Documente Academic

Documente Profesional

Documente Cultură

Fast Dissolving Oral Films An Innovative Drug

Încărcat de

Hananun ZharfaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Fast Dissolving Oral Films An Innovative Drug

Încărcat de

Hananun ZharfaDrepturi de autor:

Formate disponibile

International Journal of ChemTech Research CODEN( USA): IJCRGG ISSN : 0974-4290 Vol.2, No.

1, pp 576-583, Jan-Mar 2010

Fast Dissolving Oral Films: An Innovative Drug Delivery System and Dosage Form

Arun Arya*1, Amrish Chandra1, Vijay Sharma 2 and Kamla Pathak2

1

Department of Pharmacy, Institute of Biomedical Education and Research, Mangalayatan University, Beswan, Aligarh-202145 , India.

Department of Pharmaceutics, Rajiv Academy For Pharmacy, P.O. Chattikara, Mathura -281001,India. *Corresponding author:arya_pharma19@yahoo.co.in

Abstract : Fast-dissolving drug-delivery systems were first developed in the late 1970s as an alternative to tablets,

capsules, and syrups for pediatric and geriatric patients who experience difficulties swallowing traditional oral soliddosage forms. In response to this need, a variety of orally disintegrating tablet (ODT) formats were commercialized. Most ODT products were formulated to dissolve in less than one minute when exposed to saliva to form a solution that could then be more easily swallowed. Dissolvable oral thin films (OTFs) evolved over the past few years from the confection and oral care markets in the form of breath strips and became a novel and widely accepted form by consumers for delivering vitamins and personal care products. Companies with experience in the formulation of polymer coatings containing active pharmaceutical ingredients (APIs) for transdermal drug delivery capitalized on the opportunity to transition this technology to OTF formats. Today, OTFs are a proven and accepted technology for the systemic delivery of APIs for over-the-counter (OTC) medications and are in the early- to mid-development stages for prescription drugs.

Key words Fast dissolving films Solvent casting Semisolid casting Disintegration time Contact angle Introduction

Recent developments in the technology have presented viable dosage alternatives from oral route for pediatrics, geriatric, bedridden, nauseous or noncompliant patients. Buccal drug delivery has lately become an important route of drug administration. Various bioadhesive mucosal dosage forms have been developed, which includes adhesive tablets, gels, ointments, patches and more recently the use of polymeric films for buccal delivery, also known as mouth dissolving films1. Mouth dissolving films, a new drug delivery system for the oral delivery of the drugs, was developed based on the technology of the transdermal patch. The delivery system consists of a very thin oral strip, which is simply placed on the patients tongue or any oral mucosal tissue, instantly wet by saliva the film rapidly hydrates and adheres onto the site of application. It then rapidly disintegrates and dissolves to release the medication for oromucosal absorption or with formula modifications, will maintain the quick-dissolving aspects allow for gastrointestinal absorption to be achieved when swallowed. In contrast to other existing, rapid dissolving dosage forms, which consist of liophylisates, the rapid films can be produced with a manufacturing process that is competitive with the manufacturing costs of conventional tablets2. Pharmaceutical companies and consumers alike have embraced OTFs as a practical and accepted alternative to traditional OTC medicine forms such as liquids,

Arun Arya et al /Int.J. ChemTech Res.2010,2(1)

577

tablets, and capsules. OTFs offer fast, accurate dosing in a safe, efficacious format that is convenient and portable, without the need for water or measuring devices3. OTFs are typically the size of a postage stamp and disintegrate on a patient's tongue in a matter of seconds for the rapid release of one or more APIs4. Special features of mouth dissolving films5 Thin elegant film Available in various size and shapes Unobstructive Excellent mucoadhesion Fast disintegration Rapid release Advantages Convenient dosing No water needed No risk of chocking Taste masking Enhanced stability Improved patient compliance The mouth dissolving films has also a clear advantage over the Oral dissolving tablets (ODTs): -ODTs are sometimes difficult to carry, store and handle (fragility and friability). -Many ODTs are prepared by using the expensive lyophillisation process2. A large number of drugs can be formulated as mouth dissolving films. Innovative products may increase the therapeutic possibilities in the following indications3. -Pediatrics (antitussives, expectorants, antiasthamatics) - Geriatrics (antiepileptic, expectorants) - Gastrointestinal diseases - Nausea (e.g. due to cytostatic therapy) - Pain (e.g. migraine) - CNS (e.g. antiparkinsonism therapy) Composition of the system Mouth dissolving film is a thin film with an area of 520 cm2 containing an active ingredient. The immediate dissolution, in water or saliva respectively, is reached through a special matrix from water-soluble polymers. Drugs can be incorporated up to a single dose of 15mg. formulation considerations (plasticizers etc.) have been reported as important factors affecting mechanical properties of the films, such as shifting shifting the glass transition temperature to lower temperature2. A typical composition contains the following Drug 1-25% Water soluble polymer 40-50% Plasticizers 0-20% Fillers, colours, flavours etc. 0-40%

