Documente Academic

Documente Profesional

Documente Cultură

Ams QQ A 200 - 8

Încărcat de

Suvir Rajkumar BharilTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Ams QQ A 200 - 8

Încărcat de

Suvir Rajkumar BharilDrepturi de autor:

Formate disponibile

THIS DOCUMENT IS PROTECTED BY U.S.

COPYRIGHT It may not be reproduced, stored in a retrieval system, distributed or transmitted, in whole or in part, in any form or by any means. Downloaded from SAE International by Space Exploration Technologies, Copyright 2012 SAE International Monday, February 06, 2012 08:25:40 PM

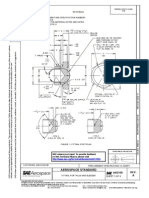

AEROSPACE MATERIAL SPECIFICATION

AMS-QQ-A-200/8

Issued Reaffirmed JUL 1997 APR 2007

Aluminum Alloy 6061, Bar, Rod, Shapes, Tube, and Wire, Extruded

A96061

RATIONALE This document has been reaffirmed to comply with the SAE 5-year Review policy. NOTICE This document has been taken directly from Federal Specification QQ-A-200/8F and contains only minor editorial and format changes required to bring it into conformance with the publishing requirements of SAE technical standards. The original Federal Specification was adopted as an SAE standard under the provisions of the SAE Technical Standards Board (TSB) Rules and Regulations (TSB 001) pertaining to accelerated adoption of government specifications and standards. TSB rules provide for (a) the publication of portions of unrevised government specifications and standards without consensus voting at the SAE Committee level, (b) the use of the existing government specification or standard format, and (c) the exclusion of any qualified product list (QPL) sections. The complete requirements for procuring aluminum alloy 6061 bar, rod, shapes, tube, and wire extruded described herein shall consist of this document and the latest issue of AMS-QQ-A-200.

SAE Technical Standards Board Rules provide that: This report is published by SAE to advance the state of technical and engineering sciences. The use of this report is entirely voluntary, and its applicability and suitability for any particular use, including any patent infringement arising therefrom, is the sole responsibility of the user. SAE reviews each technical report at least every five years at which time it may be reaffirmed, revised, or cancelled. SAE invites your written comments and suggestions. Copyright 2007 SAE International All rights reserved. No part of this publication may be reproduced, stored in a retrieval system or transmitted, in any form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of SAE. TO PLACE A DOCUMENT ORDER: Tel: 877-606-7323 (inside USA and Canada) Tel: 724-776-4970 (outside USA) Fax: 724-776-0790 Email: custsvc@sae.org http://www.sae.org

SAE WEB ADDRESS:

THIS DOCUMENT IS PROTECTED BY U.S. COPYRIGHT It may not be reproduced, stored in a retrieval system, distributed or transmitted, in whole or in part, in any form or by any means. Downloaded from SAE International by Space Exploration Technologies, Copyright 2012 SAE International Monday, February 06, 2012 08:25:40 PM

AMS-QQ-A-200/8

SAE

AMS-QQ-A-200/8

1. SCOPE AND CLASSIFICATION: 1.1 Scope: This specification covers the specific requirements for aluminum alloy 6061 bar, rod, shapes, tube, and wire produced by extrusion. 1.2 1.2.1 Classification: Tempers: Bar, rod, shapes, tube, and wire are classified in the following tempers as specified (See 6.2): O, T1, T4, T42, T4510, T4511, T51, T6, T62, T6510, or T6511. Definitions of tempers are specified in AMS-QQ-A-200. Tubing: Tubing shall be additionally classified as follows:

1.2.2

Type

Description

I - Tubing extruded from hollow billets using die and mandrel (See AMS-QQ-A-200). II - Tubing extruded from solid billets using a porthole or spider die or similar tooling (See AMS-QQ-A-200). 2. APPLICABLE DOCUMENTS: See AMS-QQ-A-200.

