Documente Academic

Documente Profesional

Documente Cultură

Data Sheet Lyonomic en 0

Încărcat de

Matias RivarolaDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Data Sheet Lyonomic en 0

Încărcat de

Matias RivarolaDrepturi de autor:

Formate disponibile

Lyonomic

GMP Configurable Freeze-Dryers

Cost effective solution Controlled supply chain and traceability Standard validation package Addresses all pharmaceutical freeze-drying

applications range of standardized sub-systems enables Broad flexible configuration

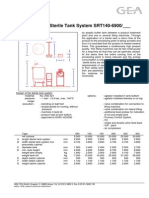

Equipment Basic Configuration

Configuration Drying chamber Cylindrical or rectangular chamber with external cylindrical ice condenser. All components mounted on a single skid. All process surfaces AISI 316L mirror polished to better than 0.5 m. Corners rounded for easy cleaning and bottom surfaces sloped towards the drain. All ports and piping connections are Tri-clamp sanitary type. Ports for validation and viewing (illuminated). Fully insulated and clad with AISI 304. Hinged. Single silicone gasket. Viewing port. Fully insulated. Cover and fascia AISI 304 for clean room integration. Better than 0.5 m satin finish AISI 316L. Better than 0.5 mm/m flatness. Side and rear guides. Vertical or Horizontal configurations. Condensing surface consisting of multiple smooth coils, polished to better than 0.5 m., constructed from AISI 316L tube. Vessel sloped towards the drain. All ports and piping connections are Tri-clamp sanitary type. Ports for validation and viewing (illuminated). Fully insulated and clad with AISI 304. Mirror finish butterfly type with EPDM gasket, pneumatically actuated.

Access door Shelves Ice condenser

Chamber-condenser isolation valve Refrigeration system 2 stage reciprocating semi-hermetic, water-cooled compressors each with independent circuits. HFC refrigerant. Shelf heat transfer Silicone oil fluid. Brazed plate heat exchangers. Canned type circulation pump. Multi-element system electrical heater. Shelf temperature control within 1 C. Shelf cooling to temperature lower than -55 C. Shelf heating to temperature up to +80 C Condenser heat Multiple independent coils with direct expansion of refrigerant. Condenser temperature lower transfer system than -75C. Temperature sensors Double PT100 for fluid temperature control. PT100 for monitoring shelf, product and each condenser coil. Vacuum system Evacuation time from atmospheric to 0.1 mbar in less than 20 minutes provided by oil sealed rotary vane vacuum pump with redundant back-up (plus roots blower on some models). Antisuck back valves and oil mist filters. Ready-to-duct oil vapour exhaust manifold.

Equipment Basic Configuration

Leak tightness Vacuum measurement Vacuum control Venting filter Internal CIP Process valves Control system Internal testing Standard documentation package Overall system pressure rise less than 2x10-2 mbar l/s. Largest individual leak less than 1x10-7 mbar l/s. Pirani type vacuum gauge at chamber (1) and at vacuum system (1). Via automatic opening and closing of the vacuum system valve. 0.22 m Chamber and condenser internal piping and nozzles. Liquid ring vacuum pump. AISI 316L angle seat valves on process side. Pneumatic actuation. Manual, semiautomatic and automatic operation. PLC controlled with touch screen interface and chart recorder. UPS included. Execution of internal test protocols. Instruction and maintenance manuals, as built drawings (layout, P&IDs, electrical and pneumatic diagrams, etc.), material and instrumentation calibration certificates.

