Documente Academic

Documente Profesional

Documente Cultură

Steel Properties

Încărcat de

Rob MorienDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Steel Properties

Încărcat de

Rob MorienDrepturi de autor:

Formate disponibile

More About Steel Alloys

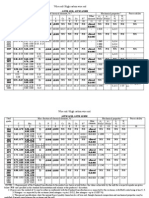

Chemical Composition Limits (%) of Steel AlloysIron makes up the remaining percentage. Warning: Chemical properties are not guaranteed and are intended only as a basis for comparison. Data is not for design purposes.

Grade A36 1018 1045 1065 1074/1075 1095 1117 1144 12L14 1215 4130 4140/4142 Modified 4140 (ETD-150) 41L40 4150 4340 8620 E52100 A2 A6 D2 H13 M2/M7 M4

Carbon 0.25-0.29% 0.15-0.20% 0.43-0.50% 0.60-0.70% 0.75% 0.90-1.03% <2%

Manganese 0.6-1.20% 0.60-0.90% 0.60-0.90% 0.60-0.90% 0.57% 0.30-0.50% <2%

Silicon 0.15-0.40% 0.15-0.30% 0.15-0.30% 0.15-0.30% 0.17% 0.15-0.30% <1%

Phosphorus 0.04% 0-0.04% 0-0.04% 0-0.035% 0.013% 0-0.04% <1%

Sulfur 0.05% 0-0.05% 0-0.05% 0-0.045% 0-0.015% 0-0.05%

Chromium None None None None 0.014% None None None None None 0.80-1.10% 0.80-1.10%

Molybdenum None None None None None None None None None None 0.15-0.25% 0.15-0.25%

Vanadium None None None None None None <1% None None None None None

<1% 0.240.40-0.48% 1.35-1.65% 0.15-0.30% 0-0.04% 0.33% 0.260.15% 0.85-1.15% None 0.04-0.09% 0.35% 0.260.09% 0.75-1.05% None 0.04-0.09% 0.35% 0.400.28-0.33% 0.060% 0.20-0.35% 0-0.04% 0-0.04% 0.38-0.45% 0.75-1.00% 0.15-0.30% 0-0.04% 0-0.04%

Other 0-0.20% Copper None None None 0.012% Nickel None <1% Aluminum, <1% Bismuth, and <1% Colombian Trace Nitrogen 0.15-0.35% Lead None None None

0.40% min. 0.38-0.43% 0.48-0.53% 0.38-0.43% 0.18-0.23% 0.95-1.10% 0.95-1.05% 0.65-0.75%

0.75-1.00% 0.75-1.00% 0.75-1.00% 0.60-0.80% 0.70-0.90% 0.25-0.45% 0-1.00% 1.80-2.45%

0.20-0.35% 0.15-0.30% 0.20-0.35% 0.20-0.35% 0.20-0.35% 0.20-0.35% 0-0.50% 0.20-0.40%

0-0.035% None 0-0.04% 0-0.025% 0-0.04% 0-0.025% None None

0-0.04% None 0-0.04% 0-0.025% 0-0.04% 0-0.025% None None None None None 0.060.22%

1.40-1.60% 0-0.60% 0-0.60% None 0.32-0.45% 0.20-0.50% 0.80-1.20% None 0.80-1.02% 0.20-0.35% 0.20-0.40% None 1.42% 0.30-0.70% None None

0.80-1.10% 0.80-1.10% 0.80-1.10% 0.70-0.90% 0.40-0.60% 1.30-1.60% 4.75-5.50% 0.90-1.10% 11.0013.00% 4.75-5.50% 3.50-4.40% 4.00%

0.15-0.25% 0.15-0.25% 0.18-0.25% 0.20-0.30% 0.15-0.25% None 0.90-1.40% 1.20-1.50% 0.70-1.20% 1.10-1.75% 4.75-9.10% 5.25%

None None None None None None 0.15-0.50% None

None 0.15-0.35% Lead None 1.65-2.00% Nickel 0.40-0.70% Nickel None 0-0.30% Nickel None

0-1.10% 0-0.30% Nickel 0.80-1.20% 0-0.30% Nickel 1.50-6.75% 1.75-2.20% Tungsten 5.50% Tungsten 1.40-1.60% Tungsten, 1.05-1.25% 7.75-8.25% Cobalt 1.00% None 0.40-0.60% 0.-0.25% Tungsten None None 0-0.50% None 0-0.30% None 0-0.10% max. None None None None None 4.00%

M42 M50 O1 P20 S2 S7 W1 Cast Gray Iron

1.05-1.13% 0.15-0.30% 0.15-0.40% None 0.81% 0.25% 0.20% 0.008% 0.85-1.00% 0.28-0.40% 0.47-0.55% 0.45-0.55% 1.00-1.35% 0.65-0.95% 0.30-0.50% 0.20-0.70% 0.20-0.45% 0.40-0.60% 0.90-1.10% 0.20-1.00% None None 0-0.03% None

None 0.008% None None 0-0.03% None

3.50-4.00% 4.00% 0.40-0.60% 1.65-1.80% None 3.00-3.50%

9.25-9.75% 4.25% None 0.40-0.48% 0.30-0.60% 1.30-1.50%

0.60-1.40% 0.10-0.40% 0.10-0.40% 0-0.025% 2.6-3.75% 0.60-0.95% 1.8-3.0% 0.15-0.35% 2.25-3.0%

