Documente Academic

Documente Profesional

Documente Cultură

Eff Boiler Heat Loss Method

Încărcat de

Hijrah Saputro RaharjoDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Eff Boiler Heat Loss Method

Încărcat de

Hijrah Saputro RaharjoDrepturi de autor:

Formate disponibile

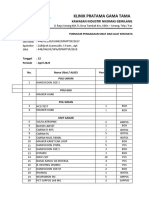

PLN (PERSERO) PUSLITBANG KETENAGALISTRIKAN

BOILER EFFICIENCY ENERGY BALANCE METHOD TANJUNG JATI B COAL FIRED POWER PLANT 4 X 660 MW

Unit Load Test Condition Date Duration

4 : 400 MW ( 60 % ECR ) : Normal Operation : 12/02/2013 : 09.00 - 10.00

BOILER EFFICIENCY BY ASME PTC 4.1

- Metric Units - Air Heater Leakage - JANAF Air and Flue Gas Properties - Losses using measured gas temperature leaving AH - CO2 Calculated by PTC 19.10

ULTIMATE FUEL ANALYSIS (Mass % As Fired Fuel) C H N O S a mf FCAF VMAF SG Carbon Hydrogen Nitrogen Oxygen Sulphur Ash Moisture Total Fixed Carbon (% mass as fired) Volatile Matter (% mass as fired) Specific Gravity (Fuel Oil)

Performance Coal

Actual

Design

Proximate Proximate Proximate Proximate

58.17 3.81 1.12 12.76 0.25 4.14 19.73 100.0 39.79 36.34

54.93 3.71 1.16 12.59 0.38 4.23 23.00 100.0 36.62 36.15 0.00

Hhv Hf

FUEL HIGHER HEATING VALUE Higher Heating Value (Btu/lbm) Higher Heating Value, Constant Pressure (kJ/kg)

Analysis Basis : 0 = Constant Pressure, 1 = Constant Volume

0 23,379.09 22,608.72

Ht LHVhfg Hfl

FUEL LOWER HEATING VALUE Total H2, including moisture (mass % kg / kg fuel) Latent heat water for LHV (kJ/kg) LHV (kJ/kg)

H + mf * 2.0159 / 18.0153 Hfg at Reference Temperature Hhv - LHVhfg * Ht / 100 / 2.0159 * 18.0153

6.02 2,429.51 22,072.54

6.28 2,436.91 22,010.65

tRA tF1 tA5 tA6SEC tA6PRI tA6 tA6D tA7SEC tA7PRI tA7 tA8SEC tA8PRI WA8SEC WA8PRI WA11 WAT HA5 HA9PRI HA11 FrPAL tA8 tA8AH tAL tA8D tA9SEC tA9PRI tA9 tA11A tA11 tG14 tG15 Wma'

TEMPERATURES & AIR FLOWS Reference Air Temperature (Deg C) Fuel Temperature (Deg C) Pulverizer Tempering Air (Deg C) Air Temperature Entering FD Fans (Deg C) Air Temperature Entering PA Fans (Deg C) Ave Ambient Dry Bulb Temperature Entering Fans (Deg C) Design Ave Air Temperature Entering Fans (Deg C) FD Fan Outlet Temperature (Deg C) PA Fan Outlet Temperature (Deg C) Ave Air Temp Lvg Fans (Deg C) Secondary AH Air In Temperature (Deg C) Primary AH Air in Temperature (Deg C) Air Flow Leaving Secondary AH ( t/h ) Air Flow Leaving Primary AH ( t/h ) Air Flow Entering Pulverizers ( t/h ) Pulverizer Tempering Air Flow ( t/h ) Entalphy of dry air @ tA5 Entalphy of dry air @ tA9PRI Entalphy of dry air @ tA11 Mass Fraction of Primary AH Leakage (Pri AH Lkg / Total AH Lkg) Avg Air Temperature Entering Unit (Deg C) Avg Air Temperature Entering Air Heaters (Deg C) Ave Air Heater Air Leakage Temperature (Deg C) Design Air Heater Air Inlet Temperature (Deg C) Air Temperature Leaving Secondary AH, (Deg C) Air Temperature Leaving Primary AH, (Deg C) Ave Air Temperature Leaving Air Heater, (Deg C) Pulverizer Coal/Air Outlet Temperature (Deg C) Pulverizer Inlet Temperature, (Deg C) Air Heater Gas Inlet Temperature (Deg C) Air Heater Gas Outlet Temperature (Deg C) Moisture in Air (kg/kg air)