Options and Accessories*

1

SIP

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

PED directive Jacket cooling FSIP Independently controlled FSIP Redundant filter Internal CIP Integrated CIP impulsion system CIP external impulsion system Stoppering device Stoppering bellows Bellows leak test Constant height Main door automatic locking Slot door Slot door automatic locking Shelf interdistance manual changeover Back-up compressor Screw compressors

Pressure vessel. Sanitary diaphragm valves in process piping. Sterilizable filter. Liquid ring pump for condensate draining and drying. SIP temperature sensor PT100, pressure transducer and sterilizable chamber vacuum sensor. Door locking with peripheral pins. GB pressure directive. Design and construction of chamber and condenser. Water circulation through chamber reinforcements for fast cooling after sterilization. Automatic filter sterilization in place (FSIP) and valves for manual WIT. Configuration for filter sterilization cycle independent from equipment SIP. Second venting filter installed in series. Included in the basic unit. Customer to supply the water at the required flow and pressure. CIP control not included. Condenser vessel is utilized as a water tank. Includes a sanitary centrifugal impulsion pump and integration with control system. Comprises an external skid with tanks, a sanitary centrifugal impulsion pump and a sanitary suction pump. Includes integration with control system. Hydraulically operated ram. Pressure applied at the shelves adjustable up to 1.5 kg/cm2. Zero clearance system (shelves can be fully closed). Unbraided flexible hoses for thermal fluid. Stainless steel 316L. Automated bellows leak test integrated with the control system. Constant height loading and unloading system. Built-in position transducer for fine shelf height positioning. Pneumatically operated mechanically linked set of peripheral pins. Automatic door latching. Position detectors to ensure correct locking. Manual locking hinged slot door. Automatic upward opening/downward closing slot door with mechanical locking device.

Set of spacer rods to change the standard shelf interdistance by stacking two or more shelves, provided that stoppering device or shelf movement system is included. Additional compressor operating in back-up mode. Replacement of the standard reciprocating compressors with screw type compressors. Includes variable frequency drives (VFD) for motors. Electronic expansion Replacement of the standard mechanical expansion valves with electronic type valves for valves (Coolstar) improved accuracy and efficiency. Back-up fluid Installation of an additional circulation pump operating in back-up mode. circulation pump Dry vacuum pumps Replacement of the standard oil-sealed vacuum pumps by dry pumps. Back-up vacuum Installation of an additional vacuum pump operating in back-up mode. pump Microbleed vacuum Substitution of the standard vacuum control of on/off valve between vacuum system and control valve condenser with a PID controlled microbleed valve.

*Tick your selections

Options and Accesories*

25 26

27 28

Capacitance vacuum gauge Loading/unloading automation (Lyogistics) Product trays SCADA package

Substitution of the chamber Pirani vacuum gauge by a capacitance manometer. Manual and semi-automatic solutions for bulk and vial applications.

Set of AISI 316L stainless steel internally polished trays for vial or bulk applications. Substitution of the touch screen HMI by a PC and SCADA control system with user-friendly graphical interface.

Documentation and Validation Options*

29 30

FAT

31

32 33

Includes a one-week FAT at Telstars premises in Shanghai, China with client present (upon request FAT can be performed in Europe). System qualification Generation and delivery of the QPP, FS and generation of DQ and FAT protocols compiled documentation (QPP, and executed by Telstar in accordance with GAMP 5. FS, DQ and FAT) System qualification Generation and delivery of the QPP, FS; generation of DQ and FAT protocols compiled documentation (QPP, and executed by Telstar in accordance with GAMP 5 and preparation of IQ/OQ protocol FS, DQ, FAT and IQ/ templates. OQ protocols) IQ/OQ execution To complement the system qualification documentation option, IQ/OQ protocols are executed at customer site by Telstar. Software validation Generation of a complete set of documentation qualifying design and testing of the software documentation modules in accordance to GAMP 5.

Service Options*

34

Freeze-drying support services

Development and/or optimization of freeze drying recipes available upon request.

Lyonomic Configurations*

Lyonomic DH/RC Horizontal configuration: 2 Vessels, Rectangular chamber, Cylindrical condenser.

Lyonomic DV/CC Vertical configuration: 2 Vessels, Cylindrical chamber, Cylindrical condenser.

Remarks & Comments

*Tick your selections

Technical Data (select your model)

Feature Useable surface area No of useable shelves Shelf clearance* Shelf dimensions w x d** Condenser capacity Shelf temperature range Final condenser temp. Approximate footprint ** Approximate weight Vial Capacity***

16 mm 2R-4R 22 mm 6R-8R 24 mm 10R-15R 30 mm 20R-25R

Unit m2 ud mm mm mm kg C C mm kg Approx.