Cast Ductile Iron 3.5-3.9%

0-0.025% 0-0.15% max. None 0.07% 0.12% max. max. None None 0.025% 0.05% max. max. None None

Copyright

2007 McMaster-Carr Supply Company. All rights reserved.

Page 1 of 8

Document 88645KAC

More About Steel Alloys

Warning: Physical and mechanical properties are not guaranteed and are intended only as a basis for comparison. Data is not for design purposes. Note: 1 ksi = 1000 psi. Thermal Conductivity Btu/sq. ft./ft./hr./ F @ 212 F (unless noted) Thermal Coefficient of Expansion per F Condition 7.06 106 (68-392 F) 7.5 106 (32 to 752 F) 7.4 106 (32 to 752 F) 7.5 106 (32 to 752 F) Not rated 8.1 106 (70 to 1200 F) Not rated Not rated Not rated Not rated 0.102 cal/sq. cm/cm/ sec./ C (@ 20 C) Not rated 7.6 106 (68 to 752 F) As rolled Annealed Normalized Annealed Normalized Annealed Normalized Not rated Normalized Cold drawn Stress relieved Cold drawn Cold drawn Annealed Normalized Annealed Normalized Quenched and tempered (full hard) 22 24.7 7.67 106 (68 to 752 F) 22 Not rated 23 30 22.3 0.10 cal/sq. cm/cm/ sec./ C (@ 20 C) Not rated 0.102 cal/sq. cm/cm/ sec./ C (@ 20 C) 30 0.102 g/sq. cm/cm/ sec./ C (@ 20 C) 7.1 106 (70 to 572 F) 7.1 106 (70 to 600 F) 6.3 106 (0 to 200 F) Not rated Annealed Normalized As drawn As rolled Annealed Normalized 30 @ 32 F 29.4

Nominal Density, lbs./cu. in. A36 0.284 1018 0.283 1045 0.283 1065 0.283 1074/1075 Not rated 1095 Not rated 30 Not rated Not rated Not rated Not rated 30 22.3 Not rated Not rated Not rated Not rated Not rated Not rated Not rated 18 27 Not rated Not rated 0.283 1117 Not rated 1144 Not rated 12L14 0.284 1215 Not rated 4130 0.283 4140 28 16.3 @ 32 F 28.75 29-30 16.2 @ 32 F 29.4 28-30 15.9 @ 32 F 29-30 15.9 @ 32 F

Modulus of Elasticity, psi 106

Electrical Resistivity, microhm-cm @ 68 F (unless noted)

Tensile Strength, ksi 58-80 60 66 90 95 91 120 Not rated 142 Not rated 115 78 87.5 81.3 97 95 148 257 95 132 150 137.6 100 155

Yield Strength, ksi 36 44 50 55 60 54 65

Elongation %

Hardness, Brinell (unless noted)

18-23

Not rated

35 36

127 135

26 23

180 190

23 16

180 245

Not rated 80 58 105 60 75 52.3 63.3 60.5 95 238 64 93 130 96.8 48 105

Not rated

Not rated

285

Not rated

137

10

229

10

163

15

187

28 25

156 197

26 18

197 302

0.283 4142 0.283 Modified 4140 (ETD-150) 0.283 41L40 0.284 4150 0.283 28-30 28-30

29

510

25 19

195 270

10.5

302

19

235-277

22 13

197 311

(Continued on next page)

Copyright

2007 McMaster-Carr Supply Company. All rights reserved.

Page 2 of 8

Document 88645KAC

More About Steel Alloys

Warning: Physical and mechanical properties are not guaranteed and are intended only as a basis for comparison. Data is not for design purposes. Note: 1 ksi = 1000 psi. Thermal Conductivity Btu/sq. ft./ft./hr./ F @ 212 F (unless noted) Thermal Coefficient of Expansion per F Condition Annealed Normalized Quenched and tempered (full hard) Annealed As drawn Annealed Cold drawn Annealed Quenched and tempered from 1750 F with 1050 F temper 7.91 106 (200 to 1200 F) Quenched and tempered from 1550 F w/ 600 F double temper for 2 hours Not rated 7.9 106 (70 to 900 F) 6.9-7.4 106 (68 to 750 F) 11.6-13.3 16.6 Btu/sq. ft./inch/ hr./ F @ 1200 F 8.1 106 (70 to 800 F) Quenched and tempered from 1825 F w/ 1000 F temper Annealed Quenched and tempered from 2150-2275 F w/ double temper above 900 F Not rated Not rated 6.63 106 (68 to 752 F) Not rated 12.03 6.58 106 (100 to 800 F) Annealed Quenched and tempered from 2200 F w/ double temper above 900 F 29-30 Not rated Not rated 7.0 106 (70 to 800 F)

Nominal Density, lbs./cu. in. 4340 0.283 8620 Not rated E52100 0.23 A2 29 Not rated Not rated 6.9 106 Not rated Not rated Not rated Not rated 29-30 30 @ 120 F 21.67 8.1 106 (0 to 1200 F)

Modulus of Elasticity, psi 106

Electrical Resistivity, microhm-cm @ 68 F (unless noted)

Tensile Strength, ksi 120 180 287 88 110 107 70-103 253

Yield Strength, ksi 80 145 270 80 101 87.5 51 200

Elongation %

Hardness, Brinell (unless noted)