1) Drugs Several class of drugs can be formulated as mouth dissolving films including antiulcer (e.g. omeprazole), antiasthamatics (salbutamol sulphate), antitussives, expectorants, antihistaminics, NSAIDS (e.g. paracetamol, meloxicam, valdecoxib)6,7,8,9. 2) Water soluble polymers Water-soluble polymers are used as film formers. The use of film forming polymers in dissolvable films has attracted considerable attention in medical and nutraceutical application. The water-soluble polymers achieve rapid disintegration, good mouthfeel and mechanical properties to the films. The disintegration rate of the polymers is decreased by increasing the molecular weight of polymer film bases. Some of the water soluble polymers used as film former are HPMC E-3 and K-3, Methyl cellulose A-3, A-6 and A-15, Pullulan, carboxmethylcellulose cekol 30, Polyvinylpyrollidone PVP K-90, Pectin, Gelatin, Sodium Alginate, Hdroxypropylcellulose, Polyvinyl alcohol, Maltodextrins and EUDRAGITRD108,9,10,11,12 .Polymerized rosin is a novel film forming polymer13. 3) Plasticizers Formulation considerations (plasticizer, etc.) have been reported as important factors affecting mechanical properties of films. The mechanical properties such as tensile strength and elongation to the films have also been improved by the addition of plasticizers. Variation in their concentration may affect these properties. The commonly used plasticizers are glycerol, di-butylpthallate, and polyethylene glycols etc10. 4) Surfactants Surfactants are used as solublising or wetting or dispersing agent so that the film is getting dissolved within seconds and release active agent immediately. Some of the commonly used are sodium lauryl sulfate, benzalkonium chloride, bezthonium chloride, tweens etc. One of the most important surfactant is polaxamer 407 that is used as solubilizing, wetting and dispersing agent14. 5) Flavour Any flavor can be added, such as intense mints, sour fruit flavors or sweet confectionery flavors15. 6) Colour A full range of colors is available, including FD&C colors, EU Colours, Natural Colours and custom Pantone-matched colours15. *Some saliva stimulating agents may also be added to

Arun Arya et al /Int.J. ChemTech Res.2010,2(1)

578

enhance the disintegration and to get rapid release. Some of these agents are citric acid, tartaric acid, malic acid, ascorbic acid and succinic acid16. Manufacturing Methods One or combination of the following process can be used to manufacture the mouth dissolving films17. i) Solvent casting ii) Semisolid casting iii) Hot melt extrusion iv) Solid dispersion extrusion v) Rolling 1) Solvent casting method In solvent casting method water soluble polymers are dissolved in water and the drug along with other Excipients is dissolved in suitable solvent then both Water soluble hydrocolloids dissolved in water to form homogenous viscous solution

the solutions are mixed and stirred and finally casted in to the Petri plate and dried. 2) Semisolid casting In semisolid casting method firstly a solution of watersoluble film forming polymer is prepared. The resulting solution is added to a solution of acid insoluble polymer (e.g. cellulose acetate phthalate, cellulose acetate butyrate), which was prepared in ammonium or sodium hydroxide. Then appropriate amount of plasticizer is added so that a gel mass is obtained. Finally the gel mass is casted in to the films or ribbons using heat controlled drums. The thickness of the film is about 0.015-0.05 inches. The ratio of the acid insoluble polymer to film forming polymer should be 1:4.

Other ingredients including active agents dissolved in small portion of aqueous solvent using high shear processor

Both mixtures are mixed to form homogenous viscous solution

Degassed under vacuum

Bubble free solution is coated on non-treated casting film

Coated film is sent to aeration drying oven

Film is cutted in to desired shape and size

3) Hot melt extrusion In hot melt extrusion method firstly the drug is mixed with carriers in solid form. Then the extruder having heaters melts the mixture. Finally the melt is shaped in to films by the dies. There are certain benefits of hot melt extrusion18. -Fewer operation units -Better content uniformity -An anhydrous process

4) Solid dispersion extrusion In this method immiscible components are extrude with drug and then solid dispersions are prepared. Finally the solid dispersions are shaped in to films by means of dies. 5) Rolling Method In rolling method a solution or suspension containing drug is rolled on a carrier. The solvent is mainly water and mixture of water and alcohol. The film is dried on the rollers and cutted in to desired shapes and sizes3.

