Documente Academic

Documente Profesional

Documente Cultură

Study The Effect of Addition of Wast Plastic On Compressive and Tensile

Încărcat de

IAEME PublicationTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Study The Effect of Addition of Wast Plastic On Compressive and Tensile

Încărcat de

IAEME PublicationDrepturi de autor:

Formate disponibile

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976 6308

(Print), ISSN 0976 6316(Online) Volume 4, Issue 2, March - April (2013), IAEME

415

STUDY THE EFFECT OF ADDITION OF WAST PLASTIC ON

COMPRESSIVE AND TENSILE STRENGTHS OF STRUCTURAL

LIGHTWEIGHT CONCRETE CONTAINING BROKEN BRICKS AS

ACOARSE AGGREGATE

Ghassan Subhi Jameel

Assistant Lecturer

Dep. of Dams &Water Resources Engineering

University of Anbar

:

-=-' - ---, '- ,`'- - ,,--`-' -'--'' -,' _,=--' _-,- ) =-= --=---'

,'' '---' ( -'-=' _' '-- --- ``- 0.5% 1% 1.5 -'-= _'= ,-== ---

' ,-'=' -- -=--'- ---' ,' -,-= ,-'-- -= . ---- ,' -,-=' ,-'-=' ='='

' '-- ACI committee211-2-82 ,-==' ='=' --- --' -,= 1:1.2:3.3 '-' --- _' ----`

0.5 ----` ,-=- 425

3

kg\m .

_'= ,'=' ='- '+-- ,=-' ,' -,-=' -'-=' _'= --- '-,= -,= `- ' =--`-

' -,= '` ' '--` -'-- '-`-` -- '=--` -- .

= _-'--' + '- ,`'- =--`-' `- _'= '=,- ` ' ,' -,-= ,-'--` -'-=' _'

-'--- ,--' ',' -'- -,= '-`-` -'-- -'= '--` -'-- - --' -'-- -'-- '--`

-- '-`-` -'-- '=--` -- 28 ',-' _'= ,, 4.4 29% 40.8 ,-=' ,-'--` -'-='' -

`- --- _'= ,'=' ,' '--- =--`-' 1 .

INTERNATIONAL JOURNAL OF CIVIL ENGINEERING AND

TECHNOLOGY (IJCIET)

ISSN 0976 6308 (Print)

ISSN 0976 6316(Online)

Volume 4, Issue 2, March - April (2013), pp. 415-432

IAEME: www.iaeme.com/ijciet.asp

Journal Impact Factor (2013): 5.3277 (Calculated by GISI)

www.jifactor.com

IJCIET

IAEME

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976 6308

(Print), ISSN 0976 6316(Online) Volume 4, Issue 2, March - April (2013), IAEME

416

ABSTRACT

This research studies the effect of adding waste plastic in three percentage 0.5% 1%

And 1.5% by volume on plain structural lightweight concrete (SLWC) produced by using

crushed bricks as coarse lightweight aggregates (LWA) in a lightweight concrete mix

designed according to ACI committee 211-2-82 with mix proportion 1:1.5:3.5 by volume

.The w\c equal to 0.5 and cement content 425 kg\m

3

. Different tests where performed for

fresh and hardened SLWC such, unit weight, compressive strength and two indirect tests of

tensile strength (splitting tensile and flexural strength).

The results demonstrated that the effect of addition of waste plastic was more

pronounced on the tensile strength of SLWC than the compressive strength.The maximum

increase of compressive, splitting tensile and flexural strengths at 28-days were 4.4; 29; 40.8

% in the SLWC containing 1% waste plastic.

Keywords: Waste plastic, crushed bricks, Compressive strength, Flexural strength.

1- DEFINITIONS

As the word population grows; so do the amount and type of wastes being

generated. Many wastes produced today will remain in the environment for hundreds and

perhaps thousands of years. The creation of non-decaying waste materials; combing with a

growing consumer population; has resulted in a waste disposal crisis. one solution of this

crisis lies in recycling wastes in to useful products [1] .Plastics are polymers, a very large

molecule made up of smaller units called monomers which are joined together in a chain by a

process called polymerization. The polymers generally contain carbon and hydrogen with,

sometimes, other elements such as oxygen, nitrogen, chlorine or Fluorine [2].

Waste plastic fibers: This term represent the using of the plastic bottles waste as fibers in

concrete that are uniformly distributed and randomly oriented. The amount of waste plastic

added to a concrete mix is measured as a percentage of the total volume of the composite

(concrete and fibers) termed Vf.

Structural lightweight concrete: The ASTM C330 [3] defines SLWC as having a

compressive strength of 17 MPa or more and a 28 day dry unit weight less than 1850 kg\m

3.

Similar gradients to normal weight concrete (NWC) except that it is made with LWA or

combination of lightweight and normal-weight aggregates but it has different properties. The

lower density and higher insulating capacity are the most obvious characteristics of Light-

Weight Aggregate Concrete (LWAC) by which it distinguishes itself from ordinary NWC

.However; these are by no means the only characteristics, which justify the increasing

attention for this (construction) material. If that were the case most of the design, production

and execution rules would apply for LWAC as for NWC, without any amendments.