18 8

250 370

11

520

18 15

179 223

17

229

26

Rockwell C18

0.28 A6 0.29 D2 0.28 H13 0.279 M2 0.294 M4 0.288 M7 0.287 31 Not rated 30.5 Not rated 28 Not rated 29-30 Not rated

29.5

Not rated

Not rated

Rockwell C55

292.5

264.3

Rockwell C55

278

214

Rockwell C56

98

74

28

Rockwell B92-99

Not rated

408

Not rated

255

Not rated

60

Not rated

225-255

392.8

Not rated

Not rated

Rockwell C65

(Continued on next page)

Copyright

2007 McMaster-Carr Supply Company. All rights reserved.

Page 3 of 8

Document 88645KAC

More About Steel Alloys

Warning: Physical and mechanical properties are not guaranteed and are intended only as a basis for comparison. Data is not for design purposes. Note: 1 ksi = 1000 psi. Thermal Conductivity Btu/sq. ft./ft./hr./ F @ 212 F (unless noted) Thermal Coefficient of Expansion per F Condition Not rated Not rated Not rated Not rated Annealed Quenched and tempered from 1475 F to 600 F temper Quenched and tempered from 1550 F w/ 1150 F temper 7.6 106 (70 to 800 F) 7.5 106 (100 to 800 F) Quenched and tempered from 1550-1600 F w/ 400 F temper 7.6 106 (70 to 932 F) 16.5 Quenched and tempered from 1725 F w/ 600 F temper 7.64 106 (68 to 932 F) Not rated 30.84 18.68 5.5 106 6.4 106 Quenched and tempered from 1450 F to 400 F temper As cast As cast Not rated Not rated

Nominal Density, lbs./cu. in. M42 0.282 M50 0.281 O1 30-31 Not rated 30 Not rated

Modulus of Elasticity, psi 106

Electrical Resistivity, microhm-cm @ 68 F (unless noted)

Tensile Strength, ksi Not rated Not rated 85 280

Yield Strength, ksi

Elongation %

Hardness, Brinell (unless noted)

Not rated

Not rated

Not rated

Not rated 70 272

Not rated

Not rated

25

185

0.283 P20 0.283 S2 0.281 S7 0.281 W1 0.283 Cast Gray Iron 0.26 Cast Ductile Iron 0.26 20 25 30 18.0 ohm-cir. mil./ft. 29-30 Not rated 30 Not rated Not rated 28-30 Not rated Not rated

31-32

Not rated

Not rated

7.1 106 (100 to 800 F)

Not rated

Rockwell C57-62

144.5

110

18

262-321

330

290

Rockwell C58

285

230

10

Rockwell C55

218

150

11

Rockwell C60

110 microhms cm 75 microhms cm

40 80

Not rated 55

Not rated

241

229

Copyright

2007 McMaster-Carr Supply Company. All rights reserved.

Page 4 of 8

Document 88645KAC

Guidelines for Heat Treating Tool Steel

A2

Hardening: Preheat thoroughly at 1450-1500 F, then raise to a hardening temperature between 1700 and 1800 F, and cool in air to 150 F. For larger sections, use high-end hardness range; for thin or smaller sections, use the lower end. Quench in still air and then temper immediately.

Tempering Data Tempering Temperature As Quenched 300 F 400 F 500 F 600 F 800 F Typical Rockwell Hardness 63.5C-65C 62.5C-64C 61C-62C 59C-59.5C 58C 56C-57C

A6

Hardening: Preheating is unnecessary. Heat to 1550-1625 F and hold until the material is heated throughout. Cool the material in freely circulating air to below 150 F before tempering. Tempering time is 2 hours, but sections larger than 2 should be tempered for a minimum of 1 hour per inch.

Tempering Data Tempering Temperature 300 F 400 F 600 F 800 F 1000 F Typical Rockwell Hardness 60C-61C 58C-59C 55C-56C 52C-53C 48C-49C

Annealing: Heat slowly and uniformly to 1550-1600 F, hold at temperature for 2 hours and then cool slowly at a rate of 40 F per hour maximum.

Annealing: Heat slowly and uniformly to 1400-1425 F. Cool in furnace at a rate of 20 F per hour maximum. Hardness will be 241 Brinell maximum.

D2

Hardening: When heating for hardening, it is necessary to protect the steel with some inert material packed in sealed containers, or to heat it in a well-regulated salt bath or controlled atmosphere furnace. Preheat to 1200 F and hold at this temperature until thoroughly soaked, usually about an hour for each inch of greatest thickness. Heat to 1850 F and hold at this temperature at least 112 hours for each inch of thickness. The pieces may then be removed from the container or furnace and cooled in still air to a temperature of 150 F and tempered immediately. Air blast cooling may be used on heavy sections.

Tempering Data Tempering Temperature 300 F 400 F 500 F 600 F 800 F Typical Rockwell Hardness 63C

H13

Hardening: Heat slowly to 1500 F at a rate not to exceed 200 F per hour. Hold for 1 hour per inch of thickness. Austenitize at 1825-1905 F for 15-40 minutes. Quench in air or in a salt bath held at 1105-1200 F. Hold in the quench until material reaches the temperature of the bath, withdraw, and allow to cool in air.

