Documente Academic

Documente Profesional

Documente Cultură

Simover C

Încărcat de

Tomuta StefanDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Simover C

Încărcat de

Tomuta StefanDrepturi de autor:

Formate disponibile

Power Transmission and Distribution

123 / 145 kV Air Insulated Substation

Simover C

Siemens movable circuit breaker - Compact solution

PTD H 2 E1/0605_E50105_W0048_U090_Description_SimoverC.doc

Page 1/12

Power Transmission and Distribution

HERAUSGEGEBEN VON: PUBLISHED BY: SIEMENS AG POWER TRANSMISSION AND DISTRIBUTION GROUP HIGH VOLTAGE SUBSTATIONS DIVISION PTD H 2 D-91050 ERLANGEN

Bei Rckfragen:

TEL.: FAX:

+49 9131 7 33642 +49 9131 7 31858

nderungen vorbehalten. Alle Rechte vorbehalten, insbesondere (auch auszugsweise) die des Nachdrucks, der Wiedergabe durch Kopieren oder hnliche Verfahren. Zuwiderhandlungen verpflichten zum Schadensersatz. Alle Rechte vorbehalten, insbesondere fr den Fall der Patenterteilung oder GM-Eintrag. Subject to change. All rights, including rights of translation, reproduction by printing, copying or similar methods, even of parts are reserved. Offenders are liable to the payment of damages. All rights are reserved in the event of the grant of patent or registration of a utility model or design.

Stand: 06.2006 Erstellt: PTD H 2 E1 Freigabe: PTD H 2 E

Lingner Nhrig

PTD H 2 E1/0605_E50105_W0048_U090_Description_SimoverC.doc

Page 2/12

Power Transmission and Distribution

1 Table of contents

1 2 3 4 5 6

6.1 6.2 6.3 6.4 6.5 6.6 6.7

TABLE OF CONTENTS DESCRIPTION FUNCTION THE ADVANTAGES IN ONE VIEW TECHNICAL DATA SIMOVER C MODULE DESCRIPTION

Circuit breaker Current transformer Ruhrtal Contact system Built-on Earthing switch mounted at instrument transformer (principle arrangement) Steel structure with driving unit Local control cubicle Transportation vehicle

3 4 4 5 6 7

8 8 9 9 10 11 11

MAINTENANCE

12

PTD H 2 E1/0605_E50105_W0048_U090_Description_SimoverC.doc

Page 3/12

Power Transmission and Distribution

2 Description

For 123 and 145 kV substations with single busbar system a suitable compact alternative is the SimoverC arrangement (Siemens movable circuit breaker). In this kind of switchgear busbar- and outgoing disconnector become inapplicable (switchgear without disconnectors). A common steel frame is the bases for all components necessary for a reliable operation. The movable circuit breaker contains the following mainly type tested standard components:

Circuit breaker type 3AP1 Disconnector contact system DBF Instrument transformer for protection- and measuring purposes Local control system Earthing switch (OHL-connection bays)

Within the client receives all components which are needed for the full function of the Simover C from one source, thus extra orders have become inapplicable. As a result the coordination also takes considerably less time. All systems are pre-assembled as much as possible. So the movable circuit breaker can be mounted efficient and faultless with the help of the installation instructions at the construction site.

3 Function

The isolating distance is reached with the moving of the circuit-breaker on the swingstructure, similar to the well-known withdrawable-unit design technique of medium voltage switchgears. In disconnected position, busbar, circuit-breaker and outgoing circuit are separated from each other by a good visible isolating distance. A drive unit ensures the uninterrupted constant moving motion to the both end positions. The circuit-breaker can only be operated in the ON-position. Mobility with switched-on circuit breaker is impossible. A faulty moving motion, which would be equal to operating a disconnector under load, is interlocked. Also with a possible malfunction of the position switch, respectively travel interruptions between disconnected position and operating position, the operation of the circuit-breaker is stopped.