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976 6308

(Print), ISSN 0976 6316(Online) Volume 4, Issue 2, March - April (2013), IAEME

417

2- INTRODUCTION

Recycled fibres from various sources have been studied as reinforcement in

concrete, including tire cords, carpet fibres, feather fibers, steel shavings, wood fibers from

paper waste, and high density polyethylene [4].

Addition of fibers makes the concrete more homogeneous and isotropic and therefore its

transformed from a brittle to amore ductile material. When concrete cracks, the randomly

oriented fibers arrest a micro cracking mechanism and limit crack propagation. The LWC

having less compressive strength than NWC .as such, a form of additional reinforcement is

needed to enhance the weakness of tensile strength in SLWC. This will achieved by using

fibers.

Advantages of using SLWC [5]:

Reduction in dead weight of structure.

Savings in steel reinforcement.

Reduction in dead weight gives better resistance to earthquake loading.

Reduced handling, transportation and construction cost for precast

Concrete elements

. Properties of FRC as compared with those of normal concrete [6]:

Higher tensile strain at failure

Higher toughness and resistance to impact

Ultimate tensile strength increased only slightly

Reduced workability of fresh concrete

Increase fatigue life

Similar elastic modulus

Similar drying shrinkage

Similar compressive creep, but lower tensile creep and flexural creep.

Abdul-khader al hadithi study the effect of adding the chips resulting from cutting the plastic

beverage bottles as fiber added to the concrete with very small percentages of concrete volume

(0.1 and 0.2%). Results proved that adding of plastic fibers leads to improvements in

compressive strength (11.28; 14.28%) and flexural strength (46.15-64.61%) of concrete

containing plastic fibers [7].

Extensive research efforts have been given to investigate the normal weight FRC [8]. Also

those studied SLWC [9] [10] [11] [12] etc. However .A research work has been undertaken to

investigate the effect of addition of waste plastic fiber in compressive and tensile strengths of

SLWC.

3- EXPERIMENTAL WORK

3-1 Materials

3-1-1 Cement

ordinary Portland cement produced by Kubaisa cement factory was used throughout

this study physical properties of used cement are listed in Table (1).The results are conformed

to the Iraqi specification No.5 1984[13].

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976 6308

(Print), ISSN 0976 6316(Online) Volume 4, Issue 2, March - April (2013), IAEME

418

Table (1) Physical properties of used cement

Limits of (I.O.S)

NO.5\1984

Test results Physical properties

1 hr (Min.)

10 hr (Max.)

1:20

3:35

Initial setting (vicat) hr

Final setting (vicat) hr

10 (Max.) 4.5 Soundness

(le-chatelier) mm

15 (Min.)

23 (Min.)

16.75

29.6

Compressive strength of

mortar MPa

3-day

7-day

3-1-2 Fine aggregate

A normal weight sand of 4.75 mm maximum size was used .Table (2) and(3)shows the

grading and physical properties of used fine aggregate .The grading was conformed to the

limits of Iraqi specifications No.45 1984[14] .

Table (2) Physical properties of used fine aggregates

Limits of (I.O.S)

NO.45\1984

Test results Physical properties

------ 2.61 Specific gravity

1450-1600 1549 Loose density (kg\m3)

1530-1800 1803 Compacted density (kg\m3)

------ 3.2 Absorption %

5(Max.) 3.6 Material finer than

75 %

------ 2.33 Fineness modulus

Table (3) Sieve analysis of fine aggregate

3-1-3 coarse lightweight aggregate

A crushed bricks were used as coarse LWA .The bricks pieces which are considered

as waste materials were crushed into smaller sizes by means of crusher machine (jaw crusher)

.Table 2 and 3 shows the grading and physical properties of coarse LWA respectively .The

grading was confirmed to ASTM C330 [2] for structural LWA .The lightweight aggregate

used in a saturated surface dry (SSD) condition recommended by ACI 211-2-82 [15 ] after

submerged in water for 1 hour and spread in laboratory until obtaining saturated surface dry

aggregates . Plate (1) and plate (2) show the course aggregate.

Limits of ASTM C330 Test results Sieve size mm

100 100 12.5

80-100 91 9.5

5-40 33 4.75

0-20 5 2.36

0-10 3 1.18

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976 6308

(Print), ISSN 0976 6316(Online) Volume 4, Issue 2, March - April (2013), IAEME

419

Table (4) Physical properties of LWA

ASTM C330 Test results Physical properties

------- 1.8 Specific gravity

------- 689 Loose density ( kg\m3)

800 Max. 800 Compacted density (kg\m3)

Table (5) Grading of LWA

Plate (1)

Limits of ASTM C330 Test results Sieve size mm

100 100 12.5

80-100 91 9.5

5-40 33 4.75

0-20 5 2.36

0-10 3 1.18

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976 6308

(Print), ISSN 0976 6316(Online) Volume 4, Issue 2, March - April (2013), IAEME

420

Plate (2)

3-1-4 water

Potable water was used in all mixes.

3-1-5 plastic fibers

Plate (3) and (4) show the waste plastic. fibers were used is the pieces of plastic

were used and become as a waste and we take it and cut to small pieces with limited length

and diameter to acts as a fiber .The properties of the used fibers are illustrated in Table (6 ) .