4440/m2 2340/m2 1970/m2 1250/m2

0,81 3 180 450 600 30

1 1,08 4 120 450 600 30

1,35 5 100 450 600 30

1,44 4 120 450 800 30

2 1,8 5 100 450 800 30

2,16 6 80 450 800 30

1260 x 3000 2000

3596 1895 1596 1013 4795 2527 2128 1350 5994 3159 2660 1688

1260 x 3250 2500

6394 3370 2837 1800 7992 4212 3546 2250 9590 5054 4255 2700

Lyonomic 3 4 2,7 3,24 3,78 3,24 3,78 5 6 7 6 7 140 110 93 110 93 600 600 600 600 600 900 900 900 900 900 65 65 65 100 100 < -55 up to +80 < -75 2000 x 4000 4000

5 6 7 4,,32 5,4 6,48 7,56 6,48 7,56 8,64 8,64 8 5 6 7 6 7 8 8 80 150 125 100 125 100 90 145 600 900 900 900 900 900 900 900 900 1200 1200 1200 1200 1200 1200 1200 100 140 140 140 216 216 216 216

2000 x 5600 6000

10000

11988 14386 16783 14386 16783 19181 23976 28771 33566 28771 33566 38362 38362 6318 7582 8845 7582 8845 10109 12636 15163 17690 15163 17690 20218 20218 5319 6383 7447 6383 7447 8510 10638 12766 14893 12766 14893 17021 17021 3375 4050 4725 4050 4725 5400 6750 8100 9450 8100 9450 10800 10800

Lyonomic Feature Useable surface area No of useable shelves Shelf clearance* Shelf dimensions w x d** Condenser capacity Shelf temperature range Final condenser temp. Approximate footprint ** Approximate weight Vial Capacity***

16 mm 2R-4R 22 mm 6R-8R 24 mm 10R-15R 30 mm 20R-25R

Unit m2 ud mm mm mm kg C C mm kg Approx.

4440/m2 2340/m2 1970/m2 1250/m2

7 8 9,72 10,8 11,88 10,8 11,88 12,96 9 10 11 10 11 12 125 110 100 110 100 90 900 900 900 900 900 900 1200 1200 1200 1200 1200 1200 216 216 216 288 288 288

2000 x 5800 10000

43157 22745 19148 12150 47952 25272 21276 13500 52747 27799 23404 14850 47952 25272 21276 13500 52747 27799 23404 14850 57542 30326 25531 16200

9 14,04 10,8 12,6 14,4 16,2 14,4 13 6 7 8 9 8 80 160 135 110 95 150 900 1200 1200 1200 1200 1200 1200 1500 1500 1500 1500 1500 288 288 288 288 288 360 < -55 up to +80 < -75 2200 x 6000 12000

62338 32854 27659 17550 47952 25272 21276 13500 55944 29484 24822 15750 63936 33696 28368 18000 71928 37908 31914 20250 63936 33696 28368 18000

10 11 16,2 18 19,8 18 19,8 21,6 23,4 9 10 11 10 11 12 13 130 115 100 160 145 130 115 1200 1200 1200 1200 1200 1200 1200 1500 1500 1500 1500 1500 1500 1500 360 360 360 468 468 468 468

2200 x 6800 13000

71928 37908 31914 20250 79920 42120 35460 22500 87912 46332 39006 24750 79920 42120 35460 22500 87912 46332 39006 24750 95904 50544 42552 27000 103896 54756 46098 29250

Feature Useable surface area No of useable shelves Shelf clearance* Shelf dimensions w x d** Condenser capacity Shelf temperature range Final condenser temp. Approximate footprint ** Approximate weight Vial Capacity***

16 mm 2R-4R 22 mm 6R-8R 24 mm 10R-15R 30 mm 20R-25R

Unit m2 ud mm mm mm kg C C mm kg Approx.