Arun Arya et al /Int.J. ChemTech Res.2010,2(1)

579

Figure1. Three roll coating unit. multiple films with different actives to be bonded together. WAFERTAB can be prepared in a variety of shapes and sizes and is an ideal method for delivery of medicines, which require fast release, or for use by patients who have difficulty swallowing. 3) FOAMBURST is a special variant of the SOLULEAVES technology where an inert gas is passed into the film during production. This results in a film with a honeycombed structure, which dissolves rapidly giving a novel mouth sensation. FOAMBURST has attracted interest from food and confectionary manufacturers as a means of carrying and releasing flavours. 4) XGEL film is at the heart of Meldex International's intellectual property, used in all its film systems and its ingestible dosage delivery technologies. XGEL film provides unique product benefits for healthcare and pharmaceutical products: it is nonanimal-derived, approved on religious grounds and is suitable for vegetarians; the film is GMO free and continuous production processing provides an economic and competitive manufacturing platform. XGEL film can be taste masked, coloured, layered, and capable of being enteric properties whilst also having the ability to incorporate active pharmaceutical ingredients. The XGEL film systems can be made to encapsulate any oral dosage form, and can be soluble in either cold or hot water. XGEL film is comprised of a range of different water-soluble polymers, specifically optimised for the intended use.

TECHNOLOGIES19 1) SOLULEAVES technology is used to produce a range of oral delivery films that can incorporate active ingredients, colours and flavours. SOLULEAVES films can be designed to dissolve rapidly on contact with saliva, quickly releasing the active ingredients and flavours. This quality makes edible films an excellent delivery method for a large range of products requiring fast release in the mouth. For pharmaceutical uses this method of administration is especially useful for paediatric or elderly patients who may have difficulty swallowing traditional tablets or capsules. The delivery system can be used for the cough/cold, gastrointestinal and pain therapeutic areas as well as delivering nutritional products. SOLULEAVES films can also be designed to adhere to mucous membranes and to release the active ingredient slowly over 15 minutes. 2) WAFERTAB is a drug delivery system that incorporates pharmaceutical actives into an ingestible filmstrip. The system provides rapid dissolution and release of actives when the strip comes into contact with saliva in the mouth. The WAFERTAB filmstrip can be flavoured for additionally improved taste masking. The active ingredient is precisely dosed and integrated into the body of a pre-manufactured XGEL film, thus preventing exposure to unnecessary heat and moisture and potentially enhancing product stability. The WAFERTAB system lends itself to many possibilities for innovative product design, enabling

Arun Arya et al /Int.J. ChemTech Res.2010,2(1)

580

All of the XGEL ingredients are well known and generally regarded as safe (GRAS). Evaluating parameters 1) Mechanical properties Mechanical properties of films are evaluated Instron using a TA.XT2 texture analyzer equipment equipped with a 5kg load cell. Films are held between two clamps positioned between 3cm. During measurement the strips were pulled at rate of 2mm/sec. The force and elongation were measured when film breaks. Three mechanical properties namely tensile strength, elastic modulus and % elongation are calculated20. a) Tensile strength Tensile strength is calculated by formula = force at break/ initial cross sectional area of film in mm2 b) Elastic modulus Elastic modulus is calculated by formula Elastic modulus = force at corresponding strain 1

*

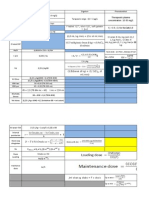

Wettre, Germany). A drop of double distilled water was placed on the surface of the dry film. Images of the water droplet were recorded within 10 seconds of deposition by means of digital camera. Digital pictures were analyzed by imageJ 1.28v software (NIH, USA) for angle determination. A minimum of five measurements, taken at different positions of the film, was carried out. The contact angle was measured on both sides of the drop and averaged21. 5) In vitro disintegration time In vitro disintegration time is determined visually in a glass dish of 25ml distilled water with swirling every 10 sec. The disintegration time is the time when the film starts to break or disintegrates10. 6) In vitro dissolution studies The in vitro dissolution study is carried out in simulated saliva solution pH 6.4 phosphate buffer using USP paddle apparatus at 370.5C. samples are withdrawn at regular time interval interval and analyzed by UV-Visible spectrophotometer6. 7) Determination of dissolution rate by conductivity method In the past 5 years several personal care products formulated in quick release film form have entered the marketplace, of which fast-dissolve breath fresheners were first. The fast dissolve oral films completely dissolve in as little as 1 minute. The majority of oral films on the market today contain ionizable components. This work presents a method for highresolution monitoring of the dissolution of fast dissolving oral films by measuring conductivity of the dissolution medium22. Equipment required Equipment(Fig.2) includes the following: - Variable speed stirrer motor: capable of 250 rpm. - Analytical balance (medium weight): capable of weighing to the nearest 0.01g and having a range not less than 400g. - Low-form beaker: 3800 ml. - Impeller: 2-inch diameter, 1 blade (stainless steel or monel metal). - Conductivity probe: capable of measuring conductivity to 0.1 siemens (Hann 8033 conductivity meter). - Laboratory equipment stand. - Double-sided clear tape: 3/4 inch-wide. - External stands to hold conductivity probe. - Scissors - Stopwatch with a second hand.