Table (6) Properties of used fibers

results property

Straight Fiber type

30 mm Fiber length

3mm Fiber diameter

1100 kg\m3 density

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976 6308

(Print), ISSN 0976 6316(Online) Volume 4, Issue 2, March - April (2013), IAEME

421

Plate(3)

Plate (4)

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976 6308

(Print), ISSN 0976 6316(Online) Volume 4, Issue 2, March - April (2013), IAEME

422

3-2 Mixing of concrete

A pan mixer of 0.1% m

3

capacity was used to mix the concrete ingredients .The mixer

was firstly cleaned from the remaining lumps of concrete .The dry mixed ingredients were

placed in the pan mixer and they were mixed for 2 minutes to ensure the homogeneity of

waste plastic and to split the agglomerations of cement particle .The required quality of water

was added to the mix and the whole constitutes were mixed for 3 minutes.

3-3 Preparation, casting, curing and types of the test specimens

Steel molds were used for casting all the tested specimens .Before casting the molds

were cleaned and oiled to avoid the adhesion of hardened concrete to the inside faces of

molds. The fresh concrete was placed inside the molds with approximately equal layers of 50

mm for all the specimens and consolidated by the mean of vibrating table for a sufficient

period .Care was taken to avoid segregation of LWA because the lightest particles of LWA

tend to float on the surface of concrete causing segregation of the mix consistent .After

casting ,the concrete surface was leveled and covered with nylon sheets to prevent

evaporation of water so as to avoid the plastic shrinkage cracks. On the second day the

specimens were remolded, marked and immersed in tap water until the test age. 100x100x100

mm cubes, 100x200mm cylinders and 100x100x500 prisms were used for compressive,

splitting tensile and flexural tensile strengths tests respectively. Plate (5) shows the some of

specimen before testing.

Plate (5)

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976 6308

(Print), ISSN 0976 6316(Online) Volume 4, Issue 2, March - April (2013), IAEME

423

3-4 Testing program

3-4-1 Slump test

The test was performed according to ASTM C143a [16].

3-4-2 Fresh and hardened unit weights

The test was performed according to ASTM C 567-85 [17].

Note: The above tests in addition to compressive strength test at 28 days were conducted to

achieve the requirements for SLWC in ASTM C330 [2]

3-4-3 Compressive strength test

The test was conducted on 100 mm cube according to BS 1881 part 116 :1989 [18] .The

test was performed at ages 7,14 and 28 days .

3-4-4 Tensile strength

3-4-4.a Splitting tensile strength test

The test was conducted on cylinders of 100x200 mm according to ASTM C496-86 [19]

.The splitting tensile strength was calculated using the following equation:

) (

l d

p

MPa strength tensile Splitting

2

=

Where: p: maximum applied load (N).

d: diameter of test specimen (mm).

L: length of test specimen (mm).

3-4-4.b Flexural strength test

The test was performed on prisms 100x100x500 mm according to BS 1881 part 118 ,

1989 [20].The flexural strength was calculated using the following equation as the failure of

all test specimens occurred in the mid part.

) (

2

d b

l p

MPa strength Flexural =

Where: p: maximum applied load (N)

L: length of test specimen (mm).

d, b : depth and width of test specimen (mm)

4-1 RESULTS AND DISCUSSION

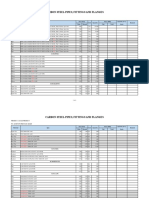

4-1-1 Compressive strength

The results of compressive strength of reference and SLWC specimens containing

0.5% , 1% and 1.5% fibers at 7,14 and 28 days are shown in Fig(1) and figure (2) .From these

results the following notes are observed :

- The reference mix is confirmed to the requirements of SLWC in ASTM C330 [2] where it

had 20.04 MPa compressive strength and 1875 kg\m

3

unit weight at 28days.

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976 6308

(Print), ISSN 0976 6316(Online) Volume 4, Issue 2, March - April (2013), IAEME

424

- All SLWC mixes, generally exhibited continuous strength gain .This is, generally, attributed

to the continuous formation of hydration products during the curing period.

-The addition of 0.5% , 1.5% and 1.5 % waste plastic fibers to the reference mix increased

the compressive strength at all ages:-

0.5% of plastic fiber is given compressive strength greater than reference mix at all

ages. The maximum increase of such concrete was 4.04% at 28 days.

1% of plastic fiber is given compressive strength greater than reference mix and mix

containing 0.5% fibers at all ages .The maximum increase of such concrete was 4.4%

at 28 days.

1.5% of plastic fiber is given compressive strength greater than reference mix but less

than mix containing 0.5% and 1% fibers .The maximum increase of such concrete

was 1.2% at 28 days.

4-1-2 Tensile strength

4-1-2 a Splitting tensile strength

The results of Splitting tensile strength of reference and SLWC specimens containing

0.5% , 1% and 1.5% fibers at 7,14 and 28 days are shown in Fig(3) and fig(4) .From these

results the following notes are observed :

-The addition of 0.5% , 1% and 1.5 % waste plastic fibers to the reference mix increased the

Splitting tensile strength at all ages:-

0.5% of plastic fiber is given Splitting tensile strength greater than reference mix at all

ages. The maximum increase of such concrete was 9.18% at 28 days.

1% of plastic fiber is given Splitting tensile strength greater than reference mix and

mix containing 0.5% fibers at all ages .The maximum increase of such concrete was

29% at 28 days.