4440/m2 2340/m2 1970/m2 1250/m2

Lyonomic 12 13 23,4 25,2 27 28,8 30,6 24,3 27 29,7 32,4 13 14 15 16 17 9 10 11 12 115 105 100 90 85 150 130 115 105 1200 1200 1200 1200 1200 1500 1500 1500 1500 1500 1500 1500 1500 1500 1800 1800 1800 1800 586 586 586 586 586 780 780 780 780 < -55 up to +80 < -75 2200 x 6800 16000 21000

103896 54756 46098 29250 111888 58968 49644 31500 119880 63180 53190 33750 127872 67392 56736 36000 135864 71604 60282 38250 107892 56862 47871 30375 119880 63180 53190 33750 131868 69498 58509 37125 143856 75816 63828 40500

14 35,1 37,8 40,5 37,8 40,5 43,2 45,9 48,6 51,3 54 13 14 15 14 15 16 17 18 19 20 95 85 80 130 120 110 104 95 90 85 1500 1500 1500 1500 1500 1500 1500 1500 1500 1500 1800 1800 1800 1800 1800 1800 1800 1800 1800 1800 780 780 780 975 975 975 975 975 975 975

2600 x 8200 21000

155844 82134 69147 43875 167832 88452 74466 47250 179820 94770 79785 50625 167832 88452 74466 47250 179820 94770 79785 50625 191808 101088 85104 54000 203796 107406 90423 57375 215784 113724 95742 60750 227772 120042 101061 64125 239760 126360 106380 67500

* Shelf clearance values for Comfortable Loading Height machines. For Constant Height machines these values will change **Width x Depth *** These values are for guidance only and represent the estimated capacity available when using various product trays or loading systems

Headquarters Av. Font i Sagu, 55 Parc Cientfic i Tecnolgic Orbital 40 08227 Terrassa (Spain) T +34 937 361 600 F +34 937 859 342

North America 1504 Grundys Lane Bristol, PA 19007 (USA) T +1 215 826 0770 F +1 215 826 0222

Far East No. 30 Jin Wen Road, Zhu Qiao Airport Ind. Zone, Nanhui District 201323 Shanghai (China) T +86 21 58 093 731 F +86 21 58 092 857

www.telstar-lifesciences.com

Version 02 12 10 I Telstar reserves the right to improvements and specifications changes without notice.

S-ar putea să vă placă și

- Quanta Freeze DryerDocument11 paginiQuanta Freeze DryercristinatubleÎncă nu există evaluări

- Cat 30RB 2013Document10 paginiCat 30RB 2013Denise Koh Chin HuiÎncă nu există evaluări

- Valvulas Diafragma InformacionDocument4 paginiValvulas Diafragma InformacionCHRISTIANCHIROQUEÎncă nu există evaluări

- In-Situ Fermentors CatalogueDocument4 paginiIn-Situ Fermentors CatalogueVineet GuptaÎncă nu există evaluări

- Environmental - CatalogDocument3 paginiEnvironmental - Catalogdéborah_rosalesÎncă nu există evaluări

- BF610Document4 paginiBF610Prasad KulkarniÎncă nu există evaluări

- Edm Aq410 2 S.1GB02.12 40-75Document52 paginiEdm Aq410 2 S.1GB02.12 40-75Advokat HadziTonicÎncă nu există evaluări

- Technical Data: Sterile Tank System SRT140-6900Document2 paginiTechnical Data: Sterile Tank System SRT140-6900Luis Guillermo Echeverri LopezÎncă nu există evaluări

- Technical YCSA 50-100Document28 paginiTechnical YCSA 50-100nairam2003Încă nu există evaluări

- Packed Bed Tower ScrubbersDocument8 paginiPacked Bed Tower Scrubberssumit_waghmareÎncă nu există evaluări

- 30GXDocument12 pagini30GXAdolfo Riquelme Novoa0% (1)

