Documente Academic

Documente Profesional

Documente Cultură

Raw Material Handling Plant

Încărcat de

Sushant KumarDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Raw Material Handling Plant

Încărcat de

Sushant KumarDrepturi de autor:

Formate disponibile

RAW MATERIAL HANDLING PLANT

RMHP is the area where raw material are handles and kept uniformly on bed and hence furthur processed and send to the required areas in the plant. Materials handled Coal Lime Stone Flux Work done in RMHP Tippling (4 tipplers) Conveying (length range from 40 to 45 KM) Stacking (7 stackers) Reclaiming (6 reclaimer) Squirrel Cage and Double Squirrel Cage Induction Motor are used in big conveyers.( 250KW power) Slip Ring Motors are used in Tippler, Crane, Tram Car Pusher(TCP) as here high starting torque is required. Variable Voltage Variable Frequency(VVVF) systems are used in RMHP. Special motors are installed which remains loaded even when speed is zero, and it is applicable at stacker, reclaimer, power cable reeling drum(PCRD). Raw Material Handling plant is meant for transporting materials from Raw material yard/Base mix yard to various process units of the plant. The Major Raw materials required for Iron and Steel making are are Iron ore lump, Iron Ore fines, Sized iron ore, Flux limestone / dolomite, manganese, Quartzite coking coal, Non-coking coal ( for Boiler operation & For Pulverized coal injection )and coke. Lump iron ores, iron ore fines and flux such as limestone and dolomite received by railway rake are unloaded in wagon tippler and stored in open storage yard with help of various stockyard machines.

Iron ore lump, flux such as limestone and dolomite, Coke is reclaimed by suitable stock yard machine and are crushed in Ore crushing plant, Flux crushing plant and coke crushing plant respectively to produce the size required. The above material is proportionately stacked by suitable stacking machine in base mix yard and blended while reclaiming by blender reclaimer, while preparing base mix which then transported to Sinter plant for sinter production.

For feeding material to new blast furnace, sized ore and flux is reclaimed by stock yard machine from respective yard and conveyed by conveyor. Sinter produced in sinter plant and coke from existing/new coke ovens is transported directly to BF-3 stock house by conveyor. Purchased coke and necessary calcined lime from stock yard and new lime calcining plant respectively is transported to SMS by Conveyor. The waste product from the plant is mainly

dust and method of their disposal is through dust suppression system and inter plant transportation.

The Raw Materials and Material Handling Plant receives, blends, stores and supplies different raw materials to Blast Furnace, Sinter Plant and Refractory Materials Plant as per their requirements. It also maintains a buffer stock to take care of any supply interruptions.

Some 9 MT of different raw materials viz. Iron ore fines and lumps, Limestone (BFand SMS grade), Dolomite lumps and chips, hard Coal and Manganese ore are handled. Iron ore and fluxes are sourced from the captive mines of SAIL situated at Kiriburu, Meghahataburu, Bhawanathpur, Tulsidamar and Kuteshwar. Washed coal is supplied from different washeries at Dugda, Kathara, Kargali and Giddi, while raw coal is obtained from Jharia coalfields.

S-ar putea să vă placă și

- Presentation SchadeDocument31 paginiPresentation SchadeEmily CamilaÎncă nu există evaluări

- Catia v6 2012x Installation GuideDocument13 paginiCatia v6 2012x Installation GuideShirley MansonÎncă nu există evaluări

- User's Manual For VRP Spreadsheet Solver: University of BathDocument20 paginiUser's Manual For VRP Spreadsheet Solver: University of BathGuido Celu100% (1)

- Chapter 14 Operation of A WarehouseDocument14 paginiChapter 14 Operation of A Warehousereaoboka stanleyÎncă nu există evaluări

- ERP Chapter 5Document32 paginiERP Chapter 5Jootoo NitishÎncă nu există evaluări

- VRPDocument22 paginiVRPVania Alodia NÎncă nu există evaluări

- Dynamic Memory AllocationDocument5 paginiDynamic Memory AllocationGihan ChanukaÎncă nu există evaluări

- Manage Inventory EfficientlyDocument95 paginiManage Inventory EfficientlyKomal SinghÎncă nu există evaluări

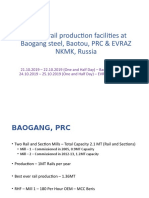

- Presentation - China and Russia - Final 01.11.2019Document38 paginiPresentation - China and Russia - Final 01.11.2019kaustavÎncă nu există evaluări