Enter zero if tA7D & tA8D not corrected for ambient air temperature

30.05 30.05 51.55 n/a n/a n/a n/a n/a 51.55 n/a 38.46 51.55 1,588.90 343.10 513.15 170.05 26.70 279.91 196.00

27.00 27.00 49.40

32.70 32.70

MrA14 - WA11 WA11 - WAT Measured WA11 * (HA9PRI - HA11) / (HA9PRI -HA5)

(tA8SEC * WA8SEC + tA8PRI * WA11) / (WA8SEC + WA11) (tA8SEC * WA8SEC + tA8PRI * WA8PRI) / (WA8SEC + WA8PRI) tA8PRI * FrPAL + tA8SEC * (1-FrPAL)

41.65 40.78 38.46 32.70 307.00 299.09 305.60 65.00 218.17 328.13 120.14 0.1814

(tA9SEC * WA8SEC + tA9PRI * WA8PRI) / (WA8SEC + WA8PRI)

135.69 0.1480

xUCb xUCe xUCf

Bottom Ash (% of total refuse) Economizer Hopper (% of total refuse) Flyash (% of total refuse)

fraksi ash - konstanta fraksi ash - konstanta

20.0 80.0

COMBUSTIBLES IN ASH UCb UCe UCf UC Hd'p' Wd'p' UBC LUC(HHV) LUC(LHV) Cb Bottom Ash (Mass % of dry refuse) Economizer Hopper (Mass % of dry refuse) Flyash (Mass % of dry refuse) Carbon in Ash (Weighted Average) (kg / kg refuse) Heating Value of Total Dry Refuse (kJ/kg) Calculated Refuse Rate (kg/kg fuel) Unburned Carbon (kg/kg fuel) Heat Loss Due to Unburned Carbon (%) Heat Loss Due to Unburned Carbon (%) Carbon Burned (kg/kg fuel) (xUCb * UCb + xUCe * UCe + xUCf * UCf) / 100 UC * 14500 * 2.326 / 100 a / (100 - UC) UC * Wd'p' / 100 Hd'p' * Wd'p' * 100 / Hf or UBC * 14500 * 2.326 * 100 / Hf Hd'p' * Wd'p' * 100 / Hfl or UBC * 14500 * 2.326 * 100 / Hfl C - Hd'p' * Wd'p' / (145*2.326) or C - UBC * 100

Actual 0.39 0.47 0.45 153.12 0.042 0.000 0.027 0.029 58.15

FLUE GAS ANALYSIS and EXCESS AIR CALCULATIONS (% by volume, dry) ECONOMIZER OUTLET O214' Ao' Vdp Ax14' O2 (% vol dry) Theoretical Air (kg/kg fuel) Volume of Dry Products of Combustion Excess Air per PTC 19.10, Section 6.04.1.9 (%) Actual 5.51 7.46 18.39 35.10 Corrected 4.21 7.06 24.65

(11.51 * Cb + 34.3 * (H - O / 7.937) + 4.335 * S) / 100 0.3132 * Cb + 0.11528 * S + 0.13443 * N O214' * (Vdp + 10.331 * Ao') / (Ao' * (2.73 - 0.13068 * O2'))

PLN (PERSERO) PUSLITBANG KETENAGALISTRIKAN

CO214' CO14' N214' CO2 per PTC 19.10, Section 6.04.1.11 (% vol dry) CO (% vol dry) N2 (% vol dry) AIR HEATER OUTLET O215' Ax15' CO215' CO15' N215' O2 (% vol dry) Excess Air per PTC 19.10, Section 6.04.1.9 (%) CO2 per PTC 19.10, Section 6.04.1.11 (% vol dry) CO (% vol dry) N2 (% vol dry) 5.74 37.10 13.87 0.00 80.39 5.83 37.79 (31.32 * Cb + 11.528 * S) / (Vdp + Ao' * (10.331+0.13068 * Ax14')) 100 - O214' - CO214' - CO14' 14.07 0.00 80.42

O215' * (Vdp + 10.331 * Ao')/(Ao' * (2.73 - 0.13068 * O215')) (31.32 * Cb + 11.528 * S) / (Vdp + Ao' * (10.331+ 0.13068 * Ax15')) 100 - O215' - CO215' - CO15'