Cross sectional area (mm ) c) % Elongation It is calculated as = Increase in length Original length

Corresponding strain

* 100

d) Folding endurance Folding endurance is determined by folding the films of uniform cross sectional area and thickness until it breaks. 2) Morphology study The morphology of the films is studied using scanning electron microscopy (SEM), at a definite magni fication6. 3) Swelling property Film swelling studies is conducted using simulated saliva solution. Each film sample is weighed and placed in a preweighed stainless steel wire mesh. The mesh containing film sample is submerged into 15ml medium in a plastic container. Increase in the weight of the film was determined at preset time interval until a constant weight was observed20. The degree of swelling was calculated using parameters wt-w0/wo, wt is weight of film at time t, and wo is weight of film at time zero. 4) Contact angle Contact angle measurements is performed at room temperature with a goniometer (AB Lorentzen and

Arun Arya et al /Int.J. ChemTech Res.2010,2(1)

581

conductivity probe. When the water completely covers the film, start the timer (approx 3sec). Then restart the impeller stirring at 250rpm. - Take a data point at every 10 sec for the first minute. The take data as appropriate.

Figure. 2 Diagram of equipment set-up

Film Preparation One side of the film is adhered to the double sided tape, and the double sided tape is cut to the dimensions of the film (Figure. 3). Test Procedure - Fill a clean beaker with 300 g (0.05g) of the deionized water. - Test the conductivity of the water to establish the background value. - Adhere the film inside the dry, clean 800ml beaker so that the centre section is even with or slightly below the 100 ml line of the beaker. Arrange theConductivity probe and the impeller in the beaker. - As quickly as possible pour the 300 ml of the water in the beaker containing the film, impeller and the Marketed Films23,24,25,26,27,28 Table 1. List of marketed fast dissolving films S.No. 1. 2. 3. 4. Product

Figure 3. Diagram of prepared film

Packaging A variety of packaging options are available for fastdissolving films. Single packaging is mandatory for films, which are pharmaceutical products; an aluminum pouch is the most commonly used packaging format. APR-Labtec has developed the Rapid card, a proprietary and patented packaging system, which is specially designed for the Rapid films. The rapid card has same size as a credit card and holds three raid films on each side. Every dose can be taken out individually2.

Manufactured By MonoSolRx Labtec Pharma Johns Hopkins undergraduate biomedical engineering students. Hughes medical corporation

Dextromethorphan HBr (cough suppressant),Diphenhydramine Citrate (cough and cold),Breath Strips Doneprezil rapid dissolving films, Ondansatron rapid dissolving films Life-saving rotavirus vaccine to infants Methylcobalamin fast dissolving films, Diphemhydramine HCl fast dissolving films,Dextromethorphan fast dissolving films, Folic Acid 1mg fast dissolving films, Caffeine fast dissolving films Altoid cinnamon strips, Boots vitamin c strips, Cool shock peppermint strips, Benzocaine films, Caffeine films

5.

Dow chemical company

Arun Arya et al /Int.J. ChemTech Res.2010,2(1)

582

6. 7.

Listerine Pocket Paks Breath Freshening Strips Energy strips - Caffeine 20mg, Acetyl Salicylic Acid (ASA), Ondansetron HCl, Dexamethasone, Nitroglycerine, Risperidone Vitamin B12, melatonin, folic acid, biotin Benzocaine, Diphenhydramine HCl, Dextrometorphan

Pfizer's Warner-Lambert consumer healthcare division ODF Technologies Inc.

Conclusion

Fast dissolving oral films have several advantages over the conventional dosage forms. So they are of great

importance during the emergency cases such as allergic reactions and astahmatic attacks whenever immediate onset of action is desired.

References

1.Malke M, Shidhaye S, Kadam VJ. , Formulation and evaluation of Oxacarbazine fast dissolve tablets. Ind J Pharm Sci. 2007;69: 211-214. 2.Vollmer U, Galfetti P. Rapid film: Oral thin films as an innovative drug delivery System and dosage form.Drug Dev Report. 2006; 64-67. http:// www.apr.ch 3.Frey.Film Strips and Pharmaceuticals. Pharma Mfg & Packag Sourcer. 2006:9293. 4.Vondrak B, Barnhart, Scott. Dissolvable Films: Dissolvable Films for Flex Product Format in Drug Delivery. Pharmatech. 2008; 1-5. 5.Suresh B, Halloran D, James L. Quick dissolving films: A novel approach to drug delivery. Drug.dev.tech. 2006;1-7. http://www.drugdeliverytech.com 6.Mashru R.C, Sutariya BC, Parikh PP. Development and evaluation of fast dissolving films of salbutamol sulphate.Drug Dev Ind Pharm. 2005 ;31:25-34.Doi: 10.1081/DDC-200043947 7.Gohel MC, Sharma R, Soniwala MM. Development of taste masked film of Valdecoxib for oral use. Ind j Pharm Sci. 2007;69:318-320. 8. http://www.hughes-medical.com/products/fast-dissolving-film.htm 9. Cilurzo F, Paola M, Andrea C. Maltodextrin Fast Dissolving Film: A Feasibility Study. Pharma Films Srl, Milano Italy. http://www.tecnova-srl.it/download/film@EUFEPS051.pdf 10. Chien M J, Tirol G, Chien C, Schmitt R.Film forming polymers in oral films. Poster presented at the 2006 Annual Meeting and Exposition of the American Association of Pharmaceutical Scientist Oct. 29 Nov.2AAPS. 2006; 1-5. 11. Cilurzo F, Minghetti P, Como A, Montanari L. Feasibility study of fast-dissolving film containing Piroxicam.The AAPS Journal. - ISSN 1550-7416. - 7:S2 (2005). pp. W4148-W4148. AAPS Annual Meeting and Exposition, Nashville, 2005 12.Chien M J, Tirol G, Charles B, Corniello C, Waston G, Sanchez I. Castable edible pharmaceutical films. Dow Chemical Company, West Haven, USA. 2007; 1-7. 13.Fulzele S V, Satturwar P M, Dorle A K. Polymerised rosin: Novel Film Forming Polymer for drug delivery. Int J Pharm. 2002; 249:175-184. Doi : 10.1016/S0378-5173(02)00529-X 14. Wale A, Weller P J. Handbook of Pharmaceutical Excipients. 2nd edition. 1994; 24, 27, 352,448. http://www.watson-inc.com/film_edible.php