-2-

THIS DOCUMENT IS PROTECTED BY U.S. COPYRIGHT It may not be reproduced, stored in a retrieval system, distributed or transmitted, in whole or in part, in any form or by any means. Downloaded from SAE International by Space Exploration Technologies, Copyright 2012 SAE International Monday, February 06, 2012 08:25:40 PM

AMS-QQ-A-200/8

SAE

AMS-QQ-A-200/8

3. REQUIREMENTS: 3.1 Chemical Composition: The chemical composition shall conform to the requirements specified in Table I. TABLE I. Chemical Composition 1/ Element Magnesium Silicon Copper Iron Chromium Zinc Titanium Manganese Other Elements, each Other Elements, total 2/ Aluminum Percent Minimum Maximum 0.8 1.2 0.40 0.8 0.15 0.40 -0.7 0.04 0.35 -0.25 -0.15 -0.15 -0.05 -0.15 Remainder

1/ Analysis shall routinely be made only for the elements specifically mentioned in Table I. If, however, the presence of other elements is indicated or suspected in amounts greater than the specified limits, further analysis shall be made to determine that these elements are not present in excess of the limits specified. 2/ The sum of those "Others" metallic elements 0.010 percent or more each, expressed to the second decimal before determining the sum.

-3-

THIS DOCUMENT IS PROTECTED BY U.S. COPYRIGHT It may not be reproduced, stored in a retrieval system, distributed or transmitted, in whole or in part, in any form or by any means. Downloaded from SAE International by Space Exploration Technologies, Copyright 2012 SAE International Monday, February 06, 2012 08:25:40 PM

AMS-QQ-A-200/8

SAE

AMS-QQ-A-200/8

3.2 3.2.1

Mechanical Properties: Mechanical Properties of Material as Supplied: The mechanical properties in the direction of extrusion shall conform to requirements specified in Table II. TABLE II. Mechanical Properties Yield Strength at 0.2 percent Offset or at extension indicated

Temper O T1 T4, T4510, and T4511 T42 3/ T51 T6, T62 3/, T6510 and T6511

Thickness, (bar and shapes); diameter, (rod and wire); wall thickness (tube) Inches All Up thru 0.625 All All Up thru 0.625 Up thru 0.249 0.250 and over

Elongation in Tensile Extension 2 inches or 4 Strength under load times D 1/, 4/ Minimum Minimum inch per Minimum ksi ksi inch percent 2/ 26.0 26.0 26.0 35.0 38.0 38.0 2/ 14.0 16.0 12.0 30.0 35.0 35.0 0.0036 0.0034 0.0036 0.0032 0.0050 0.0055 0.0055 16 16 16 16 8 8 10

1/ D represents specimen diameter. 2/ No minimum; maximum tensile and yield strengths are 22.0 ksi and 16.0 ksi, respectively. 3/ Material in the T42 or T62 temper is not available from material producers. 4/ See AMS-QQ-A-200 for elongation requirement exceptions. 3.2.2 Mechanical Properties After Heat Treatment: In addition to conforming to requirements of 3.2.1, materials identified in the following paragraphs shall, after having been heat-treated to other tempers also identified therein, have properties in the extrusion direction conforming to those specified in Table II, as applicable. Material in the O Temper: Material in the O temper, without the subsequent imposition of cold work or forming operations, shall, after proper solution heat treatment and natural aging, develop the properties specified in Table II for the T42 temper. Material in the T1, T4, T42, T4510 and T4511 Tempers: Material in the T1, T4, T42, T4510, and T4511 tempers shall be age-hardenable artificially to the properties specified for T51, T6, T62, T6510, and T6511 tempers, respectively. Such capability shall be demonstrated when specified (See 6.2).

-4-

3.2.2.1

3.2.2.2

THIS DOCUMENT IS PROTECTED BY U.S. COPYRIGHT It may not be reproduced, stored in a retrieval system, distributed or transmitted, in whole or in part, in any form or by any means. Downloaded from SAE International by Space Exploration Technologies, Copyright 2012 SAE International Monday, February 06, 2012 08:25:40 PM

AMS-QQ-A-200/8

SAE

AMS-QQ-A-200/8

3.3

Heat Treatment: Unless otherwise specified in the contract or purchase order for T4, T4510, T4511, T6, T6510, and T6511 material, the producer may use an alternative heat treating procedure in lieu of a furnace heat treatment covered by MIL-H-6088, provided the material conforms to all other requirements of this specification when sampled and tested in accordance with 4.2. The alternative heat treatment shall be performed on the whole of a piece, never on a part only, and shall be performed on the whole of a piece, never a part only, and shall be performed in a manner that will produce the utmost uniformity (See 6.2).

3.4

Marking: In addition to marking required by AMS-QQ-A-200, material in the T51, T6, T6510, and T6511 tempers and, when specified (See 6.2), material in the T1, T4, T4510, and T4511 tempers, shall also be identified by inspection lot number, marked in at least one location on each piece.