- Air TransportationDocument89 paginiAir TransportationFTU-ERÎncă nu există evaluări

- Motor Transport Top 100 2009Document5 paginiMotor Transport Top 100 2009Road Transport MediaÎncă nu există evaluări

- Wal-Mart - Supply Chain MGMTDocument15 paginiWal-Mart - Supply Chain MGMTkapiiiiiiiiiiiiiiiiiÎncă nu există evaluări

- University of MumbaiDocument63 paginiUniversity of MumbaiFAIZ RZIÎncă nu există evaluări

- Android Chapter13 SQL DatabasesDocument74 paginiAndroid Chapter13 SQL DatabasesAzmi Azis Al FgbsdÎncă nu există evaluări

- COURS CISCO Protocole Frame RelayDocument67 paginiCOURS CISCO Protocole Frame RelaybaikariÎncă nu există evaluări

- Maximizing Growth Through Port Operations and TechnologyDocument81 paginiMaximizing Growth Through Port Operations and TechnologyNha LuongÎncă nu există evaluări

- State of Indian Railways PDFDocument22 paginiState of Indian Railways PDFMeir VickyÎncă nu există evaluări

- GreenBridge Multimodal Transport SolutionsDocument12 paginiGreenBridge Multimodal Transport SolutionsNkugwa Mark WilliamÎncă nu există evaluări

- SAP S4 HANA Cloud For Master Data ManagementDocument44 paginiSAP S4 HANA Cloud For Master Data ManagementDarren OsoreÎncă nu există evaluări

- PFE-RACHED HamzaDocument54 paginiPFE-RACHED HamzaHamza RachedÎncă nu există evaluări

- International LogisticsDocument341 paginiInternational LogisticsIsmail BaigÎncă nu există evaluări

- # 4 Vehicle Routing 1Document97 pagini# 4 Vehicle Routing 1Harsha DeshpandeÎncă nu există evaluări

- Key Supply Chain and Logistics Terms DefinedDocument10 paginiKey Supply Chain and Logistics Terms DefinednarasimhaÎncă nu există evaluări

- Introduction to Deep Learning Object Detection MetricsDocument59 paginiIntroduction to Deep Learning Object Detection MetricsDuc Le HongÎncă nu există evaluări

- Transportation and Distribution Network AssignmentDocument3 paginiTransportation and Distribution Network AssignmentMadhurima BhandariÎncă nu există evaluări

- GCP-30 Series: Genset Control Package Mains & Generator Protection & ControlDocument4 paginiGCP-30 Series: Genset Control Package Mains & Generator Protection & ControlRavi KumarÎncă nu există evaluări

- Vizhinjam International Seaport Emgerging Transshipment Hub PortDocument75 paginiVizhinjam International Seaport Emgerging Transshipment Hub Portj4jitsÎncă nu există evaluări

- Traffic Flow Prediction Models A Review of Deep Learning TechniquesDocument25 paginiTraffic Flow Prediction Models A Review of Deep Learning Techniquesoseni wunmiÎncă nu există evaluări

- Walmart'S Logistics and Supply Chain Management: Executive Summary On WalmartDocument4 paginiWalmart'S Logistics and Supply Chain Management: Executive Summary On WalmartKamana Thp MgrÎncă nu există evaluări

- Materials Management (MM) : Curriculum: Introduction To ERP Using Global BikeDocument46 paginiMaterials Management (MM) : Curriculum: Introduction To ERP Using Global BikePeter LeeÎncă nu există evaluări

- 22 PAUCAR - A Collaborative Defense For Securing Protective Relay Settings in Electrical Cyber Physical SystemsDocument6 pagini22 PAUCAR - A Collaborative Defense For Securing Protective Relay Settings in Electrical Cyber Physical Systemstecnologia para el cambioÎncă nu există evaluări

- PepsiCo SupplychainDocument24 paginiPepsiCo SupplychainSagarSuryavanshiÎncă nu există evaluări

- Exercises On Distribution Network DesignDocument6 paginiExercises On Distribution Network DesignLidia G. MazzesiÎncă nu există evaluări

- Smart WorkspaceDocument10 paginiSmart Workspaceapi-301516894Încă nu există evaluări

- Atop Pick Put To Light ENDocument20 paginiAtop Pick Put To Light ENanggi sonyaÎncă nu există evaluări