- 0000-MPC-A 0500-SP-Philips MX-8000 IDT 16 Slice CT Scanner Medical ChillerDocument5 pagini0000-MPC-A 0500-SP-Philips MX-8000 IDT 16 Slice CT Scanner Medical ChillerJorge GrajedaÎncă nu există evaluări

- Frigomilk G9 IngDocument2 paginiFrigomilk G9 IngAlberto Salazar OrrilloÎncă nu există evaluări

- Trane Submittal CVGF 650Document10 paginiTrane Submittal CVGF 650jun005Încă nu există evaluări

- Almig Belt GB WebDocument8 paginiAlmig Belt GB WebIPV_UAÎncă nu există evaluări

- Pneutrainer eDocument24 paginiPneutrainer eSiscaNduetz-NduetzGaxMauGalauÎncă nu există evaluări

- PULSATRON A Plus طلمبات حقن الكيماويات الكهربائيةDocument8 paginiPULSATRON A Plus طلمبات حقن الكيماويات الكهربائيةRheoserve Industrial SolutionsÎncă nu există evaluări

- FOCSWATER.C Water Cooled Chiller - R134aDocument8 paginiFOCSWATER.C Water Cooled Chiller - R134antt_121987Încă nu există evaluări

- SRC Alpha Version1 PDFDocument26 paginiSRC Alpha Version1 PDFRajat JainÎncă nu există evaluări

- Yca PDFDocument44 paginiYca PDFsugirin100% (2)

- BR Lyoquest en 0111 - 0 PDFDocument4 paginiBR Lyoquest en 0111 - 0 PDFmarcelloairesÎncă nu există evaluări

- HPB Brochure 0708Document12 paginiHPB Brochure 0708musaluddinÎncă nu există evaluări

- Electric Submersible Sewage PumpsDocument8 paginiElectric Submersible Sewage PumpsMiroslavCrnogoracÎncă nu există evaluări

- PETOIL BOSS Characteristics Rev - Jun09 - EnglishDocument8 paginiPETOIL BOSS Characteristics Rev - Jun09 - EnglishSelma SelminhaÎncă nu există evaluări

- Steriline TunnelDocument8 paginiSteriline TunnelHutHeoÎncă nu există evaluări

- Air DryerDocument4 paginiAir Dryerrashm006ranjanÎncă nu există evaluări

- Automatic Boiler ControlDocument16 paginiAutomatic Boiler ControlbadpplÎncă nu există evaluări

- Csa 10 To 20Document6 paginiCsa 10 To 20peterpunk75Încă nu există evaluări

- Kinney LR PumpsDocument20 paginiKinney LR Pumpsnarupv100% (1)

- CGAT Catalog0303Document2 paginiCGAT Catalog0303Chinith HengÎncă nu există evaluări

- 8-1 3750 Pressurisation Unit BrochureDocument8 pagini8-1 3750 Pressurisation Unit BrochureAmeet Gupte0% (1)

- Liquid Ring PumpDocument48 paginiLiquid Ring Pumpkalyanm203515100% (1)

- Vatech SB6-2YDocument4 paginiVatech SB6-2YAlexander GuzmánÎncă nu există evaluări

- HFD Catalog SentinelDocument12 paginiHFD Catalog SentinelGuido Moreno PeredoÎncă nu există evaluări

- Pkgds 6Document88 paginiPkgds 6alcomechÎncă nu există evaluări

- Control ValvesDocument26 paginiControl ValvesTirado Melchor Angel Miguel100% (1)

- Guth VSR Modulating ValvesDocument8 paginiGuth VSR Modulating ValvesRaul Guevara TorresÎncă nu există evaluări

- FOCSWATER.C Water Cooled Chiller - R134a - 2012!01!01Document15 paginiFOCSWATER.C Water Cooled Chiller - R134a - 2012!01!01ntt_121987Încă nu există evaluări

- 741 VLB BrochureDocument4 pagini741 VLB BrochureMohammad Ali ZamanÎncă nu există evaluări

- Desaireador GKMOSS - Tray - Deaerator - Brochure PDFDocument6 paginiDesaireador GKMOSS - Tray - Deaerator - Brochure PDFCdMoraSÎncă nu există evaluări