4. QUALITY ASSURANCE PROVISIONS: See AMS-QQ-A-200 and the following: 4.1 4.1.1 Heat Treatment: Aging Treatment Before Testing: Test specimens selected from material in the T1, T4, T42, T4510, and T4511 tempers may be tested within 4 days following solution heat treatment. In the event of test failures caused by insufficient aging, retests shall be performed using material aged for 4 days or longer. Test specimens shall be prepared from the same coupons or location in the lot or lots from which the previously tested specimens were taken. Additional Sampling and Testing of Material Heat-Treated by Methods Not Covered by MIL-H-6088: Alloy Heat-Treated to the T6, T6510, or T6511 Tempers: When material in the T6, T6510, or T6511 tempers has not been heat-treated by a method covered by MIL-H-6088, internal quality controls shall be applied to establish that product so-treated meets all requirements of this detail specification and AMS-QQ-A-200. Compliance with the requirements of Table II may be determined by hardness tests followed by tension tests performed on samples from the two softest extrusions in the inspection lot. The method of hardness testing shall be left to the discretion of the producer. Alloy Heat-Treated to the T4, T4510, or T4511 Tempers: When material in the T4, T4510, or T4511 temper has not been solution heat-treated by a method covered by MIL-H-6088, internal quality controls shall be applied to establish that product so-treated meets all requirements of this detail specification and AMS-QQ-A-200. In addition, specimens taken from extrusions in these tempers shall be artificially aged to determine conformance to 3.2.2.2, as applicable, and be hardnesstested and tension-tested in accordance with 4.2.1. Any specimen blank selected for an agehardenability determination shall be removed from the softest extrusion in the lot undergoing inspection.

4.2 4.2.1

4.2.2

-5-

THIS DOCUMENT IS PROTECTED BY U.S. COPYRIGHT It may not be reproduced, stored in a retrieval system, distributed or transmitted, in whole or in part, in any form or by any means. Downloaded from SAE International by Space Exploration Technologies, Copyright 2012 SAE International Monday, February 06, 2012 08:25:40 PM

AMS-QQ-A-200/8

SAE

AMS-QQ-A-200/8

4.3

Number of Tests After Heat Treatment: From material in each temper of those specified for heat treatment capability demonstrations in 3.2.2 and the purchase documents (See 6.2), an additional number of specimens equal to that required by AMS-QQ-A-200 shall be taken and tested after heat treatment to each temper specified to determine conformance to 3.2.2.

5. PREPARATION FOR DELIVERY: See AMS-QQ-A-200. 6. NOTES: 6.1 Intended Use: This alloy is intended for use where good strength and workability are required. The T4510 and T6510 tempers are intended primarily to provide material with low residual stresses and consequent minimum distortion during machining. The T4511 and T6511 tempers are straightened T4510 and T6510 material, respectively, and may have unknown residual stresses and may or may not distort during machining. 6.2 Mechanical Properties After Solution Heat Treatment: Material in the T1, T4511, T51, T6, T6510, and T6511 tempers may not meet the requirements of Table II for T42 temper after re-solution heat treatment because of a tendency for grain growth. 6.3 Properties After Heat Treatment: Mechanical properties and corrosion properties, where applicable, are certified for the temper of material supplied. The producers capability demonstration is not evidence that user-treated material conforms to property requirements of a given temper. Frequently, user-heat-treated material may develop a lower level of properties, especially if any cold, warm, or hot work is introduced, prior to solution heat treatment. The user should be held responsible for demonstration that his processing will yield properties meeting requirements.

-6-

THIS DOCUMENT IS PROTECTED BY U.S. COPYRIGHT It may not be reproduced, stored in a retrieval system, distributed or transmitted, in whole or in part, in any form or by any means. Downloaded from SAE International by Space Exploration Technologies, Copyright 2012 SAE International Monday, February 06, 2012 08:25:40 PM

AMS-QQ-A-200/8

SAE

AMS-QQ-A-200/8

6.4

Ordering Data: Purchasers should select the preferred options permitted herein and include the following information in procurement documents: Title, number, and date of this specification. Form, quantity, and temper required (See 1.2.1). Dimensions required. Requirements for sizes not specifically covered (See AMS-QQ-A-200). When lot number marking for material in the T1, T4, T4510, or T4511 temper is required (See 3.4). Which, if any, heat treatment capabilities shall be demonstrated where such demonstrations are purchasers options (See 3.2.2.2). Whether heat treatments not covered by MIL-H-6088 are disallowed (See 3.3). Special end use requirements. Selection of applicable levels of preservation and packing, whether Level A, Level B, or commercial (See AMS-QQ-A-200). Whether Type I tubing is required (See 1.2.2); (where no type is specified, Type I should be applied).