PTD H 2 E1/0605_E50105_W0048_U090_Description_SimoverC.doc

Page 4/12

Power Transmission and Distribution

4 The advantages in one view

Reduction of total costs compared with the conventional switchbay design. Due to the fact that the control cubicle is directly mounted onto the supporting frame with local operation, interlocking and protection devices, the movable circuit breaker is on principle with a auxiliary supply ready for operation. Because the control cubicle is located at operation operation/control of the movable circuit breaker is possible. height, a trouble-free

An eventually necessary modernisation of the control room is not really necessary because of the integrated control cubicle and can occur at a later point of time. The assembling can be done by the user himself at site. No special erector is needed only the final commissioning and adjustment of the contact system has to be done according to installation instructions. A reduction of required space up to approximately 50% compared with conventional switchbays is achieved because of the compact construction of the movable circuit breaker. The application as an indoor switchbay is possible. Short installation time needed at the construction site because of the pre-assembling at factory. Short terms of delivery because of standardised design as well as using standard type tested components. Because of standard components like circuit breaker 3 AP1 FG / FI no special education for the local staff is necessary

PTD H 2 E1/0605_E50105_W0048_U090_Description_SimoverC.doc

Page 5/12

Power Transmission and Distribution

5 Technical data

Rated Voltage: Rated lightning impulse withstand voltage: Rated current: Short circuit current Rated peak withstand current: Auxiliary voltage (Heater): Control voltage: Drive unit: Creepage distance: Max. Altitude Ambient temperature range: 145 kV 650 kV 1600 A 40 kA, 3 s 108 kA 230 V AC, single phase 110 V DC (others on request) 400/230 V AC 25 mm / kV < 1000 m -25 C / + 40 C

PTD H 2 E1/0605_E50105_W0048_U090_Description_SimoverC.doc

Page 6/12

Power Transmission and Distribution

6 Simover C module description

Each module of the movable Circuit breaker SimoverC consists of: Section 6.1 6.2 6.3 6.4 6.5 6.6 Quantity 1 pc. 3 pcs 1 set 1 set 1 set 1 pc 1 set 3 pcs 1 set 1 set Description 145 kV Circuit Breaker 3AP1FI-145 kV with 1 spring operating mechanism and suitable for single and three phase autoreclosing Current transformer e.g Trench, IOSK 145 or similar Ruhrtal Contactsystem Built-on earthing switch, motor or manual operated, manufacturer Ruhrtal Motive unit Local control cubicle with all necessary equipment for the electrical controlling and electrical interlocking. Position switches (magnetic) Post insulators C6-650 Tubular Busbar conductors and connectors Steel structures and fixing material

PTD H 2 E1/0605_E50105_W0048_U090_Description_SimoverC.doc

Page 7/12

Power Transmission and Distribution

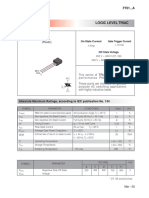

6.1

Circuit breaker

6.2

Current transformer

PTD H 2 E1/0605_E50105_W0048_U090_Description_SimoverC.doc

Page 8/12

Power Transmission and Distribution

6.3

Ruhrtal Contact system

6.4

Built-on Earthing switch mounted at instrument transformer (principle arrangement)

PTD H 2 E1/0605_E50105_W0048_U090_Description_SimoverC.doc

Page 9/12

Power Transmission and Distribution

6.5

Steel structure with motive unit and high voltage equipment

PTD H 2 E1/0605_E50105_W0048_U090_Description_SimoverC.doc

Page 10/12

Power Transmission and Distribution

6.6

Local control cubicle

6.7

Transportation vehicle

If required a transportation vehicle can be provided. The Circuit Breaker can be moved from the closed position towards the open position and further to spot the CB on the support of the vehicle. After moving the motive unit back to closed position the CB can be lowered and move away on the vehicle. The shut-down of the busbar is not required. For moving a plain surfaced access way is desirable. If there is gravel or another surface a temporary road way system (e.g. perforated steel panels) can be used.

PTD H 2 E1/0605_E50105_W0048_U090_Description_SimoverC.doc

Page 11/12

Power Transmission and Distribution

7 Maintenance

All equipment is designed and manufactured for highest reliability with low-maintenance and a use under severe operating conditions. The effort on maintenance depends on the locations of installation. In a clean environment allows a perfect operation above several years. A high polluted location requires more frequent maintenance work. The maintenance schedule for normal environment conditions: A X X X X X X X X

A Checks

1)

B Functional test Tightening of bolts

Maintenance service General visual inspection of all components

Interval 2 years 2 years 2 years 2 years1) 2 years 2 years1) 2 year1) 5 years1)

Greasing of all link joints of the motive unit Cleaning and degreasing of all insulators Cleaning and degreasing of main contacts system and new greasing Cleaning and new greasing of spindles Draining of gear oil, cleaning acc. to manufacturer description and refilling

B Maintenance

Maintenance intervals 2 years or 2000 operating cycles

For the Circuit breaker please consider the maintenance schedule of the manufacturer.