1.5% of plastic fiber is given splitting tensile strength greater than reference mix but

less than mix containing 1% fibers .The maximum increase of such concrete was

15.94% at 28 days.

The increasing of Splitting tensile strength with percent greater than compressive

strength refers to important of using waste plastic fiber because my search appearance

the advantage of this uses like economical and increasing the strength of concrete

against tension stress . An initial crack (a pre-existing crack-like flaw) is allowed to

propagate when the stress intensity factor reaches the toughness of the brittle material.

In fiber reinforced cement composites, cracks are bridged by fibers, which in turns

govern the behavior of the crack in growth stability, length and crack opening profile

[21].

4-1-2 b Flexural strength

The flexural strength was determined at 7, 14 and 28 days and illustrated in Fig (5) and

fig (6). From these results the following notes are observed:

-The addition of 0.5% , 1% and 1.5 % waste plastic fibers to the reference mix increased the

flexural strength at all ages:-

0.5% of plastic fiber is given flexural strength greater than reference mix at all ages.

The maximum increase of such concrete was 20% at 28 days.

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976 6308

(Print), ISSN 0976 6316(Online) Volume 4, Issue 2, March - April (2013), IAEME

425

1% of plastic fiber is given flexural strength greater than reference mix and mix

containing 0.5% fibers at all ages .The maximum increase of such concrete was

40.8% at 28 days.

1.5% of plastic fiber is given flexural strength greater than reference mix but less than

mix containing 1% fibers .The maximum increase of such concrete was 32% at 28

days.

The results indicate that the SLWC mixes had similar behavior in flexural strength

corresponding to splitting tensile strengths .This may be related to the fact that the splitting

and flexural strength tests are indirect tests of tensile strength .The difference is the higher

values of flexural strength at all ages due to the different between tests procedures and the

shape of test specimens. On the other hand, Fig (5) demonstrates that 1%-SLWC showed

higher flexural strength gain between 7, 14 and 28 days corresponding to 0.5%; 1.5% and R-

SLWC.

We note that the mixes With 1.5% of waste plastic had tension strength less than mixes

with 1% this case attributed to the masses of the waste plastic , this case called

(segregation).

Note: as well as the increasing in magnitude of strength that caused by using of waste plastic

we notice that there is addition advantage. There is very important advantage is called

(mode of failure) this specification convert the way of failure from brittle (collapse) to ductile

as we show this appearance in down pictures. Plate (6), (7), (8) and (9) shows the modes of

failures in plain mix and mix containing waste plastic.

Plate (6) Section from specimen after testing of plain concrete

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976 6308

(Print), ISSN 0976 6316(Online) Volume 4, Issue 2, March - April (2013), IAEME

426

.

Plate (7) Mode of failure of reference mix plate (8) mode of failure with use fibers

Plate (9) Waste plastic act as abridge even after failure

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976

(Print), ISSN 0976 6316(Online) Volume 4, Issue 2, March

0

5

10

15

20

25

30

14.25

17

C

o

m

p

r

e

s

s

i

v

e

S

t

r

e

n

g

t

h

(

M

p

a

)

fig(2)the compressive strength of plain mix compared with mixes

R

14

15

16

17

18

19

20

21

22

7

C

o

m

p

r

e

s

s

i

v

e

S

t

r

e

n

g

t

h

(

M

P

a

)

figure (1) The compressive Strength of plain mix compared with mix

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976

6316(Online) Volume 4, Issue 2, March - April (2013), IAEME

427

7

14

28

17.23

20.04

16.11

18.4

20.85

16.31

18.8

20.93

16

18.1

20.28

)the compressive strength of plain mix compared with mixes

containing waste plastic fiber

w1

w2 w3

14 28

Age (day)

) The compressive Strength of plain mix compared with mix

containing waste plastic fiber

R w1 w2 w3

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976 6308

April (2013), IAEME

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976

(Print), ISSN 0976 6316(Online) Volume 4, Issue 2, March

1

1.3

1.6

1.9

2.2

2.5

2.8

S

p

i

l

t

T

e

s

i

l

e

S

t

r

e

n

g

t

h

(

M

P

a

)

figure (3) The Split Tensile Strength of plain mix compared with

0

0.5

1

1.5

2

2.5

3

3.5

1.05

1.

S

p

l

i

t

e

T

e

n

s

i

l

e

S

t

r

e

n

g

t

h

(

M

P

a

)

Figure (4) Split Tensile Strength for plain concrete compared with

mixes containing waste plastic fiber

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976

6316(Online) Volume 4, Issue 2, March - April (2013), IAEME

428

7 14 28

Age (day)

) The Split Tensile Strength of plain mix compared with

mix containing waste plastic fiber

R w1 w2 w3

7

14

28

.343

2.07

1.2

1.7

2.26

1.5

2

2.67

1.3

1.8

2.4

) Split Tensile Strength for plain concrete compared with

mixes containing waste plastic fiber

R M1 M2 M

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976 6308

April (2013), IAEME

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976

(Print), ISSN 0976 6316(Online) Volume 4, Issue 2, March

1

1.25

1.5

1.75

2

2.25

2.5

2.75

3

3.25

3.5

3.75

7

F

e

x

u

r

a

l

S

t

r

e

n

g

t

h

(

M

P

a

)

figure(5) The flexural Strength of plain mix compared with mix

R

0

0.5

1

1.5

2

2.5

3

3.5

4

4.5

1.96

f

l

e

c

t

u

r

a

l

S

t

r

e

n

g

t

h

(

M

P

a

)