- Technical YLAEDocument16 paginiTechnical YLAEnairam2003Încă nu există evaluări

- Eg en YlcsDocument52 paginiEg en YlcsItalo LeivaÎncă nu există evaluări

- Chiller Data SheetDocument7 paginiChiller Data SheetMohammed AzharÎncă nu există evaluări

- 633LS ProdspecDocument14 pagini633LS ProdspecAdrian AbellaÎncă nu există evaluări

- Valvulas FC WoodwortDocument2 paginiValvulas FC WoodwortMigue MedZa100% (1)

- Ycsa 50 60 80 100Document48 paginiYcsa 50 60 80 100george1582100% (1)

- Horizontal Autoclave PDFDocument11 paginiHorizontal Autoclave PDFYash KumarÎncă nu există evaluări

- Bertoli Corporate 2015 en Rev1Document30 paginiBertoli Corporate 2015 en Rev1Andres GarcíaÎncă nu există evaluări

- IF Commercial Ironer Feeder Folder Brochure PDFDocument2 paginiIF Commercial Ironer Feeder Folder Brochure PDFAl AdcockÎncă nu există evaluări

- Eaton - Internormen Wind Power SolutionsDocument12 paginiEaton - Internormen Wind Power SolutionsEaton FiltrationÎncă nu există evaluări

- Medical Air Systems Product Selection Guide: Oil-Less Scroll... Oil-Less Reciprocating... Enclosed Scroll..Document6 paginiMedical Air Systems Product Selection Guide: Oil-Less Scroll... Oil-Less Reciprocating... Enclosed Scroll..Orlando Chancafe AngelesÎncă nu există evaluări

- Air 4 Bar PlantDocument7 paginiAir 4 Bar PlantAbu ZakaÎncă nu există evaluări

- Series 825Y Specification SheetDocument2 paginiSeries 825Y Specification SheetFEBCOÎncă nu există evaluări

- Continuous Emissions Monitoring System II: Gasmet Technologies, April 2010Document27 paginiContinuous Emissions Monitoring System II: Gasmet Technologies, April 2010Andy LuthorÎncă nu există evaluări

- Gruenberg Depyrogenation Oven PDFDocument4 paginiGruenberg Depyrogenation Oven PDFEPSovensÎncă nu există evaluări

- York Cat LC 2012 enDocument148 paginiYork Cat LC 2012 enMary Andrews100% (1)

- CCI DRAG® Compressor RecycleAnti-surge ValveDocument8 paginiCCI DRAG® Compressor RecycleAnti-surge ValvescribdkhatnÎncă nu există evaluări

- Data Sheet Milk Reception Unit.1 enDocument2 paginiData Sheet Milk Reception Unit.1 enBoricean Gheorghita100% (1)

- in The Matter of The Estate of Remigia SaguinsinDocument3 paginiin The Matter of The Estate of Remigia SaguinsinAila AmpieÎncă nu există evaluări

- AWS Solution Architect SampleDocument3 paginiAWS Solution Architect SamplepandiecÎncă nu există evaluări

- Time-Series Forecasting: 2000 by Chapman & Hall/CRCDocument9 paginiTime-Series Forecasting: 2000 by Chapman & Hall/CRCeloco_2200Încă nu există evaluări

- Thick Walled Cylinders and SpheresDocument0 paginiThick Walled Cylinders and Spherescrossfirex30Încă nu există evaluări

- 4-Sided Planer & Moulder Operation Manual: For Spares and Service ContactDocument48 pagini4-Sided Planer & Moulder Operation Manual: For Spares and Service ContactAlfred TsuiÎncă nu există evaluări

- Lesson 2. WHAT IS AGROTECHNOPRENEURSHIPDocument23 paginiLesson 2. WHAT IS AGROTECHNOPRENEURSHIPRhea Jane DugadugaÎncă nu există evaluări