Tempering Data Tempering Temperature 300 F 500 F 700 F 61C 900 F 59C 1100 F 58C 58C 46C-50C 52C-53C Typical Rockwell Hardness 49C-50C 50C 50C-51C

Annealing: Heat to 1555-1650 F. Hold 1 hour per inch of cross section. Cool slowly in furnace to 1000 F at a rate not to exceed 55 F per hour, after which a faster cooling rate will not affect final hardness. Hardness will be 192-229 Brinell.

Annealing: Packing in some inert material in a sealed container to prevent decarburization is recommended; otherwise, use a controlled atmosphere furnace. Heat slowly to approximately 1650 F and hold at that temperature for about 112 hours for each inch of greatest thickness. Cool slowly at a rate of about 20-25 F per hour to 1000 F, after which it may be allowed to cool down with the furnace. It may also be annealed without slow-cooling in the furnace, provided that after it has reached about 1200 F it is reheated to 1425 F and held at that temperature for 5 hours followed by air cooling.

Copyright

2007 McMaster-Carr Supply Company. All rights reserved.

Page 5 of 8

Document 88645KAC

Guidelines for Heat Treating Tool Steel

M2

Hardening: Preheat slowly to 1350-1550 F and hold until thoroughly heated. Next, heat rapidly to 2150-2275 F. Total heating time varies from a few minutes to a maximum of 15 minutes depending on the size of the piece. Oil quenching is recommended for developing full hardness, although air quenching and quenching in hot salt can also be done. When the material has reached a temperature of 150 to 200 F in the quench, temper immediately. The best tempering range is 10001100 F. Double tempering is recommended.

Tempering Data Tempering Temperature As Hardened 300 F 400 F 600 F 800 F 1000 F 1100 F Typical Rockwell Hardness 64C-65C 64C-65C 62C-63C 61C 61C-62C 64C-65C 63C-64C

M4

Hardening: Preheat to 1500-1550 F. Preheat a second time to 1850-1900 F, which is suggested for high-temperature hardening in a vacuum. Use a high heat of 2150-2200 F for cutting tools. For cold applications, use a temperature of 1876-2125 F. Quench in oil, salt, or atmosphere to 1000-1100 F, then air cool to below 125 F. Vacuum or atmosphere quench between 1850 and 1300 F. This range is critical to achieve optimum heat treat response. Double temper at 1000 F minimum. Triple temper recommended when hardening from 2100 F and higher. Two hours minimum each temper. Air cool to room temperature between tempers.

Tempering Data Tempering Temperature As Quenched 1000 F 1100 F Typical Rockwell Hardness 59.5C-66C 58.5C-66C 54C-62.5C

Annealing: Heat to 1600, hold for 2 hours, then slow cool at 30 F per hour to a maximum of 1000 F. Air or furnace cool to room temperature. Hardness will be 225-255 Brinell.

Annealing: Heat to 1600-1650 F, then cool in a furnace at 30-40 F per hour to 900 F. Air cool. Hardness will be 241 Brinell maximum.

M42

Hardening: Preheat at 1350-1555 F. Preheating time, after all sections of the material have reached equal temperature, should be twice the length of required time required at the austenitizing temperature. Heat rapidly from the preheated temperature to the austenitizing temperature. Austenitize at 2125-2175 F for 2-5 minutes. Quench in oil, air, or salt.

Tempering Data Tempering Temperature As Quenched 200 F 400 600 F 800 F 1000 F 1200 F Typical Rockwell Hardness 64C-65C 63-64C 63C 62C 64C 70C 53C

M50

Hardening: Preheat to 1500 F and equalize. Transfer parts to superheated furnace at 2010 F. Superheat only long enough to allow material to reach temperature of superheated furnace; follow immediately by quenching to room temperature. Then cool material to approximately 105 F and hold for 1 hour. Double temper at 1000 F.

Tempering Data Tempering Temperature As Quenched 900 F 950 F 1000 F 1050 F 1100 F 1150 F 1200 F Typical Rockwell Hardness 64C-65C 60C-62C 61C-63C 62C-64C 61C-63C 60C-62C 55C-58C 53C-56C

Annealing: Heat to 1600-1650 F. Material should be held at temperature for 1 hour per inch of thickness. Cool slowly in the furnace to 1200 F at a rate not to exceed 40 F per hour. Hardness will be 235-269 Brinell.

Annealing: Heat uniformly to 1555-1650 F, then cool slowly at a rate not to exceed 20 F per hour. Hardness will be 235 Brinell.

Copyright

2007 McMaster-Carr Supply Company. All rights reserved.

Page 6 of 8

Document 88645KAC

Guidelines for Heat Treating Tool Steel

O1

Hardening: Heat slowly to 1450-1550 F; hold at temperature for 10-30 minutes. Oil quench; temper according to chart below.

Tempering Data Tempering Data Tempering Temperature As Quenched 300 F 400 F 500 F 600 F 800 F 1000 F Typical Rockwell Hardness 64C-65C 64C-65C 600 F 61C-62C 800 F 58C-59C 1000 F 56C-57C 1200 F 51C-52C 44C 26C 41C 46C 50C Tempering Temperature 400 F Typical Rockwell Hardness 53C

P20

Hardening: Heat to 1500-1650 F, using the higher end for larger pieces. Hold at the hardening temperature for 1 hour per inch of the greatest thickness. Quench in oil to 150 F and temper immediately.

Annealing: Heat to 1400-1500 F and hold for 1 hour per inch of the greatest thickness. Cool at a rate of 40 F per hour to 1000 F, then air cool to room temperature. Hardness will be 212 Brinell max.

