Documente Academic

Documente Profesional

Documente Cultură

42 Letical

Încărcat de

amir_hossein858Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

42 Letical

Încărcat de

amir_hossein858Drepturi de autor:

Formate disponibile

269

Technical solutions of Bassara Dam due to unfavorable foundation conditions

Die technische Lsung fr den Bassara-Staudamm aufgrund der ungnstigen Grndungsbedingungen

Vicko Letica, Vladislav Skoko, Biljana Trajkovic

Abstract

The Bassara Dam site is located in north-eastern part of Iraq. The primary role of this 67 m high dam is to provide reservoir storage for irrigation purposes. According to the foundation conditions at the dam site, a design solution of combined RCC and gravel fill dam was elaborated. Planning, Final Design and Tender documentations were done by JV of ITSC-IK Co (UK-Serbia) and Stucky Co (Swiss). Keywords: Dam, RCC, geology conditions.

Zusammenfassung

Der Bassara-Staudamm liegt im nordstlichen Teil des Iraks. Die Hauptaufgabe dieses 67 m hohen Dammes ist es, Speicherraum fr die landwirtschaftliche Bewsserung zur Verfgung zu stellen. Wegen der Grndungsbedingungen an der zuknftigen Sperrenstelle ist der Damm als eine Kombination aus einem RCC (Roller Compacted Concrete Walzbeton) Damm und einem Steinschttdamm geplant worden. Planung, Final Design und Ausschreibungsunterlagen wurden in Zusammenarbeit von ITSC-IK Co (UK-Serbien) und der Stucky Co (Schweiz) erstellt..

Introduction

Bassara project site is located in north-eastern part of Iraq, on the Tawooq Chai river, one of three main tributaries of the Adhaim river. It is about 20 km far from Sulaimaniya and 40 km upstream of Qadir Karam. Bassara Dam of 67 m height and reservoir of 59.7 mil m3 were envisaged to provide storage and regulation of the Tawooq Chai for irrigation of Bassara Irrigation field, situated some 11 km downstream of the dam. The regulation of river and head difference created by the dam enable generation of the hydroelectric energy that will be a secondary benefit of this project. The dam was designed by JV of ITSC-IK and Stucky in period from 2005 to 2007. The general layout given in Project preliminary phase was elaborated based on the preliminary estimate of the geological conditions at the dam site. The subsequent detailed field and laboratory investigations, performed in 2006, made a significant impact on the selection of the final layout of dam and appurtenant structures and their designs.

Topography, hydrology and geology of the site

The Tawooq Chai, in its upstream part, flows along the cut in Jabal Durbandy Bassara ridge. This 3.8 km long cut Bassara gorge - separates an upstream hilly mountainous region from

270 the flat and plain zones downstream of the gorge. The proposed location of the dam is in the Bassara gorge at its entrance. The catchment area controlled by this dam covers 574 km2, and its altitudes range from 670 m to 1735 m. The average annual precipitation is 905 mm and the annual specific runoff for Bassara dam site is 13.9 l/s/km2. Area of Bassara belongs to High folded zone with well exposed anticline and syncline structures. The geological formations are all of Tertiary age and comprise Eocene deposits Sinjar limestones and Gercus marls and sandstone. The bedrock of the proposed dam site belongs to Gercus formation which includes reddish and purple shale, mudstone, sandy and gritty marls. Gercus is overlaid by Pila Spi limestone that is well bedded and locally bitumen impregnated. The lower parts of Pila Spi consist of massive white limestones, while the higher parts contain bands of green and white chalky marls. Regarding the seizmicity of the North Iraq region, there are many indications of neotectonic activities. In North Iraq during last decades only small earthquake were observed with characteristic transversal, but small intensity waves.