AIR HEATER LEAKAGE CALCULATIONS WG14' WG15' WA14' WA15' Inlet Dry Gas Weight per PTC 19.10 - Sec 6.03.5.1 (kg/kg fuel) (44.01 * CO214' + 32 * O214' + 28.02 * N214' + 28.01 * CO14') * (Cb + 12.01 / 32.07 * S) / (1201 * (CO214' + CO14')) Outlet Dry Gas Weight per PTC 19.10 - Sec 6.03.5.1 (kg/kg fuel) (44.01 * CO215'' + 32 * O215'' + 28.02 * N215'' + 28.01 * CO15'') * (Cb + 12.01 / 32.07 * S) / (1201 * (CO215'' + CO15'')) Weight of Dry Air in Gas Leaving Econ (kg/kg fuel) (28.02 * N214' * (Cb + 12.01 / 32.07 * S) / (1201 * (CO214' + CO14')) - N / 100) / 0.7685 Weight of Dry Air in Gas Leaving AH (kg/kg fuel) (28.02 * N215' * (Cb + 12.01 / 32.07 * S) / (1201 * (CO215' + CO15')) - N / 100) / 0.7685 Flue Gas Moisture (kg/kg fuel) Flue Gas Moisture (kg/kg fuel) Flue Gas Ash (kg/kg fuel) (if > 0.0537 kg/kJ) Inlet Wet Gas Weight (kg/kg fuel) Outlet Wet Gas Weight (kg/kg fuel) Air Heater Leakage (%) Enthalpy of Dry Gas @ tG15 (kJ/kg) Enthalpy of Water Vapor @ tG15 (kJ/kg) Enthalpy of Wet Gas @ tG15 (kJ/kg) Molecular Weight of Dry Flue Gas AH Out Enthalpy of Dry Gas @ tG15NL (kJ/kg) Enthalpy of Water Vapor @ tG15NL (kJ/kg) Enthalpy of Wet Gas @ tG15NL (kJ/kg) Enthalpy of Dry Air @ tA8AH (kJ/kg) Enthalpy of Water Vapor @ tA8AH (kJ/kg) Moisture in wet air, (kg/kg wet air) Enthalpy of Wet Air @ tA8AH (kJ/kg) Enthalpy of Dry AH Lkg Air @ tAL (kJ/kg) Enthalpy of Water Vapor @ tAL, (kJ/kg) Enthalpy of Wet AH Lkg Air @ tAL, (kJ/kg) Enthalpy of Dry Air @ tG15 (kJ/kg) Enthalpy of Wet Air @ tG15 (kJ/kg) Mean Wet Air Specific Heat of Lkg Air (kJ/kg C) Mean Wet Gas Specific Heat (kJ/kg C) Air Heater Gas Exit Temperature No Leakage (Deg C) Air Heater Gas Side Efficiency (%) 8.936 * H / 100 + mf / 100 + Wma' * WA14' 8.936 * H / 100 + mf / 100 + Wma' * WA15' a / 100 WG14' + WmG14 WG15' + WmG15 100 * (WG15 - WG14) / WG14 10.51 10.65 10.09 10.23 8.80 9.73 9.20

WmG14 WmG15 WashG WG14 WG15 AL HG15' HWV15 HWG15 IMdg HG15NL' HWV15NL HG15NL HA8' HWV8 Wma HWA8 HAL' HWVAL HWAL HA15' HWA15 CpA CpG tG15NL nG

2.37 2.39 0.04 12.88 13.05 1.29 94.85 178.99 110.29 30.47 96.24 178.99 111.43 15.86 29.44 0.1535 17.94 13.52 25.10 15.30 95.95 108.70 1.144 0.82 121.53 72.12 136.30 9.91 10.85

(1 - WmG15 / WG15) * HG15' + HWV15 * WmG15 / WG15 (44.01*CO215'+28.02*N215'+28.01*CO15'+32*O215')/100

(1-WmG15 / WG15) * HG15NL'+HWVNL15*WmG15/WG15

Wma' / (1 + Wma') (1 - Wma) * HA8' + Wma * HWV8

(1 - Wma) * HAL' + Wma * HWVAL

(1 - Wma) * HA15' + Wma * HWV15 (HWA15 - HWA8) / (tG15 - tA8) (HG15NL - HWG15) / (tG15 - tG15NL) AL * CpAL * (tG15 - tA8) / (100 * CpG) + tG15 [(tG14 - tG15NL) / (tG14 - tA8)] x 100