Annealing: Heat to 1400-1450 F, cool at a maximum rate of 40 F per hour to 900 F and then air cool. Hardness will be 183-212 Brinell.

S2

Hardening: Heat slowly. Preheat to 1200 F. Austenitize at 15551650 F, hold for 5-20 minutes, then quench in brine (salt water) or water.

Tempering Data Tempering Temperature As Quenched 200 F 400 F 600 F 800 F Typical Rockwell Hardness 58C-62C 57C-61C 56C-58C 54C-55C 49C-50C

S7

Hardening: Preheat thoroughly to 1200-1300 F and raise to an austenitizing temperature of 1700-1750 F in a furnace for 30 minutes per inch of greatest thickness. Sections up to 212 thick may be cooled in air. Sections 212 to 6 thick should be quenched in oil until black (1000 F) then air cooled to 150 F. Sections larger than 6 should be oil quenched to 150 F and tempered immediately. Material should be held at least 2 hours at the tempering temperature before air cooling.

Tempering Data Tempering Temperature 400 F 600 F 800 F 1000 F 1200 F Typical Rockwell Hardness 57C-58.5C 54C 52.5C 50.5C-51.5C 37.5C

Annealing: Heat to 1400-1455 F. Use lower limit for small sections and upper limit for large sections. Holding time varies from approximately 1 hour for small sections to approximately 4 hours for large sections. Cool at a rate not to exceed 40 F per hour. Hardness will be 192-217 Brinell.

Annealing: Heat to 1500-1550 F in an inert material. Hold at temperature for 1-112 hours for each inch of greatest thickness. Cool slowly at a maximum rate of 25 F per hour to below 1000 F, then air cool to a hardness of 187-223 Brinell.

Copyright

2007 McMaster-Carr Supply Company. All rights reserved.

Page 7 of 8

Document 88645KAC

Guidelines for Heat Treating Tool Steel

W1

Hardening: Heat slowly to 1400-1555 F; using temperatures at the upper end of the temperature range will increase hardenability. Austenitize for 10 minutes for small sections; up to 30 minutes for large sections. Quench in agitated water or brine (salt water).

Tempering Data Tempering Temperature As Quenched 300 F 400 F 500 F 600 F 700 F 800 F Typical Rockwell Hardness 66C-67C 64C-65C 61C-62C 58C-59C 54C-55C 50C-51C 46C-47C

Annealing: Heat to 1365-1455 F. Use lower limit for small sections and upper limit for large sections. Holding time varies. Sections up to 1 require at least 20 minutes; 8 sections require 212 hours. For pack annealing, hold for 1 hour per inch of cross section. Cool to 1000 F at a rate not to exceed 50 F per hour, after which controlled cooling is not necessary. Hardness will be 156-201 Brinell.

Cast Gray Iron and Cast Ductile Iron

Hardening: Can be hardened by conventional quench and temper methods.

Tempering Data Tempering Temperature Oil quench 1600 F Typical Rockwell Hardness 50C

Copyright

2007 McMaster-Carr Supply Company. All rights reserved.

Page 8 of 8

Document 88645KAC

S-ar putea să vă placă și

- Indian Standard Steel SectionsDocument9 paginiIndian Standard Steel SectionsAmitava SilÎncă nu există evaluări

- Weight CalculatorDocument5 paginiWeight CalculatorNaveen Kumar PatelÎncă nu există evaluări

- Angles Section WeightDocument2 paginiAngles Section WeightVikas Gupta50% (2)

- En 19Document1 paginăEn 19Parvee K Nakwal100% (1)

- Is 1367 Part 7Document3 paginiIs 1367 Part 7Otavio1230% (1)

- ISMC StandardDocument2 paginiISMC StandardauazarÎncă nu există evaluări

- SS 430, Type 430, WNR 1.4016, UNS S43000, AISI 430, ASTM 430, Grade 430, AFNOR Z8C-17Document3 paginiSS 430, Type 430, WNR 1.4016, UNS S43000, AISI 430, ASTM 430, Grade 430, AFNOR Z8C-17Harish AmpoluÎncă nu există evaluări

- Material EquivalentDocument2 paginiMaterial EquivalentdilipÎncă nu există evaluări

- Weight of The MS PlateDocument8 paginiWeight of The MS PlateprashantÎncă nu există evaluări

- Tool Steel Grade and Standard DesignationDocument7 paginiTool Steel Grade and Standard DesignationMustafa SevimliÎncă nu există evaluări

- Demo Weld Cost Calc XLDocument10 paginiDemo Weld Cost Calc XLKhalid Ahmod ShibleeÎncă nu există evaluări

- C 45Document10 paginiC 45mohsen_267Încă nu există evaluări

- Stainless Steel FastenersDocument3 paginiStainless Steel FastenersStainless Steel FastenersÎncă nu există evaluări

- Thumb Rules For Steel DesignDocument3 paginiThumb Rules For Steel Designpranit_rai100% (1)

- High Carbon Wire RodDocument9 paginiHigh Carbon Wire Rodninganray6316100% (1)

- Is 1367 14 3 2002Document20 paginiIs 1367 14 3 2002rohitsingla4Încă nu există evaluări

- Aluminium WeightDocument30 paginiAluminium WeightEngr.Mmosaad100% (1)