Dam design proposed technical solutions

In preliminary project phase, a layout with rockfill dam with vertical clay core was considered. Diversion tunnel was designed in the right river embankment, while the left embankment hosted the side channel spillway with chute and stilling basin. Results of the performed site investigations jeopardized the proposed preliminary solution. The most significant finding is the presence of app. 30 m thick overburden stratum on the left riverbank that consists of clayey soils and rock blocks. This condition prevented the location of side channel spillway on the left bank due to the low bearing capacity of thick overburden and difficulties to provide feasible cut off structure in the ground that will prevent seepage erosion of the spillway structure foundation soils. The bedrock situated on the right bank and in the river bed area (sandstone and siltstone rock units) provided the possibility to implement the RCC dam structure. Combined design solution consisting of the RCC dam at the right bank and river bed with and compacted gravel fill dam on the left bank with cut-off diaphragm is proposed as the most appropriate for the actual geological and geotechnical conditions. The overflow for flood water is ensured by the dam - spillway section situated in the zone of river bed. General layout is presented on Figure 1. Dam longitudinal section with geology profile is presented on Figure 2. Low levels of bed rock on the left bank limited the implementation of the RCC dam to three connection blocks as a supporting part of the RCC dam in connection with the fill dam. Dam spillway section (overflow part), founded at elevation 653.0 m, is the central part of the RCC dam. It is divided into three blocks by expansion joints. Each block has a spillway bay, 11.5 m wide, 59.85 m long and 53.00 m high. Thickness of the spillway lateral walls is 2.0 m. Bridge of 11.50 m span and 9.2 m width is located at the upstream part of the crest enabling the crane and other traffic passage.

271

Figure 1: Bassara Dam General Layout The spillway crest level is 706.00 m. Normal water level of 715.00 m will be kept by the radial gates. A radial gate with the clear gate opening of 11.50 m is provided at each spillway bay. For maximum water level of 716.5 m radial gates have to be fully opened and the corresponding downstream water level is 676.1 m. Criteria used for selection of the spillway layout were, firstly to direct the flood flow in the same as river flow, and secondly, to enable a sufficient space for the stilling basin. The spillway capacity will be sufficient to convey the maximum designed flood with available retention in the reservoir. The designed flood would result in reservoir surcharge of 1.5 m above normal water

272 level (maximum water level is 716.5 m a.s.l.) and corresponding maximum spillway discharge is 2,380 m3/s. Dam non-overflow sections are located between the fill dam and the spillway section, on the left and on the right side, between the spillway section and the right river bank. They are composed of massive blocks of 15 m, in width. The upstream vertical face and downstream (1:0.90) outer slopes of the RCC dam are designed to provide standard safety factors. The fill dam with central concrete diaphragm is designed on the left bank. The dam crest, 9.20 m wide, is at the elevation 719.50 m (same as for RCC) thus providing the free board of 3.0 m above the maximum reservoir level during full discharge of the flood waters over the spillway structure and free board of 1.00 m in the emergency case when one gate is not in operation. The upstream (1:1.7) and downstream (1:1.7) outer dam slopes provide usual safety margin against sliding under critical loading conditions (full reservoir with steady seepage for the downstream slope). The concrete diaphragm wall is designed as an impervious barrier along the fill dam axis. The upper part of the diaphragm will be made of reinforced concrete to ensure the diaphragm against cracking that may be caused by inertia forces during strong earthquakes, while the lower parts and the seepage protection parts in the left bank will be constructed using the concrete with addition of bentonite for improvement of its water tightness. The central concrete diaphragm wall with maximal depth of 76.35 m, is 155.7 m long and 1.4 m wide.

FEM analysis for RCC dam

The finite element method (FEM) analysis of the RCC dam was performed for relevant loadings. For the computational model of the dam-foundation interaction, a plane 2D model was chosen. FEM analysis comprised the highest spillway section. The spillway section was approximated with 280 plane stress elements. Foundation was approximated with 1800 plane strain elements. Contact between concrete dam and foundation are simulated with nonlinear gap elements. Upstream contact between conventionally placed mass concrete (CMC) and roller compacted concrete (RCC) are simulated with frame elements. The main objective of the analysis of temperature effects on the RCC dam structure was to determine appropriate shape of the dam body and zoning different type of RCC. Temperature influences were calculated as unusual load, and various constant temperatures along sections were used as input parameters (temperature load). For practical calculation, change of the RCC hydratation temperature was assumed as an exponential function, while change of ambient temperature was assumed as a sinusoidal function. For determination of the temperature differences, temperature of the mixture after 24h was adopted as basic temperature. Relation of the temperature change through sections was calculated by use of a numerical method of finite differences. This approximate calculation gives satisfactory results for further analysis of temperature effects on the dam structure. Linear elastic FEM analysis (Static analysis) for the usual and unusual loads (dead weight, hydrostatic influences and temperature) were applied.

