Emergency Fire SHTMLFahad MaqsoodÎncă nu există evaluări

- 556630.CCA-1886-11 Alajbeg 2nd Revision From AuthorsDocument20 pagini556630.CCA-1886-11 Alajbeg 2nd Revision From AuthorsFahad MaqsoodÎncă nu există evaluări

- Vigon SDS US EnglishDocument14 paginiVigon SDS US EnglishFahad MaqsoodÎncă nu există evaluări

- 2.4 Attachments - Risk Assessment and Method StatementDocument10 pagini2.4 Attachments - Risk Assessment and Method StatementFahad MaqsoodÎncă nu există evaluări

- 2075 Turpentine Oil Rectified SDSDocument5 pagini2075 Turpentine Oil Rectified SDSFahad MaqsoodÎncă nu există evaluări

- IOSH Managing Safely: Special Fee Discount OfferDocument1 paginăIOSH Managing Safely: Special Fee Discount OfferFahad MaqsoodÎncă nu există evaluări

- Chemical Identification &controlDocument2 paginiChemical Identification &controlFahad MaqsoodÎncă nu există evaluări

- Study in Germany, Land of IdeasDocument66 paginiStudy in Germany, Land of IdeasFahad MaqsoodÎncă nu există evaluări

- Base Oil SN 600:: Property Kinematic Viscosity at 100 °C AstmDocument1 paginăBase Oil SN 600:: Property Kinematic Viscosity at 100 °C AstmFahad MaqsoodÎncă nu există evaluări

- IGC 2 Element 8Document74 paginiIGC 2 Element 8Fahad Maqsood100% (4)

- Scholarship Sad SP 15Document4 paginiScholarship Sad SP 15Fahad MaqsoodÎncă nu există evaluări

- Notes-Lecture1 Introduction Communication SkillsDocument34 paginiNotes-Lecture1 Introduction Communication SkillsFahad MaqsoodÎncă nu există evaluări

- Chemsical IndustrieDocument8 paginiChemsical IndustrieFahad MaqsoodÎncă nu există evaluări

- Analytical Ability TipsDocument9 paginiAnalytical Ability TipsFahad MaqsoodÎncă nu există evaluări

- Wet SludgeDocument9 paginiWet SludgeFahad MaqsoodÎncă nu există evaluări

- LMKR Oil & Gas Directory 2010 MuzammilDocument95 paginiLMKR Oil & Gas Directory 2010 MuzammilMuhammad MuzammilÎncă nu există evaluări

- Estimate Settle-Out Pressure and Temperature in Compressor LoopDocument3 paginiEstimate Settle-Out Pressure and Temperature in Compressor LoopFahad Maqsood100% (1)

- Effluent Traetment Plant SopDocument45 paginiEffluent Traetment Plant SopFahad Maqsood100% (2)

- FugacityDocument7 paginiFugacityATUL SONAWANEÎncă nu există evaluări

- Controller TYpesDocument10 paginiController TYpesFahad MaqsoodÎncă nu există evaluări

- Why Is It Important PH and AlkalinitDocument4 paginiWhy Is It Important PH and Alkalinitibnu samsiÎncă nu există evaluări