Documente Academic

Documente Profesional

Documente Cultură

Beer Quality Characteristics

Încărcat de

Kapithas EswaranDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Beer Quality Characteristics

Încărcat de

Kapithas EswaranDrepturi de autor:

Formate disponibile

Beer Quality Characteristics and Quality defects The main quality characteristics of beer are the scent and

flavor, color and clarity, foaminess and foam retention. The visual quality of beer depends on its foam, color and clarity. Beer color originates principally with Maillard reaction products formed during malting within the grain used to prepare the wort for fermentation. Kilning malted barley creates the greatest input to beer color while boiling wort can add substantial color in lighter colored worts, along with the oxidation of grain and hop polyphenols. In some instances, beer color is modified post-fermentation using caramel color or roasted malt extracts. The conventional method for measuring beer color throughout much of the world examines the absorbance at 430 nm. While this works well for light colored lagers it lacks the ability to measure nuances of darker, redder beer or cloudy beer color. 1. Foam An important aspect of beer quality is the formation of a stable head of foam when the beer is poured. Lipids are considered to be detrimental to beer foam, while hop derived bitter components and proteins originating from barley are important for the formation of foam. The investigation of which proteinaceous compounds in beer are involved in foam formation has been pursued for decades, mainly by fractionation of beer proteins. Foams are colloidal systems comprising of a discontinuous gaseous phase and a continuous liquid or solid phase. The amount of liquid held up in beer foam is time dependent, with more or less wet foam rapidly draining to leave an essentially solid network of bubble walls. These walls are deposited from the liquid phase, a process which begins immediately upon the formation of the bubbles. The process of foam drying is often termed drainage, as generally the liquid leaves the foam under the influence of gravity. Indeed, many foam measurements are based on liquid drainage, not least because measurement of drained liquid volumes over a specified time period is relatively straightforward. However, drainage is not the only parameter by which beer foam can be judged. From a consumer point of view, drainage results in a modest change of foam volume and may not be as apparent as bubble coalescence- the combination of two or more bubbles to form fewer, larger bubbles; or disproportionation - where the larger bubbles increase in volume at the expense of smaller bubbles. These latter two can be readily perceived visually, as they give a coarser, less aesthetically pleasing foam. For many beer foams, drainage precedes coalescence and disproportionation, so that the determination of drainage essentially reflects the early lifetime of beer foam. 2. Foaminess and Foam Retention The bubbles of carbon dioxide create foam in the glass of beer. The steady, thick and lofty foam is a sign of good quality beer. The foam 4 cm high should stay for 3-4 minutes. Good foam leaves a trace on the glass walls which the beer-makers and beer fans call "Brussels lace". Beer with thick and dense foam has a fullness of taste and long lasting freshness.

3. Flavor Beer flavour is a very complex subject. Over 800 compounds have been identified that contribute to the characteristic flavour of beer. The beer flavor mainly depends on: Beer yeast and fermentation by-products Type and quantity of hop, Organic sulphurous compounds. The main flavour characteristics are the bitter taste derived primarily from the hops, an alcoholic note from ethanol and a carbonation mouthfeel from CO2. Secondary flavour notes include fruity estery flavours, alcoholic notes from higher alcohols and various sulphur components. However, most of the flavour compounds are present in very small quantities (below their individual taste threshold) and act synergistically to provide the balanced and refreshing taste of good beer. Occasionally undesirable flavour components may appear, giving the beer various off-flavours. The flavour components and their precursors originate from the raw materials, namely malt, adjuncts, water or hops, or are produced by the yeast during fermentation of the wort. Consequently, the selection of raw materials and/or yeast strain has great impact on the flavour. However, the flavour is also influenced by technological factors which affect the composition of the wort, and the conditions during fermentation, maturation, filtration and bottling. Flavour assessment is therefore very important in quality control of beer. One of the most important tools is the sensory analysis by a panel of well-trained tasters. To enable a precise description of a beer sample a common terminology has been elaborated. Each flavour impression is quantified on a scale of 0-10. In recent years the methods for chemical analysis have improved dramatically. It is now possible to monitor the concentration of many flavour active components. Quantification of higher alcohols and esters by headspace analysis using a gas chromatograph is now a routine analysis in many breweries. Beer is a very fragile liquid which will deteriorate rapidly unless stored under cold and dark conditions. The stale "cardboard" flavour which may appear upon storage is mainly due to very small amounts of trans-2-nonenal, a lipid degradation product formed during malting and wort production. 4. Taste The integrity of taste is determined mainly by super activeness of wort: higher it is, fuller is the taste. The fullness of taste depends of alcohol, residual sugar, oligosaccharides, highprotein cleavage products, bitter and astringent compounds of hops, esters, amino acids and other substances. The refreshing feature of beer is conditioned by the content of carbon dioxide in it, which should be granular and linked. This ensures the slow release of gas and the sparkling.