273

Figure 2: Dam Longitudinal Section with geological profile

274 The dynamical analyses were carried out in accordance with the Time history method for the highest RCC structure. The Time history earthquake response analysis is based on linearelastic analysis for all characteristics and elements except for contact between concrete and foundation where non-linear analysis was applied. It means that linear time history analysis with material nonlinearity in the gap elements was applied. Interaction between the dam and impounded water was determined using generated Westergard formulation with added masses attached to the dam. Strong motion record (Manjil, June 20, 1990), as an oscillatory type recorded earthquake, with peak accelerations for OBE 117.72 cm/sec2, was used. Maximal compression stresses are at foundation contact level on upstream and downstream part and their values are up to 4.0 MPa. In all other zones of the structure compression stresses are less than 1.5 MPa. Maximal tension stresses for temperature decrease load case and usual load case are 2.25 MPa. At CMC and RCC contact level, tension stresses do not occur even for seismic load cases (Figure 3). Taking this into consideration, one layer of CMC 2.00 m thick was designed on the foundation contact level. First horizontal RCC layer 3.00 m thick, with better characteristics, was designed right above CMC layer. On the upstream dam face one zone of RCC with better characteristics was designed. All other concrete zones, except spillway superstructures, will be of primal RCC Type 1. The upstream dam face will be covered with precast elements 0.12 m thick and 1.5 m high, which are protection of water leaking and are used as a formwork during RCC placing. Expansion joints will be provided with two waterstop layers. Between these layers, vertical drainage pipes will be placed. Drainage pipes will collect eventual leakage water and drain it through the drainage galleries to the stilling basin. This 1.0 m wide zone in which waterstops and drainage pipe are placed shall be made of CMC.

Concluding remarks

Due to the unfavorable geology conditions at the dam site, the design solution of combined RCC dam at one river bank and river bed and fill dam on the other bank with cut-off diaphragm is proposed. A thorough stability and structural analyses was performed and excerpt of FEM analyses presented in this paper. Construction of this 67 m high dam is planned to commence in summer 2007. As is known, it will be the first high RCC dam constructed in Iraq.

275

Figure 3: Temperature influence and RCC type

276

Authors Names and Affiliation

Vicko Letica, M.Sc..B.Sc.C.E. Deputy Director for Civil Structures Engineering IK Consulting Engineers 4/I Studentski Trg 11 000 Belgrade Serbia vickoletica@yahoo.com Vladislav Skoko, B.Sc. C.E. Head of Structural Department IK Consulting Engineers 4/I Studentski Trg 11 000 Belgrade Serbia dam@ikconseng.co.yu Biljana Trajkovic, M.Sc..B.Sc.C.E. Senior Engineer IK Consulting Engineers 4/I Studentski Trg 11 000 Belgrade Serbia biljana.trajkovic@gmail.com

S-ar putea să vă placă și

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Song FlowDocument4 paginiSong FlowEhij ZheyÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Notice: Agency Information Collection Activities Proposals, Submissions, and ApprovalsDocument2 paginiNotice: Agency Information Collection Activities Proposals, Submissions, and ApprovalsJustia.comÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- PI SQC 2015 R3 User GuideDocument50 paginiPI SQC 2015 R3 User Guideislam ahmedÎncă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- A Daily Miracle2Document1 paginăA Daily Miracle2LizZelencichÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

