Documente Academic

Documente Profesional

Documente Cultură

028005

Încărcat de

diemnganDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

028005

Încărcat de

diemnganDrepturi de autor:

Formate disponibile

SB16

SEAT BELT SEAT BELT WARNING SYSTEM

Front Passenger Side Seat Belt Warning Light Malfunction

DESCRIPTION

The occupant detection ECU detects the state of the front seat inner belt assembly RH and road sensor when the front passenger seat is occupied with the power switch on (IG). If the front passenger seat belt is not fastened, the front seat belt warning light on the clock display blinks. If the seat belt is fastened, the warning light goes off.

SB

WIRING DIAGRAM

F1 Combination Meter Assembly Center Airbag Sensor Assembly Occupant Detection ECU Front Seat Inner Belt RH

CANH 9 P/SB CANL

CANH FSP+ CANL FSPFSR-

BSW FSR+ BGN

Road Sensor FL SV1 SIG1 F3 Clock Assembly 10 Road Sensor RL SGD1

PBEW IG 3 from GAUGE No. 2 fuse

SV3 SIG3 SGD3 SV2 SIG2 Road Sensor RR SGD2 SV4 SIG4 SGD4

Road Sensor FR

19

GND1

: CAN

B140735E01

SEAT BELT SEAT BELT WARNING SYSTEM

SB17

INSPECTION PROCEDURE

1

Result

CHECK FOR DTCs (a) Check for DTCs.

Result No output DTC Output DTC (CAN communication) Output DTC (Occupant detection) Proceed to A B C

SB

B C A

GO TO CAN COMMUNICATION SYSTEM GO TO OCCUPANT CLASSIFICATION SYSTEM

CHECK WIRE HARNESS (BATTERY POSITIVE AND BODY GROUND) (a) Disconnect the clock assembly connector. (b) Measure the voltage and resistance according to the value(s) in the table below. Standard voltage

Tester Connection F3-3 (IG) - Body ground Condition Power switch on (IG) Specified Condition 10 to 14 V

F3

Standard resistance

Tester Connection

B137073E01

Condition Always

Specified Condition Below 1

F3-19 (GND1) - Body ground

NG OK

REPAIR OR REPLACE GAUGE NO. 2 FUSE, HARNESS OR CONNECTOR

CHECK CLOCK ASSEMBLY (a) Disconnect the clock assembly connector. (b) Apply battery voltage to the connector according to the table below. Standard

Condition Battery positive (+) Terminal 3 (IG) Battery negative (-) Terminal 10 (PBEW), 19 (GND1) Specified Condition Lights up (Seat belt warning light)

F3

B137074E01

NG

REPLACE CLOCK ASSEMBLY

SB18 OK

SEAT BELT SEAT BELT WARNING SYSTEM

CHECK WIRE HARNESS (CLOCK ASSEMBLY - COMBINATION METER ASSEMBLY) (a) Disconnect the combination meter assembly and clock assembly connectors. (b) Measure the resistance according to the value(s) in the table below. Standard resistance

Tester Connection Condition Always Always Specified Condition Below 1 10 k or higher F1-9 (P/SB) - F3-10 (PBEW)

SB

Clock Assembly:

F3 PBEW Combination Meter Assembly: P/SB

F1-9 (P/SB) - Body ground

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

F1

B137077E01

OK REPLACE COMBINATION METER ASSEMBLY

S-ar putea să vă placă și

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

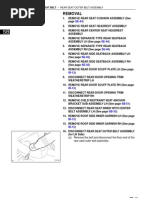

- Reassembly: Seat - Front Seat Assembly (For Power Seat)Document5 paginiReassembly: Seat - Front Seat Assembly (For Power Seat)diemnganÎncă nu există evaluări

- Installation: SB-34 23. Remove Rear Seat Inner With Center Belt Assembly LHDocument3 paginiInstallation: SB-34 23. Remove Rear Seat Inner With Center Belt Assembly LHdiemnganÎncă nu există evaluări

- Rear Seat Assembly: ComponentsDocument6 paginiRear Seat Assembly: ComponentsdiemnganÎncă nu există evaluări

- FRONT SEAT ASSEMBLY (For Power Seat) : ComponentsDocument4 paginiFRONT SEAT ASSEMBLY (For Power Seat) : ComponentsdiemnganÎncă nu există evaluări

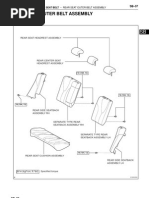

- Disposal: Seat Belt - Front Seat Outer Belt AssemblyDocument5 paginiDisposal: Seat Belt - Front Seat Outer Belt AssemblydiemnganÎncă nu există evaluări