PTD H 2 E1/0605_E50105_W0048_U090_Description_SimoverC.doc

Page 12/12

S-ar putea să vă placă și

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusDe la EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusÎncă nu există evaluări

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document19 paginiInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768FeDe Aavina Glez100% (1)

- Samples Instrumentation KKS EnglishDocument143 paginiSamples Instrumentation KKS EnglishTomuta StefanÎncă nu există evaluări

- lm386 PDFDocument11 paginilm386 PDFNicolás MoraÎncă nu există evaluări

- Kit NEXYS To APM303 - Install Procedure-EnglishDocument7 paginiKit NEXYS To APM303 - Install Procedure-Englishzawmintun zpeÎncă nu există evaluări

- Masterpact: Installation RecommendationsDocument16 paginiMasterpact: Installation RecommendationsAsif ShahÎncă nu există evaluări

- Circuit Protection Selection: Fuji Electric Ul 489 Rated Molded Case Circuit Breakers (MCCBS)Document4 paginiCircuit Protection Selection: Fuji Electric Ul 489 Rated Molded Case Circuit Breakers (MCCBS)oadipphone7031Încă nu există evaluări

- Installation and Maintenance: This Manual Is To Be Given To The End UserDocument12 paginiInstallation and Maintenance: This Manual Is To Be Given To The End UserHoang GiangÎncă nu există evaluări

- VT GuardDocument2 paginiVT GuardHamed GolzadehÎncă nu există evaluări

- Owners Manual Kubota Silent-Comap Amf20Document27 paginiOwners Manual Kubota Silent-Comap Amf20CarlosÎncă nu există evaluări

- SupportServices Motors PDFDocument92 paginiSupportServices Motors PDFMarKusELNÎncă nu există evaluări

- Designing Service Entrance Panelboard EquipmentDocument99 paginiDesigning Service Entrance Panelboard EquipmentSoc Saballa100% (1)

- Franklin SubMonitorDocument20 paginiFranklin SubMonitor15265562Încă nu există evaluări

- ABB 4028enDocument4 paginiABB 4028enThangco HutÎncă nu există evaluări

- Sivacon 8PT-Busbar Rear-Technical CatalogueDocument69 paginiSivacon 8PT-Busbar Rear-Technical CatalogueLaurentiu CatalinÎncă nu există evaluări

- PowerWizard 1 (GB) (0208) PDFDocument2 paginiPowerWizard 1 (GB) (0208) PDFايمن الهدام100% (1)

- HCI634H - Winding 311 and 312: Technical Data SheetDocument9 paginiHCI634H - Winding 311 and 312: Technical Data Sheet3efooÎncă nu există evaluări

- Sdmo V500C2Document5 paginiSdmo V500C2ChristopheÎncă nu există evaluări

- FRENIC Ace Solar Pumping ManualDocument78 paginiFRENIC Ace Solar Pumping ManualSINES FranceÎncă nu există evaluări

- 2307882Document116 pagini2307882Jimmy McynsÎncă nu există evaluări

- Hitachi P50H401 Service ManualDocument139 paginiHitachi P50H401 Service ManualMoto0524Încă nu există evaluări

- AVR R180 DatasheetDocument20 paginiAVR R180 Datasheetjean sanchezÎncă nu există evaluări

- Conzerv 6438Document10 paginiConzerv 6438Pur WantoÎncă nu există evaluări

- Caterpillar XQ20 Towable Diesel Generator SetDocument5 paginiCaterpillar XQ20 Towable Diesel Generator SetMacAllister MachineryÎncă nu există evaluări

- TLG 12esx PDFDocument9 paginiTLG 12esx PDFGeiler Benitez PiñaÎncă nu există evaluări

- Phase Sequence Relay PFN Mecotron: OperationDocument1 paginăPhase Sequence Relay PFN Mecotron: Operationhonafa- R.O.N.OÎncă nu există evaluări

- AEG GC14 K ACBsDocument18 paginiAEG GC14 K ACBsPaulo H TavaresÎncă nu există evaluări

- Bac06 Series (BAC06A/BAC06V) Switch-Type Battery Charger: User ManualDocument6 paginiBac06 Series (BAC06A/BAC06V) Switch-Type Battery Charger: User ManualJermaine PeñaÎncă nu există evaluări