6.5

Product produced and marked to the requirements of AMS-QQ-A-200/8 also meets the requirements of QQ-A-200/8F. Product produced and marked to the requirements of QQ-A-200/8F also meets the requirements of AMS-QQ-A-200/8. The properties listed in 3.2.1 are exactly the same as QQ-A-200/8, Revision F. These properties have not been substantiated in accordance with the Manual for Preparation of Aerospace Specifications.

6.6

PREPARED UNDER THE JURISDICTION OF AMS COMMITTEE "D"

-7-

S-ar putea să vă placă și

- Sae Ams-Qq-A-250-4a-2010Document8 paginiSae Ams-Qq-A-250-4a-2010vinicius_bacellar100% (2)

- Ams 81200Document29 paginiAms 81200BacksniperÎncă nu există evaluări

- Ams 4928Document8 paginiAms 4928REKHA100% (3)

- As 5169Document5 paginiAs 5169Wuod JipangaÎncă nu există evaluări

- Astm B211Document13 paginiAstm B211SCRIBD DOCSÎncă nu există evaluări

- AMS 5355jv005Document11 paginiAMS 5355jv005Anonymous T6GllLl0100% (2)

- Aerospace Material SpecificationDocument8 paginiAerospace Material SpecificationDUÎncă nu există evaluări

- Aerospace Material SpecificationDocument6 paginiAerospace Material SpecificationQuality2010100% (5)

- AMS 2759-9-C - Nov 2007Document5 paginiAMS 2759-9-C - Nov 2007gillou3vÎncă nu există evaluări

- AMS-5639 304 - 304L Stainless PDFDocument7 paginiAMS-5639 304 - 304L Stainless PDFJesse KrebsÎncă nu există evaluări

- Ams 2175 Rev.Document22 paginiAms 2175 Rev.Johnny OhÎncă nu există evaluări

- Ams5732j PDFDocument7 paginiAms5732j PDFMichael SkrableÎncă nu există evaluări

- Ams 5622 DDocument11 paginiAms 5622 DPma CorpÎncă nu există evaluări

- Sae Ams 5518M-2014Document5 paginiSae Ams 5518M-2014Mehdi Mokhtari100% (1)

- Alloy A286 Ams 5731 Ams 5732 Ams 5737Document2 paginiAlloy A286 Ams 5731 Ams 5732 Ams 5737gowtham raju buttiÎncă nu există evaluări

- Sae Ams-H-6875b-2010Document22 paginiSae Ams-H-6875b-2010dmt1905100% (1)

- SAE - AMS 5659mv004Document9 paginiSAE - AMS 5659mv004Nilesh PatilÎncă nu există evaluări

- Sae Ams QQ A 225 9a 2014Document7 paginiSae Ams QQ A 225 9a 2014Sinan ChenÎncă nu există evaluări

- Ams 2471JDocument8 paginiAms 2471JMarco ChiereghinÎncă nu există evaluări

- Aerospace Material SpecificationDocument8 paginiAerospace Material SpecificationNav Talukdar100% (2)

- Aerospace Material Specification: (R) In-Process Welding of CastingsDocument13 paginiAerospace Material Specification: (R) In-Process Welding of CastingsRamesh R100% (1)

- Free-Machining Stainless Steel Bars: Standard Specification ForDocument4 paginiFree-Machining Stainless Steel Bars: Standard Specification ForLuciano Grassi KuyvenÎncă nu există evaluări

- Astm A434Document3 paginiAstm A434Evandro Luis Gomes100% (1)

- Sae Ams5659p (2014)Document9 paginiSae Ams5659p (2014)Yeonggeun Lee50% (2)

- A401A401M-10 Standard Specification For Steel Wire, Chromium-Silicon AlloyDocument4 paginiA401A401M-10 Standard Specification For Steel Wire, Chromium-Silicon Alloytjt4779Încă nu există evaluări

- Ams 2470Document9 paginiAms 2470Anonymous T6GllLl0Încă nu există evaluări

- Ams 2406Document8 paginiAms 2406Anonymous T6GllLl0Încă nu există evaluări

- National Aerospace Standard: Fed. Supply ClassDocument4 paginiNational Aerospace Standard: Fed. Supply ClassGlenn CHOU100% (1)