- Training ModuleDocument44 paginiTraining ModulegereÎncă nu există evaluări

- Engineering Steels 1018 Product GuideDocument2 paginiEngineering Steels 1018 Product GuidejangaswathiÎncă nu există evaluări

- Spread Calculation of Rod RollingDocument6 paginiSpread Calculation of Rod RollingSubrata ChakrabortyÎncă nu există evaluări

- MS SAIL TolerancesDocument30 paginiMS SAIL TolerancesAmirthasubash Rajendran100% (1)

- Galvanising ManualDocument199 paginiGalvanising Manualdc12dcÎncă nu există evaluări

- Calculate Product Weight from DimensionsDocument2 paginiCalculate Product Weight from Dimensionssanghvi_mukeshÎncă nu există evaluări

- Atlas 3CR12 DatasheetDocument3 paginiAtlas 3CR12 DatasheettridatylÎncă nu există evaluări

- Jindal Steel Product Catalogue PDFDocument32 paginiJindal Steel Product Catalogue PDFkalaiÎncă nu există evaluări

- Dsc-Disc Springs To DIN 2093 UsDocument6 paginiDsc-Disc Springs To DIN 2093 UsYoe NoesÎncă nu există evaluări

- Cast Iron Types PDFDocument8 paginiCast Iron Types PDFGeorge_Wabag_2014Încă nu există evaluări

- PART 166 What Is Spot WeldingDocument4 paginiPART 166 What Is Spot Weldingravindra_jivaniÎncă nu există evaluări

- 4 STD Data 2011-12 Irrg CGG (16-07-11)Document374 pagini4 STD Data 2011-12 Irrg CGG (16-07-11)Govardhan AlurÎncă nu există evaluări

- Formula of Calculation Weight For S.S Sheet, S.S Circle, SDocument2 paginiFormula of Calculation Weight For S.S Sheet, S.S Circle, SDonald Toledo100% (1)

- Mechanical Design SpreadsheetDocument1 paginăMechanical Design SpreadsheetHoney TiwariÎncă nu există evaluări

- Rolled Steel Beams Indian StandardDocument5 paginiRolled Steel Beams Indian Standardjagadeesh_kumar_20Încă nu există evaluări

- High Tensile Steel SpecificationDocument3 paginiHigh Tensile Steel SpecificationRuano Andreola StumpfÎncă nu există evaluări

- Cast Basalt Information SheetDocument4 paginiCast Basalt Information SheetVijayakumar AtthuluriÎncă nu există evaluări

- Press Brake Metric Tonnage Chart For Air BendingDocument1 paginăPress Brake Metric Tonnage Chart For Air BendingkokyawzawÎncă nu există evaluări

- Expansion JointDocument3 paginiExpansion JointsudipÎncă nu există evaluări

- Stainless Steel Grade Composition ChartDocument8 paginiStainless Steel Grade Composition Chart23OtterÎncă nu există evaluări

- Beam (Isbm, Isjb, Islb) Weight in KG Per MTR: Hot Rolled Steel Sections ChartDocument1 paginăBeam (Isbm, Isjb, Islb) Weight in KG Per MTR: Hot Rolled Steel Sections ChartrajatÎncă nu există evaluări

- Bucket ToothDocument16 paginiBucket Toothjorge CarvalhoÎncă nu există evaluări

- Section Modulus CalculatorDocument14 paginiSection Modulus CalculatorSuyenthan SathishÎncă nu există evaluări

- BS Standard NoDocument35 paginiBS Standard NomvooÎncă nu există evaluări

- Steel Data ChartDocument2 paginiSteel Data Chartsmartcad60Încă nu există evaluări

- Team Trust & Technology - Riddhi Steel & Tube LtdDocument16 paginiTeam Trust & Technology - Riddhi Steel & Tube LtdSimeneh ShiferawÎncă nu există evaluări

- A 488A 488M 01 Welding Qualifications of Procedures and Personnel PDFDocument16 paginiA 488A 488M 01 Welding Qualifications of Procedures and Personnel PDFshakeelahmadjsrÎncă nu există evaluări

- Chapter 5 - Shaft DesignDocument0 paginiChapter 5 - Shaft DesignwanpudinÎncă nu există evaluări

- AISI Type 302 Stainless Steel (UNS S30200) : Chemical CompositionDocument4 paginiAISI Type 302 Stainless Steel (UNS S30200) : Chemical CompositionnagboccaÎncă nu există evaluări

- Nisshin Steel Quality Products GuideDocument26 paginiNisshin Steel Quality Products GuidejonnhlÎncă nu există evaluări

- Carbon Hollow Bar ST 52Document2 paginiCarbon Hollow Bar ST 52JeganeswaranÎncă nu există evaluări

- Chemical Analyses-Stainless Steels Duplex and Special AlloysDocument8 paginiChemical Analyses-Stainless Steels Duplex and Special AlloysStuartÎncă nu există evaluări

- Aisi 4140Document8 paginiAisi 4140ViruzTrisnaÎncă nu există evaluări

- ASTM A312/A358/A778 Pipe Wall Thickness and DimensionsDocument3 paginiASTM A312/A358/A778 Pipe Wall Thickness and DimensionsEdisonÎncă nu există evaluări

