Documente Academic

Documente Profesional

Documente Cultură

Experion Universal Process I - O

Încărcat de

morpheussDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Experion Universal Process I - O

Încărcat de

morpheussDrepturi de autor:

Formate disponibile

Process Solutions

Product Information Note

Experion Universal Process I/O

Universal Process I/O improves your projects performance by simplifying your process control system infrastructure. Honeywells innovative I/O solution provides enhanced flexibility in the design & implementation of control systems, while reducing system footprint, wiring, spares and delays due to late changes in an easy and cost effective manner. Experion PKS - The Knowledge to Make it Possible.

The introduction of the Universal Process IO module adds another key capability to Honeywells innovative, award-winning & proven Series C technology. Experions Universal Process I /O leverages Honeywells experience in process control technology with more than 25 million channels in operation across the globe. It also supports on-process migration to enable easy access to valuable new capabilities without unnecessary downtime and lost production.

Universal Benefits

Allows for prepackaged solutions for faster project execution Adapts to I/O changes late in the design, mitigating schedule risks Supports remote location deployment thereby reducing cables and cabinets Offers a DIN RAIL mount option Reduces the spares needed on site and makes maintenance easy Allows for process and safety I/O to be located in same cabinet, saving on infrastructure costs

Universal Channel Technology

Honeywell is the first to use Universal Channel Technology to completely liberate safety and process I/O, as well as the control cabinets from channel type dependency. This concept offers flexibility in I/O type, eliminating the need for custom hardware alignment with different I/O configurations. Universal Cabinets, enabled by Universal Channel Technology allow the cabinets to be standardized, since any field signal can be connected to any I/O channel. Universal Cabinet designs significantly reduce engineering cost and schedule when applied broadly across a project. Our approach reduces or eliminates marshalling, but most importantly, allows immediate configuration without the need for additional hardware. It simplifies engineering and configuration during the design stage of a project, and can save up to 33% of the installation costs. Late configuration changes can be done through remote access (rather than having someone manipulating hardware in the field), so they can be handled in minutes rather than days. In addition, Honeywells Universal I/O can be deployed to be fully redundant to help protect vital systems from going down.

Universal Features

Universal Process I/O provides all the benefits of the Series C I/O family and introduces the following new features: 32 Universal Channels per module Each channel individually configurable as AI, AO, DI or DO HART 7 support for AI & AO True soft configuration with no additional hardware needed to switch I/O configuration Full optional I/O redundancy Local and remote deployment capability Cabinet & DIN RAIL mounting options Extended temperature range (-40 to +70 Deg C)

Experion Universal Process I/O

Reducing / Eliminating Marshalling

The Honeywell Universal Process I/O solution re-defines the way to design, engineer, install and commission a process control system. Universal I/O brings the futuristic trend of virtualization (in this case by insulating the interface between the control system and the plant instrumentation) for the first time at the control system I/O level, making implementation a more flexible experience and reducing overhead costs. The Universal I/O solution delivers this high level of flexibility by enabling continuous changes in system design at the software level with no additional hardware requirements or changes at any stage in the project. With this new way of I/O deployment, field wires can now be terminated on any Universal I/O module / channel regardless of signal type. This eliminates the scrambling needed in conventional marshalling approaches, thus reducing the hardware complexity around installation, commissioning and maintenance of the system, resulting in savings on marshalling cabinets, inter-panel wiring, cabinet space, power requirements and the traditional time needed to deploy these.

Quick Install and Commission

Installation and commissioning is the most dynamic and challenging time in a projects lifecycle due to late changing requirements and fixed project deadlines and budgets. Honeywells Universal I/O provides much-needed flexibility to any project, and allows for any changes in cable schedule or field instrument schedule during the commissioning stage without the need to change terminations on the I/O modules. This approach reduces the schedule risk and helps accelerate the commissioning toward early start-up for early returns, despite late changes.

SMART Engineering

Universal I/O and Universal Cabinets take engineering efficiency to its next level. They combine standard packaging options with standard hardware drawings which are repeatable with no need to create separate cabinet layouts, wiring diagrams, and power and heat calculations. This approach can save precious hardware engineering hours, reduces errors by delivering a standard design and substantially reduces acceptance testing, while providing the flexibility to change the I/O configurations at any stage of the project. Effectively, Universal I/O also allows delaying the design freeze dates, without impacting the project schedule, bringing the best of both worlds together standardization & flexibility.