Arun Arya et al /Int.J. ChemTech Res.2010,2(1)

583

15. http://www. Patent storm.us /patents/6740332/claims.html 16. Chapdelaine A H, Zyck D J, Dzija M R. Edible film formulations containing maltodextrin. US Patent May 25, 2004 US Patent 6740332 17.Mishra R, Amin A. Quick API Delivery. Pharmaceutical Technology Europe, pp. 1-5. 18.Coppens K A, Hall M J, Mitchell S A, Read M D. Hypromellose, Ethyl cellulose and Polyethylene oxide used in hot melt extrusion.Pharmaceutical Technology. September 2005;1-6. 19.http://www.meldexinternational.com/Development/Enabling_Systems/Orally_Dissolving_Films/ SOLULEAVES%e2%84%a2/default.aspx?id=1016 20.Peh K K, Wong CF. Polymeric film as vehicle for buccal delivery: swelling, Mechanical and Bioadhesive properties.J Pharm Pharm Sci.1999; 2:53-61. 21. Bettini R, Antonello A, Mariana M, Borghetti F. Physiochemical and cell adhesion properties of chitosan films prtepared from sugar and phosphate containing Solutuions. Eu J Pharm and Biopharm. 2008;68:74-81. Doi : 10.1061/j.ejpb.2007.03.026 22. Jayjock E, Schmitt R, Chein C. Determination of fast dissolve oral film dissolution rate via conductivity. Dow Chemical Company. 2005; 1-4. 23. http://www.monosolrx.com/products.html 24. http://www.physorg.com/news98376482.html (Rotavirus) 25. http://www.smilox.com/smile/ora-film-pain-relief-strips-6pk.cfm 26. http://www.monosolrx.com/advantages.html 27. http://www.helikon.com.tr/strip.asp 28. http://www.odftechnologies.com

*****

S-ar putea să vă placă și

- The Leukotrienes: Chemistry and BiologyDe la EverandThe Leukotrienes: Chemistry and BiologyLawrence ChakrinÎncă nu există evaluări

- Properties of Cardiac MuscleDocument60 paginiProperties of Cardiac MuscleBukhari Husain0% (1)

- Pediatric Melatonin IngestionsDocument5 paginiPediatric Melatonin IngestionsNational Content DeskÎncă nu există evaluări

- Hematologic Disorders: JeffreyDocument582 paginiHematologic Disorders: JeffreyPalak GuptaÎncă nu există evaluări

- TONGUE SeminarDocument82 paginiTONGUE SeminarArun MamachanÎncă nu există evaluări

- Synapse & NeurotransmissionDocument21 paginiSynapse & Neurotransmissionزين العابدين محمد عويشÎncă nu există evaluări

- BP U9e Metabolism of Nucleic AcidsDocument49 paginiBP U9e Metabolism of Nucleic AcidsChristian Angelo AgbunagÎncă nu există evaluări

- Nanoparticle Drug Delivery System: Apt. Fitri Wulandari, M.Clin - PharmDocument18 paginiNanoparticle Drug Delivery System: Apt. Fitri Wulandari, M.Clin - PharmDian GabriellaÎncă nu există evaluări

- Trigeminal NerveDocument61 paginiTrigeminal NerveTanu ShreyaÎncă nu există evaluări

- لقطة شاشة 2022-04-21 في 11.10.40 صDocument55 paginiلقطة شاشة 2022-04-21 في 11.10.40 صEngi KazangyÎncă nu există evaluări

- Chapter 8 - Brain and Spinal CordDocument45 paginiChapter 8 - Brain and Spinal CordJayden FergusonÎncă nu există evaluări

- Risk Factors in Bone Augmentation Procedures: Peter K. Moy - Tara AghalooDocument15 paginiRisk Factors in Bone Augmentation Procedures: Peter K. Moy - Tara Aghalooxiaoxin zhangÎncă nu există evaluări