- Astm E280Document3 paginiAstm E280hlagos123100% (1)

- Astm G47Document6 paginiAstm G47brunodrÎncă nu există evaluări

- Astm A838Document4 paginiAstm A838RATHNAKUMARAÎncă nu există evaluări

- Aerospace Material SpecificationDocument6 paginiAerospace Material SpecificationAnonymous T6GllLl0Încă nu există evaluări

- Aerospace Material SpecificationDocument6 paginiAerospace Material Specificationvsraju2Încă nu există evaluări

- Astm F 2215-03 E04Document33 paginiAstm F 2215-03 E04Jorge ToribioÎncă nu există evaluări

- Astm b160Document6 paginiAstm b160Kevin Almeida100% (1)

- ASME B18 8 100M 2000 Spring PinsDocument57 paginiASME B18 8 100M 2000 Spring Pinshcsharma1967Încă nu există evaluări

- AMS Specifications in Aluminium PDFDocument2 paginiAMS Specifications in Aluminium PDFSuresh Kumar50% (2)

- Ams4928v PDFDocument8 paginiAms4928v PDFNav TalukdarÎncă nu există evaluări

- A 1070 - 16Document8 paginiA 1070 - 16Nguyễn Như ThếÎncă nu există evaluări

- Sae Ams 2759-11-2014Document5 paginiSae Ams 2759-11-2014reynaldoUH100% (2)

- ASTMB152 Spec (B152B152M - Gees4464)Document5 paginiASTMB152 Spec (B152B152M - Gees4464)CEDÎncă nu există evaluări

- Norma ASTM B733Document14 paginiNorma ASTM B733diegohrey239100% (3)

- Sae Ams5639j-2017Document7 paginiSae Ams5639j-2017Yeonggeun Lee100% (1)

- Sae J2484 2002 (En)Document11 paginiSae J2484 2002 (En)Juan David Bolaños AguilarÎncă nu există evaluări

- Standard Sae Ams H 6875aDocument29 paginiStandard Sae Ams H 6875agsv98850% (2)

- JB Nas76 PDFDocument1 paginăJB Nas76 PDFXto PeregrinÎncă nu există evaluări

- Aerospace Material Specification: Steel Cleanliness, Aircraft Quality Magnetic Particle Inspection ProcedureDocument15 paginiAerospace Material Specification: Steel Cleanliness, Aircraft Quality Magnetic Particle Inspection ProcedureMarcelino Navarrete EvaristoÎncă nu există evaluări

- National Aerospace Standard: Fed. Sup ClassDocument6 paginiNational Aerospace Standard: Fed. Sup ClassАлександр Цымбал100% (1)

- Nasm21209 AiaDocument8 paginiNasm21209 Aiastaedtlerp100% (3)

- B16B16M-10 (2015) Standard Specification For Free-Cutting Brass Rod, Bar and Shapes For Use in Screw Machines PDFDocument5 paginiB16B16M-10 (2015) Standard Specification For Free-Cutting Brass Rod, Bar and Shapes For Use in Screw Machines PDFislamakthamÎncă nu există evaluări

- Aerospace Material Specification: Aluminum Alloy 2024, Plate and SheetDocument8 paginiAerospace Material Specification: Aluminum Alloy 2024, Plate and SheetyouÎncă nu există evaluări

- AISI 8620 SteelDocument2 paginiAISI 8620 SteelVinit AhluwaliaÎncă nu există evaluări

- Detecting Heat Damage in Aircraft PartsDocument16 paginiDetecting Heat Damage in Aircraft PartsDimitris GrimanelisÎncă nu există evaluări

- Mil STD 870cDocument13 paginiMil STD 870cKrishnan DandapaniÎncă nu există evaluări

- AMS 2447D Coating, Thermal Spray High Velocity Oxygen Fuel ProcessDocument11 paginiAMS 2447D Coating, Thermal Spray High Velocity Oxygen Fuel ProcessJose Gaspar100% (1)

- AMS 2759 8A Ion NitridingDocument12 paginiAMS 2759 8A Ion NitridingSinan YıldızÎncă nu există evaluări

- TMS6900Document14 paginiTMS6900Josue Garcia QuiniÎncă nu există evaluări

- Astm f136 Rev ADocument4 paginiAstm f136 Rev AAhmad BrianÎncă nu există evaluări