- Hci634y 312Document9 paginiHci634y 312Nos GoteÎncă nu există evaluări

- Automatic Transfer SwitchDocument50 paginiAutomatic Transfer SwitchCpe_CarloÎncă nu există evaluări

- RM35 UA... Voltage Control, Single-Phase and D.C.Document4 paginiRM35 UA... Voltage Control, Single-Phase and D.C.Ketha LeroyÎncă nu există evaluări

- 1010KVADocument6 pagini1010KVAK RameshÎncă nu există evaluări

- DSEP100 PC Software ManualDocument30 paginiDSEP100 PC Software ManualSon DoÎncă nu există evaluări

- KP-C500P (KTA19-G3A) Generating Set Technical Data SheetDocument5 paginiKP-C500P (KTA19-G3A) Generating Set Technical Data SheetMario CastroÎncă nu există evaluări

- Features Description: Deep Sea Electronics Amf and InstrumentationDocument4 paginiFeatures Description: Deep Sea Electronics Amf and Instrumentationabduallah muhammad100% (1)

- Datakom D700 PRESENTATION PDFDocument44 paginiDatakom D700 PRESENTATION PDFAlexÎncă nu există evaluări

- ABB Drives Rtac-01 Pulse Encoder Interface Module User's ManualDocument23 paginiABB Drives Rtac-01 Pulse Encoder Interface Module User's ManualJohn SimancaÎncă nu există evaluări

- Masterpact NW-NTDocument184 paginiMasterpact NW-NTCarito Ahumada100% (1)

- Automatic Engine Control For John Deere: Ecu-Can70BcDocument2 paginiAutomatic Engine Control For John Deere: Ecu-Can70BcCarlos Andrés Marín ArcosÎncă nu există evaluări

- Thyristors 3Document30 paginiThyristors 3afzal ansariÎncă nu există evaluări

- Esm-7710 Man Env04Document44 paginiEsm-7710 Man Env04itsirc67Încă nu există evaluări

- Auto Start & Auto Mains Failure Control Modules: GensetDocument3 paginiAuto Start & Auto Mains Failure Control Modules: Gensetrazaq athabÎncă nu există evaluări

- Toshiba PLCDocument10 paginiToshiba PLCMohsin RazaÎncă nu există evaluări

- EZM-9930 en MDocument48 paginiEZM-9930 en MFawzi AlzubairyÎncă nu există evaluări

- Datakom DKG109 Control Auto Start Panel Engine GensetDocument46 paginiDatakom DKG109 Control Auto Start Panel Engine GensetWira Karya DieselÎncă nu există evaluări

- Khenkikian Avr210m 20aDocument2 paginiKhenkikian Avr210m 20aSreegith ChelattÎncă nu există evaluări

- QJ71C24N PDFDocument358 paginiQJ71C24N PDFalbertoÎncă nu există evaluări

- ss5k3 Manual PDFDocument3 paginiss5k3 Manual PDFmarvin17100% (1)

- Carregador CCL Sentinel 150Document8 paginiCarregador CCL Sentinel 150José Da Silva MataÎncă nu există evaluări

- Controls: Powerwizard 2.0 - Digital Control PanelDocument2 paginiControls: Powerwizard 2.0 - Digital Control PanelEduardo DavidÎncă nu există evaluări

- MD556 DDocument3 paginiMD556 DAlex Tello vÎncă nu există evaluări

- Excel ApodysDocument4 paginiExcel ApodysjeremiahÎncă nu există evaluări

- Manual Avr Leroy Somer Mod. R 181 - enDocument8 paginiManual Avr Leroy Somer Mod. R 181 - enMiguel Angel Pavon CarbonellÎncă nu există evaluări

- Sepam 2000Document12 paginiSepam 2000Anonymous KHPe40mSFrÎncă nu există evaluări

- Catalogue Ats NT PDFDocument60 paginiCatalogue Ats NT PDFmiguel angel pavonÎncă nu există evaluări

- Applications: Certified ISO 9001:2008 / ISO 14001:2004Document2 paginiApplications: Certified ISO 9001:2008 / ISO 14001:2004WET 2016Încă nu există evaluări

- AVK Voltage Regulator COSIMAT C2Document1 paginăAVK Voltage Regulator COSIMAT C2ibrahim salemÎncă nu există evaluări