- Specification For Wrought Austenitic Stainless Steel Piping FittingsDocument10 paginiSpecification For Wrought Austenitic Stainless Steel Piping FittingsAnilÎncă nu există evaluări

- Krishna Yadav Cell#+91-9540308010: BjectiveDocument6 paginiKrishna Yadav Cell#+91-9540308010: BjectiveIssac JohnÎncă nu există evaluări

- Formal Methods Assignment PDFDocument25 paginiFormal Methods Assignment PDFAdla FikriyahÎncă nu există evaluări

- Type SAP Usage / Definition Example Procurement RotablesDocument4 paginiType SAP Usage / Definition Example Procurement Rotablessabya1411Încă nu există evaluări

- Unified HACKTBDocument15 paginiUnified HACKTBKali PentesterÎncă nu există evaluări

- 04 Handout 1 (Midterms)Document14 pagini04 Handout 1 (Midterms)Emmanuel DelarosaÎncă nu există evaluări

- SEMIKRON DataSheet SK 30 GD 066 ET 24914960Document5 paginiSEMIKRON DataSheet SK 30 GD 066 ET 24914960prajwalÎncă nu există evaluări

- Transportation Problem 2Document11 paginiTransportation Problem 2Chasity WrightÎncă nu există evaluări

- ACLU Letter of ConcernDocument5 paginiACLU Letter of ConcernRyan FinnertyÎncă nu există evaluări

- Creating Website Banners With Photoshop PDFDocument18 paginiCreating Website Banners With Photoshop PDFLiza ZakhÎncă nu există evaluări

- Full Download Test Bank For Accounting Information Systems Hall 8th Edition PDF Full ChapterDocument36 paginiFull Download Test Bank For Accounting Information Systems Hall 8th Edition PDF Full Chapterfluiditytrenail7c8j100% (16)

- Analysis of Methodologies For The Evaluation of Power Outage Costs PDFDocument5 paginiAnalysis of Methodologies For The Evaluation of Power Outage Costs PDFHachimenum AmadiÎncă nu există evaluări

- JSSG-2010-7 - Crash Systems Handbook PDFDocument155 paginiJSSG-2010-7 - Crash Systems Handbook PDFdaymonÎncă nu există evaluări

- Electrical Engineering: Scheme of Undergraduate Degree CourseDocument2 paginiElectrical Engineering: Scheme of Undergraduate Degree CourseSuresh JainÎncă nu există evaluări

- 13 Ways The Coronavirus Pandemic Could Forever Change The Way We WorkDocument20 pagini13 Ways The Coronavirus Pandemic Could Forever Change The Way We WorkAbidullahÎncă nu există evaluări

- ABSTRACT (CG To Epichlorohydrin)Document5 paginiABSTRACT (CG To Epichlorohydrin)Amiel DionisioÎncă nu există evaluări

- Topic: Matrix Addition and SubtractionDocument6 paginiTopic: Matrix Addition and SubtractionAnonyÎncă nu există evaluări

- Literature Review On Climate Change in NigeriaDocument9 paginiLiterature Review On Climate Change in Nigeriac5rn3sbr100% (1)

- Vande Bharat Exp Chair Car (CC) : Electronic Reserva On Slip (ERS)Document2 paginiVande Bharat Exp Chair Car (CC) : Electronic Reserva On Slip (ERS)Subhash KumarÎncă nu există evaluări

- MyFlixer - Watch Movies and Series Online Free in Full HD On MyFlixerDocument1 paginăMyFlixer - Watch Movies and Series Online Free in Full HD On MyFlixerGeanina OlteanuÎncă nu există evaluări

- New Micra BrochureDocument14 paginiNew Micra BrochureGlobalGroupOfDealersÎncă nu există evaluări

- 2008 Almocera vs. OngDocument11 pagini2008 Almocera vs. OngErika C. DizonÎncă nu există evaluări

- Episode 1Document10 paginiEpisode 1ethel bacalso100% (1)

- 42 Investors Awareness Towards Mutual FundsDocument8 pagini42 Investors Awareness Towards Mutual FundsFathimaÎncă nu există evaluări