5. Color Beer color distinguishes different types of beer, from light to dark. High quality light beer should have full transparency and should twinkle. High gloss speaks of product purity and perfection. The color of beer is a critical parameter for many consumers, as it allows instant classification of beer type - lager, ale, stout - and therefore requires careful control. The color of the foam is to some extent dependent upon bubble size/bubble density, being reliant upon the radii of film curvatures and their thicknesses. The simplest method used to measure colour is by direct comparison with a set of colour standards. This is attractive from the perspective that the human eye is very sensitive to deviations in colour. However, it can prove difficult to create color standards which are not susceptible to change with age. Some liquid standards have been suggested, including solutions of iodine and potassium dichromate as these have colour characteristics reminiscent of commercial beers. It is easily appreciated though that such standards are themselves not stable. For instance the orange dichromate is readily, if only slowly, reduced to green chromium (III). 6. Clarity Beer clarity is readily appraised by the consumer. The visual effects can vary, from a slight dulling of brightness to the observation of discrete particles. Here the discussion will be restricted to the factors which primarily affect the clarity of fresh beer, particularly the interplay between liquids and solids during the various brewing operations. The clarity of fresh beer is dependent on an effective filtration operation. The processes that go before can both help to protect the beer from haze formation during its shelf-life and enhance the filterability of the final beer. 7. Bitterness Beer bitterness, first of all, is ensured by hop. The best types of hop give pleasant bitterness and delicate flavor to it. Microbiological contamination and beer quality The presence of microbiological contaminants during beer production and in-pack not only compromises beer flavour, but also generates haze as the number of bacteria increase. Flavour defects include an increase in acidity, the formation of volatile sulfur compounds, acetaldehyde, phenolics, diacetyl, ethanol and nitrite. The formation of ethanol is also considered to be a product safety issue, particularly in low- or nonalcoholic beers, whilst nitrite is a known hazard. Whilst not dangerous, clearly a hazy beer with significant offflavours is to be avoided. The occurrence of microbiological problems is minimized by continual monitoring, good hygiene, effective cleaning and disinfection, and adequate sterilisation methodology (e.g. pasteurisation, sterile filtration).

References; Hughes, P.S and Baxter, E.D (2001) BEER: QUALITY, SAFETY AND NUTRITIONAL ASPECTS, The Royal Society of Chemistry, First edition, UK, 138pp. Bamforth, C.W (2004) Beer: Health and Nutrition, Blackwell Science Ltd, UK, First edition, 184pp. kellers (2012) About beer, accessed on ; 21. October 2012, http://www.kellers.am/index.php?option=com_content&view=article&id=50&Itemid=54&la ng=en#quality

S-ar putea să vă placă și

- Danisco - Litesse Q A LeafletDocument8 paginiDanisco - Litesse Q A LeafletKapithas EswaranÎncă nu există evaluări

- Reproduction in FishDocument9 paginiReproduction in FishKapithas EswaranÎncă nu există evaluări

- Wi FiDocument14 paginiWi FiKapithas EswaranÎncă nu există evaluări

- Beer Quality CharacteristicsDocument4 paginiBeer Quality CharacteristicsKapithas Eswaran100% (1)