- SD8 ManualDocument4 paginiSD8 ManualWaqar AhmedÎncă nu există evaluări

- MUS108 Mains de Coupling Device eDocument9 paginiMUS108 Mains de Coupling Device ejjcanoolivaresÎncă nu există evaluări

- Generator Operation ManualDocument31 paginiGenerator Operation Manuallliu yunÎncă nu există evaluări

- Shinmyung 2005 KompletDocument74 paginiShinmyung 2005 KompletJurgen CokuÎncă nu există evaluări

- 3AP1 DTC en - V9 - Epost PDFDocument8 pagini3AP1 DTC en - V9 - Epost PDFjoan75Încă nu există evaluări

- 1VGA671031 - UniGear ZVC-At LeafletDocument2 pagini1VGA671031 - UniGear ZVC-At Leafletnbashir786Încă nu există evaluări

- Micom C264C / C264 Modular Bay Controller - MBC: Ieds GatewayDocument2 paginiMicom C264C / C264 Modular Bay Controller - MBC: Ieds GatewayTomuta StefanÎncă nu există evaluări

- Battery Alarm 300Document8 paginiBattery Alarm 300Tomuta StefanÎncă nu există evaluări

- Vigilohm IM10, IM20 User Manual PDFDocument60 paginiVigilohm IM10, IM20 User Manual PDFTomuta StefanÎncă nu există evaluări

- NDV1600 2500 - Komplett Engl PDFDocument19 paginiNDV1600 2500 - Komplett Engl PDFTomuta StefanÎncă nu există evaluări

- Micom C964C / C964 Modular Remote Terminal Unit - Rtu: Ieds GatewayDocument2 paginiMicom C964C / C964 Modular Remote Terminal Unit - Rtu: Ieds GatewayTomuta StefanÎncă nu există evaluări

- Is300enbr EaDocument12 paginiIs300enbr EaTomuta StefanÎncă nu există evaluări

- Istat 300 Electrical TransducersDocument8 paginiIstat 300 Electrical TransducersTomuta StefanÎncă nu există evaluări

- TA Series Moulded Case Current TransformersDocument8 paginiTA Series Moulded Case Current TransformersTomuta StefanÎncă nu există evaluări

- Eriiends AaDocument1 paginăEriiends AaTomuta StefanÎncă nu există evaluări

- Traction InstrumentsDocument8 paginiTraction InstrumentsTomuta StefanÎncă nu există evaluări

- Cooper SectionalizingDocument8 paginiCooper SectionalizingTomuta StefanÎncă nu există evaluări

- Unified SolutionDocument8 paginiUnified SolutionTomuta StefanÎncă nu există evaluări

- Micom E10: Indications and ControlsDocument2 paginiMicom E10: Indications and ControlsTomuta StefanÎncă nu există evaluări

- Norma CelDocument2 paginiNorma CelTomuta StefanÎncă nu există evaluări

- DIVAC Breaker 13200-002Document2 paginiDIVAC Breaker 13200-002Tomuta StefanÎncă nu există evaluări

- Bay Module Protection GatewayDocument2 paginiBay Module Protection GatewayTomuta StefanÎncă nu există evaluări

- Offer Unitech Solutions W1314100Document8 paginiOffer Unitech Solutions W1314100Tomuta StefanÎncă nu există evaluări

- Stepup StepdownDocument18 paginiStepup StepdownTomuta StefanÎncă nu există evaluări

- Divac Instruction Manual ENGDocument21 paginiDivac Instruction Manual ENGTomuta StefanÎncă nu există evaluări

- CCR Control System Interface Handbook - 6jun2012Document17 paginiCCR Control System Interface Handbook - 6jun2012Tomuta StefanÎncă nu există evaluări

- Sma SMC 9000tl-11000tl enDocument2 paginiSma SMC 9000tl-11000tl enTomuta StefanÎncă nu există evaluări

- Vac On Step EnglDocument4 paginiVac On Step EnglTomuta StefanÎncă nu există evaluări

- 101-Enclosures & Junction BoxesDocument216 pagini101-Enclosures & Junction BoxesDan IonescuÎncă nu există evaluări

- EnclosurecatalogueDocument153 paginiEnclosurecatalogueTomuta StefanÎncă nu există evaluări

- Slides 1, Power Electronics Circuits Devices and Applications 3ed Ed M H RashidDocument43 paginiSlides 1, Power Electronics Circuits Devices and Applications 3ed Ed M H Rashidjohnyrock07100% (2)