- Aerospace Material Specification-AMS 2759Document11 paginiAerospace Material Specification-AMS 2759Guru Samy50% (2)

- 34 Samss 117Document9 pagini34 Samss 117naruto256Încă nu există evaluări

- WPS PQR As Per IsDocument3 paginiWPS PQR As Per Istarun kaushalÎncă nu există evaluări

- ASTM D3966-07 (Lateral)Document18 paginiASTM D3966-07 (Lateral)Rahmat100% (2)

- Polished Rod Profile - NEWDocument7 paginiPolished Rod Profile - NEWKevin XuÎncă nu există evaluări

- Cable Raws MaterialDocument7 paginiCable Raws MaterialAgustina EffendyÎncă nu există evaluări

- Hot Rolled Round Steel BarsDocument20 paginiHot Rolled Round Steel BarsNomoÎncă nu există evaluări

- Brown and Sharpe Handbook Young MachinistsDocument326 paginiBrown and Sharpe Handbook Young Machinistscegur23100% (1)

- Metal-Cored: Gmaw-CDocument16 paginiMetal-Cored: Gmaw-CChandrajeet ShelkeÎncă nu există evaluări

- Emtek 2013 Price BookDocument160 paginiEmtek 2013 Price BookSecurity Lock Distributors0% (1)

- Lesson 3 - Ductile and Brittle Fracture PDFDocument80 paginiLesson 3 - Ductile and Brittle Fracture PDFJavier Ayala HuamanÎncă nu există evaluări

- Asme Section II A Sa-194 Sa-194mDocument18 paginiAsme Section II A Sa-194 Sa-194mAnonymous GhPzn1x100% (1)

- 2 - Wheels and Castors CatalogueDocument116 pagini2 - Wheels and Castors CataloguedpquicenoÎncă nu există evaluări

- Bench Working and Fitting Shop: (1) Holding DeviceDocument10 paginiBench Working and Fitting Shop: (1) Holding DeviceAashish KushwahaÎncă nu există evaluări

- Altracs: A Superior Thread-Former For Light AlloysDocument8 paginiAltracs: A Superior Thread-Former For Light AlloysSquidwardÎncă nu există evaluări

- DSR PuneDocument16 paginiDSR Punedigvijayjagatap0% (1)

- 14 - Rebar Spacer For ConcreteDocument2 pagini14 - Rebar Spacer For Concreteecko markÎncă nu există evaluări

- Principles of Failure AnalysisDocument109 paginiPrinciples of Failure Analysisalexis_viteri100% (1)

- Everything You Need to Know About TungstenDocument24 paginiEverything You Need to Know About TungstenGottumukkala Venkateswara RaoÎncă nu există evaluări

- Carbon Steel GradesDocument4 paginiCarbon Steel GradesKiky IchanafiÎncă nu există evaluări

- Catalogue Challenge Piñón Cónico 82-57c (3535)Document476 paginiCatalogue Challenge Piñón Cónico 82-57c (3535)Isma MorenoÎncă nu există evaluări

- Strip Heaters 375 StripDocument6 paginiStrip Heaters 375 StripEliasÎncă nu există evaluări

- Technitube CatalogeDocument343 paginiTechnitube Catalogefcoac50% (2)

- Biomaterials For Dental ImplantsDocument136 paginiBiomaterials For Dental ImplantsAmit Bhargav100% (1)

- Is-16003-2012-Specification and Qualification of WeldingDocument23 paginiIs-16003-2012-Specification and Qualification of WeldingvijaykumarnÎncă nu există evaluări

- Bilah Tramontina Century Stainless Steel Paring KnifeDocument1 paginăBilah Tramontina Century Stainless Steel Paring KnifeOryza NurFaÎncă nu există evaluări

- Cast and Wrought Galvanic Zinc Anodes: Standard Specification ForDocument3 paginiCast and Wrought Galvanic Zinc Anodes: Standard Specification ForRony Yuda100% (1)

- Seal CoolerDocument2 paginiSeal CoolerJulio Adolfo López Portocarrero100% (1)

- 002 API 510 Course Puspatri Apr 09Document185 pagini002 API 510 Course Puspatri Apr 09ahmadlie100% (5)

- Presentation On MicrometerDocument19 paginiPresentation On MicrometerSHIJINÎncă nu există evaluări

- Geography ProjectDocument15 paginiGeography ProjectShefali JainÎncă nu există evaluări