Figure (6) The flextural Strength of plain mix compared with mix

R

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976

6316(Online) Volume 4, Issue 2, March - April (2013), IAEME

429

14 28

Age (day)

) The flexural Strength of plain mix compared with mix

contaning plastic waste fiber

R w1

w2

w3

7

1

2

96

2.22

2.72

1.8

2.42

3

2.2

2.76

3.52

2

2.56

3.3

) The flextural Strength of plain mix compared with mix

containing waste plastic fiber

w1

w2 w3

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976 6308

April (2013), IAEME

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976 6308

(Print), ISSN 0976 6316(Online) Volume 4, Issue 2, March - April (2013), IAEME

430

4-1-3 the relationship between compressive and tensile strength of R, 0.5%; 1% and

1.5%mixes

Figs (7) and (8) show the relationship between compressive and tensile strength for R,

0.5%; 1% and 1.5% mix. Where the tensile strength tested in two indirect tests (splitting

tensile and flexural strength).Results indicate that the tensile strength of all LWC mixes

increases with the increase of compressive strength .In Fig (7) and (8) it is apparent that the

R-SLWC showed lower values and slope in such relation corresponding to 0.5%; 1% and 1.5

% SLWC. The higher slope was observed in 1%-SLWC .On the other hand, the effect of

waste plastic was more clearly in flexural strength than splitting tensile strength of all SLWC

mixes .This may be due to significant bond improvement gained by using this material.

Fig (7) the relationship between compressive and splitting tensile strength

Fig (8) the relationship of compressive and flexural strength

1

1.2

1.4

1.6

1.8

2

2.2

2.4

2.6

2.8

15 16 17 18 19 20 21 22

S

p

l

i

t

t

i

n

g

t

e

n

s

i

l

e

s

t

r

e

n

g

t

h

(

M

p

a

)

Compressive strength(Mpa)

R

W1

W2

W3

1.5

2

2.5

3

3.5

4

15 16 17 18 19 20 21 22

F

l

e

x

t

u

r

a

l

s

t

r

e

n

g

t

h

(

M

p

a

)

Compressive strength(Mpa)

R

W1

W2

W3

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976 6308

(Print), ISSN 0976 6316(Online) Volume 4, Issue 2, March - April (2013), IAEME

431

CONCLUSION

Based on the results of present study the following conclusions can be drawn:

1- The produced R-LWC using crushed bricks as a LWA were confirmed to the requirements

of SLWC.

2- The addition of waste plastic increased the compressive strength of R- SLWC at all ages

up to 28 days.

3-The addition of waste plastic provided clear increment in the tensile strength more than

compressive strength especially flexural strength.

4-The use of 0.5% and 1.5% waste plastic in SLWC increase the compressive ,splitting

tensile and flexural strength 4.04;1.2;9.18;15.94;20;32% respectively at 28 days while the

use of 1% showed superior performance .The corresponding increment was 4.4;29; and

40.8%.

6-Adition of 0.5 and 1.5% waste plastic increase the slope of relationship between

compressive and tensile strength .Superior increase of such slope was observed in 1%-

SLWC.

REFERENCES

1. B.v.kiran Kumar and P.prakash use of waste plastics in cement concrete pavement.

2. Converting Waste Plastics into a Resource United Nations Environmental

ProgrammeDivision of Technology, Industry and Economics International

Environmental Technology Centre. Osaka/Shiga.

3. Johnston, C. "Fiber Reinforced Concrete." Significance Properties of Concrete and

Concrete-Making Material, ASTM STP 169C, 1994, pp. 547-561.

4. Wang, Youjiang, Wu, H.C. and Li, Victor C. "Concrete Reinforcement with Recycled

Fibers ", Journal of Materials in Civil Engineering, Vol. 12, No. 4, 2000, 314-319.

5. ASTM C 330-87, " Standard specification for lightweight aggregate for structural

concrete " Annual book of ASTM standards , Vol. 04.02 ,1989 ,pp. 112-118 .

6. Concrete Technology, Progress in Concrete Technology , University of Washington,

http://nersp.nerdc.ufl.edu/~tia/3501-11.pdf

7. Some concrete properties of concrete using waste plastic fiber with a very

smallpercentageAl-hadithi A.I.Asecond hallab conference.

8. Concrete Technology,Progress in Concrete Technology , University of Washington,

http://courses.washington.edu/cm425/.

9. Newman , J.B. and Bremner , T.W. , The testing of structural lightweight concrete ,

Proceeding of the second international congress on lightweight concrete , The concrete

society , London 1980 , pp. 152-171 .

10. Seabrook, P.I. , and Wilson , H.S. , High strength lightweight concrete for use in

offshore structures : utilization of fly ash and silica fume , The international journal of

cement campsites and lightweight concrete , Vol. 10,No.3, Aug.1988,pp. 183-192.