- Ft0107ma PDFDocument4 paginiFt0107ma PDFAnatoly WolkoffÎncă nu există evaluări

- Darlington: Silicon NPN Triple Diffused Planar TransistorDocument1 paginăDarlington: Silicon NPN Triple Diffused Planar TransistorsilvertronicÎncă nu există evaluări

- Electronics RegularDocument169 paginiElectronics RegularNazeerÎncă nu există evaluări

- MR-1010R2 Im Eng 0 PDFDocument72 paginiMR-1010R2 Im Eng 0 PDFRobin LalÎncă nu există evaluări

- RTS151KEY (A) Remote Test Station: Installation and Maintenance InstructionsDocument2 paginiRTS151KEY (A) Remote Test Station: Installation and Maintenance InstructionsGerardo GonzalezÎncă nu există evaluări

- Microprocessor Supervisory Circuit: Ma Max)Document6 paginiMicroprocessor Supervisory Circuit: Ma Max)Ivan AlyaevÎncă nu există evaluări

- 10 Dermadrive GD 113 DermatomoDocument36 pagini10 Dermadrive GD 113 DermatomoGonzalo RoldanÎncă nu există evaluări

- MV, LV, Control & Bare (Specification)Document13 paginiMV, LV, Control & Bare (Specification)- Docs Tài liệuÎncă nu există evaluări

- AAMCS S-Band AmplifierDocument14 paginiAAMCS S-Band AmplifierMazlum ÜnalÎncă nu există evaluări

- D.I.Y. Contact MicrophoneDocument8 paginiD.I.Y. Contact MicrophonenoseÎncă nu există evaluări

- Method Statement of Stringing Activities at PK Bari - 132 KV: Prior To Start The Stringing ActivityDocument2 paginiMethod Statement of Stringing Activities at PK Bari - 132 KV: Prior To Start The Stringing ActivitySujit Kumar pahiÎncă nu există evaluări

- SW-505DS 505DWDocument8 paginiSW-505DS 505DWหนึ่ง สกลÎncă nu există evaluări

- Em + EU R 10 EM + 7 0,025: QuestãoDocument6 paginiEm + EU R 10 EM + 7 0,025: QuestãoWilliam LeiteÎncă nu există evaluări

- Forum Diskusi 4-2 (Resistance Circuits) - YosuaDocument5 paginiForum Diskusi 4-2 (Resistance Circuits) - YosuaYosua Kharisma Adi SantosoÎncă nu există evaluări

- APFCDocument12 paginiAPFCpandiÎncă nu există evaluări

- 11 KV Network ElementDocument11 pagini11 KV Network ElementKuldip PrasadÎncă nu există evaluări

- SG AS Servo Driver User MnualDocument129 paginiSG AS Servo Driver User MnualKamran ManafzadeÎncă nu există evaluări

- TX 500/S TX 1000/S "PLUS SERIES": FM Broadcasting ExciterDocument4 paginiTX 500/S TX 1000/S "PLUS SERIES": FM Broadcasting Exciterguestisor100% (1)

- fw450 Helicopter ManualDocument8 paginifw450 Helicopter ManualMaria luizaÎncă nu există evaluări

- AccuLoad III X InstallationDocument89 paginiAccuLoad III X InstallationTecnico A Lazaro CardenasÎncă nu există evaluări

- DR Ahmed Heikal Lecture 4 PDFDocument47 paginiDR Ahmed Heikal Lecture 4 PDFArman KhanÎncă nu există evaluări

- 4-CA3250P25K15L3T1E5A80-DW014H-electrical Wiring DiagramDocument1 pagină4-CA3250P25K15L3T1E5A80-DW014H-electrical Wiring DiagramJesus gomez corvalanÎncă nu există evaluări

- SFC4 AutronicaDocument1 paginăSFC4 AutronicaFab SgnÎncă nu există evaluări

- Control IC For Single-Ended and Push-Pull Switched-Mode Power Supplies (SMPS) TDA 4700 TDA 4718Document21 paginiControl IC For Single-Ended and Push-Pull Switched-Mode Power Supplies (SMPS) TDA 4700 TDA 4718Wellison RodriguesÎncă nu există evaluări

- Easy Modicon M200 - TM200CE40RDocument13 paginiEasy Modicon M200 - TM200CE40RSanja TinaÎncă nu există evaluări