CORRECTIONS TO CONTRACT CONDITIONS

Corrected Unburned Carbon LUC(HHV) UBCD UCD Cbd Unburned Carbon Loss (%) Design Unburned Carbon (kg/kg fuel) Design Unburned Carbon (kg/kg refuse) Carbon Burned (kg/kg fuel) UBC * 14500 * 2.326 * 100 / Hf UBC * Hfd / Hf 10000 * UBCD / (aD + 100 * UBCD) CD - UBCD * 100 0.027 0.0002 0.00 54.93

Air Heater Exit Gas Temperature Corrections DTTAI DTTGI WG14DEV DTMGI DTXR tG15CA Correction for entering air temperature (Deg C) (tA8D * (tG14 - tG15) + tG14 * (tG15 - tA8AH)) / (tG14 - tA8AH) - tG15 Correction for entering gas temperature (Deg C) (tG14D *(tG15 -tA8AH) + tA8AH x (tG14 - tG15)) / (tG14 - tA8AH) - tG15 Deviation from base gas weight ent AH (%) 100*(MrG14D - MrG14) / MrG14D Entering Gas Mass Flow Correction, Curve fit function of WG14DEV (Deg C) From X-Ratio calculation program (Deg C) Corrected gas temperature leaving air heater for deviation from design boundary conditions (deg C) tG15 + DTTAI + DTTGI + DTMGI + DTXR -5.85 1 = Applicable, 0 = NOT Applicable: 0.00 11.67 0.00 0.00 114.29

1 = Applicable, 0 = NOT Applicable:

BOILER EFFICIENCY CALCULATIONS : HEAT CREDITS

Heat Supplied by Entering Air WA15' HRA HA8 CpA8 tRA tA8 BAe Weight of Dry Air (kg/kg fuel) Enthalpy of Dry Air @ tRA (kJ/kg) Enthalpy of Dry Air @ tA8' (kJ/kg) Mean Specific Heat of Dry Air @ tA8, tRA Reference Air Temperature (Deg C) Air Temperature Entering Air Heater (Deg C) Heat Credit (kJ/kg fuel) Heat Credit (% Fuel Input, HHV) Heat Credit (% Fuel Input, LHV) See Air Heater Leakage Calculations See Air Heater Leakage Calculations (HA8'-HRA')/(TA8-TRA) 10.23 5.06 16.73 0.93 30.05 41.65 110.48 0.47 0.50 8.80 7.73 27.00 32.70 68.02

WA15' x CpA8 x (tA8-tRA) 100 * BAe / Hf 100 * BAe / Hfl

Heat Supplied by Sensible Heat in Fuel Cpf tF1 Bfe Specific Heat of Fuel (kJ/kg*C) Fuel Temperature (Deg C) Heat Credit (kJ/kg fuel) Cpf * (tF1 - tRA) 1.26 30.05 0.00 74.40

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- 2017 09Document164 pagini2017 09sowabar100% (1)

- Northern Hemisphere Electronic Navigation Resources: Day Skipper and Watch LeaderDocument8 paginiNorthern Hemisphere Electronic Navigation Resources: Day Skipper and Watch LeaderSean DolanÎncă nu există evaluări

- Medical WaiverDocument1 paginăMedical WaiverCheerBUÎncă nu există evaluări

- Stakeholder RegisterDocument7 paginiStakeholder Registerrouzbehk6515Încă nu există evaluări

- Clearings 2018Document22 paginiClearings 2018ldxb2001100% (1)

- Expansion Joint Treatment Materials and TechniquesDocument15 paginiExpansion Joint Treatment Materials and TechniquesMAHAK GUPTAÎncă nu există evaluări

- Belajar Kerusakan AlatDocument126 paginiBelajar Kerusakan AlatHijrah Saputro RaharjoÎncă nu există evaluări

- Katalog Material Mo 5 Unit PLTMG Sei GelamDocument5 paginiKatalog Material Mo 5 Unit PLTMG Sei GelamHijrah Saputro RaharjoÎncă nu există evaluări

- 2.1 Template Kit - Part Number (Admin Unit)Document212 pagini2.1 Template Kit - Part Number (Admin Unit)Hijrah Saputro RaharjoÎncă nu există evaluări

- ReadmeDocument8 paginiReadmeyusuke123456789Încă nu există evaluări

- ReadmeDocument8 paginiReadmeyusuke123456789Încă nu există evaluări

- Bombas en Plantas BinariasDocument6 paginiBombas en Plantas BinariasCamilo Manuel García FernándezÎncă nu există evaluări