Easy Maintenance

Maintenance departments are under ever increasing pressure to reduce their budgets year over year. The Universal I/O module reduces equipment needs because there is no need for custom hardware with different I/O configurations. The Universal I/O module replaces four conventional I/O modules (AI, AO, DI & DO). The obvious result is significant savings related to spares inventory and associated holding costs. It also greatly reduces the complexity for maintenance personnel during repairs with only one module to choose.

For More Information Learn more about how Honeywells Experion can improve project performance, visit our website www.honeywellprocess.com or contact your Honeywell account manager. Honeywell Process Solutions Honeywell 1250 West Sam Houston Parkway South Houston, TX 77042 Honeywell House, Arlington Business Park Bracknell, Berkshire, England RG12 1EB UK Shanghai City Centre, 100 Junyi Road Shanghai, China 20051 www.honeywellprocess.com

Experion is a registered trademark of Honeywell International Inc.

PN-12-14-ENG November 2012 2012 Honeywell International Inc.

S-ar putea să vă placă și

- FSC To Safety Manager Migration Solution NoteDocument2 paginiFSC To Safety Manager Migration Solution NotememtÎncă nu există evaluări

- Honeywell Tps ManualsDocument2 paginiHoneywell Tps ManualsMILOÎncă nu există evaluări

- Product Data Sheet Deltav Virtualization Hardware Deltav en 57678Document14 paginiProduct Data Sheet Deltav Virtualization Hardware Deltav en 57678Marco Antonio Agnese100% (1)

- Process Control System A Complete Guide - 2020 EditionDe la EverandProcess Control System A Complete Guide - 2020 EditionÎncă nu există evaluări

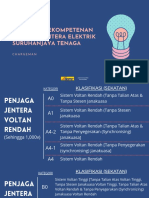

- Kategori Kompeten Penjaga Jentera Elektrik STDocument9 paginiKategori Kompeten Penjaga Jentera Elektrik STAbun ParadoxsÎncă nu există evaluări

- G1 - PPT - Design and Simulation of Microstrip Patch Antenna For Wireless ApplicationsDocument18 paginiG1 - PPT - Design and Simulation of Microstrip Patch Antenna For Wireless Applicationspooja yadav100% (1)

- Honeywell Experion I/O PinDocument7 paginiHoneywell Experion I/O PinFebri Rio CahyonoÎncă nu există evaluări

- Plant Intelligent Automation and Digital Transformation: Volume I: Process and Factory AutomationDe la EverandPlant Intelligent Automation and Digital Transformation: Volume I: Process and Factory AutomationÎncă nu există evaluări

- Experion Field Personnel SafetyDocument4 paginiExperion Field Personnel SafetyGeorge_02Încă nu există evaluări

- PIN Experion R400Document2 paginiPIN Experion R400thillai312Încă nu există evaluări

- Experion Scada PDFDocument2 paginiExperion Scada PDFLaceyÎncă nu există evaluări

- ADAPCTL Honeywell ExperionDocument50 paginiADAPCTL Honeywell ExperionAr MenonrÎncă nu există evaluări

- Exp Station PINDocument9 paginiExp Station PINKhalid AliÎncă nu există evaluări

- Experion ACEDocument3 paginiExperion ACENguyen Tuan DanhÎncă nu există evaluări

- PDS DeltaV DocLibraryDocument3 paginiPDS DeltaV DocLibrarygohviccÎncă nu există evaluări

- Experion Site Planning Guide EPDCX686Document132 paginiExperion Site Planning Guide EPDCX686nubbler67% (3)

- Quick Start Guide Honeywell ExperionDocument18 paginiQuick Start Guide Honeywell Experionsina20795Încă nu există evaluări

- Configuration Utility User's GuideDocument136 paginiConfiguration Utility User's Guidethillai312Încă nu există evaluări

- Networks in Process AutomationDocument24 paginiNetworks in Process AutomationRajeshÎncă nu există evaluări

- Modbus FAQDocument5 paginiModbus FAQspoof183Încă nu există evaluări

- Experion Pks PDFDocument2 paginiExperion Pks PDFSarahÎncă nu există evaluări

- Experion LCN Tech Spec PDFDocument27 paginiExperion LCN Tech Spec PDFjashkishoreÎncă nu există evaluări

- Honeywell Migration Solutions Marjorie Ochsner Monte Cadle Gene ChenDocument47 paginiHoneywell Migration Solutions Marjorie Ochsner Monte Cadle Gene ChenJitendra Mishra100% (1)

- Deltav PK ControllerDocument15 paginiDeltav PK ControllerevbaruÎncă nu există evaluări

- FDT - Field Device Tool PDFDocument8 paginiFDT - Field Device Tool PDFcalripkenÎncă nu există evaluări

- TRICON Product Spec PDFDocument78 paginiTRICON Product Spec PDFUdaya Kumar Krishnan100% (1)