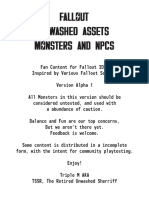

- Fallout Unwashed Assets Monsters and NpcsDocument4 paginiFallout Unwashed Assets Monsters and NpcsVeritas VeritatiÎncă nu există evaluări

- CS101 Solved File For Final Term MCQS 1 To 45 LecturesDocument130 paginiCS101 Solved File For Final Term MCQS 1 To 45 LecturesHisan Mehmood64% (28)

- The Perception of Veggie Nilupak To Selected Grade 11 Students of Fort Bonifacio High SchoolDocument4 paginiThe Perception of Veggie Nilupak To Selected Grade 11 Students of Fort Bonifacio High SchoolSabrina EleÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Understanding The School Curriculum Close Encounter With The School Curriculum SPARK Your InterestDocument12 paginiUnderstanding The School Curriculum Close Encounter With The School Curriculum SPARK Your InterestJoshua Lander Soquita CadayonaÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Activity 1 Which Is WhichDocument1 paginăActivity 1 Which Is WhichRhanna Lei SiaÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Lesson 20 PerdevDocument7 paginiLesson 20 PerdevIvan Joshua RemosÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Policing System Indonesia PolicingDocument5 paginiPolicing System Indonesia Policingdanilo bituin jrÎncă nu există evaluări

- Italian CuisineDocument29 paginiItalian CuisinekresnayandraÎncă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Federal Election Commission Complaint Filed Against Tennessee State Sen. Brian Kelsey, OthersDocument66 paginiFederal Election Commission Complaint Filed Against Tennessee State Sen. Brian Kelsey, OthersUSA TODAY NetworkÎncă nu există evaluări

- 2.peace Treaties With Defeated PowersDocument13 pagini2.peace Treaties With Defeated PowersTENDAI MAVHIZAÎncă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- 2019 National Innovation PoliciesDocument98 pagini2019 National Innovation PoliciesRashmi SinghÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- 6.4 Past Simple Affirmative: 0 Called HadDocument1 pagină6.4 Past Simple Affirmative: 0 Called HadSashkaKoreckajaÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- сестр главы9 PDFDocument333 paginiсестр главы9 PDFYamikÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- 2-Port Antenna Frequency Range Dual Polarization HPBW Adjust. Electr. DTDocument5 pagini2-Port Antenna Frequency Range Dual Polarization HPBW Adjust. Electr. DTIbrahim JaberÎncă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Aalborg Engineering Sg8 EngDocument4 paginiAalborg Engineering Sg8 EngHenrique de OliveiraÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Dlis103 Library Classification and Cataloguing TheoryDocument110 paginiDlis103 Library Classification and Cataloguing Theoryabbasimuhammadwaqar74Încă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- 1416490317Document2 pagini1416490317Anonymous sRkitXÎncă nu există evaluări

- Abnormal Menstrual Cycle - MenorrhagiaDocument5 paginiAbnormal Menstrual Cycle - MenorrhagiaSandhyaPrem100% (1)

- Fish Immune System and Vaccines-Springer (2022) - 1Document293 paginiFish Immune System and Vaccines-Springer (2022) - 1Rodolfo Velazco100% (1)

- Articles On Philippine Obligation and ContractsDocument114 paginiArticles On Philippine Obligation and ContractsKriz Batoto100% (1)

- The SPIN Model CheckerDocument45 paginiThe SPIN Model CheckerchaitucvsÎncă nu există evaluări

- Ring Spinning Machine LR 6/S Specification and Question AnswerDocument15 paginiRing Spinning Machine LR 6/S Specification and Question AnswerPramod Sonbarse100% (3)

- Exam in Analytic Geometry With AnswersDocument4 paginiExam in Analytic Geometry With Answersmvmbapple100% (6)

- Case DigestsDocument12 paginiCase DigestsHusni B. SaripÎncă nu există evaluări

- Sustainable Cities:: Why They MatterDocument2 paginiSustainable Cities:: Why They MatterbokugairuÎncă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- The Liberal Welfare Reforms 1906Document5 paginiThe Liberal Welfare Reforms 1906Skye G-sÎncă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)