- Penilaian Kinerja Malcolm BaldridgeDocument24 paginiPenilaian Kinerja Malcolm BaldridgeHijrah Saputro RaharjoÎncă nu există evaluări

- Guide To Preparing Tax Research MemosDocument2 paginiGuide To Preparing Tax Research MemoscglaskoÎncă nu există evaluări

- Pengadaan Obat Dan Alkes TGL 22 April 2021 Klinik PembantuDocument8 paginiPengadaan Obat Dan Alkes TGL 22 April 2021 Klinik PembantuIsma Prasetya WardaniÎncă nu există evaluări

- Fuzzy Logic Tutorial: What Is, Application & ExampleDocument7 paginiFuzzy Logic Tutorial: What Is, Application & ExampleDe' LufiasÎncă nu există evaluări

- Thrust Equation For A Turbofan Double Inlet/Outlet: Joshtheengineer April 8, 2017Document7 paginiThrust Equation For A Turbofan Double Inlet/Outlet: Joshtheengineer April 8, 2017Muhammad RidwanÎncă nu există evaluări

- Resil Mojares Writing About OurselvesDocument21 paginiResil Mojares Writing About OurselvesSalimÎncă nu există evaluări

- MTBF and MTTR For Metal-Enclosed Capacitor Banks and Harmonic Filter SystemsDocument4 paginiMTBF and MTTR For Metal-Enclosed Capacitor Banks and Harmonic Filter SystemsbansalrÎncă nu există evaluări

- C 6 Slings SafetyDocument29 paginiC 6 Slings SafetyAshraf BeramÎncă nu există evaluări

- Holt MCD Earth Science Chapter 30Document34 paginiHolt MCD Earth Science Chapter 30ADEDAMOPE ODUESOÎncă nu există evaluări

- MT Co234 - Merged - MergedDocument73 paginiMT Co234 - Merged - MergedPavas ManoharÎncă nu există evaluări

- Lecture 3Document16 paginiLecture 3Awil MohamedÎncă nu există evaluări

- Boyut AnaliziDocument65 paginiBoyut AnaliziHasan Kayhan KayadelenÎncă nu există evaluări

- Reformasi Birokrasi Di AustraliaDocument54 paginiReformasi Birokrasi Di Australiazaky ahmadÎncă nu există evaluări

- Mass Transfer in Industrial ApplicationsDocument1 paginăMass Transfer in Industrial ApplicationsMPD19I001 VITHISHA MÎncă nu există evaluări

- QUANTUM TELEPORTATIONDocument23 paginiQUANTUM TELEPORTATIONalkagabaÎncă nu există evaluări

- LGBT Workplace Equality Policy and Customer Satisfaction: The Roles of Marketing Capability and Demand InstabilityDocument20 paginiLGBT Workplace Equality Policy and Customer Satisfaction: The Roles of Marketing Capability and Demand InstabilityFatima ZafarÎncă nu există evaluări

- CED-2021 EnergyTransition ReportDocument75 paginiCED-2021 EnergyTransition ReportCityNewsTorontoÎncă nu există evaluări

- Pulungmasle High School: Boy Scouts of The Philippines - Pulungmasle High School Chapter Work Plan For S.Y 2018-2019Document3 paginiPulungmasle High School: Boy Scouts of The Philippines - Pulungmasle High School Chapter Work Plan For S.Y 2018-2019Rd DavidÎncă nu există evaluări

- Bubble Sort: For (K 0 K X (K + 1) ) Swaparay (X, K, K + 1)Document7 paginiBubble Sort: For (K 0 K X (K + 1) ) Swaparay (X, K, K + 1)Vikas PuniaÎncă nu există evaluări

- Katie Nelson PDFDocument3 paginiKatie Nelson PDFKatie NÎncă nu există evaluări

- Western Preços - SPDocument28 paginiWestern Preços - SPRobertaoJasperÎncă nu există evaluări

- New Economics HAND BOOKDocument29 paginiNew Economics HAND BOOKGrisvia AgustinÎncă nu există evaluări

- Brent Academy of Northern Cebu, Inc: Talisay, Daanbantayan, Cebu First Periodical TestDocument2 paginiBrent Academy of Northern Cebu, Inc: Talisay, Daanbantayan, Cebu First Periodical TestKristine RosarioÎncă nu există evaluări

- SCHEMACSC520Document3 paginiSCHEMACSC520fazaseikoÎncă nu există evaluări