- WP DeltaV Grounding OptionsDocument6 paginiWP DeltaV Grounding OptionsPrateek RajÎncă nu există evaluări

- Fieldbus OverviewDocument65 paginiFieldbus OverviewRajib Nag100% (1)

- PCS7 OpenOS 3rdparty Integration Foxboro V9.0 enDocument56 paginiPCS7 OpenOS 3rdparty Integration Foxboro V9.0 enricardo gonzalezÎncă nu există evaluări

- HIMA HIQUAD SystemsDocument3 paginiHIMA HIQUAD Systemssina20795Încă nu există evaluări

- FDT DTMDocument6 paginiFDT DTMsathyabnÎncă nu există evaluări

- Foundation Fieldbus Questions and AnswersDocument14 paginiFoundation Fieldbus Questions and Answerssandystays100% (1)

- HONEYWELL Experion Software Installation Users GuideDocument120 paginiHONEYWELL Experion Software Installation Users Guidejashkishore100% (1)

- DV PDS DeltaV AnalyzeDocument8 paginiDV PDS DeltaV AnalyzeKarthik SelvaÎncă nu există evaluări

- 08 20R300 1 EXCEL SimulationDocument6 pagini08 20R300 1 EXCEL Simulationavandetq15100% (1)

- Profibus EvolutionDocument16 paginiProfibus EvolutionnourÎncă nu există evaluări

- Production Software Within Manufacturing Reference ArchitecturesDocument13 paginiProduction Software Within Manufacturing Reference ArchitecturesNilesh ChavanÎncă nu există evaluări

- MTL IS Interfaces PDFDocument30 paginiMTL IS Interfaces PDFmasimeriseÎncă nu există evaluări

- Deltav Workstation Hardware EmersonDocument23 paginiDeltav Workstation Hardware EmersonmhaioocÎncă nu există evaluări

- Wonderware Historian Installation GuideDocument80 paginiWonderware Historian Installation GuidecrsswaÎncă nu există evaluări

- Network Selection GuideDocument52 paginiNetwork Selection Guideaugur886100% (1)

- Digital PID ControllersDocument21 paginiDigital PID Controllerssopan saÎncă nu există evaluări

- AADvance Controller Safety Manual Icstt-rm446P-En-pDocument110 paginiAADvance Controller Safety Manual Icstt-rm446P-En-pSGan GÎncă nu există evaluări

- ML Experion IntegrationDocument148 paginiML Experion IntegrationArnab DeÎncă nu există evaluări

- Connecting To Allen-BradleyDocument16 paginiConnecting To Allen-Bradleycjutp86Încă nu există evaluări

- Buses and The DeltaV SystemDocument10 paginiBuses and The DeltaV Systemarviel_lea31Încă nu există evaluări

- Ep03 500 310 FteDocument15 paginiEp03 500 310 FtePramod WaghuldeÎncă nu există evaluări

- Experion PKS - Virtual Process OverviewDocument21 paginiExperion PKS - Virtual Process OverviewProtheuss01100% (1)

- Pds Deltav Sis CslsDocument57 paginiPds Deltav Sis Cslsrogelio surcoÎncă nu există evaluări

- Delta V Charm IODocument8 paginiDelta V Charm IOturboedÎncă nu există evaluări

- BRO DeltaV SIS System OverviewDocument20 paginiBRO DeltaV SIS System Overviewelio_hbÎncă nu există evaluări

- HPM - Specification and Technical DataDocument48 paginiHPM - Specification and Technical DataVitor Nunes BragaÎncă nu există evaluări

- Experion PKS Startup GuideDocument108 paginiExperion PKS Startup Guidethillai312100% (4)

- DeltaV I-O Subsystem Carriers PDS January 2008Document12 paginiDeltaV I-O Subsystem Carriers PDS January 2008esakkiraj1590Încă nu există evaluări

- Write Protected BlockDocument1 paginăWrite Protected BlockMILOÎncă nu există evaluări

- Fieldbus Systems and Their Applications 2005: A Proceedings volume from the 6th IFAC International Conference, Puebla, Mexico 14-25 November 2005De la EverandFieldbus Systems and Their Applications 2005: A Proceedings volume from the 6th IFAC International Conference, Puebla, Mexico 14-25 November 2005Miguel Leon ChavezÎncă nu există evaluări

- Distributed Process Control ReportDe la EverandDistributed Process Control ReportÎncă nu există evaluări

- RSLOGIX5000 Programming A Clear and Concise ReferenceDe la EverandRSLOGIX5000 Programming A Clear and Concise ReferenceÎncă nu există evaluări