- Dental ProductsDocument22 paginiDental ProductsAbdur Raquib100% (1)

- Pei RanoDocument10 paginiPei RanoMayang WulanÎncă nu există evaluări

- Status Epilepticus in Pregnancy A Literature Review and A ProtocolDocument12 paginiStatus Epilepticus in Pregnancy A Literature Review and A Protocolmaria arenas de ita100% (1)

- MEDICATION ADMINISTRATION StudentsDocument53 paginiMEDICATION ADMINISTRATION StudentsMary Ann G. CorsanesÎncă nu există evaluări

- Effect of Heat Treatment On Edible Yam (Dioscorea Activity: Kinetic and Thermodynamic AnalysisDocument10 paginiEffect of Heat Treatment On Edible Yam (Dioscorea Activity: Kinetic and Thermodynamic Analysisاجي تقرى100% (1)

- Principles of Managent of Hypovolemic Shock in ADocument43 paginiPrinciples of Managent of Hypovolemic Shock in Aasi basseyÎncă nu există evaluări

- Drug Interaction 2Document65 paginiDrug Interaction 2alhader libraryÎncă nu există evaluări

- Long-COVID-international Guidelines-2023Document201 paginiLong-COVID-international Guidelines-2023Zezinho zéÎncă nu există evaluări

- Pharmacological Treatment of Vertigo: Timothy C. Hain and Mohammed UddinDocument16 paginiPharmacological Treatment of Vertigo: Timothy C. Hain and Mohammed UddinFan AccountÎncă nu există evaluări

- Clinical Pharmacology Reviewer. RespiDocument4 paginiClinical Pharmacology Reviewer. RespiSister RislyÎncă nu există evaluări

- Solid Dosage Form Part 3Document24 paginiSolid Dosage Form Part 3Claire Marie AlvaranÎncă nu există evaluări

- Form 2 Exams PDF DownloadDocument120 paginiForm 2 Exams PDF DownloadLessinaÎncă nu există evaluări

- Premedication: Presenter-Dr - Srishti Moderator-Dr.R.Pal (Professor) Dr.P. Jain (Associate Professor)Document34 paginiPremedication: Presenter-Dr - Srishti Moderator-Dr.R.Pal (Professor) Dr.P. Jain (Associate Professor)Viresh Upase Roll No 130. / 8th termÎncă nu există evaluări

- Growth and DevelopmentDocument32 paginiGrowth and DevelopmentHumera MisterÎncă nu există evaluări

- Choice of Surgical Methods in Patients With Urinary Stone DiseaseDocument6 paginiChoice of Surgical Methods in Patients With Urinary Stone DiseaseCentral Asian StudiesÎncă nu există evaluări

- II-Pharmacology of The Autonomic Autonomic Ne Nervous Rvous Sys System TEMDocument88 paginiII-Pharmacology of The Autonomic Autonomic Ne Nervous Rvous Sys System TEMks asÎncă nu există evaluări

- 1introDocument158 pagini1introDea MaharanisÎncă nu există evaluări

- EcosanoidsDocument21 paginiEcosanoidsfmduniaÎncă nu există evaluări

- Rational Antibiotic Practice: Under IAP Action Plan 2014 Academic Grant From Delcure PharmaDocument164 paginiRational Antibiotic Practice: Under IAP Action Plan 2014 Academic Grant From Delcure PharmaGurmeet SinghÎncă nu există evaluări

- CorticosteroidsDocument60 paginiCorticosteroidssimran singhÎncă nu există evaluări

- Intrauterine Growth RestrictionDocument13 paginiIntrauterine Growth RestrictionAnca AdamÎncă nu există evaluări

- Strategy of The Netherlands in The Field of Rare DiseasesDocument20 paginiStrategy of The Netherlands in The Field of Rare DiseasesGehd JdifkÎncă nu există evaluări

- SULFONAMIDES Dr. NeenuDocument37 paginiSULFONAMIDES Dr. Neenuneenu csÎncă nu există evaluări

- Mowrer's Two Factor Theory (Read)Document6 paginiMowrer's Two Factor Theory (Read)PratikaÎncă nu există evaluări

- Surpass 1Document13 paginiSurpass 1Fernando DominguezÎncă nu există evaluări

- Management of Acute MalnutritionDocument64 paginiManagement of Acute MalnutritionDO or DIEÎncă nu există evaluări

- Objective:: Grade Level: 1st - 5th T Ype: Biology/PhysiologyDocument3 paginiObjective:: Grade Level: 1st - 5th T Ype: Biology/PhysiologyPuteri PamelaÎncă nu există evaluări

- Case Presentation On Seborrheic DermatitisDocument23 paginiCase Presentation On Seborrheic DermatitisEsha Bhatia100% (1)

- Pre and Post Operative Care: To: DR - Biniyam.G By: Biniam.MDocument93 paginiPre and Post Operative Care: To: DR - Biniyam.G By: Biniam.MBini JaminÎncă nu există evaluări