- 131 COGI IssueDocument5 pagini131 COGI IssueAmit SharmaÎncă nu există evaluări

- Upgrading The Storage Management, SVP Software, and Storage System FirmwareDocument20 paginiUpgrading The Storage Management, SVP Software, and Storage System FirmwareRAZUÎncă nu există evaluări

- Setup For Simple Inbound ProcessDocument14 paginiSetup For Simple Inbound ProcessnaysarÎncă nu există evaluări

- Tesco's ERP SystemsDocument14 paginiTesco's ERP SystemsMichael ObinnaÎncă nu există evaluări

- CV RobahjkDocument1 paginăCV Robahjkemiyou100% (1)

- Girish Karanth J Internship Report MBA (IT&LM) 2020 2022Document78 paginiGirish Karanth J Internship Report MBA (IT&LM) 2020 2022Satendra Singh ParmarÎncă nu există evaluări

- Brochure Integrated Container Terminal Planning Optimization EN PDFDocument10 paginiBrochure Integrated Container Terminal Planning Optimization EN PDFHerum ManaluÎncă nu există evaluări

- Recen RC A11 Pro Catalog - OptDocument7 paginiRecen RC A11 Pro Catalog - OptINFO TOP SKYÎncă nu există evaluări

- ABM312 Financial Accounting 2015 ModuleDocument77 paginiABM312 Financial Accounting 2015 ModuleDAVY SIMONGAÎncă nu există evaluări

- Marketing Mix at JerseyDocument86 paginiMarketing Mix at JerseynaveenÎncă nu există evaluări

- Warehouse and Inventory Management: UNIT-1Document29 paginiWarehouse and Inventory Management: UNIT-1Amitrajeet kumarÎncă nu există evaluări

- Brochure Integrated Rail Freight Planning enDocument12 paginiBrochure Integrated Rail Freight Planning enphiluca7Încă nu există evaluări

- WMSDocument15 paginiWMStushar2001Încă nu există evaluări

- Virtualization Technology Trends: Intel CorporationDocument35 paginiVirtualization Technology Trends: Intel CorporationVinay BhandariÎncă nu există evaluări

- PDF 6Document50 paginiPDF 6فرزاد ”Angra“ mavaraniÎncă nu există evaluări

- Product DistributionDocument3 paginiProduct DistributionRichard RuizÎncă nu există evaluări

- Sales Order Processing DocumentDocument25 paginiSales Order Processing DocumentSUBHOJIT BANERJEEÎncă nu există evaluări

- A Look at Technological Challenges Facing Africa: Thi-Mai TRAN Managing Director MoroccoDocument21 paginiA Look at Technological Challenges Facing Africa: Thi-Mai TRAN Managing Director MoroccoRizki Fajar NovantoÎncă nu există evaluări

- Quick overview of Purchase Planning functionality and stock situation indicatorsDocument5 paginiQuick overview of Purchase Planning functionality and stock situation indicatorsasadshoaibÎncă nu există evaluări

- Fiche Technique Onduleur TSR RACK 1 2 3KVADocument3 paginiFiche Technique Onduleur TSR RACK 1 2 3KVAfares pelo100% (1)

- Agile UP Intro-LarmanDocument25 paginiAgile UP Intro-LarmanFenil Desai100% (1)

- Logistics Report: Department Induction: Name: Ganesh Swar Designation: GET Employee Code: 49978Document17 paginiLogistics Report: Department Induction: Name: Ganesh Swar Designation: GET Employee Code: 49978REDDYÎncă nu există evaluări

- Inventory Management Techniques and Cost CalculationsDocument6 paginiInventory Management Techniques and Cost Calculations1 KohÎncă nu există evaluări

- INDEX: Contents of The ReportDocument34 paginiINDEX: Contents of The Reportrahul rayÎncă nu există evaluări

- Durgapur Steel Plant's integrated steelmaking processDocument7 paginiDurgapur Steel Plant's integrated steelmaking processKunalKumarSingh0% (1)

- QlikView Business Intelligence Tool OverviewDocument11 paginiQlikView Business Intelligence Tool OverviewMithun LayekÎncă nu există evaluări

- WT Lab ManualDocument44 paginiWT Lab ManualVenkatanagasudheer Thummapudi100% (1)