11. Wilson , H.S. , and Malhotra , V.M. , Development of high strength lightweight

concrete of structural applications The international journal of cement composites and

lightweight concrete ,Vol.10,No.2, May 1988, pp. 79-90.

12. Zhang, M.H. and Gjorv , O.E. , Permeability of high strength lightweight concrete

ACI material journal , Vol.88 , No.5, Sep.-Oct. 1991, pp.463-469 .

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976 6308

(Print), ISSN 0976 6316(Online) Volume 4, Issue 2, March - April (2013), IAEME

432

13. Al-Hadad, M.Y., Durability of porcelinite lightweight concrete against chloride and

sulfate solution , M.Sc. Thesis, University of technology, Aug.2001.

14. 5 --' 1984 --`-,-' ----` (I.O.S ,' ,-',-' --,-' )

15. 45 --' 1984 ,,-=' '--' ' (I.O.S ,' ,-',-' --,-' )

16. '--' -'-=' -=---'

17. ACI committee 211, Standard practice for selecting proportions for structural

lightweight concrete (ACI 211.2-81), ACI manual of concrete practice, part 1 1990,

pp.211.2-1-18.

18. ASTM C 143-89a,Standard test method for slump of hydraulic cement concrete ,

Annul book of ASTM standards, Vol. 0402, 1989, pp. 85-86.

19. ASTM C 567-85 Standard test method for unite weight of structural lightweight

concrete , Annul book of ASTM standards, Vol. 0402, 1989, pp. 277-279. . .

20. BS 1881, part 116, 1989 Standard test method for determination of compressive

strength of concrete cubes British Standard Institution, pp.3.

21. BS 1881 , part 117 ,1989 Standard test method for determination of splitting tensile

strength " British Standard Institution ,pp. 4 .

22. BS 1881, part 118, 1989 Standard test method for determination of flexural strength of

concrete cubes British Standard Institution, pp.3.

23. 15th ASCE Engineering Mechanics Conference June 2-5, 2002, Columbia University,

New York, NY.

24. Dr. Prahallada. M.C., Dr. Shanthappa B.C. and Dr. Prakash. K.B., Effect of Redmud

on the Properties of Waste Plastic Fibre Reinforced Concrete an Experimental

Investigation, International Journal of Civil Engineering & Technology (IJCIET),

Volume 2, Issue 1, 2011, pp. 25-34, ISSN Print: 0976 6308, ISSN Online: 0976

6316.

25. Dr. Abdulkader Ismail Abdulwahab Al-Hadithi., Improving Impact and Mechanical

Properties of Gap-Graded Concrete by Adding Waste Plastic Fibers, International

Journal of Civil Engineering & Technology (IJCIET), Volume 4, Issue 2, 2013,

pp. 118 - 131, ISSN Print: 0976 6308, ISSN Online: 0976 6316.

26. D.B.Mohite and S.B.Shinde, Experimental Investigation on Effect of Different Shaped

Steel Fibers on Flexural Strength of High Strength Concrete, International Journal of

Civil Engineering & Technology (IJCIET), Volume 4, Issue 2, 2013, pp. 332 - 336,

ISSN Print: 0976 6308, ISSN Online: 0976 6316.

S-ar putea să vă placă și

- Analyse The User Predilection On Gpay and Phonepe For Digital TransactionsDocument7 paginiAnalyse The User Predilection On Gpay and Phonepe For Digital TransactionsIAEME PublicationÎncă nu există evaluări

- Determinants Affecting The User's Intention To Use Mobile Banking ApplicationsDocument8 paginiDeterminants Affecting The User's Intention To Use Mobile Banking ApplicationsIAEME PublicationÎncă nu există evaluări

- Broad Unexposed Skills of Transgender EntrepreneursDocument8 paginiBroad Unexposed Skills of Transgender EntrepreneursIAEME PublicationÎncă nu există evaluări

- A Study On The Reasons For Transgender To Become EntrepreneursDocument7 paginiA Study On The Reasons For Transgender To Become EntrepreneursIAEME PublicationÎncă nu există evaluări

- Impact of Emotional Intelligence On Human Resource Management Practices Among The Remote Working It EmployeesDocument10 paginiImpact of Emotional Intelligence On Human Resource Management Practices Among The Remote Working It EmployeesIAEME PublicationÎncă nu există evaluări

- Influence of Talent Management Practices On Organizational Performance A Study With Reference To It Sector in ChennaiDocument16 paginiInfluence of Talent Management Practices On Organizational Performance A Study With Reference To It Sector in ChennaiIAEME PublicationÎncă nu există evaluări

- Visualising Aging Parents & Their Close Carers Life Journey in Aging EconomyDocument4 paginiVisualising Aging Parents & Their Close Carers Life Journey in Aging EconomyIAEME PublicationÎncă nu există evaluări

- Voice Based Atm For Visually Impaired Using ArduinoDocument7 paginiVoice Based Atm For Visually Impaired Using ArduinoIAEME PublicationÎncă nu există evaluări

- A Study of Various Types of Loans of Selected Public and Private Sector Banks With Reference To Npa in State HaryanaDocument9 paginiA Study of Various Types of Loans of Selected Public and Private Sector Banks With Reference To Npa in State HaryanaIAEME PublicationÎncă nu există evaluări