- Removal: Seat Belt - Rear Seat Inner Belt AssemblyDocument2 paginiRemoval: Seat Belt - Rear Seat Inner Belt AssemblydiemnganÎncă nu există evaluări

- FRONT SEAT ASSEMBLY (For Manual Seat) : ComponentsDocument3 paginiFRONT SEAT ASSEMBLY (For Manual Seat) : ComponentsdiemnganÎncă nu există evaluări

- Removal: Seat - Front Seat Assembly (For Power Seat)Document2 paginiRemoval: Seat - Front Seat Assembly (For Power Seat)diemnganÎncă nu există evaluări

- Removal: Seat Belt - Rear Seat Outer Belt AssemblyDocument4 paginiRemoval: Seat Belt - Rear Seat Outer Belt AssemblydiemnganÎncă nu există evaluări

- Removal: (A) Remove The 3 Screws. (B) Disconnect The Connector and Remove The Power Seat SwitchDocument4 paginiRemoval: (A) Remove The 3 Screws. (B) Disconnect The Connector and Remove The Power Seat SwitchdiemnganÎncă nu există evaluări

- Front Seatback Heater: ComponentsDocument2 paginiFront Seatback Heater: ComponentsdiemnganÎncă nu există evaluări

- Rear Seat Inner Belt Assembly: ComponentsDocument3 paginiRear Seat Inner Belt Assembly: ComponentsdiemnganÎncă nu există evaluări

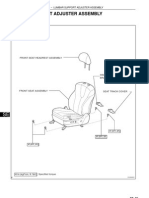

- Lumbar Support Adjuster Assembly: ComponentsDocument2 paginiLumbar Support Adjuster Assembly: ComponentsdiemnganÎncă nu există evaluări

- Front Seat Cushion Heater: ComponentsDocument2 paginiFront Seat Cushion Heater: ComponentsdiemnganÎncă nu există evaluări

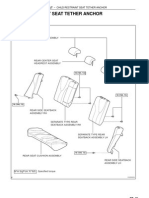

- Child Restraint Seat Tether Anchor: ComponentsDocument3 paginiChild Restraint Seat Tether Anchor: ComponentsdiemnganÎncă nu există evaluări

- Seat Heater Switch: ComponentsDocument4 paginiSeat Heater Switch: ComponentsdiemnganÎncă nu există evaluări

- Rear Seat Outer Belt Assembly: ComponentsDocument3 paginiRear Seat Outer Belt Assembly: ComponentsdiemnganÎncă nu există evaluări

- Child Restraint Seat Anchor Bracket: ComponentsDocument2 paginiChild Restraint Seat Anchor Bracket: ComponentsdiemnganÎncă nu există evaluări

- Front Power Seat Lumbar Switch: ComponentsDocument2 paginiFront Power Seat Lumbar Switch: ComponentsdiemnganÎncă nu există evaluări

- Removal: Seat - Front Seat Assembly (For Manual Seat)Document2 paginiRemoval: Seat - Front Seat Assembly (For Manual Seat)diemnganÎncă nu există evaluări

- Diagnosis System: CG SG SIL CanhDocument2 paginiDiagnosis System: CG SG SIL CanhdiemnganÎncă nu există evaluări

- System Diagram: Driver SideDocument2 paginiSystem Diagram: Driver SidediemnganÎncă nu există evaluări

- Power Seat Switch: ComponentsDocument2 paginiPower Seat Switch: ComponentsdiemnganÎncă nu există evaluări

- Seat Heater System: PrecautionDocument2 paginiSeat Heater System: PrecautiondiemnganÎncă nu există evaluări

- Removal: Seat - Front Power Seat Lumbar SwitchDocument2 paginiRemoval: Seat - Front Power Seat Lumbar SwitchdiemnganÎncă nu există evaluări

- Removal: Seat - Front Seatback HeaterDocument2 paginiRemoval: Seat - Front Seatback HeaterdiemnganÎncă nu există evaluări

- Seat Belt Warning System: PrecautionDocument2 paginiSeat Belt Warning System: PrecautiondiemnganÎncă nu există evaluări

- Front Seat Frame With Adjuster: InspectionDocument2 paginiFront Seat Frame With Adjuster: InspectiondiemnganÎncă nu există evaluări

- Removal: Seat - Front Seat Cushion HeaterDocument2 paginiRemoval: Seat - Front Seat Cushion HeaterdiemnganÎncă nu există evaluări

- System Diagram: E55 Seat Heater SwitchDocument2 paginiSystem Diagram: E55 Seat Heater SwitchdiemnganÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Battery Management System For Unmanned Electric Vehicles With CAN BUS and Internet of ThingsDocument24 paginiBattery Management System For Unmanned Electric Vehicles With CAN BUS and Internet of ThingsgulestuÎncă nu există evaluări