- Group: SS COIL/SHEETS (Raw Material) All MC: Item Details Unit Op. Qty. Qty. in Qty. Out Cl. Qty. Rate AmountDocument2 paginiGroup: SS COIL/SHEETS (Raw Material) All MC: Item Details Unit Op. Qty. Qty. in Qty. Out Cl. Qty. Rate AmountDHARMENDRAÎncă nu există evaluări

- Overview of Materials For Low Carbon Steel: CategoriesDocument6 paginiOverview of Materials For Low Carbon Steel: CategoriesAmin Ali AminÎncă nu există evaluări

- Ws - No. C Si MN P S CR Mo Ni NB Ti Ws - No. DIN BS Astm / Aisi Gost % % % % % % % % % % Germany Great Britain USA RussiaDocument1 paginăWs - No. C Si MN P S CR Mo Ni NB Ti Ws - No. DIN BS Astm / Aisi Gost % % % % % % % % % % Germany Great Britain USA RussiamengineeringÎncă nu există evaluări

- Salem Product CatalogueDocument6 paginiSalem Product Cataloguedramilt0% (1)

- Ningbo Scientz Biotechnology Co.,Ltd: SC Series Constant Temperature Water (Oil) Bath With Digital ControlDocument7 paginiNingbo Scientz Biotechnology Co.,Ltd: SC Series Constant Temperature Water (Oil) Bath With Digital ControlYusid AbdullayevÎncă nu există evaluări

- MiniSensors B57861 S861Document14 paginiMiniSensors B57861 S861vkmsÎncă nu există evaluări

- New Mill Cert Format in WordDocument3 paginiNew Mill Cert Format in WordpunujcÎncă nu există evaluări

- Aluminium ExtruderDocument108 paginiAluminium ExtruderGoutam BiswasÎncă nu există evaluări

- Thermal Properties of Aluminium AlloysDocument4 paginiThermal Properties of Aluminium Alloysgopinadh57Încă nu există evaluări

- Lecture 5 COMPUTATIONAL HYDRODYNAMICSDocument21 paginiLecture 5 COMPUTATIONAL HYDRODYNAMICSRob MorienÎncă nu există evaluări

- Lecture 5 COMPUTATIONAL HYDRODYNAMICSDocument21 paginiLecture 5 COMPUTATIONAL HYDRODYNAMICSRob MorienÎncă nu există evaluări

- Mme20110200008 80272865Document9 paginiMme20110200008 80272865Rob MorienÎncă nu există evaluări

- Lecture - 4 - 2nd Law and EntropyDocument29 paginiLecture - 4 - 2nd Law and EntropyRob MorienÎncă nu există evaluări

- Infinite Sequences and SeriesDocument8 paginiInfinite Sequences and SeriesRob MorienÎncă nu există evaluări

- Propeller Moment of InertiaDocument8 paginiPropeller Moment of InertiaRob MorienÎncă nu există evaluări

- Reynold's Number - Flow ExamplesDocument2 paginiReynold's Number - Flow ExamplesRob MorienÎncă nu există evaluări

- Elliptical Loading LHS PDFDocument3 paginiElliptical Loading LHS PDFRob MorienÎncă nu există evaluări

- Flat Plate Drag ForceDocument1 paginăFlat Plate Drag ForceRob MorienÎncă nu există evaluări

- Mathematics - A Course in Fluid Mechanics With Vector FieldDocument198 paginiMathematics - A Course in Fluid Mechanics With Vector FieldprashanthreddyhÎncă nu există evaluări

- Arnolds Chest RoutineDocument1 paginăArnolds Chest RoutineRob MorienÎncă nu există evaluări

- Pin On Disc Tribometer CM 9112 DucomDocument4 paginiPin On Disc Tribometer CM 9112 DucomRob MorienÎncă nu există evaluări

- What Is Cultural AwarenessDocument3 paginiWhat Is Cultural AwarenessEmmaÎncă nu există evaluări

- Derivation of 3d Rotation MatrixDocument5 paginiDerivation of 3d Rotation MatrixRob MorienÎncă nu există evaluări

- Turkey 2Document9 paginiTurkey 2Rob MorienÎncă nu există evaluări

- Vectorsinthe Linear Algebra, Vector Calculus, and Physics PackagesDocument31 paginiVectorsinthe Linear Algebra, Vector Calculus, and Physics PackagesRob MorienÎncă nu există evaluări

- 3 D OscillatorDocument23 pagini3 D OscillatorAniruddh FaujdarÎncă nu există evaluări

- Updated Stresses in Threads 2Document46 paginiUpdated Stresses in Threads 2Christopher GarciaÎncă nu există evaluări

- Design of Lifting and Tailing LugsNetsc001Document30 paginiDesign of Lifting and Tailing LugsNetsc001Tshilidzi Irene Netselo100% (1)

- Propeller Moment of InertiaDocument8 paginiPropeller Moment of InertiaRob MorienÎncă nu există evaluări

- Kinematic Analysis of GearsDocument91 paginiKinematic Analysis of GearsParas ThakurÎncă nu există evaluări

- Navier PDFDocument2 paginiNavier PDFRickyHerreraÎncă nu există evaluări

- DropletDocument9 paginiDropletRob MorienÎncă nu există evaluări

- Aml715 17Document13 paginiAml715 17Rob MorienÎncă nu există evaluări

- Chapter 9Document17 paginiChapter 9Sooraj RajendranÎncă nu există evaluări

- Weld Design by FEADocument11 paginiWeld Design by FEAAdarsh D. KarkiÎncă nu există evaluări