- Samsung TV Model Numbers MeaningDocument3 paginiSamsung TV Model Numbers MeaningKapithas EswaranÎncă nu există evaluări

- Stevia PerceptionsDocument18 paginiStevia PerceptionsKapithas EswaranÎncă nu există evaluări

- Assign Toxi1Document2 paginiAssign Toxi1Kapithas EswaranÎncă nu există evaluări

- WHO Guidelines For Drinking Water PDFDocument564 paginiWHO Guidelines For Drinking Water PDFshekharvkate100% (3)

- 6th Central Pay Commission Salary CalculatorDocument15 pagini6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Sports DrinksDocument2 paginiSports DrinksKapithas EswaranÎncă nu există evaluări

- Danisco - Litesse Q A LeafletDocument8 paginiDanisco - Litesse Q A LeafletKapithas EswaranÎncă nu există evaluări

- FAO - Rice in Human NutritionDocument166 paginiFAO - Rice in Human NutritionKapithas EswaranÎncă nu există evaluări

- (International Consultative Group On Food IrradiatDocument53 pagini(International Consultative Group On Food IrradiatKapithas EswaranÎncă nu există evaluări

- Modern Extraction Methods For Preparation of Bioactive Plant ExtractsDocument19 paginiModern Extraction Methods For Preparation of Bioactive Plant ExtractsKapithas Eswaran100% (1)

- Ice CreamDocument10 paginiIce Creamarchusaran7313Încă nu există evaluări

- Introduction of Palmyrah PalmDocument4 paginiIntroduction of Palmyrah PalmKapithas Eswaran100% (2)

- Safety in Academic Chemistry Laboratories StudentsDocument48 paginiSafety in Academic Chemistry Laboratories Studentsapi-266788121Încă nu există evaluări

- Haccp ManualDocument95 paginiHaccp ManualGuglielmo Miriello100% (3)

- 001 TerasiDocument2 pagini001 TerasiKapithas EswaranÎncă nu există evaluări

- Common Irregular Verb ListDocument4 paginiCommon Irregular Verb Listapi-27488371100% (1)

- Submitted By: Kiran Naz O7-Arid-64 FT 6 SemesterDocument42 paginiSubmitted By: Kiran Naz O7-Arid-64 FT 6 SemesterKiran NiaziÎncă nu există evaluări

- Carbonated BeveragesDocument7 paginiCarbonated BeveragesKapithas EswaranÎncă nu există evaluări

- Ice CreamDocument10 paginiIce Creamarchusaran7313Încă nu există evaluări

- Problems With Paired Preference TestsDocument7 paginiProblems With Paired Preference TestsKapithas EswaranÎncă nu există evaluări

- Potentially Hazardous FoodDocument10 paginiPotentially Hazardous FoodKapithas EswaranÎncă nu există evaluări

- D ValuegDocument17 paginiD ValuegKapithas EswaranÎncă nu există evaluări

- Labelling Requirements For Meat Products CDocument7 paginiLabelling Requirements For Meat Products CKapithas EswaranÎncă nu există evaluări

- D ValuegDocument17 paginiD ValuegKapithas EswaranÎncă nu există evaluări

- Can Anaemia Be Hereditary WDocument6 paginiCan Anaemia Be Hereditary WKapithas EswaranÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Nursing Care Plan For Breast Cancer NCP PDFDocument2 paginiNursing Care Plan For Breast Cancer NCP PDFMaina BarmanÎncă nu există evaluări

- Agriculture's Role in An Age of AbundanceDocument21 paginiAgriculture's Role in An Age of AbundanceNational Press FoundationÎncă nu există evaluări

- Welcome To CIFOR Updated 2014Document55 paginiWelcome To CIFOR Updated 2014Muhamad RismanÎncă nu există evaluări

- MM Module 1 A Prelude To The World of MarketingDocument11 paginiMM Module 1 A Prelude To The World of MarketingAbhishek MukherjeeÎncă nu există evaluări