- Gem Car Repair and Maintenance-Service Manual PDFDocument0 paginiGem Car Repair and Maintenance-Service Manual PDFjscarrilloz100% (1)

- Mech Syllabus 2013 14Document126 paginiMech Syllabus 2013 14netraÎncă nu există evaluări

- Liebert NX UPS: User Manual-10-30kVA, 208V, 60HzDocument112 paginiLiebert NX UPS: User Manual-10-30kVA, 208V, 60Hzamk2009Încă nu există evaluări

- Murphy IGuardDocument65 paginiMurphy IGuardJorge Muñoz ArroboÎncă nu există evaluări

- Manual Xbox 360 Slim 4gbDocument78 paginiManual Xbox 360 Slim 4gbafc171Încă nu există evaluări

- DSEE400 Installation InstructionsDocument2 paginiDSEE400 Installation InstructionsYasser JaviÎncă nu există evaluări

- Eet ch2Document12 paginiEet ch2xeemac100% (1)

- Pentax PCS-300 PCS-315 325 335 PDFDocument30 paginiPentax PCS-300 PCS-315 325 335 PDFLuis Aguirre100% (1)

- Theben Ramses 811 TopDocument16 paginiTheben Ramses 811 ToppucascÎncă nu există evaluări

- Comparison Static UPS - Rotary UPSDocument1 paginăComparison Static UPS - Rotary UPSdelmar02Încă nu există evaluări

- Li2013 PDFDocument10 paginiLi2013 PDFSamundra GurungÎncă nu există evaluări

- Penguin'S Philosophy: List of OptionsDocument4 paginiPenguin'S Philosophy: List of OptionsMohamed Ghazy Jr.Încă nu există evaluări

- Compex Guide PDFDocument49 paginiCompex Guide PDFMAGAfonsoÎncă nu există evaluări

- SP r5200Document103 paginiSP r5200lada1119Încă nu există evaluări

- Lifebook Nh570: System Operating ManualDocument83 paginiLifebook Nh570: System Operating ManualMichael BoutsakisÎncă nu există evaluări

- Battery Specification SheetDocument3 paginiBattery Specification SheetEdwique Kudzai MukuzeÎncă nu există evaluări

- Final Report-Hydrogen Fuel Cell Vehicle - F10Document56 paginiFinal Report-Hydrogen Fuel Cell Vehicle - F10Nur Khairunnisa100% (1)

- Xindao 2012 Obiecte Promotionale XD 2012 - Obiecte Promotionale Iasi - Obiecte Promotionale Bucuresti - Gadgets 2012 - Promotionale PersonalizateDocument175 paginiXindao 2012 Obiecte Promotionale XD 2012 - Obiecte Promotionale Iasi - Obiecte Promotionale Bucuresti - Gadgets 2012 - Promotionale PersonalizateAdicenter IasiÎncă nu există evaluări

- Gutor TechnologyDocument2 paginiGutor TechnologyFELIXDEJÎncă nu există evaluări

- ZJMY Business PlanDocument16 paginiZJMY Business PlanAnonymous fe4knaZWjmÎncă nu există evaluări

- Sma Sunny Island 3 4 4 DatasheetDocument4 paginiSma Sunny Island 3 4 4 DatasheetWael BadriÎncă nu există evaluări

- AIE 920-smDocument31 paginiAIE 920-smyu3zaÎncă nu există evaluări

- 1200 Series DatasheetDocument2 pagini1200 Series DatasheetJosip PobranÎncă nu există evaluări

- I418 Manual de Montagem e Desmontagem PDFDocument138 paginiI418 Manual de Montagem e Desmontagem PDFTchuca100% (1)

- Nasa Tech Briefs May 2012Document102 paginiNasa Tech Briefs May 2012Iulian BarascuÎncă nu există evaluări

- Chapter 20 PetrucciDocument67 paginiChapter 20 PetruccicoppernitrateÎncă nu există evaluări

- Uit Ultimate Gps Breakout v3 Tutorial For The Raspberry Pi 3Document12 paginiUit Ultimate Gps Breakout v3 Tutorial For The Raspberry Pi 3api-248437787Încă nu există evaluări

- Sebu8079-11 MDocument73 paginiSebu8079-11 MMartinDiazÎncă nu există evaluări

- How To Find Happiness With Lifepo4 (Lithium-Ion) BatteriesDocument2 paginiHow To Find Happiness With Lifepo4 (Lithium-Ion) BatteriesЮлия БÎncă nu există evaluări