- Distributed Control System A Complete Guide - 2020 EditionDe la EverandDistributed Control System A Complete Guide - 2020 EditionÎncă nu există evaluări

- Programming SCADA Complete Self-Assessment GuideDe la EverandProgramming SCADA Complete Self-Assessment GuideÎncă nu există evaluări

- Distributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979De la EverandDistributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979T. J. HarrisonÎncă nu există evaluări

- CPP ReportDocument5 paginiCPP ReportSujay Hazra100% (1)

- Water Cooled Chiller (SHUBAILY GRAND MALL)Document40 paginiWater Cooled Chiller (SHUBAILY GRAND MALL)kdpmansiÎncă nu există evaluări

- SA35AC E01 MergedDocument87 paginiSA35AC E01 MergedClassyÎncă nu există evaluări

- 8.3 Solving Equilibrium Problems For Bases (SCH4U)Document3 pagini8.3 Solving Equilibrium Problems For Bases (SCH4U)Michelle NgÎncă nu există evaluări

- Chapter 3 Waveform Coding Techniques PDFDocument33 paginiChapter 3 Waveform Coding Techniques PDFEunielyn SecretoÎncă nu există evaluări

- Banana ChipsDocument5 paginiBanana Chipsbikram limbuÎncă nu există evaluări

- Network Protocol TutorialDocument43 paginiNetwork Protocol TutorialGiovanni RadiciÎncă nu există evaluări

- Lincoln PowerMaster III 2011Document10 paginiLincoln PowerMaster III 2011Manuel Aguirre PiconÎncă nu există evaluări

- Is 2571-1970Document27 paginiIs 2571-1970Deboline MitraÎncă nu există evaluări

- 6 Energy Calculation: UDEC Version 4.0Document28 pagini6 Energy Calculation: UDEC Version 4.0Rakshit MishraÎncă nu există evaluări

- Research Report (JAHANGIR'S TOMB)Document24 paginiResearch Report (JAHANGIR'S TOMB)ahmerÎncă nu există evaluări

- Honpe CatalogueDocument23 paginiHonpe CatalogueGrupo XDSÎncă nu există evaluări

- Instructions VbamDocument2 paginiInstructions VbamAustin Yu LiuÎncă nu există evaluări

- How To Build Your Own Solid State OscilloscopeDocument100 paginiHow To Build Your Own Solid State OscilloscopemariopilarÎncă nu există evaluări

- GP2500S/GP2501S - STN Color: Pro-Face Graphic Operator InterfacesDocument2 paginiGP2500S/GP2501S - STN Color: Pro-Face Graphic Operator Interfacesthanh_cdt01Încă nu există evaluări

- 06-DC Compound MotorDocument44 pagini06-DC Compound MotorN. iManÎncă nu există evaluări

- SR en 10025-04Document8 paginiSR en 10025-04pukla100% (2)

- Durability of Clay BricksDocument18 paginiDurability of Clay BricksEmmanuel okelloÎncă nu există evaluări

- V 112Document4 paginiV 112simon_someone217Încă nu există evaluări

- Compare Models - RitchieSpecsDocument4 paginiCompare Models - RitchieSpecsMochammad JihadÎncă nu există evaluări

- AC 43.13-1B Section 5 Penetrant InspectionDocument8 paginiAC 43.13-1B Section 5 Penetrant Inspection320338100% (1)

- Microsoft SQL Server 2005 Express Edition &Document95 paginiMicrosoft SQL Server 2005 Express Edition &lgmep350Încă nu există evaluări

- Removal of SO2 From Low Sulfur Coal Combustion Gases by Limestone ScrubbingDocument12 paginiRemoval of SO2 From Low Sulfur Coal Combustion Gases by Limestone ScrubbingCaballero MarioÎncă nu există evaluări

- Low Cost Axial Vactrols: VTL5C3, 5C4Document2 paginiLow Cost Axial Vactrols: VTL5C3, 5C4sillyÎncă nu există evaluări

- Isolation Selector GuideDocument12 paginiIsolation Selector GuidesandeepbhallaÎncă nu există evaluări

- PICP Manual 3rd Edition PDFDocument62 paginiPICP Manual 3rd Edition PDFanmolÎncă nu există evaluări

- Lab Report For Epoxy Resin Polymer Concrete by GroupbbbbbbbDocument23 paginiLab Report For Epoxy Resin Polymer Concrete by GroupbbbbbbbBetelhem KifleÎncă nu există evaluări

- Protection For HV Line BayDocument3 paginiProtection For HV Line BayhasaladÎncă nu există evaluări