- Vol 4 Div G ODS Part 1 of 2-Pages-18-55Document38 paginiVol 4 Div G ODS Part 1 of 2-Pages-18-55debapriyoÎncă nu există evaluări

- GBU Profile 12 PDFDocument5 paginiGBU Profile 12 PDFsurabhidivyaÎncă nu există evaluări

- IEEE Modeling of Generator Controls For Coordinating Generator Relays Draft 4.0Document65 paginiIEEE Modeling of Generator Controls For Coordinating Generator Relays Draft 4.0Alex PAÎncă nu există evaluări

- How To Build A Backyard PergolaDocument15 paginiHow To Build A Backyard PergolaMichael Wilkins100% (1)

- PC Pump ManualDocument540 paginiPC Pump ManualtelephonicaÎncă nu există evaluări

- NUVE EN 032-055-120 Incubators BrochureDocument2 paginiNUVE EN 032-055-120 Incubators BrochureDinhtrung TruongÎncă nu există evaluări

- Inspection Checklist For Lifting Tools & TacklesDocument2 paginiInspection Checklist For Lifting Tools & Tacklesnil thaeu100% (1)

- Fitter ToolsDocument7 paginiFitter ToolsSainadhReddy100% (1)

- G100-G102-Chassis-Manual #1Document151 paginiG100-G102-Chassis-Manual #1Daihatsu Charade BanjarnegaraÎncă nu există evaluări

- 92v Parts List ViperDocument194 pagini92v Parts List Viperreltih18Încă nu există evaluări

- TMForumOpenAPIs EnablingAZeroIntergrationAPIeconomyDocument30 paginiTMForumOpenAPIs EnablingAZeroIntergrationAPIeconomyjdaoukÎncă nu există evaluări

- Iec 62097-2009Document170 paginiIec 62097-2009luis.alvaradoÎncă nu există evaluări

- Nuclear ReactorsDocument45 paginiNuclear ReactorsAtul100% (3)

- Total Internal Reflection and Critical Angle VedioDocument16 paginiTotal Internal Reflection and Critical Angle VedioNor AzizahÎncă nu există evaluări

- SPE143315-Ultrasound Logging Techniques For The Inspection of Sand Control Screen IntegrityDocument18 paginiSPE143315-Ultrasound Logging Techniques For The Inspection of Sand Control Screen IntegrityYovaraj KarunakaranÎncă nu există evaluări

- Coverage of Quiz 1Document24 paginiCoverage of Quiz 1Ben RileyÎncă nu există evaluări

- Micom p343Document66 paginiMicom p343kjfenÎncă nu există evaluări

- Slip and Crystallographic TexturesDocument34 paginiSlip and Crystallographic TexturesSunkulp GoelÎncă nu există evaluări

- Manual de Partes y Operación de Trituradora Vsi Canica Modelo 65Document105 paginiManual de Partes y Operación de Trituradora Vsi Canica Modelo 65Jose AlfaroÎncă nu există evaluări

- Detailed Lesson Plan in Science IVDocument12 paginiDetailed Lesson Plan in Science IVAgnes DumlaoÎncă nu există evaluări

- CRI PumpsDocument13 paginiCRI Pumpscrigroups0% (1)

- Nba Sar B.tech. Electronics UgDocument171 paginiNba Sar B.tech. Electronics UgSaurabh BhiseÎncă nu există evaluări

- Well Control - Fundamental - W2 - Well Control PrincipleDocument17 paginiWell Control - Fundamental - W2 - Well Control PrincipleGilbert SunaryoÎncă nu există evaluări

- Transient Analysis of Electrical Circuits Using Runge-Kutta Method and Its ApplicationDocument5 paginiTransient Analysis of Electrical Circuits Using Runge-Kutta Method and Its ApplicationSwati kÎncă nu există evaluări

- Pass4sure 200-120 PDF DownloadDocument8 paginiPass4sure 200-120 PDF DownloadEleanor19Încă nu există evaluări

- Ibm Lenovo Whistler Rev s1.3 SCHDocument52 paginiIbm Lenovo Whistler Rev s1.3 SCH1cvbnmÎncă nu există evaluări

- Reduce Drum Pitch, Yarn Tension and Cradle LoadDocument16 paginiReduce Drum Pitch, Yarn Tension and Cradle LoadJigneshSaradavaÎncă nu există evaluări

- ManualDocument14 paginiManualnas_hoÎncă nu există evaluări