- Assessment of OrthopedicVersus Neurologic Causes of Gait Change in Dogs and CatsDocument9 paginiAssessment of OrthopedicVersus Neurologic Causes of Gait Change in Dogs and CatsAristoteles Esteban Cine VelazquezÎncă nu există evaluări

- Mucoadhesive AgentsDocument33 paginiMucoadhesive AgentsParth BhattÎncă nu există evaluări

- DistrofiaDocument48 paginiDistrofiaMD IurieÎncă nu există evaluări

- ADC Dental Mock2Document44 paginiADC Dental Mock2Tanmay JhulkaÎncă nu există evaluări

- Guided Worksheet 1Document7 paginiGuided Worksheet 1EveÎncă nu există evaluări

- Formulation Development and Evaluations of Pulsatile Drug Delivery of Tiotropium BromideDocument76 paginiFormulation Development and Evaluations of Pulsatile Drug Delivery of Tiotropium BromideG.MANOHAR BABUÎncă nu există evaluări

- Oral Health Knowledge, Attitude and Behaviour of Medical and Dental StudentsDocument2 paginiOral Health Knowledge, Attitude and Behaviour of Medical and Dental StudentsTahir AliÎncă nu există evaluări

- Wolfram SyndromeDocument8 paginiWolfram SyndromeMariela AlvarezÎncă nu există evaluări

- Community Medicine - PAST QUESTIONS (2005-2020) : Basic Definitions and Concept of Health & DiseaseDocument63 paginiCommunity Medicine - PAST QUESTIONS (2005-2020) : Basic Definitions and Concept of Health & DiseaseSaher ShahzadÎncă nu există evaluări

- Lipids and Its Metabolism ProjectDocument51 paginiLipids and Its Metabolism ProjectJopeter Alicer TinayaÎncă nu există evaluări

- Clinical Evaluation and Comparison of Quality of Obturation and Instrumentation Time For Pulpectomy in Primary Molars With or Without A Magnifying Loupe An Invivo StudyDocument9 paginiClinical Evaluation and Comparison of Quality of Obturation and Instrumentation Time For Pulpectomy in Primary Molars With or Without A Magnifying Loupe An Invivo StudyInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Strategic Uses of Poison in Ancient Times According To AyurvedDocument5 paginiStrategic Uses of Poison in Ancient Times According To AyurvedIJRASETPublicationsÎncă nu există evaluări

- Streptococcal PharyngitisDocument28 paginiStreptococcal PharyngitissylviaÎncă nu există evaluări

- Activity OverviewDocument44 paginiActivity OverviewSnezana MihajlovicÎncă nu există evaluări

- EYE Histology: Dr. OkoloDocument60 paginiEYE Histology: Dr. OkoloAbiola NerdÎncă nu există evaluări

- Phoenix Diffusion Testing Systems PDFDocument4 paginiPhoenix Diffusion Testing Systems PDFAllenMarkLibradoÎncă nu există evaluări

- 1955Document30 pagini1955Luis GarciaÎncă nu există evaluări

- ClinicumDocument8 paginiClinicummirza_baig_46Încă nu există evaluări

- Seminar On Films and StripsDocument22 paginiSeminar On Films and StripskeyurÎncă nu există evaluări

- Basic Iv Fluid PDFDocument77 paginiBasic Iv Fluid PDFDesi AdiyatiÎncă nu există evaluări

- Hipertensi AND Kemoterapi PDFDocument11 paginiHipertensi AND Kemoterapi PDFHananun ZharfaÎncă nu există evaluări

- Ich Q3C (R4)Document25 paginiIch Q3C (R4)Ravishankar NagarajanÎncă nu există evaluări

- Click To Edit Master Subtitle StyleDocument4 paginiClick To Edit Master Subtitle StyleRobertoArandaÎncă nu există evaluări

- 232 439 1 SMDocument10 pagini232 439 1 SMHananun ZharfaÎncă nu există evaluări

- JNC 8Document14 paginiJNC 8amiwahyuniÎncă nu există evaluări

- Kasus AsmaDocument5 paginiKasus AsmaHananun Zharfa0% (3)

- Resume RumusDocument4 paginiResume RumusHananun ZharfaÎncă nu există evaluări

- Resume RumusDocument4 paginiResume RumusHananun ZharfaÎncă nu există evaluări

- Stifar Komplemen2013Document44 paginiStifar Komplemen2013Hananun ZharfaÎncă nu există evaluări

- 14 13 1 PB PDFDocument9 pagini14 13 1 PB PDFRizki PuspitasariÎncă nu există evaluări

- Internasional PDFDocument10 paginiInternasional PDFHananun ZharfaÎncă nu există evaluări

- Pembuatan Fase Gerak KKT: KarbohidratDocument4 paginiPembuatan Fase Gerak KKT: KarbohidratHananun ZharfaÎncă nu există evaluări

- Citri-How To Get ScholarDocument15 paginiCitri-How To Get ScholarHananun ZharfaÎncă nu există evaluări