- Gear AnalysisDocument33 paginiGear AnalysisRob Morien100% (1)

- HW1Document9 paginiHW1Rob MorienÎncă nu există evaluări

- Ice Age Trail DistancesDocument1 paginăIce Age Trail DistancesRob MorienÎncă nu există evaluări

- NXC GuideDocument123 paginiNXC GuidehawkstersÎncă nu există evaluări

- Rebound Hammer Test Procedure For Concrete HardnessDocument4 paginiRebound Hammer Test Procedure For Concrete HardnessSite Engineer.2p2Încă nu există evaluări

- F3 Maths 2012 1stexam Paper1Document3 paginiF3 Maths 2012 1stexam Paper1YiuhangLeung100% (2)

- Chemistry Project: To Study The Quantity of Casein Present in Different Samples of MilkDocument14 paginiChemistry Project: To Study The Quantity of Casein Present in Different Samples of Milkveenu68Încă nu există evaluări

- GEC 104 Week 1 Lesson 1 Math Modern WorldDocument4 paginiGEC 104 Week 1 Lesson 1 Math Modern WorldJahnna Marie PomaresÎncă nu există evaluări

- Analysis of Truss Using Abaqus SoftwareDocument7 paginiAnalysis of Truss Using Abaqus SoftwareKarthick NÎncă nu există evaluări

- Improve Steel Quality with Electromagnetic StirrersDocument4 paginiImprove Steel Quality with Electromagnetic Stirrerst_pradipÎncă nu există evaluări

- Chemical Engineering Magazine Abril 2009 PDFDocument108 paginiChemical Engineering Magazine Abril 2009 PDFFélix Vargas Santillán100% (1)

- Design and Manufacturing of Automatic Gear Shifter For BicycleDocument10 paginiDesign and Manufacturing of Automatic Gear Shifter For BicycleMannam RujendraÎncă nu există evaluări

- AP PHYSICS B 1988 MC + AnswersDocument17 paginiAP PHYSICS B 1988 MC + AnswersbastardÎncă nu există evaluări

- Basic Simulation LabDocument69 paginiBasic Simulation LabkamalahasanmÎncă nu există evaluări

- Light Class 7 Science Chapter 15Document11 paginiLight Class 7 Science Chapter 15Gaurav Sethi100% (1)

- 2oo3plus - A New Design of Electro-Hydraulic Safety Controls For Critical ApplicationsDocument6 pagini2oo3plus - A New Design of Electro-Hydraulic Safety Controls For Critical Applicationsultrasonic81Încă nu există evaluări

- 6314Document18 pagini6314Simone RizzoÎncă nu există evaluări

- Fjbzr6wn50 - Class 7 Timetable - Fua 2024Document2 paginiFjbzr6wn50 - Class 7 Timetable - Fua 2024mrs.prernajainÎncă nu există evaluări

- Physics SL Paper 3 TZ2Document20 paginiPhysics SL Paper 3 TZ2Dongjean SeoÎncă nu există evaluări

- Real Gas ThermodynamicsDocument112 paginiReal Gas ThermodynamicsJohn AllenÎncă nu există evaluări

- Applications of Nano Biotechnology in Wastewater Treatment PDFDocument9 paginiApplications of Nano Biotechnology in Wastewater Treatment PDFswaroop_exlncÎncă nu există evaluări

- Reability PDFDocument396 paginiReability PDFMarcelo Ziulkoski100% (1)

- Measuring Elastic Modulus of Beams Using Deflection MethodDocument14 paginiMeasuring Elastic Modulus of Beams Using Deflection MethodHaziq PazliÎncă nu există evaluări

- Curriculum-Of Mathematics Government College Women University, SialkotDocument119 paginiCurriculum-Of Mathematics Government College Women University, SialkotHuzaifa GurmaniÎncă nu există evaluări

- A Study of Manufacturing of Steam TurbinesDocument40 paginiA Study of Manufacturing of Steam TurbinesSaketh Varma MudunuriÎncă nu există evaluări

- Francis Bacon, Logic of SensationDocument2 paginiFrancis Bacon, Logic of SensationShrankhla NaryaÎncă nu există evaluări

- Datasheet MPX5100DPDocument16 paginiDatasheet MPX5100DPKemahyanto Exaudi SiahaanÎncă nu există evaluări

- Introduction To Tribology and Tribological ParametersDocument13 paginiIntroduction To Tribology and Tribological ParametersEsteban CorderoÎncă nu există evaluări

- Thermal Engineering PDFDocument76 paginiThermal Engineering PDFKartik KuriÎncă nu există evaluări

- Study Guide For Mid-Term 3 SolutionsDocument8 paginiStudy Guide For Mid-Term 3 Solutionskuumba0% (3)

- Precast BeamDocument8 paginiPrecast BeamMahmoud ShakerÎncă nu există evaluări

- The D and F Block Elements PDFDocument8 paginiThe D and F Block Elements PDFTr Mazhar PunjabiÎncă nu există evaluări

- The Physics of Lorentz Transformation (A Simple Derivation of Lorentz Transformation)Document5 paginiThe Physics of Lorentz Transformation (A Simple Derivation of Lorentz Transformation)Glen PeachÎncă nu există evaluări

- Magnetic Field Intensity (H)Document5 paginiMagnetic Field Intensity (H)M HASIN ISHMAM JEETÎncă nu există evaluări