- Modeling and Analysis of Surface Roughness and White Later Thickness in Wire-Electric Discharge Turning Process Through Response Surface MethodologyDocument14 paginiModeling and Analysis of Surface Roughness and White Later Thickness in Wire-Electric Discharge Turning Process Through Response Surface MethodologyIAEME PublicationÎncă nu există evaluări

- A Study On The Impact of Organizational Culture On The Effectiveness of Performance Management Systems in Healthcare Organizations at ThanjavurDocument7 paginiA Study On The Impact of Organizational Culture On The Effectiveness of Performance Management Systems in Healthcare Organizations at ThanjavurIAEME PublicationÎncă nu există evaluări

- Gandhi On Non-Violent PoliceDocument8 paginiGandhi On Non-Violent PoliceIAEME PublicationÎncă nu există evaluări

- Attrition in The It Industry During Covid-19 Pandemic: Linking Emotional Intelligence and Talent Management ProcessesDocument15 paginiAttrition in The It Industry During Covid-19 Pandemic: Linking Emotional Intelligence and Talent Management ProcessesIAEME PublicationÎncă nu există evaluări

- A Multiple - Channel Queuing Models On Fuzzy EnvironmentDocument13 paginiA Multiple - Channel Queuing Models On Fuzzy EnvironmentIAEME PublicationÎncă nu există evaluări

- Role of Social Entrepreneurship in Rural Development of India - Problems and ChallengesDocument18 paginiRole of Social Entrepreneurship in Rural Development of India - Problems and ChallengesIAEME PublicationÎncă nu există evaluări

- EXPERIMENTAL STUDY OF MECHANICAL AND TRIBOLOGICAL RELATION OF NYLON/BaSO4 POLYMER COMPOSITESDocument9 paginiEXPERIMENTAL STUDY OF MECHANICAL AND TRIBOLOGICAL RELATION OF NYLON/BaSO4 POLYMER COMPOSITESIAEME PublicationÎncă nu există evaluări

- Moderating Effect of Job Satisfaction On Turnover Intention and Stress Burnout Among Employees in The Information Technology SectorDocument7 paginiModerating Effect of Job Satisfaction On Turnover Intention and Stress Burnout Among Employees in The Information Technology SectorIAEME PublicationÎncă nu există evaluări

- A Study On Talent Management and Its Impact On Employee Retention in Selected It Organizations in ChennaiDocument16 paginiA Study On Talent Management and Its Impact On Employee Retention in Selected It Organizations in ChennaiIAEME PublicationÎncă nu există evaluări

- A Proficient Minimum-Routine Reliable Recovery Line Accumulation Scheme For Non-Deterministic Mobile Distributed FrameworksDocument10 paginiA Proficient Minimum-Routine Reliable Recovery Line Accumulation Scheme For Non-Deterministic Mobile Distributed FrameworksIAEME PublicationÎncă nu există evaluări

- Application of Frugal Approach For Productivity Improvement - A Case Study of Mahindra and Mahindra LTDDocument19 paginiApplication of Frugal Approach For Productivity Improvement - A Case Study of Mahindra and Mahindra LTDIAEME PublicationÎncă nu există evaluări

- Various Fuzzy Numbers and Their Various Ranking ApproachesDocument10 paginiVarious Fuzzy Numbers and Their Various Ranking ApproachesIAEME PublicationÎncă nu există evaluări

- Financial Literacy On Investment Performance: The Mediating Effect of Big-Five Personality Traits ModelDocument9 paginiFinancial Literacy On Investment Performance: The Mediating Effect of Big-Five Personality Traits ModelIAEME PublicationÎncă nu există evaluări

- Quality of Work-Life On Employee Retention and Job Satisfaction: The Moderating Role of Job PerformanceDocument7 paginiQuality of Work-Life On Employee Retention and Job Satisfaction: The Moderating Role of Job PerformanceIAEME PublicationÎncă nu există evaluări

- Optimal Reconfiguration of Power Distribution Radial Network Using Hybrid Meta-Heuristic AlgorithmsDocument13 paginiOptimal Reconfiguration of Power Distribution Radial Network Using Hybrid Meta-Heuristic AlgorithmsIAEME PublicationÎncă nu există evaluări

- Dealing With Recurrent Terminates in Orchestrated Reliable Recovery Line Accumulation Algorithms For Faulttolerant Mobile Distributed SystemsDocument8 paginiDealing With Recurrent Terminates in Orchestrated Reliable Recovery Line Accumulation Algorithms For Faulttolerant Mobile Distributed SystemsIAEME PublicationÎncă nu există evaluări

- Knowledge Self-Efficacy and Research Collaboration Towards Knowledge Sharing: The Moderating Effect of Employee CommitmentDocument8 paginiKnowledge Self-Efficacy and Research Collaboration Towards Knowledge Sharing: The Moderating Effect of Employee CommitmentIAEME PublicationÎncă nu există evaluări

- Analysis of Fuzzy Inference System Based Interline Power Flow Controller For Power System With Wind Energy Conversion System During Faulted ConditionsDocument13 paginiAnalysis of Fuzzy Inference System Based Interline Power Flow Controller For Power System With Wind Energy Conversion System During Faulted ConditionsIAEME PublicationÎncă nu există evaluări