- Citri-How To Get ScholarDocument15 paginiCitri-How To Get ScholarHananun ZharfaÎncă nu există evaluări

- GrafikDocument7 paginiGrafikHananun ZharfaÎncă nu există evaluări

- Citri-How To Get ScholarDocument15 paginiCitri-How To Get ScholarHananun ZharfaÎncă nu există evaluări

- Analisis ParetoDocument1 paginăAnalisis ParetoHananun ZharfaÎncă nu există evaluări

- Shiatsu Diagnosis &treatment EDDocument2 paginiShiatsu Diagnosis &treatment EDEscu Nyku100% (1)

- 45 Llps Vs HlbsDocument4 pagini45 Llps Vs HlbsSudhir MishraÎncă nu există evaluări

- Medivac Drill MAn Over Boat-2Document2 paginiMedivac Drill MAn Over Boat-2yogakharismaÎncă nu există evaluări

- RAdiology of HIVAIDSDocument928 paginiRAdiology of HIVAIDSbalÎncă nu există evaluări

- Surgical Hand PreparationDocument28 paginiSurgical Hand PreparationyafetÎncă nu există evaluări

- Esthetics in Tooth PreparationDocument25 paginiEsthetics in Tooth PreparationAishwarya Patel100% (2)

- Pasion ThesisDocument55 paginiPasion ThesisMagiePasion100% (1)

- DGFHJKDocument3 paginiDGFHJKRavish MalhotraÎncă nu există evaluări

- Anubhut Yog Sangrah (Bhag-2), Best Ayurvedic Medicine BookDocument331 paginiAnubhut Yog Sangrah (Bhag-2), Best Ayurvedic Medicine Bookashok1_ratm84% (19)

- Pain Management in Endodontics PDFDocument6 paginiPain Management in Endodontics PDFdavid bbÎncă nu există evaluări

- Advantage: A Health Cover For at The Cost of Your Monthly Internet BillDocument4 paginiAdvantage: A Health Cover For at The Cost of Your Monthly Internet BillAmitabh WaghmareÎncă nu există evaluări

- 1307 Ascot Bpla (Sever)Document8 pagini1307 Ascot Bpla (Sever)Fernando CamargoÎncă nu există evaluări

- Combination Hyperbaric Oxygen and Temozolomide Therapy in c6 Rat Glioma ModelDocument5 paginiCombination Hyperbaric Oxygen and Temozolomide Therapy in c6 Rat Glioma ModelDICKY PANDUWINATAÎncă nu există evaluări

- Uncensored Magazine 4th QTR 2006 PDFDocument100 paginiUncensored Magazine 4th QTR 2006 PDFKorisnik1956Încă nu există evaluări

- Miltex General Instruments BrochureDocument5 paginiMiltex General Instruments BrochureMichael Angelo Detalla MacolorÎncă nu există evaluări

- Daniel Medina BarselonaDocument24 paginiDaniel Medina BarselonaDusan OrescaninÎncă nu există evaluări

- Heart FailureDocument6 paginiHeart FailureAnthony Philip Patawaran CalimagÎncă nu există evaluări

- Tweeds AnalysisDocument7 paginiTweeds AnalysisDrmrunalni ChoukseyÎncă nu există evaluări

- Comparison of Joint Perception Between Posterior-Stabilized and Ultracongruent Total Knee Arthroplasty in The Same PatientDocument9 paginiComparison of Joint Perception Between Posterior-Stabilized and Ultracongruent Total Knee Arthroplasty in The Same PatientNuno PaisÎncă nu există evaluări

- Permission To Travel Form: Bentonville High SchoolDocument4 paginiPermission To Travel Form: Bentonville High Schoolapi-199664950Încă nu există evaluări

- Greek Philosophy and PsychotherapyDocument8 paginiGreek Philosophy and PsychotherapytantravidyaÎncă nu există evaluări

- Growth Plate InjuriesDocument10 paginiGrowth Plate InjuriesraissanindyaÎncă nu există evaluări

- Management of The Urologic Sepsis SyndromeDocument10 paginiManagement of The Urologic Sepsis SyndromeNur Syamsiah MÎncă nu există evaluări

- 18 JL 7Document15 pagini18 JL 7Irma SihotangÎncă nu există evaluări

- Biotechnology Advances 34 2016Document13 paginiBiotechnology Advances 34 2016Ajay KumarÎncă nu există evaluări

- Skryabin 2021Document14 paginiSkryabin 2021cupin 69PKÎncă nu există evaluări

- Hemorrhagic Disease of NewbornDocument29 paginiHemorrhagic Disease of NewbornLittleThingsInside100% (1)

- Nclex BulletsDocument34 paginiNclex Bulletssaroberts2202100% (1)

- Dissertation - 0207 (1) FinalDocument34 paginiDissertation - 0207 (1) FinalVP OFFICEÎncă nu există evaluări

- Integrative Case Study RubricDocument2 paginiIntegrative Case Study Rubricapi-338917055Încă nu există evaluări