- Thesis 1-25Document13 paginiThesis 1-25Harry PeterÎncă nu există evaluări

- Evs PDFDocument12 paginiEvs PDFNaitik SinghÎncă nu există evaluări

- Jonathan's Last Day: True FalseDocument2 paginiJonathan's Last Day: True FalseDiego Luis Gonzalez RestrepoÎncă nu există evaluări

- Reviion Sheet 16Document6 paginiReviion Sheet 16tarekmosbahi mosbahiÎncă nu există evaluări

- QuestionnaireDocument8 paginiQuestionnaireMelvin HonorioÎncă nu există evaluări

- Aavin QuestionnaireDocument7 paginiAavin QuestionnaireRama padmavathi75% (8)

- Institutional-Assessment 3Document5 paginiInstitutional-Assessment 3Miko Salvacion BrazaÎncă nu există evaluări

- FinancialStatement 2014 Tahunan BUDI PDFDocument224 paginiFinancialStatement 2014 Tahunan BUDI PDFafidatul fitriaÎncă nu există evaluări

- Jalgaon IIDocument9 paginiJalgaon IIRam K YadavÎncă nu există evaluări

- Kellogg's All-Bran - IPA Case StudyDocument11 paginiKellogg's All-Bran - IPA Case Studyallan61Încă nu există evaluări

- Building System Design Plate 3-Ground Floor PLanDocument1 paginăBuilding System Design Plate 3-Ground Floor PLanLester de GuzmanÎncă nu există evaluări

- Kunjungan Sales 2Document255 paginiKunjungan Sales 2Nana RMSbogorÎncă nu există evaluări

- DairyDocument12 paginiDairyHimanshu SoniÎncă nu există evaluări

- Slides - Polite RequestDocument18 paginiSlides - Polite Requestliandra.araujoÎncă nu există evaluări

- Bryan Babylon Café/Naya International LLCDocument2 paginiBryan Babylon Café/Naya International LLCKBTXÎncă nu există evaluări

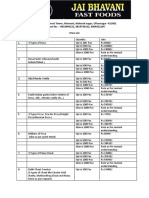

- Jai Bhavani Catering ServiceDocument3 paginiJai Bhavani Catering ServiceLaxmikant TradingÎncă nu există evaluări

- Design and Fabrication of Paddy Cleaning MachineDocument5 paginiDesign and Fabrication of Paddy Cleaning MachineDave RoneÎncă nu există evaluări

- Are You Ready For Food Created by An AI - NotCo Is Now Making Its AI Available To Food Companies - by Mercedes' Lens - Jan, 2023 - MediumDocument5 paginiAre You Ready For Food Created by An AI - NotCo Is Now Making Its AI Available To Food Companies - by Mercedes' Lens - Jan, 2023 - MediumMerce CarrizoÎncă nu există evaluări

- Present Simple and Present ContinuousDocument23 paginiPresent Simple and Present ContinuousLidia Gil González0% (1)

- Baked Mac and CheeseDocument7 paginiBaked Mac and Cheeseapi-551082382Încă nu există evaluări

- Class 12th Chemistry Project On Cleaning Action of SoapsDocument22 paginiClass 12th Chemistry Project On Cleaning Action of SoapsPremlata JoshiÎncă nu există evaluări

- A Case Study On KFCDocument18 paginiA Case Study On KFCManish Singh89% (18)

- Creature Feature Burskan GundarkDocument3 paginiCreature Feature Burskan GundarkSW-FanÎncă nu există evaluări

- Walmart PowerpointDocument25 paginiWalmart PowerpointNikki DargahiÎncă nu există evaluări

- 21 Days of Menus - 975 PDFDocument7 pagini21 Days of Menus - 975 PDFron sharmaÎncă nu există evaluări

- Rules of Subject Verb Agreement Are All You NeedDocument8 paginiRules of Subject Verb Agreement Are All You Needalexandra jacobÎncă nu există evaluări