- Prediction of Average Total Project Duration Using Artificial Neural Networks, Fuzzy Logic, and Regression ModelsDocument13 paginiPrediction of Average Total Project Duration Using Artificial Neural Networks, Fuzzy Logic, and Regression ModelsIAEME PublicationÎncă nu există evaluări

- Analysis On Machine Cell Recognition and Detaching From Neural SystemsDocument9 paginiAnalysis On Machine Cell Recognition and Detaching From Neural SystemsIAEME PublicationÎncă nu există evaluări

- A Review of Particle Swarm Optimization (Pso) AlgorithmDocument26 paginiA Review of Particle Swarm Optimization (Pso) AlgorithmIAEME PublicationÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Ansi Asme b16.5 Class 150 Forged Flanges VJVMCHDocument1 paginăAnsi Asme b16.5 Class 150 Forged Flanges VJVMCHZachary HuffmanÎncă nu există evaluări

- Vernacular ArchitectureDocument22 paginiVernacular ArchitectureSharmae Rongavilla100% (1)

- R.C ProjectDocument3 paginiR.C ProjectMustafa HusseinÎncă nu există evaluări

- Lifting MethodsDocument10 paginiLifting Methodsselva1965Încă nu există evaluări

- Unconfined Compressive Strength of Cohesive SoilsDocument4 paginiUnconfined Compressive Strength of Cohesive SoilsZedrickTrinidad100% (1)

- Without LoadsDocument184 paginiWithout LoadsRajen Y. DhariaÎncă nu există evaluări

- Upgrading Skills For Pipe Fitters FabricatorsDocument4 paginiUpgrading Skills For Pipe Fitters FabricatorsKentDemeterio0% (1)

- Shear Strengthening of RC Beams With Web-Bonded Continuous Steel PlatesDocument12 paginiShear Strengthening of RC Beams With Web-Bonded Continuous Steel PlatesRachida KrachaiÎncă nu există evaluări

- Final Exam FINDocument8 paginiFinal Exam FINJoshua PowellÎncă nu există evaluări

- Flange SupportDocument1 paginăFlange SupportvijayanmksÎncă nu există evaluări

- Perno A325 HDG 5-8 X 1 1-4 (TKR+D7042279)Document1 paginăPerno A325 HDG 5-8 X 1 1-4 (TKR+D7042279)Alexander Ortiz CarrionÎncă nu există evaluări

- KREBS Technequip Knife Gate Valves BrochureDocument9 paginiKREBS Technequip Knife Gate Valves BrochureneshaÎncă nu există evaluări

- BuTech Pipe Valves and FittingsDocument28 paginiBuTech Pipe Valves and FittingsThiago LimaÎncă nu există evaluări

- Sample Installation MSRA (Complete)Document65 paginiSample Installation MSRA (Complete)Dihar RaviÎncă nu există evaluări

- Concrete Hollow Block LayeringDocument7 paginiConcrete Hollow Block LayeringMichael Adrian Magbanua100% (1)

- Imw 50 Single Con CabinaDocument1 paginăImw 50 Single Con CabinaIgnacio LopezÎncă nu există evaluări

- Monthly Management Meeting #12: Dhaka Water Supply Sector Development ProjectDocument25 paginiMonthly Management Meeting #12: Dhaka Water Supply Sector Development ProjectAl JawadÎncă nu există evaluări

- CONTRACT OF SERVICEDocument4 paginiCONTRACT OF SERVICER13 PENRO Surigao Del NorteÎncă nu există evaluări

- Ga 11 A Ga22 PDFDocument22 paginiGa 11 A Ga22 PDFSAUL OSPINOÎncă nu există evaluări

- CISC HandbookRev10 2 PDFDocument12 paginiCISC HandbookRev10 2 PDFbasilecoqÎncă nu există evaluări

- The Best Practice Guide For Environmental Protection in Construction SiteDocument50 paginiThe Best Practice Guide For Environmental Protection in Construction SiteGary LoÎncă nu există evaluări

- Titanium and Titanium AlloysDocument24 paginiTitanium and Titanium AlloysGuilherme FranzoiÎncă nu există evaluări

- Environment, Health & Safety Murra Warra Stage 2 Wind Farm: WTG SWMS RegisterDocument1 paginăEnvironment, Health & Safety Murra Warra Stage 2 Wind Farm: WTG SWMS RegisterAndrew RobertsÎncă nu există evaluări

- CARBON STEEL PIPES AND FITTINGS PRICE LISTDocument4 paginiCARBON STEEL PIPES AND FITTINGS PRICE LISTIlham KelanaÎncă nu există evaluări

- Item 603 - GuardrailDocument18 paginiItem 603 - GuardrailGlorybelle T. ValerioÎncă nu există evaluări

- Inconel 718Document28 paginiInconel 718aavadepa100% (1)

- Crackwidth For Wall (Combined Bending and Tension)Document3 paginiCrackwidth For Wall (Combined Bending and Tension)mukhleshÎncă nu există evaluări

- Kss Cable TieDocument32 paginiKss Cable Tieismail alwainiÎncă nu există evaluări

- Kobelco Excavator Cyl Repair Kit SK60 SK450 K903 K916 SeriesDocument6 paginiKobelco Excavator Cyl Repair Kit SK60 SK450 K903 K916 SeriesPhilÎncă nu există evaluări